Dehydrating device and dehydrating method for optical fiber powdery loose rod body

A dehydration device and powder technology, applied in the field of optical fiber manufacturing, can solve problems such as poor group removal effect, and achieve the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

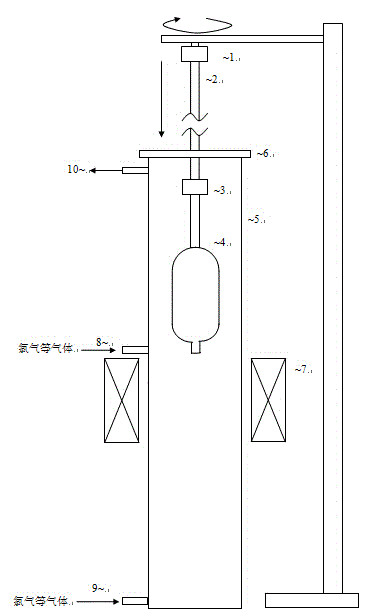

[0028] The device of the embodiment of the present invention is as figure 1 As shown, it includes a sintering cylinder 5, the sintering cylinder is an airtight long cylinder made of quartz glass, the top of the sintering cylinder is equipped with a cover plate 6, the cover plate is a half-opening structure, and the cover plate A sealing hole seat is provided in the middle to be configured with the rotating shaft. A lower air inlet 9 is provided on the bottom side of the sintering cylinder, an upper air inlet 8 is provided on the middle side of the sintering cylinder, and the upper and lower air inlets are respectively connected to the mixed gas source through a gas flow controller , the flow controller is controlled by a computer, an air outlet 10 is installed on the top side of the sintering cylinder, and a heating furnace 7 is installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com