Manufacturing method of infrared reflecting device

An infrared reflection and device technology, applied in chemical instruments and methods, instruments, building components, etc., can solve the problems that the optical performance cannot be changed, and people cannot be satisfied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

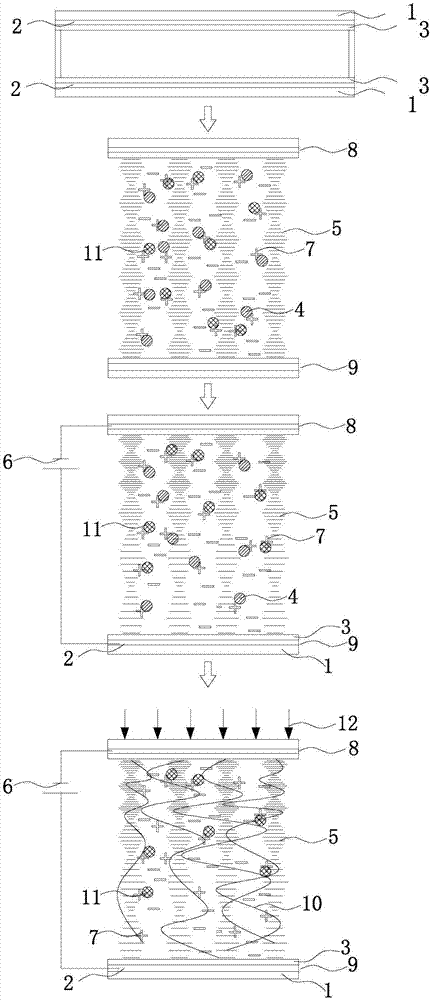

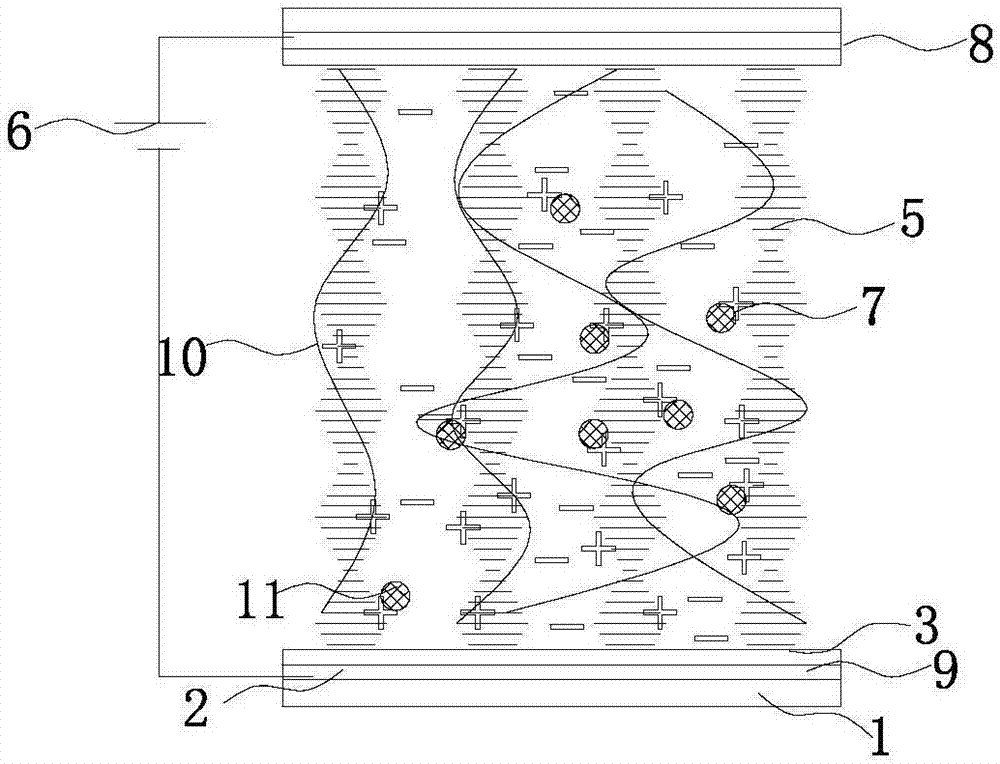

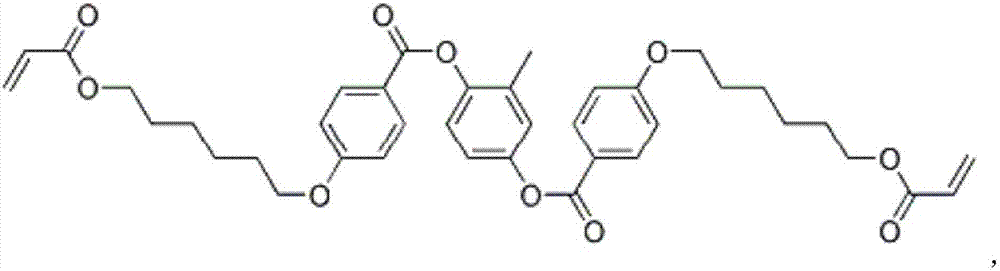

[0028] refer to figure 1 Prepare the infrared reflective device according to the following steps, firstly prepare the first conductive light-transmitting substrate 8 and the second conductive light-transmitting substrate 9, the first conductive light-transmitting substrate 8 and the second conductive light-transmitting substrate 9 are arranged oppositely, so The first conductive light-transmitting substrate 8 and the second conductive light-transmitting substrate 9 both include a substrate 1, and the opposite surfaces of the two substrates 1 are covered with a conductive layer 2; The alignment layer 3 is spin-coated on the opposite surface of the second conductive light-transmitting substrate 9, and rubbed in parallel orientation, that is, the alignment layer 3 is spin-coated on the conductive layer 2; the first conductive light-transmitting substrate 8 and the second The conductive light-transmitting substrate 9 is prepared into a liquid crystal cell; according to the mass ra...

Embodiment 2

[0038] This example is basically the same as Example 1, except that the mass ratio of the negative liquid crystal: chiral dopant: photopolymerizable monomer: photoinitiator is 79.5:14.5:5:1, and the The liquid crystal monomer has an ester group capable of trapping cations. The liquid crystal monomer is RM257. The chiral dopant is R811. Described photoinitiator is Irgacure-369, and its structural formula is:

[0039]

[0040] The negative liquid crystal is HNG30400-200. Ultraviolet light irradiates the liquid crystal cell from one side of the first conductive light-transmitting substrate.

Embodiment 3

[0042] This example is basically the same as Example 1, except that the mass ratio of the negative liquid crystal: chiral dopant: photopolymerizable monomer: photoinitiator is 80.4:13.6:5:1, and the The chiral dopant has an ester group capable of trapping cations. The liquid crystal monomer is M04031. The chiral dopant is S1011. The photoinitiator is Irgacure-369. The negative liquid crystal is HNG708200-100.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com