High capacity solid solution composite positive electrode material preparation method

A composite positive electrode material and composite material technology are applied in the field of preparation of high-capacity solid solution composite positive electrode materials, which can solve the problems of many processing procedures, cumbersome operations, low theoretical capacity, etc., and achieve simple process engineering, simple equipment, and accelerated ion diffusion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

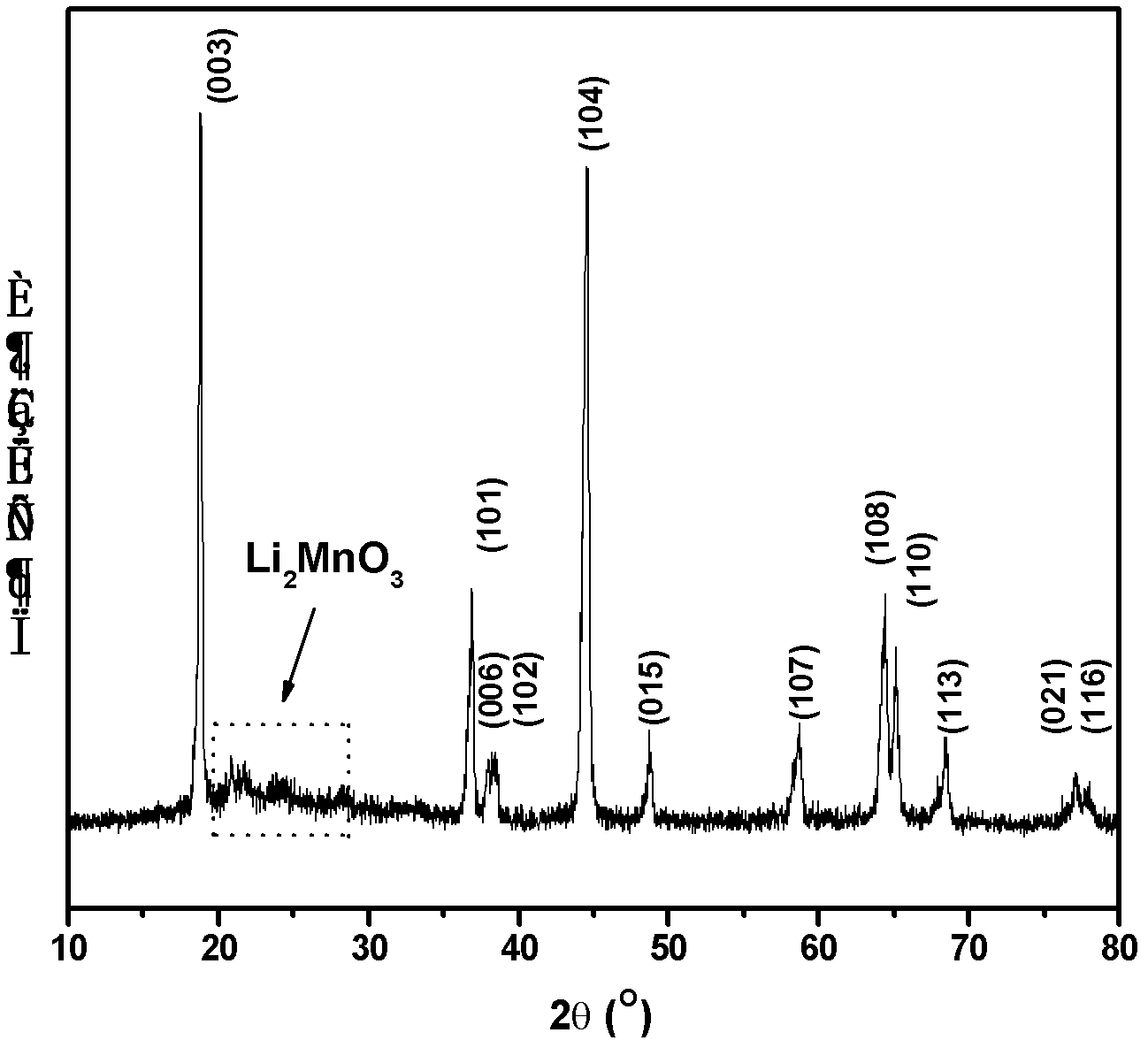

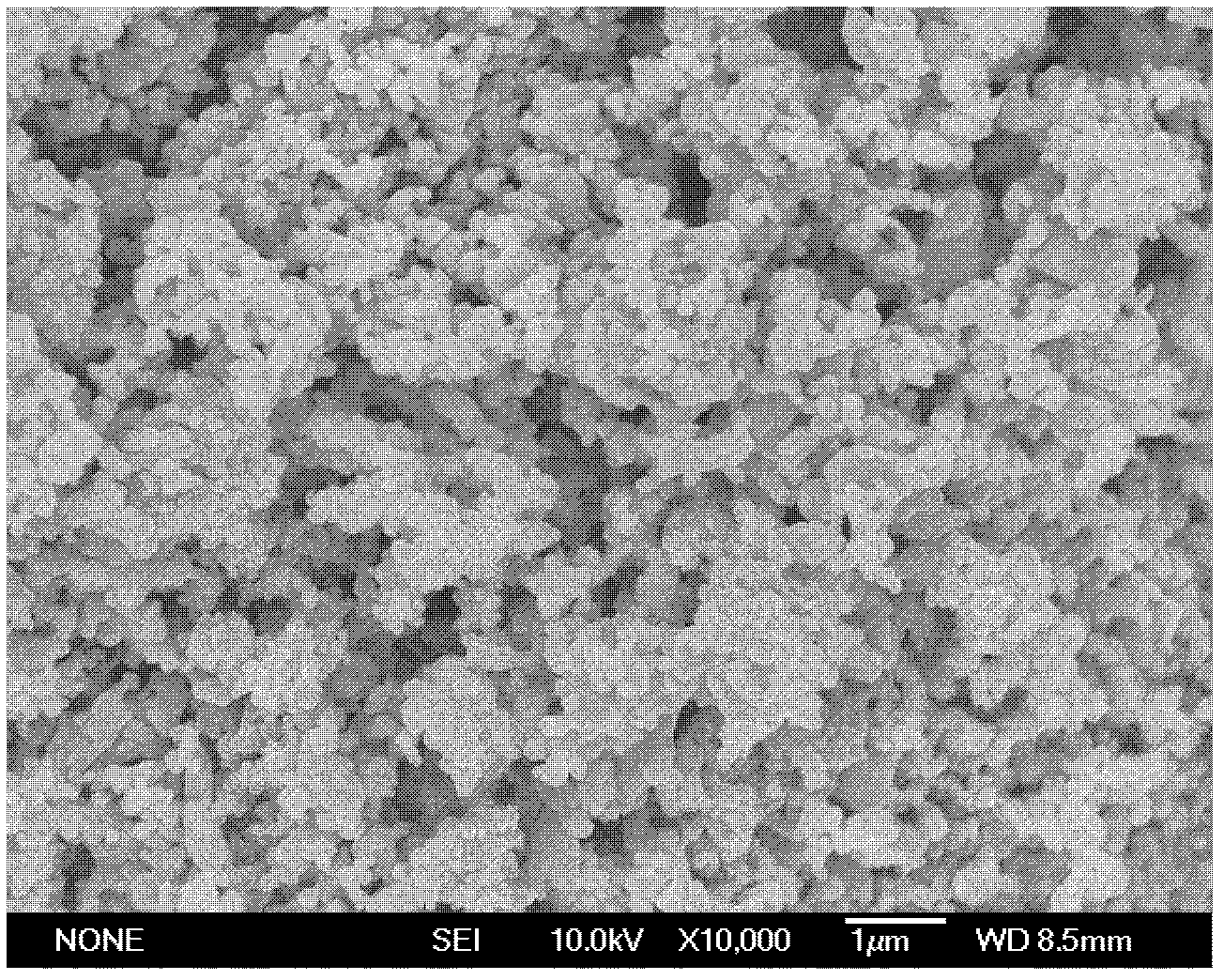

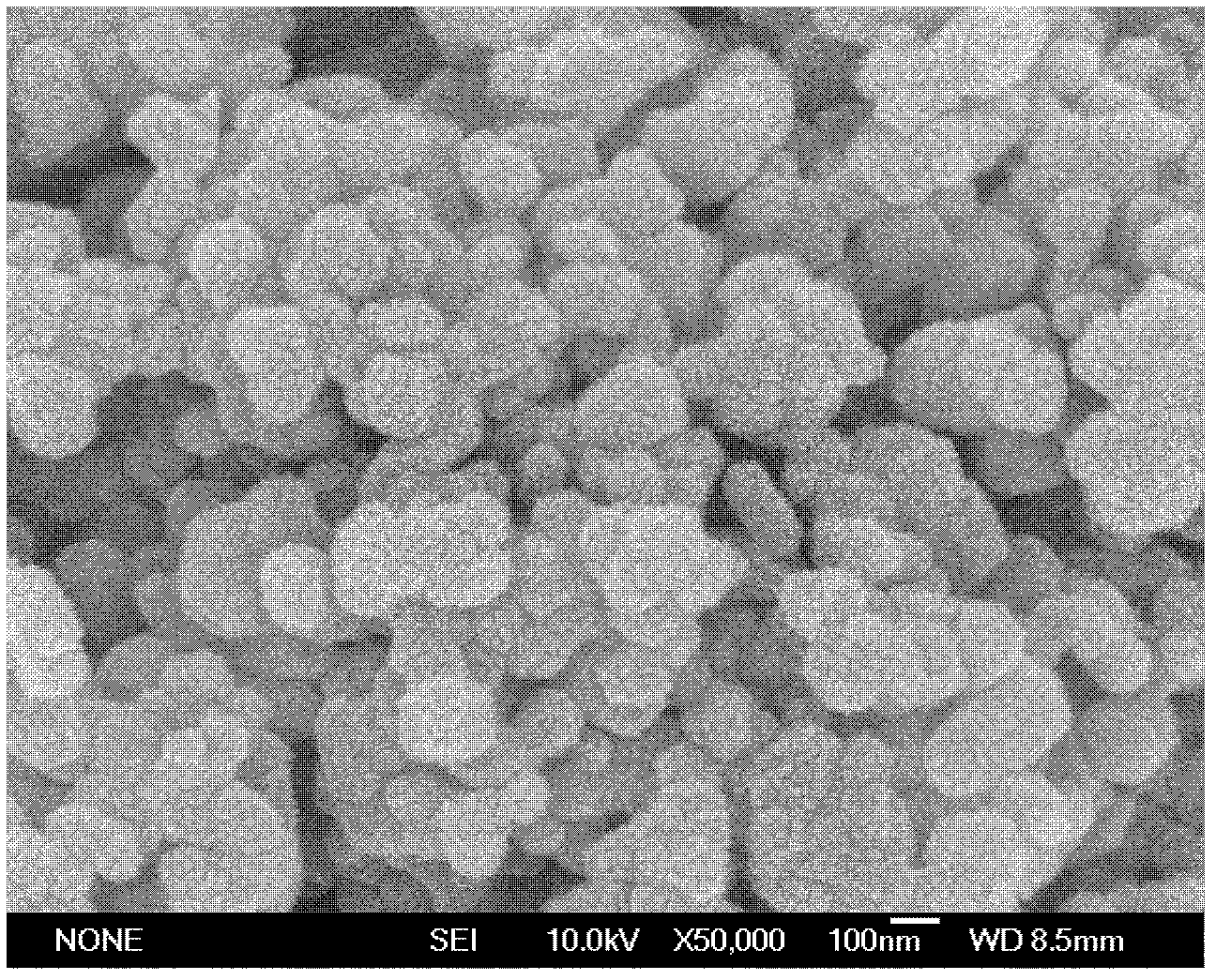

[0033] Example 1: 0.3Li 2 MnO 3 0.7LiMn 0.5 Ni 0.5 o 2 Preparation of cathode material

[0034]Lithium acetate, manganese acetate, nickel acetate, and sodium hydroxide were used as starting materials, and 6.5 mmol of manganese acetate, 3.5 mmol of nickel acetate, 13.4 mmol of lithium acetate, and 70.2 mmol of sodium hydroxide were weighed. Ball mill the mixture at room temperature for 2 hours, dry the ball-milled mixture at 180°C for 4 hours to obtain off-white lumps; after grinding the off-white lumps fully, first heat treatment at 350°C for 10 hours, and then heat up to 900°C Heat treatment for 16 hours, and cool down to room temperature with the furnace to obtain a gray-black blocky substance; wash the substance with deionized water several times to obtain a residue; dry the obtained residue at 180°C for 6 hours to obtain a primary product; After the product was pressed into tablets, it was heat-treated at 500°C for 3 hours, then heated to 900°C for 16 hours, and final...

Embodiment 2

[0035] Example 2: 0.1Li 2 MnO 3 0.9LiMn 0.5 Ni 0.5 o 2 Preparation of cathode material

[0036] Lithium acetate, manganese acetate, nickel acetate, and sodium hydroxide were used as starting materials, and 5.5 mmol of manganese acetate, 4.5 mmol of nickel acetate, 11.3 mmol of lithium acetate, and 64.0 mmol of sodium hydroxide were weighed. Ball mill the mixture at room temperature for 2 hours, dry the ball-milled mixture at 180°C for 4 hours to obtain off-white lumps; after grinding the off-white lumps fully, first heat treatment at 350°C for 10 hours, and then heat up to 900°C Heat treatment for 16 hours, and cool down to room temperature with the furnace to obtain a gray-black blocky substance; wash the substance with deionized water several times to obtain a residue; dry the obtained residue at 180°C for 6 hours to obtain a primary product; After the product is pressed into tablets, it is heat-treated at 500°C for 3 hours, then heated up to 900°C for 16 hours, and fin...

Embodiment 3

[0037] Example 3: 0.2Li 2 MnO 3 0.8LiMn 0.5 Ni 0.5 o 2 Preparation of cathode material

[0038] Lithium acetate, manganese acetate, nickel acetate, and sodium hydroxide were used as starting materials, and 6.0 mmol of manganese acetate, 4.0 mmol of nickel acetate, 12.3 mmol of lithium acetate, and 66.9 mmol of sodium hydroxide were weighed. Ball mill the mixture at room temperature for 2 hours, dry the ball-milled mixture at 180°C for 4 hours to obtain off-white lumps; after grinding the off-white lumps fully, first heat treatment at 350°C for 10 hours, and then heat up to 900°C Heat treatment for 16 hours, and cool down to room temperature with the furnace to obtain a gray-black blocky substance; wash the substance with deionized water several times to obtain a residue; dry the obtained residue at 180°C for 6 hours to obtain a primary product; After the product was pressed into tablets, it was heat-treated at 500°C for 3 hours, then heated to 900°C for 16 hours, and fina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com