Film pressure thermal dehydration method and equipment for high-moisture sludge

A technology of membrane pressure and high water content, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of complex process equipment and difficult operation, and achieve the effect of simple process flow, small concentration gradient and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

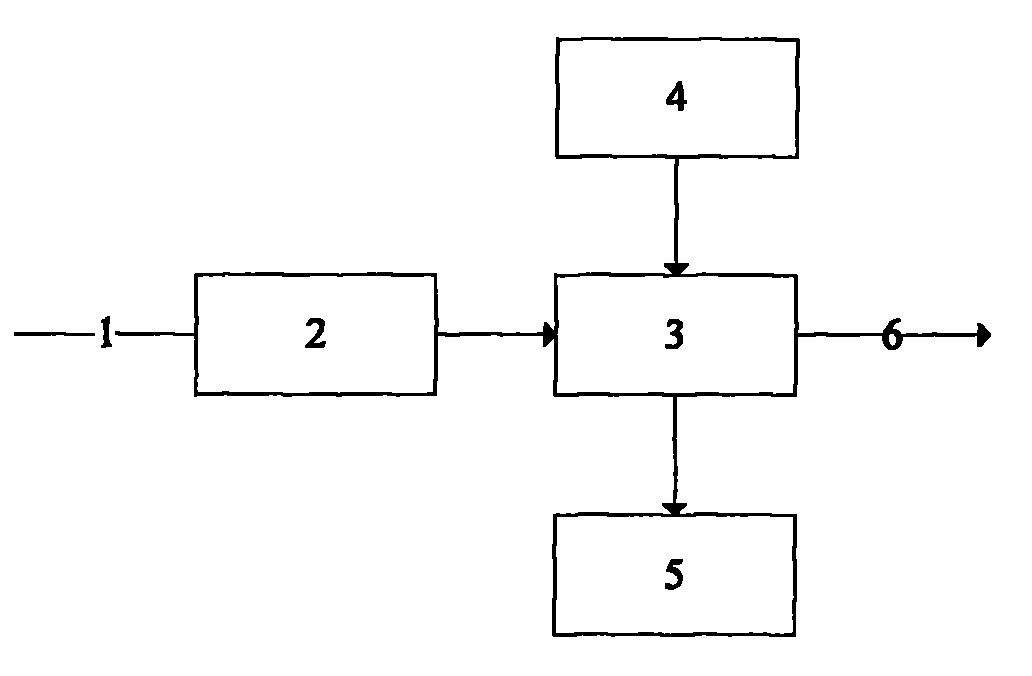

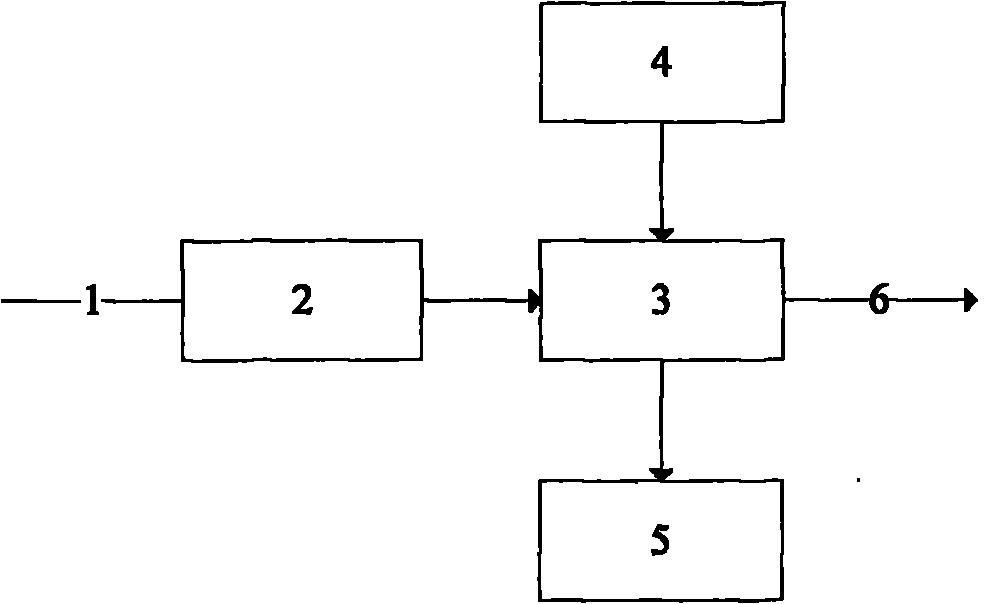

[0019] Embodiment 1: the membrane pressure thermal dehydration method of sludge with high water content

[0020] The process of membrane pressure heat dehydration method for sludge with high water content includes: mechanically dewatered sludge 1 passes through film cloth 2, then heat extrusion 3 after temperature adjustment and pressure adjustment 4, and finally separates dewatered water 5 and is treated After thermal dewatering sludge6.

Embodiment 2

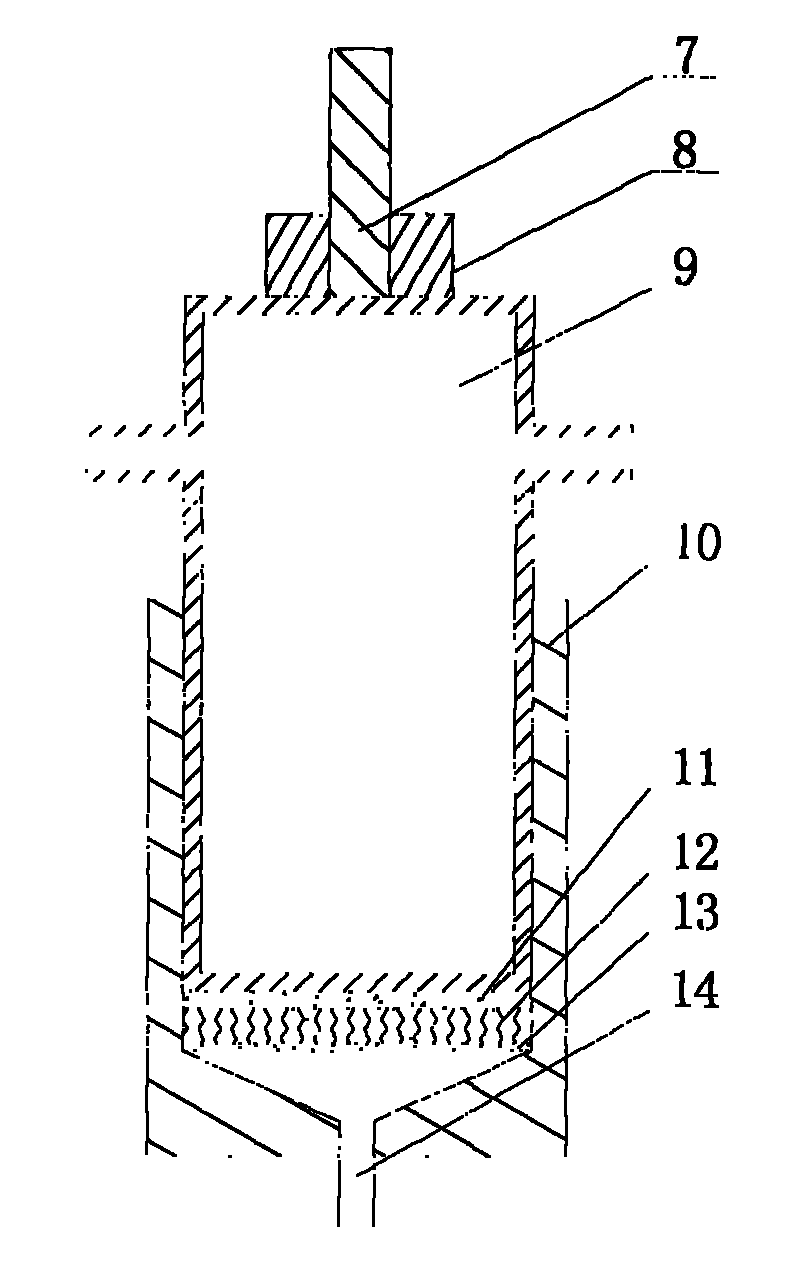

[0021] Example 2: High water content sludge membrane pressure dehydration equipment

[0022] The working process of the high water content sludge membrane pressure dehydration equipment is as follows: fix the filter material such as 30 mesh to 60 mesh stainless steel support frame 13 on the support cavity 10, place a rigid filter material 12 on it, such as sintered metal filter material, The filter material is coated with a sludge sample 11 with a moisture content of about 80% after simple mechanical pretreatment with a thickness of less than 10mm, and then the heating chamber 9 whose outer surface size closely matches the inner size of the support chamber 10 is placed on the sludge surface , the heating temperature of the heating chamber 9 can be adjusted in different ways according to different heating methods, the pressure is adjusted by the number of pressure weights 8 placed on the weight column 7, and the extruded water filtered by the filter material 12 passes through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com