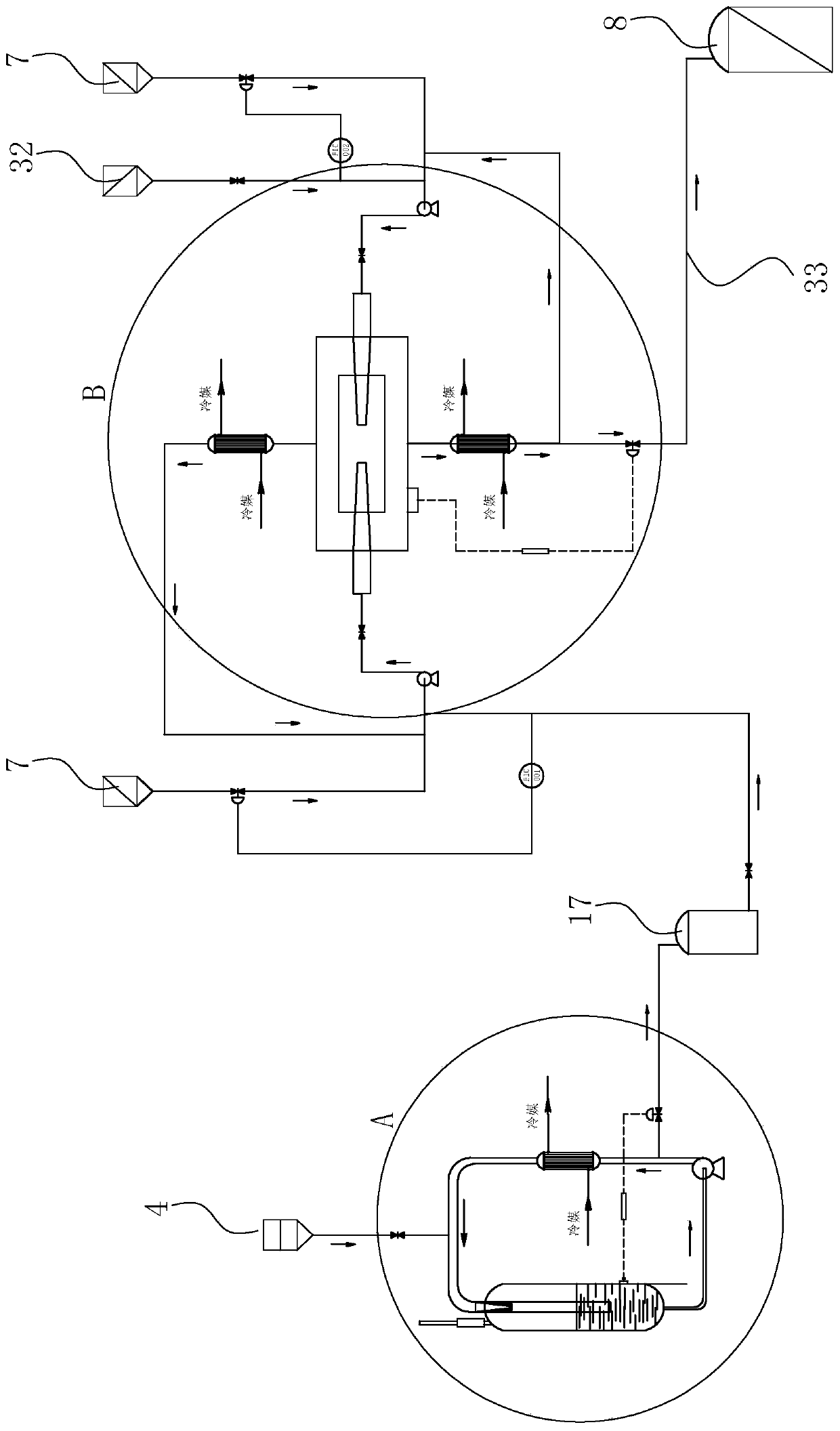

Automatic continuous liquid azo dye production process and synthesis system

An azo dye and production process technology, applied in azo dyes, monoazo dyes, organic dyes, etc., can solve the problems of difficult control, complex reactor structure, complex process, etc., and achieve good mass transfer effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Diazo component: 2,4-dinitro-6-chloroaniline;

[0048] Coupling component: N,N-diethyl-3-acetamidoaniline;

[0049] The structure of the product Disperse Violet 93:1:

[0050] Nitrite solution: a commercially available nitrosyl sulfuric acid solution of 30% by weight;

[0051] Diazo component: commercially available 2,4-dinitro-6-chloroaniline solid, content 98%;

[0052] Coupling component solution: a 10% by weight aqueous solution of N,N-diethyl-3-acetamidoaniline, adjusted to pH 2-3 with 30% saline.

[0053] Dispersant solution: 30% aqueous solution of commercially available dispersant MF.

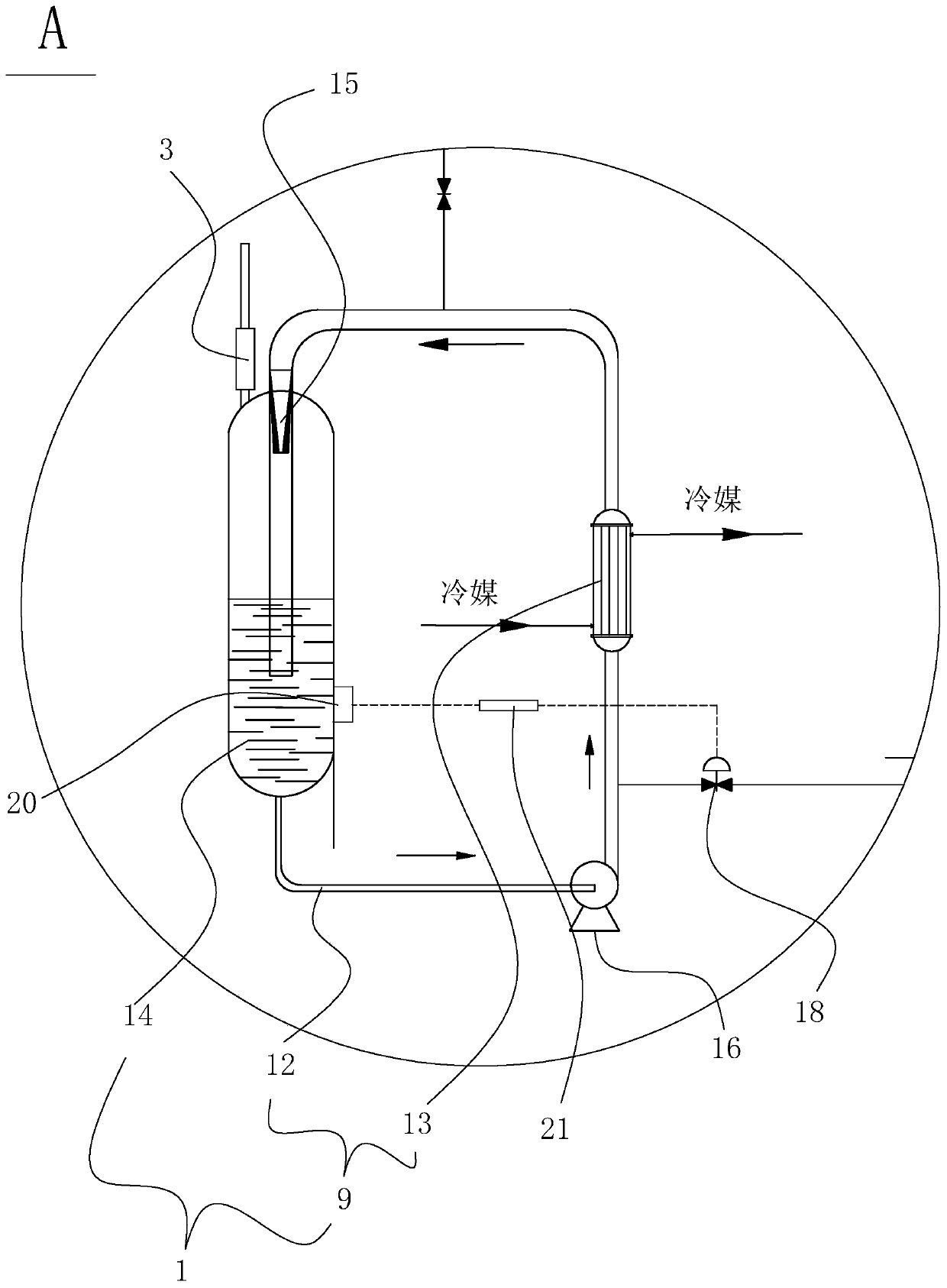

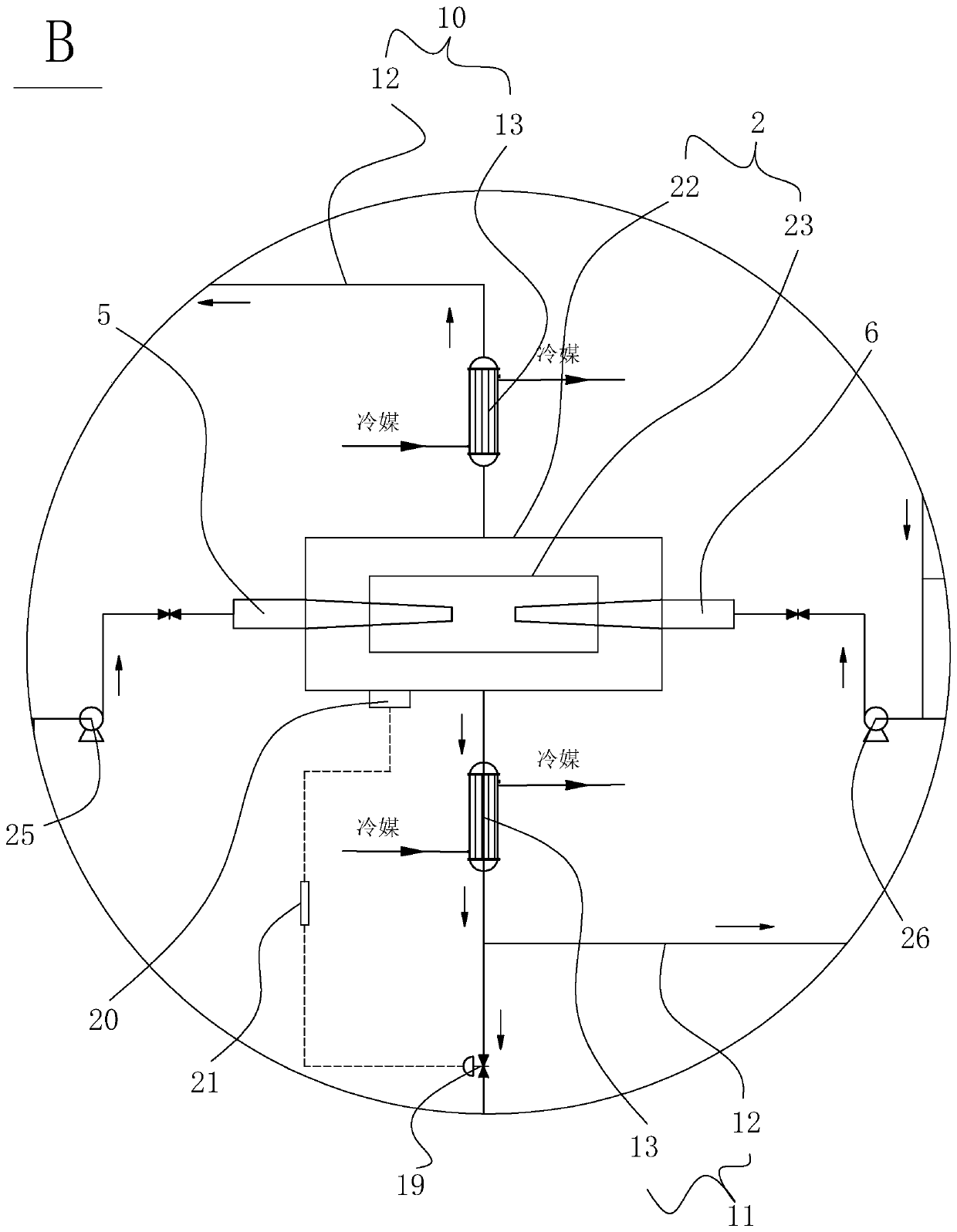

[0054] After checking whether the entire continuous production system and the automatic control system are normal, add 100 kg of 2,4-dinitro-6-chloroaniline into the diazotization reactor 14 . Turn on the diazotization circulation pump 16, turn on the refrigerant feed to the heat exchanger 13 of the first circulation temperature control device 9, and control the tempera...

Embodiment 2

[0056] Diazo component: 5-amino-6-bromo-2-methylindole-1,3-dione;

[0057] Coupling component: N,N-diethyl-3-acetamidoaniline;

[0058] The structure of the product Disperse Violet 107:

[0059] Nitrite solution: a 30% aqueous solution of sodium nitrite by weight;

[0060] Diazo component solution: 20% by weight of 5-amino-6-bromo-2-methylindole-1,3-dione hydrochloric acid solution (ie: 50 kilograms of 5-amino-6-bromo-2- Methylindole-1,3-dione is dissolved in 200 kilograms of 30% hydrochloric acid solution);

[0061] Coupling component solution: an aqueous solution of 10% by weight of N,N-diethyl-3-acetamidoaniline, adjusted to pH 2-3 with 30% brine;

[0062] Dispersant solution: 30% aqueous solution of commercially available dispersant MF.

[0063] After checking whether the entire continuous production system and the automatic control system are normal, add 520 kg of diazo component solution into the diazotization reactor 14, turn on the diazotization circulation p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com