Overlapped microbial fuel cell in-situ test system and application thereof

A fuel cell and in-situ test technology, applied in the field of bioelectrochemistry, to reduce difficulty, improve pollutant removal ability, and overcome the limited effect of system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

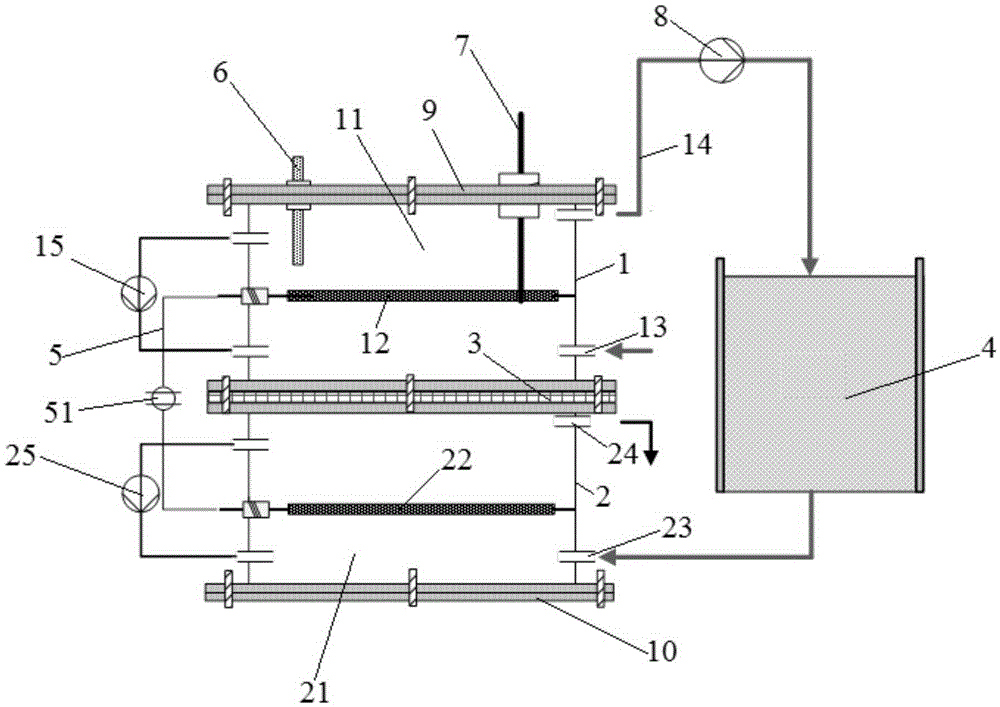

[0054] Such as figure 1 As shown, the present embodiment is a stacked type microbial fuel cell in-situ testing system, which includes an anode chamber 1 formed by stacking an anode reaction module in series, a cathode chamber 2 formed by stacking a cathode reaction module in series, and is arranged on the anode The proton exchange membrane 3 between the chamber 1 and the cathode chamber 2 and the external nitrification reactor 4 connected to the anode chamber 1 and the cathode chamber 2 respectively, the anode chamber 1 and the cathode chamber 2 can be arranged oppositely, and the anode chamber An external adjustable resistance circuit 5 is also provided between 1 and the cathode chamber 2.

[0055] Wherein, the anode reaction module includes an anode reaction chamber 11 and an anode biofilm 12 horizontally arranged in the anode reaction chamber 11, and the anode biofilms 12 in adjacent two anode reaction chambers 11 are arranged in series by a circuit; the cathode reaction mo...

Embodiment 2

[0069] In this embodiment, the anode chamber 1 is composed of 3 anode reaction modules stacked in series, the cathode chamber 2 is composed of 3 cathode reaction modules stacked in series, and the single filament diameter of the activated carbon fiber filler in the external nitrification reactor 4 is 20 μm. All the other are with embodiment 1.

Embodiment 3

[0071] In this embodiment, the anode chamber 1 is composed of five anode reaction modules stacked in series, the cathode chamber 2 is composed of five cathode reaction modules stacked in series, and the single filament diameter of the activated carbon fiber filler in the external nitrification reactor 4 is 15 μm. All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament diameter | aaaaa | aaaaa |

| Monofilament diameter | aaaaa | aaaaa |

| Monofilament diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com