Cooked gelatine powder and preparation method thereof

A technology of cooked rubber powder and starch, applied in the direction of starch-derived adhesives, adhesive types, adhesive additives, etc., can solve the problems of low reaction efficiency, uneven reaction of cooked rubber powder, low degree of substitution, etc., and achieve utilization High efficiency, improved reaction efficiency and substitution degree, high substitution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

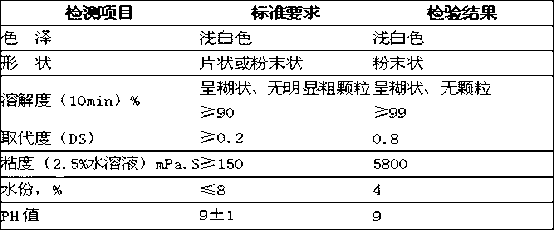

Embodiment 1

[0034] 1) Thin and activate 85 parts of corn starch and 2 parts of sodium alginate in a microcomputer to refine the original starch to 2000 mesh, destroying the starch crystal structure, and the structure of starch granules changes from a crystalline structure to a non-crystalline structure. Crystal structure transformation, effectively increasing the surface area of starch granules, and making the exposed hydroxyl groups of starch active without recrystallization through modifiers;

[0035] 2) Add the activated starch obtained in step 1) and 8 parts of potassium hydroxide into the mixing reactor, set the temperature of the mixer at 80°C, the stirring speed at 2000 rpm, and high-speed stirring for 5 minutes. Under this condition, the starch unit The exposed hydroxyl groups on C2, C3 and C6 undergo condensation reaction with potassium hydroxide, so that the starch non-crystalline structure is completely in an active state, and the reaction process is: St-OH+KOH→St-OK+H 2 O; ...

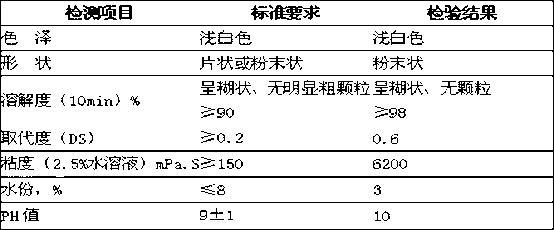

Embodiment 2

[0041] 1) Thinning and activating 50 parts of potato starch, 30 parts of corn starch, 2 parts of polyvinyl alcohol and 2 parts of sodium polyacrylate in a microcomputer to refine the original starch to 2000 mesh, destroying the starch crystal structure, The structure of starch granules changes from a crystalline structure to an amorphous structure, effectively increasing the surface area of the starch granules, and making the exposed hydroxyl groups of the starch active without recrystallization;

[0042] 2) Add the activated starch obtained in step 1) and 6 parts of potassium hydroxide into the mixing reactor, set the temperature of the mixer at 80°C, the stirring speed at 2000 rpm, and high-speed stirring for 8 minutes. Under this condition, the starch unit The exposed hydroxyl groups on C2, C3 and C6 undergo condensation reaction with potassium hydroxide, so that the starch non-crystalline structure is completely in an active state, and the reaction process is: St-OH+KOH→S...

Embodiment 3

[0048] 1) 70 parts of 200-mesh tapioca starch and 5 parts of polymaleic anhydride were refined and activated in a SLG300 vortex jet mill to 1250 mesh;

[0049] 2) Add the activated starch obtained in step 1) and 5 parts of sodium hydroxide catalyst into a high-speed mixing reactor, set the temperature of the mixer to 80°C, stir at a speed of 1400 rpm, and react with high-speed stirring for 10 minutes;

[0050] 3) Set the temperature of the mixing reactor in step 2) at 100°C, add 10 parts of etherifying agent while stirring at a high speed, keep the temperature of the mixing reactor at a constant temperature of 100°C, and react for 15 minutes at a stirring speed of 1400 rpm. Then add 2 parts of thickener hydroxyethyl cellulose and 0.5 parts of sodium bentonite and continue to stir for 1-2 minutes to disperse evenly, then discharge and cool;

[0051] 4) The material obtained in step 3) is fed into the enhanced extrusion reactor, and the starch hydrogen bond is broken and disinte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com