Preparation of medicinal disintegrating agent with biological enzymatic isolation method

A bio-enzyme and disintegrant technology, which is applied in the field of bio-enzymatic hydrolysis to prepare pharmaceutical disintegrants, can solve the problems of affecting the efficacy of drugs, increasing costs, and poor disintegration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

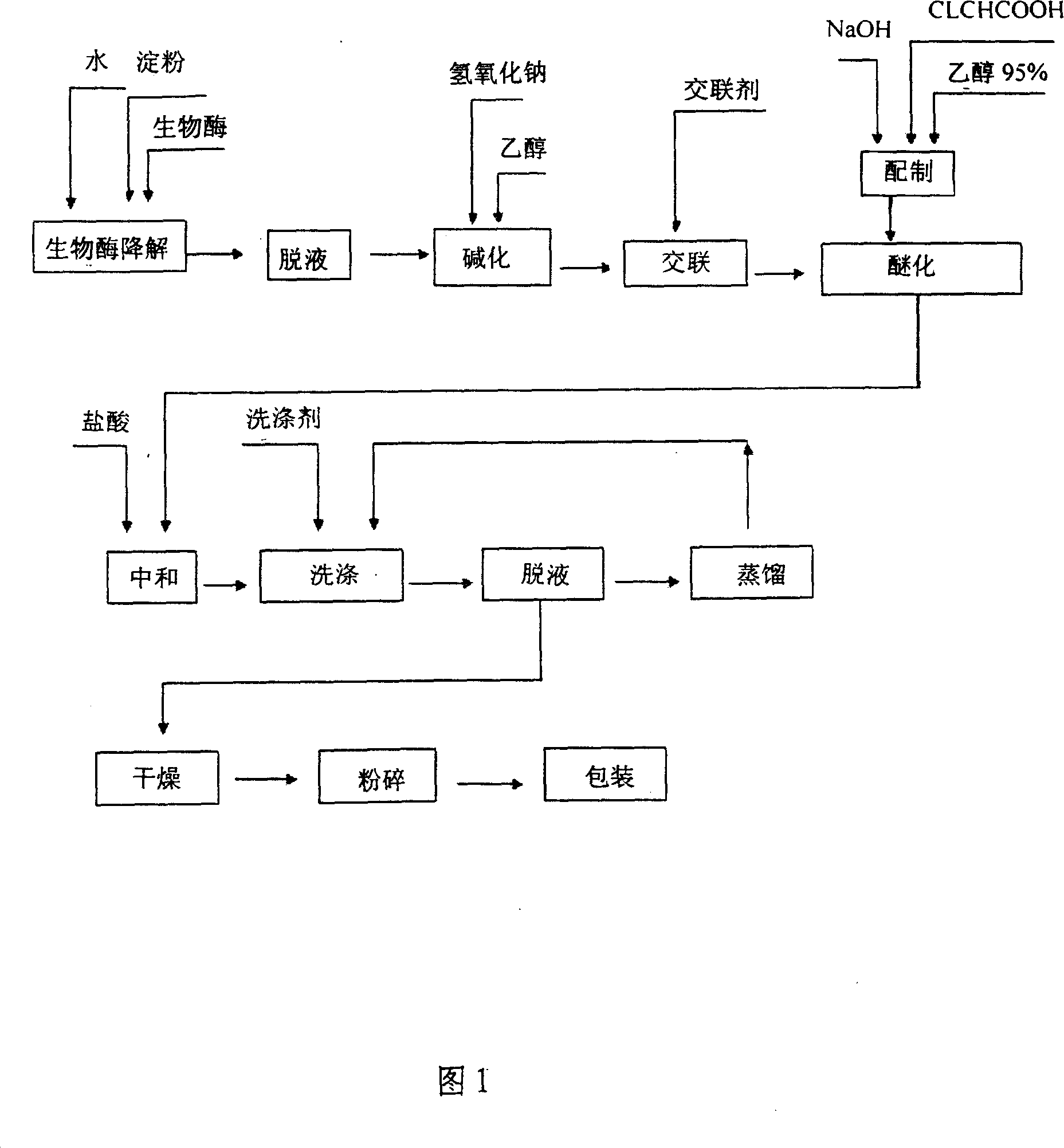

Method used

Image

Examples

Embodiment 1

[0037] In the stainless steel enzymatic hydrolysis kettle, add 100Kg of starch to make 40% starch milk, start stirring, add 5Kg of α-amylase, heat up to 50°C, react for 5 minutes, centrifuge and deliquify, then add to the stainless steel etherification kettle, Add 250Kg ethanol, 0.25Kg sodium trimetaphosphate, add dropwise 52Kg of 25% sodium hydroxide solution, alkalinize and crosslink for 1 hour at 40°C, and add etherification agent dropwise three times every 20 minutes (by, 50Kg ethanol, 30Kg Chloroacetic acid, 25% sodium hydroxide solution 52Kg preparation) carries out etherification, and jacket feeds hot water heating, and material temperature is maintained at 50 ℃, and after keeping warm for 10 hours, drops to room temperature, neutralization, washing, drying, Crushed into finished products.

Embodiment 2

[0039] Taking the preparation method of producing 1 ton of super disintegrant as an example, add 1000Kg of starch to make 40% starch milk in a stainless steel enzymatic hydrolysis kettle, start stirring, add 50Kg of α-amylase, heat up to 50°C, and react for 5 minutes. After centrifugation and dehydration, add to the stainless steel etherification kettle, add 2500Kg ethanol, 2.5Kg sodium trimetaphosphate, 520 kg of 25% sodium hydroxide solution, alkalinize and cross-link for 1 hour at 40 ° C, and divide it into three times with an interval of 20 minutes each time Etherifying agent (500 kilograms of ethanol, 300 kilograms of chloroacetic acid, 520 kilograms of 25% sodium hydroxide solution) is added dropwise to carry out etherification, and the jacket is passed into hot water for heating, and the material temperature is kept at 50° C. to room temperature, neutralized, washed, dried and pulverized to obtain the finished product.

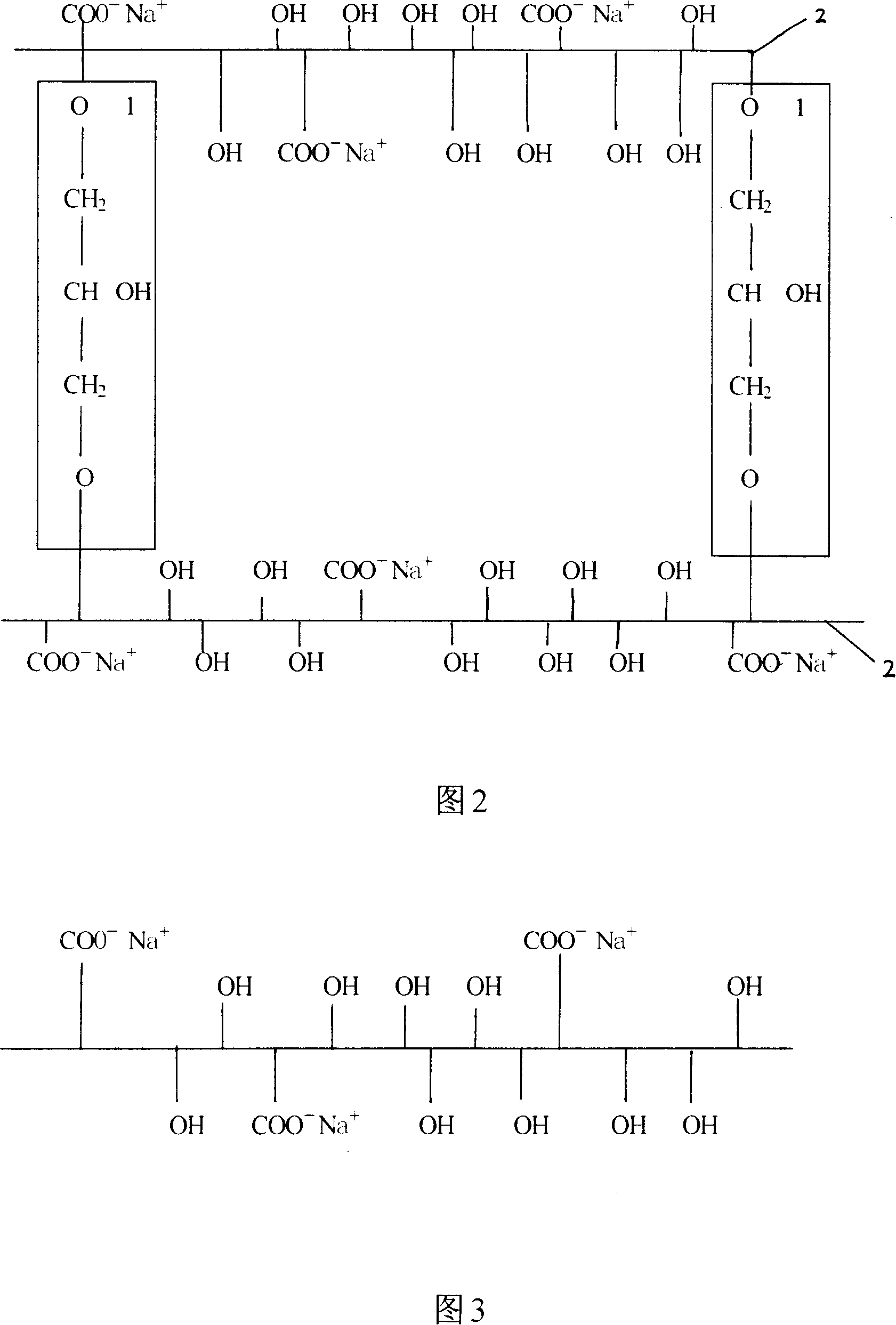

[0040] Figure 2 is a schematic diagram of the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com