Method for synthesizing supercritical fluid of ceramic precursor polycarbosilane

A supercritical fluid and ceramic precursor technology, which is applied in the production of bulk chemicals, can solve problems such as uneven molecular weight distribution, low synthesis yield, and inability to solve reaction uniformity well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

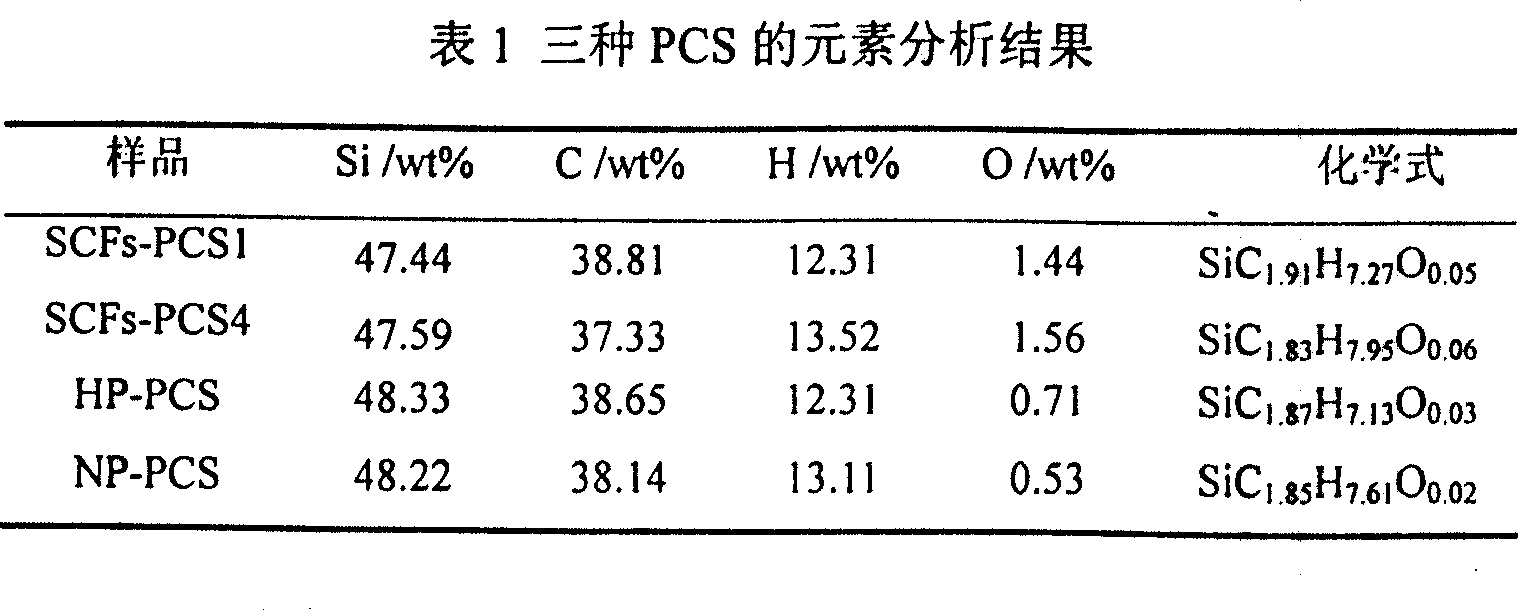

[0027] Embodiment 1, take PDMS as raw material, xylene as supercritical fluid medium supercritical synthesis of PCS:

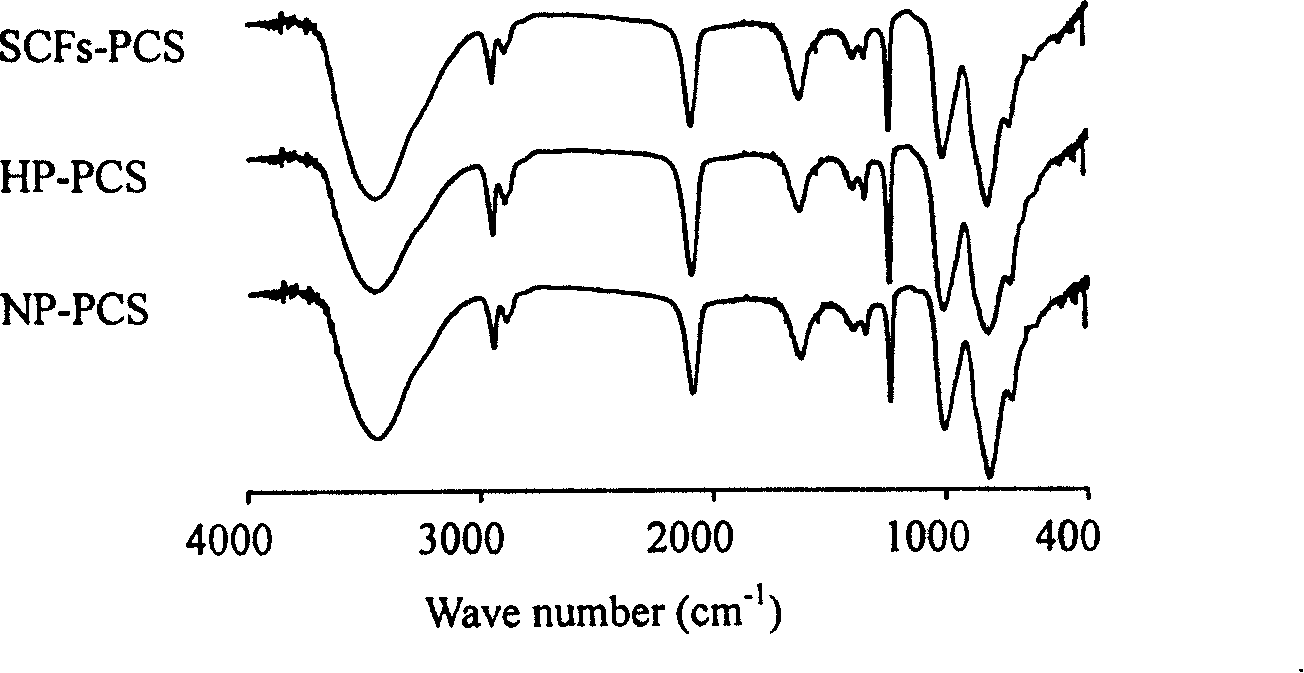

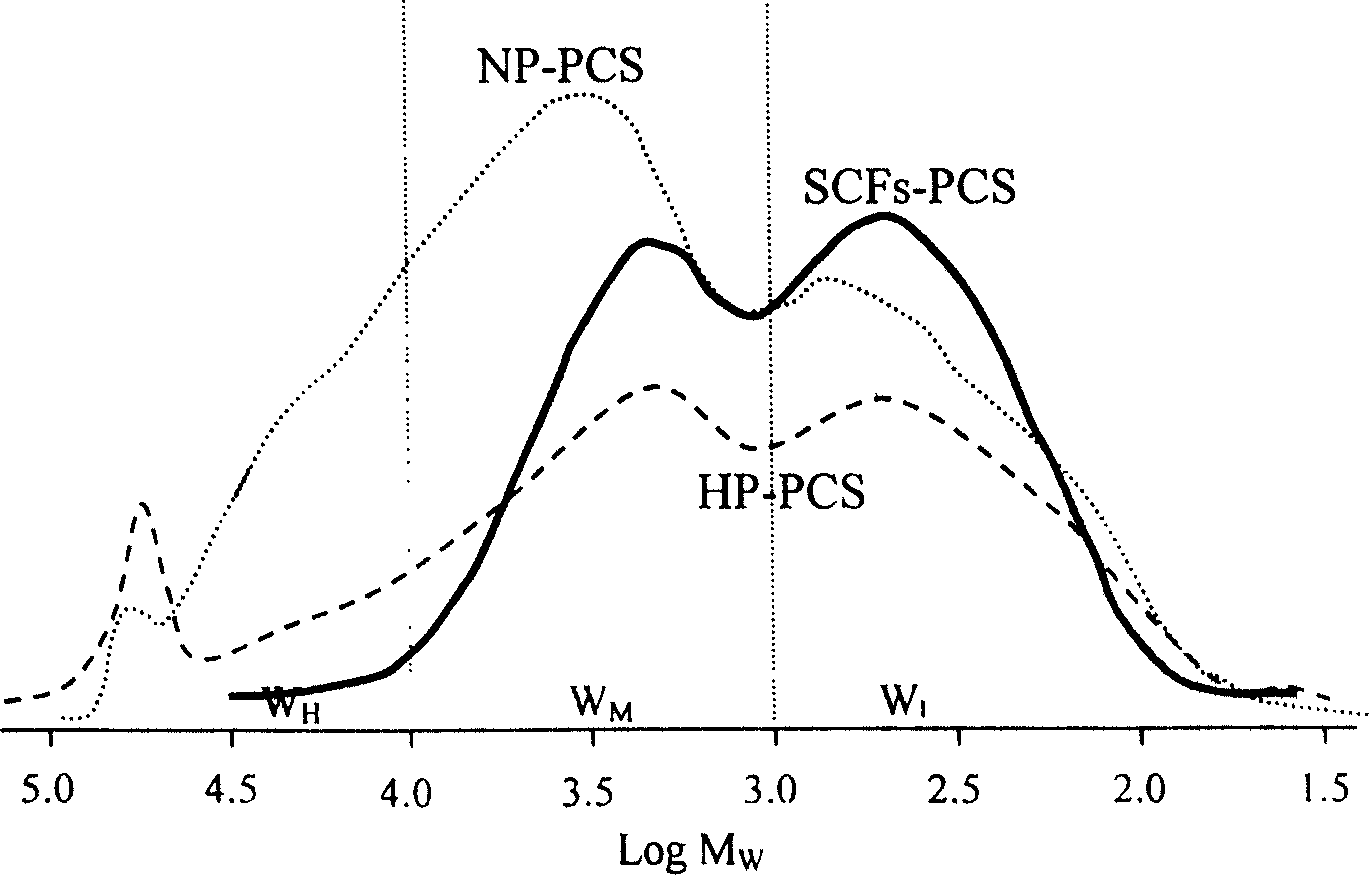

[0028] Put 150g of PDMS and 100ml of xylene in the autoclave, stir evenly, evacuate and replace the gas in the autoclave with high-purity nitrogen twice, and then pre-add 4.0MPa of N 2 Pressure, seal. Then the temperature was raised to 380° C., and the reaction was carried out for 20 hours. The maximum reaction pressure was 6.0 MPa. After cooling, the crude product of PCS was obtained. The crude product was dissolved in xylene, filtered, and the filtrate was distilled under reduced pressure at 380° C. for 30 minutes. After cooling, a pale yellow resinous PCS precursor (SCFs-PCS1) was obtained. The synthesis yield of the SCFs-PCS1 is 65.8%, the softening point is 210.9-232.9° C., the number average molecular weight is 1826, and the molecular weight distribution coefficient Mw / Mn=1.23. The infrared spectrum of the product was determined as figure 1 shown (see...

Embodiment 2

[0029] Embodiment 2, using PDMS as raw material, xylene as supercritical fluid medium supercritical synthesis of PCS:

[0030] Using the same method as in Example 1, 200 g of PDMS and 125 ml of xylene were placed in an autoclave, reacted at 550 ° C for 1 h, and were post-treated in the same way to obtain SCFs-PCS2. The synthesis yield of the SCFs-PCS2 is 60.2%, the softening point is 156.5-172.7°C, the number average molecular weight is 1097, the molecular weight distribution coefficient Mw / Mn=1.45, and the typical Si-H, Si- CH 3 Absorbance ratio of the absorption peak A Si-H / A Si-CH3 = 0.938.

Embodiment 3

[0031] Embodiment 3, using PDMS as raw material, xylene as supercritical fluid medium supercritical synthesis of PCS:

[0032] Using the same method as in Example 1, 200 g of PDMS and 125 ml of xylene were placed in an autoclave, reacted at 460° C. for 4 h, and were post-treated in the same way to obtain SCFs-PCS3. The synthesis yield of the SCFs-PCS3 is 61.8%, the softening point is 203.8-238.7°C, the number average molecular weight is 1560, the molecular weight distribution coefficient Mw / Mn=1.78, and the typical Si-H, Si- CH 3 Absorbance ratio of the absorption peak A Si-H / A Si-CH3 = 0.917.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com