Axial vibrating flat sheet membrane device capable of improving membrane flux and effectively controlling membrane pollution

A technology of axial vibration and flat membrane, applied in the direction of membrane, membrane technology, semi-permeable membrane separation, etc., can solve the problem that the microfiltration membrane or ultrafiltration membrane is easy to be polluted, so as to increase the cleaning frequency, improve the membrane flux, The effect of reducing breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

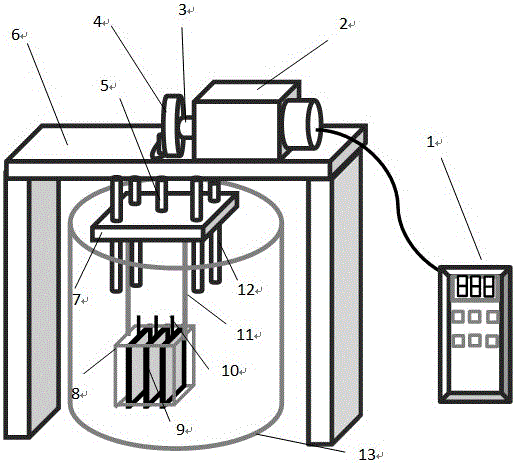

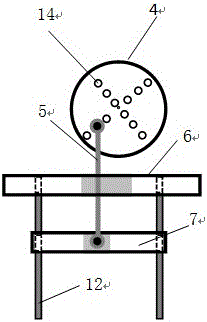

Method used

Image

Examples

Embodiment 2

[0024] Using the device described in Example 1, when the concentration of microalgae is 0.3g / L, a flat ultrafiltration membrane with a pore size of 0.1 micron is used to filter microalgae, and the membrane area is 0.02m 2 . Depend on image 3 It can be seen that at a certain fixed amplitude, as the frequency increases from 5 to 10 Hz, the critical flux of the membrane also increases; similarly, at a certain frequency, the critical flux increases from 5 to 20mm improve. Therefore, by increasing the frequency or amplitude (shear rate) the device can increase the critical flux.

Embodiment 3

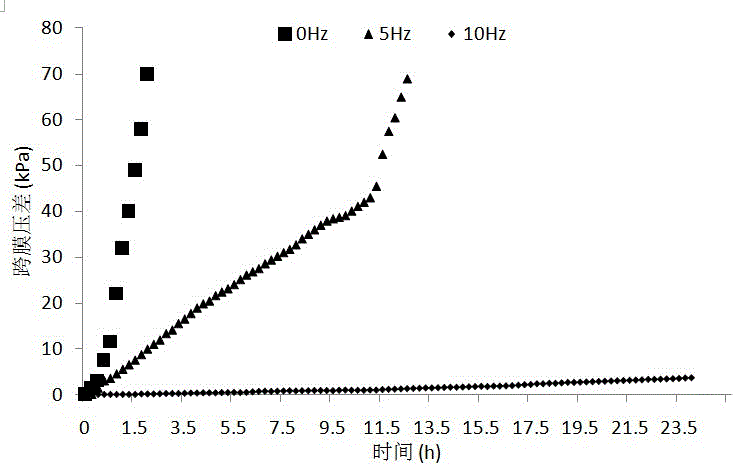

[0026] Using the device described in Example 1, when the concentration of microalgae is 0.3g / L, a flat ultrafiltration membrane with a pore size of 0.1 micron is used to filter microalgae, and the membrane area is 0.02m 2 . Depend on Figure 4 It can be seen that when the amplitude is 1cm, the flux is 40L / m 2 In the case of h, the transmembrane pressure difference decreased significantly with the increase of frequency, indicating that the increase of frequency can effectively slow down membrane fouling. At 0Hz, the transmembrane pressure difference rose to 70kPa after filtration for only 2 hours; at 5Hz for 12 hours, the transmembrane pressure difference rose to 69kPa; and at 10Hz, after 24 hours of filtration, the transmembrane pressure difference The membrane pressure difference has only risen to 3.5kPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com