Dry-method double-modified starch continuous production device

A dual-modified starch and production device technology, applied in the field of machinery, can solve the problems of narrow product promotion and application, high solvent method production cost, large product quality fluctuation, etc., and achieves significant ecological and environmental protection benefits, low production costs, and stable product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

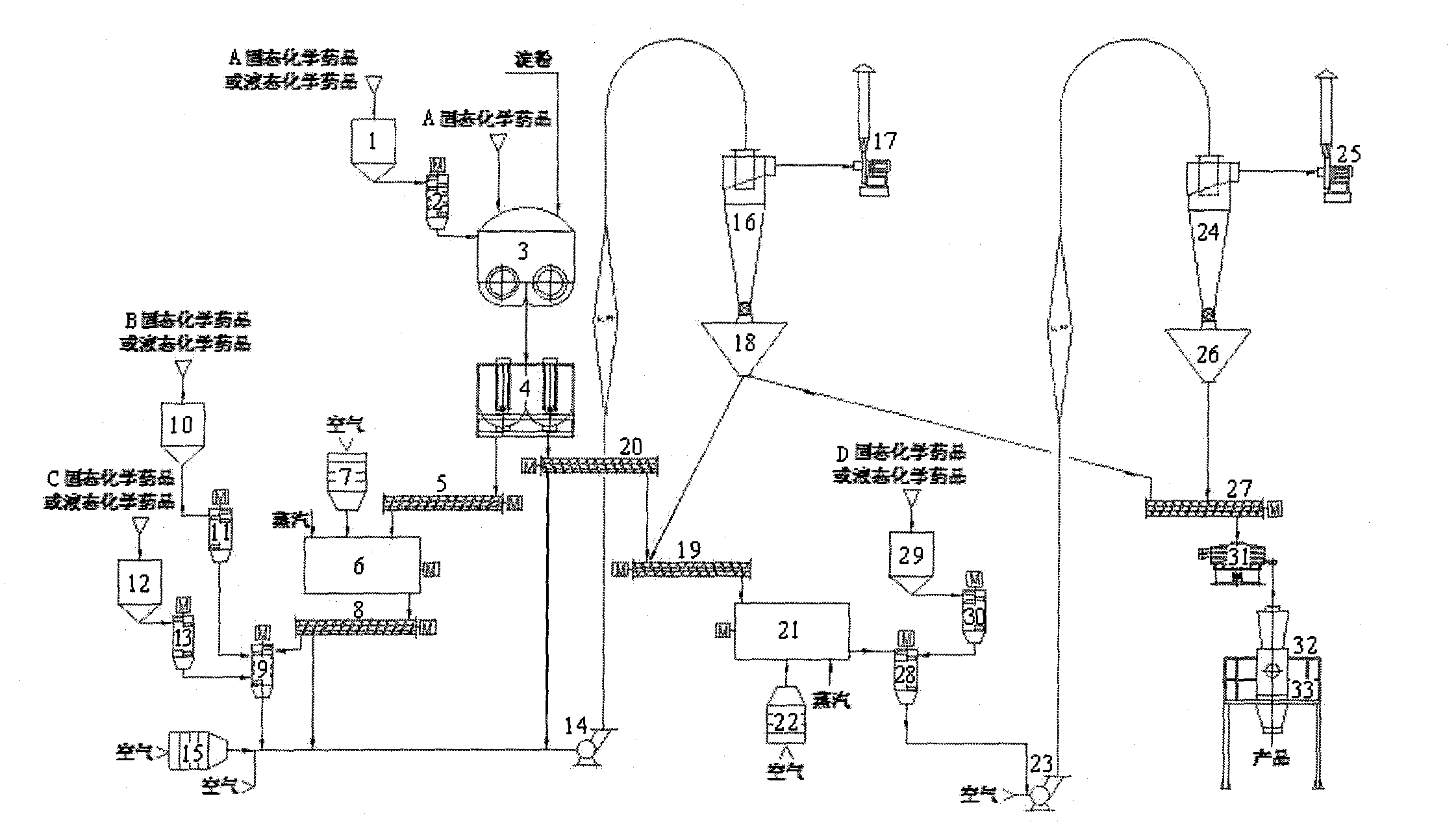

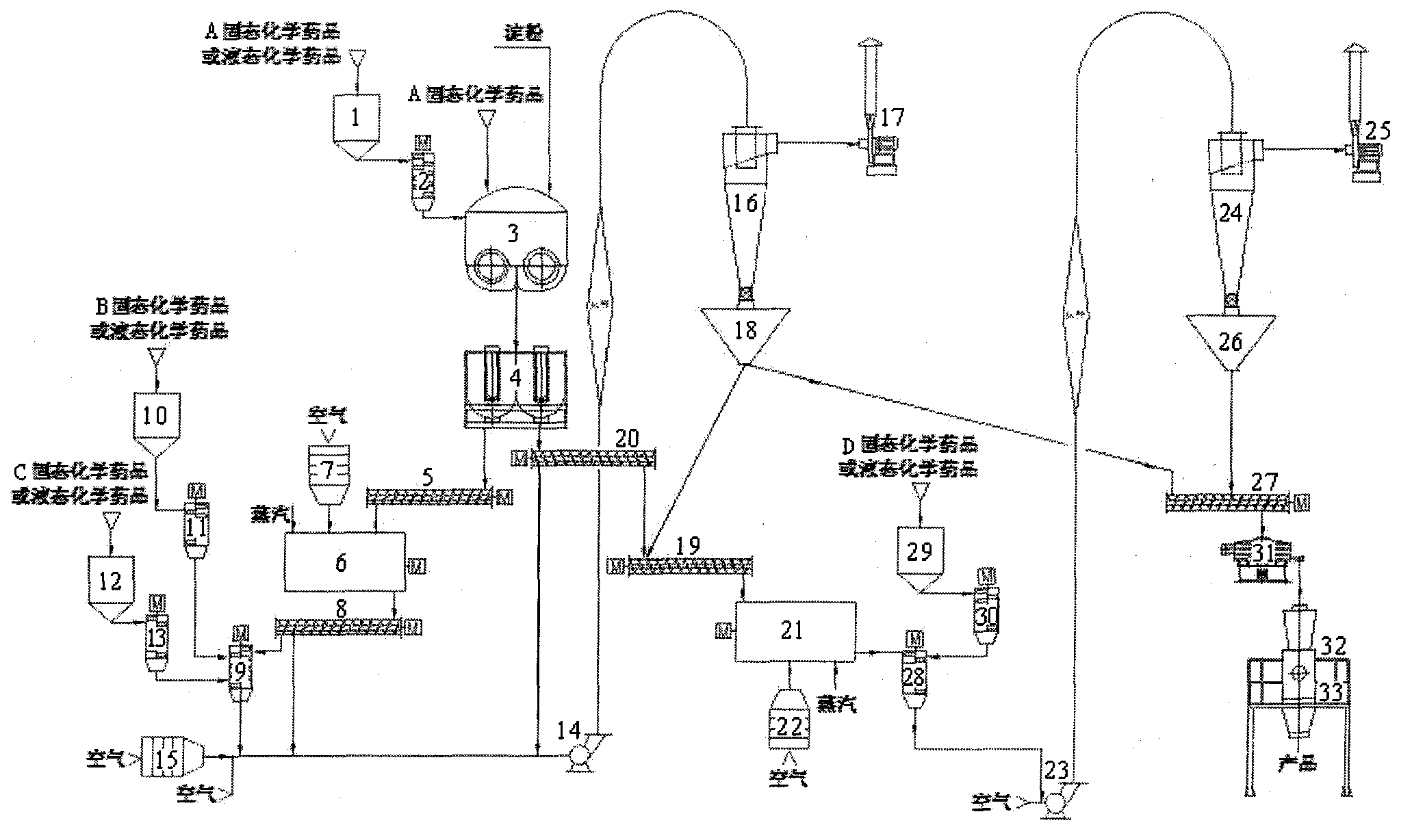

[0028] Embodiment 1: the structure of dry method double-modified starch continuous production device

[0029] Dry-process double-modified starch continuous production device, equipped with liquid medicine tanks 1, 10, 12 and 29, atomization devices 2, 11, 13 and 30, mixer 3, powder storage tank 4, speed-adjustable metering powder feeders 5 and 19 , reactors 6 and 21, heaters 7, 15 and 22, screw conveyors 8, 20 and 27, continuous mixers 9 and 28, lifters 14 and 23, classifiers 16 and 24, induced draft fans 17 and 25, Powder collection tank 18 and 26, vibrating screen 31, weighing scale 32 and packaging machine 33.

[0030] The connection of the device is: A liquid medicine tank 1, A atomization device 2, mixer 3, powder storage tank 4, A speed regulating metering powder feeder 5, A reactor 6, A screw conveyor 8, A continuous mixer 9. A lifter 14, A classifier 16, A powder collecting tank 18, B speed regulating metering powder feeder 19, B reactor 21, B continuous mixer 28, B l...

Embodiment 2

[0031] By formula weight parts starch or / and the chemicals that add with powder are continuously metered into the mixer, while 6 parts by weight concentration is 69% 3-chloro-2-hydroxypropyl trimethyl ammonium chloride and 2.8 weight parts Parts of sodium hydroxide with a concentration of 30% are fully mixed in the A drug solution tank 1 and continuously sprayed into the mixer 3 through the A atomization device 2, and the starch and chemicals are fully mixed and then unloaded into the powder storage tank 4; The fast metering powder feeder 5 continuously adds starch to A reactor 6 and raises the temperature to 50-100°C. The starch in A reactor 6 realizes the continuous reaction of continuous feeding and discharging, and the speed metering powder feeder 5 can be adjusted by adjusting A. The speed of adding powder, control the reaction time of starch in A reactor 6, control the reaction temperature by adjusting the flow rate of A heater 7 hot air and steam, so as to meet the needs...

Embodiment 3

[0032] Embodiment 3: the continuous production of dry process dextrin

[0033] It is 10% hydrochloric acid solution that preparation concentration is in A chemical solution tank 1 and is continuously sprayed in the cassava starch of continuous metering feed by A atomizing device 2, and the weight ratio of starch and hydrochloric acid solution is 100: 2, and starch and hydrochloric acid are in After being fully mixed in the mixer 3, it is unloaded into the storage tank 4; a part of the starch is continuously transported to the A reactor 6 through the A speed-adjusting metering powder feeder 5 and heated to 150-170°C, and the other part of the starch is transported through the B screw conveyor 20 , through the B speed-adjusting metering powder feeder 19, it is continuously added to the B reactor 21 and heated to 150-170°C. The starch is continuously fed and discharged in the A and B reactors respectively. The powder feeding speed of the powderers 5 and 19 controls the reaction t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com