Method for rapidly and stably starting wastewater nitrite type mixotrophic desulfurization and denitrification system

A technology of nitrite and nitrification system is applied in the field of start-up of nitrite-type facultative desulfurization and denitrification system of wastewater, which can solve the problems of repeated system start-up stages, unstable removal effect, and inconspicuous dominant flora, etc. Conducive to stable operation, promoting rapid enrichment and film formation, and improving controllability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

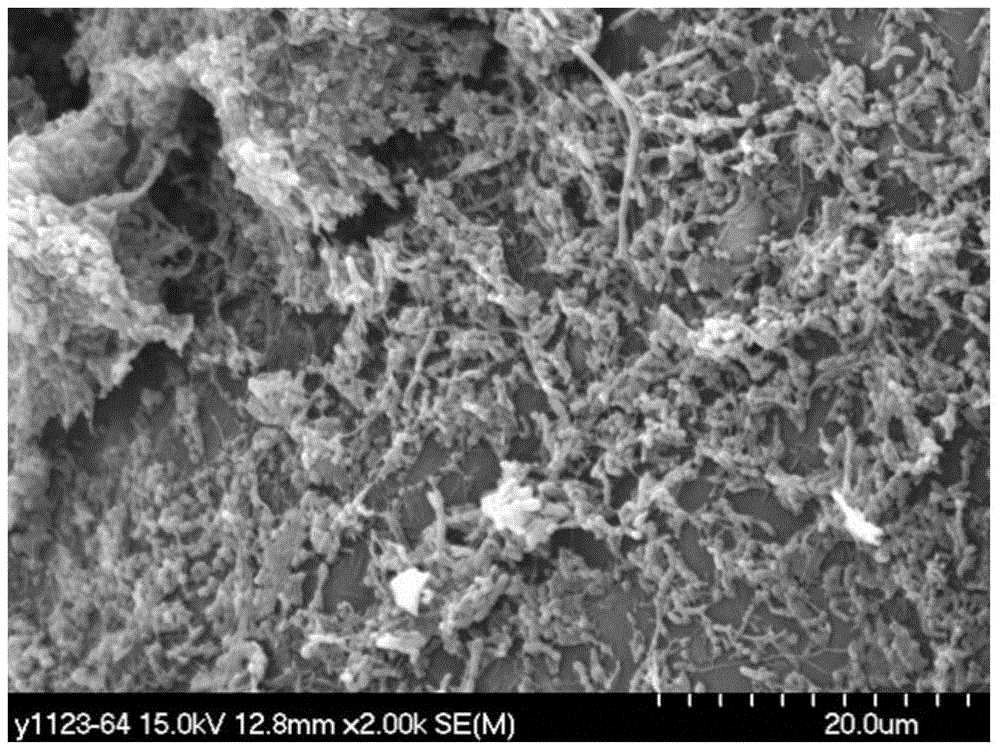

[0055] This embodiment is for NO 3 - and S 2- The organic waste water is treated to quickly start the concurrent biofilm system to verify the effect of the present invention. The anaerobic activated sludge is taken from the residual sludge return pipe of the secondary sedimentation tank of the northern sewage plant in Shenyang. This kind of sludge is located in the area Precipitation state, high concentration, strong activity, which is conducive to the rapid start-up of the system in the early stage. The filler used is a sponge block of 1cm×1cm×1cm. Compared with other kinds of fillers, this kind of filler has uniform pore size, large specific surface area, and rough surface, which is conducive to the rapid attachment and film formation of microorganisms. The specific operation is as follows:

[0056] The first step is to fully mix the high-concentration anaerobic activated sludge taken from the residual sludge return pipe of the secondary sedimentation tank of the northern...

Embodiment 2

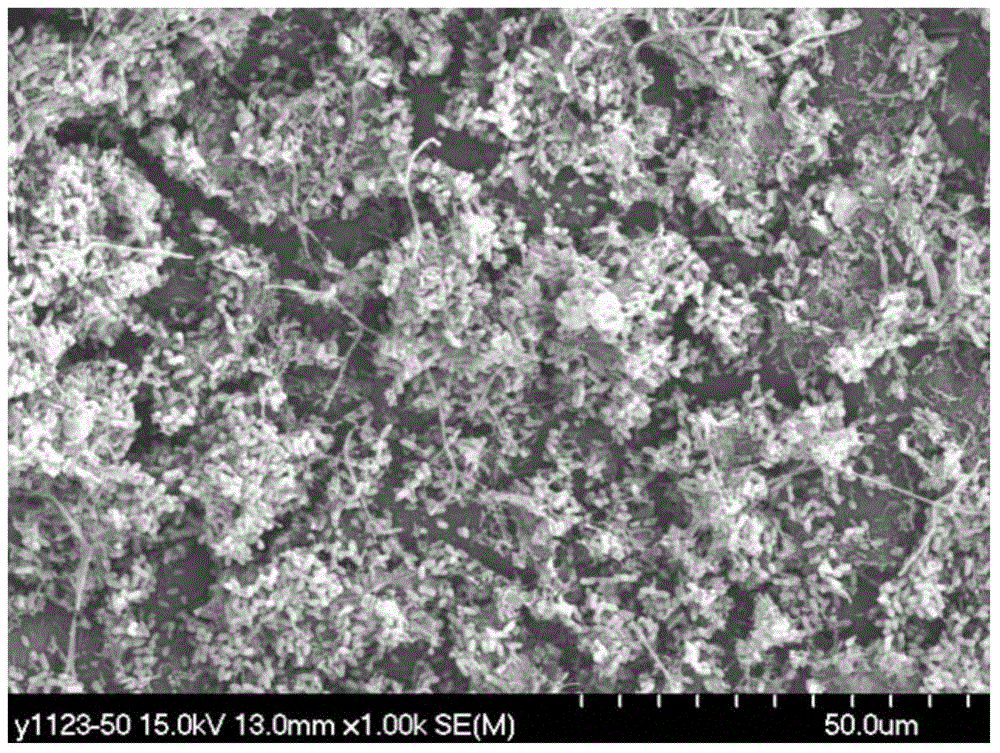

[0062] In this embodiment, the anaerobic activated sludge is taken from the residual sludge return pipe of the secondary sedimentation tank of the northern Shenyang sewage plant, and a sponge block with a filler of 1 cm×1 cm×1 cm is used. The specific operation is as follows:

[0063] The first step is to fully mix the high-concentration anaerobic activated sludge with a 1cm×1cm×1cm sponge block and then put it into the upflow anaerobic reactor, and the NO 3 - and S 2- The inorganic wastewater is passed into the reactor to domesticate sulfur-autotrophic denitrification microorganisms, increase their activity and quantity, and NO 3 - The concentration of N is 87.5mg / L, S 2- The concentration of S is 300mg / L, and the process operating conditions are: pH value 7, temperature 35°C, 2L of water inflow every 24h, each time of water inflow is 2h, and the reflux of the effluent makes the rising flow rate in the reactor 2m / h , NO 3 - and S 2- Removal rates reached over 90% resp...

Embodiment 3

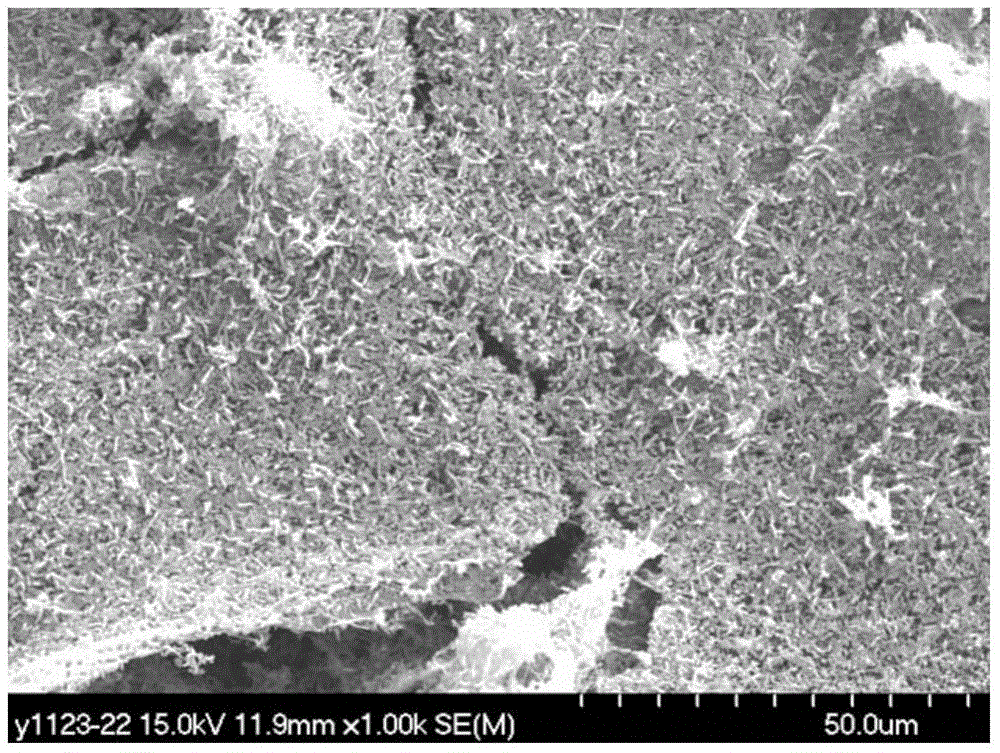

[0068] In this embodiment, the anaerobic activated sludge is taken from the residual sludge return pipe of the secondary sedimentation tank of the northern Shenyang sewage plant, and the filler is columnar activated carbon with a diameter of 2mm-4mm. The specific operation is as follows:

[0069] The first step is to fully mix the high-concentration anaerobic activated sludge with columnar activated carbon particles with a diameter of 2mm-4mm, and then put them into the upflow anaerobic reactor. 3 - and S 2- The inorganic wastewater is passed into the reactor to domesticate sulfur-autotrophic denitrification microorganisms, increase their activity and quantity, and NO 3 - The concentration of N is 30mg / L, S 2- The concentration of S is 100mg / L, and the process operating conditions are: PH value 9, temperature 30°C, 4L of water inflow every 24h, each time of water inflow is 0.5h, and the reflux of the effluent makes the rising flow rate in the reactor 0.5m / h, NO 3 - and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com