Box-type multi-purpose furnace for metal heat treatment

A metal heat treatment and multi-purpose furnace technology, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve problems such as uneven carbon and nitrogen mixing, inability to guarantee product quality and reproducibility, and carbon deposition. Achieve the effects of reducing temperature rise, improving reaction efficiency and uniformity, and reducing carbon deposition in the tube

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

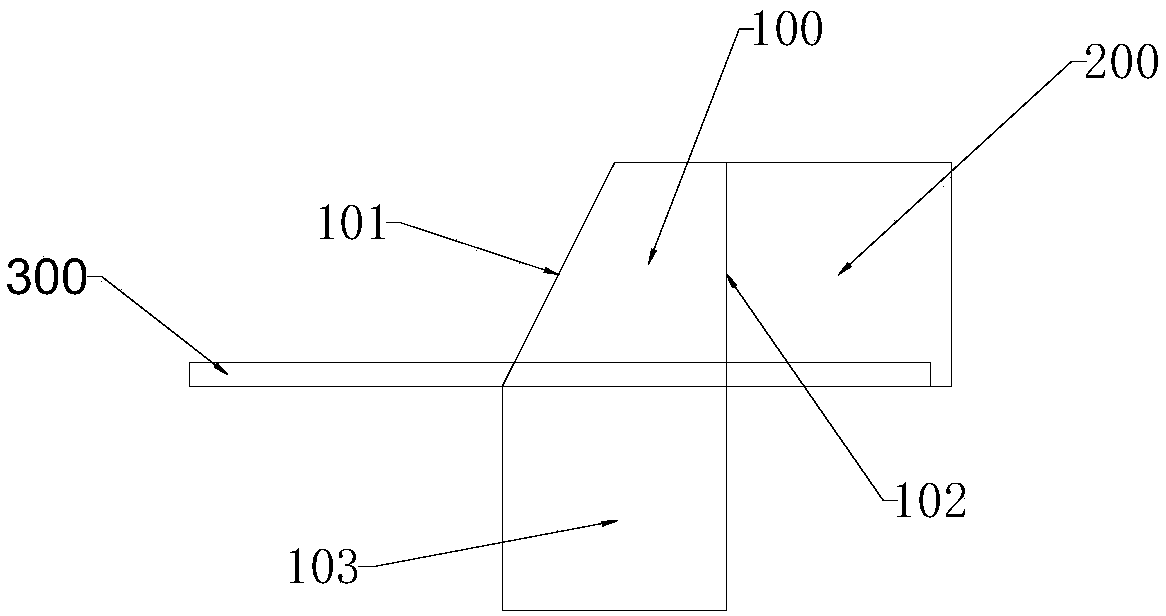

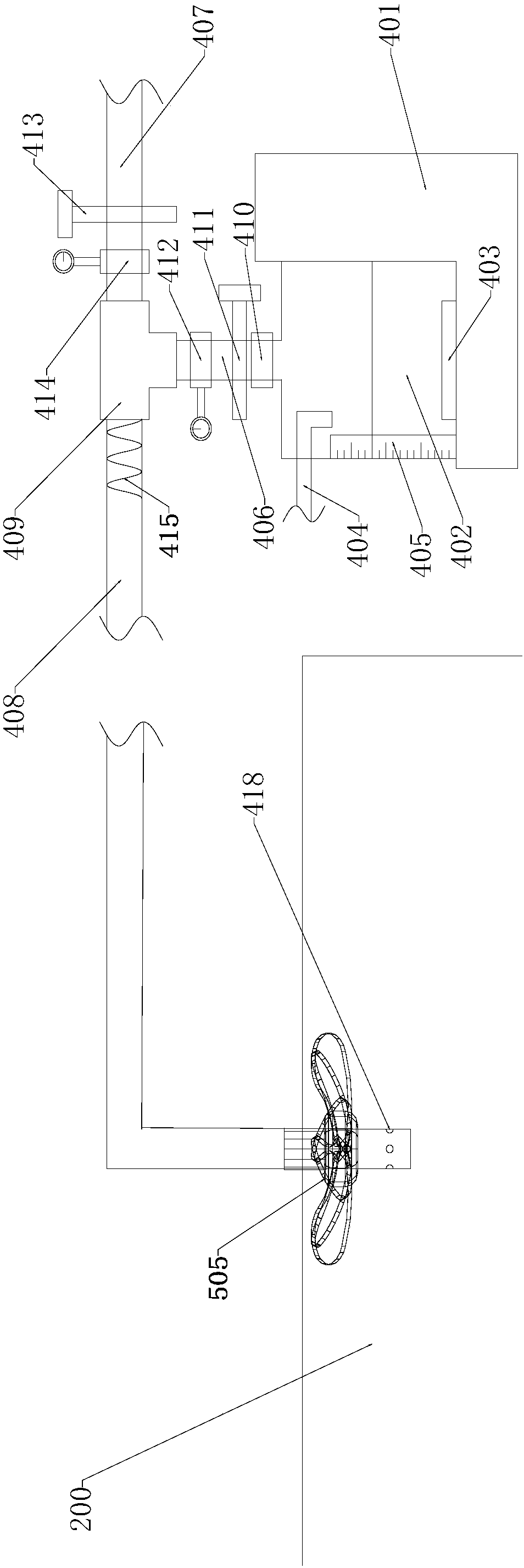

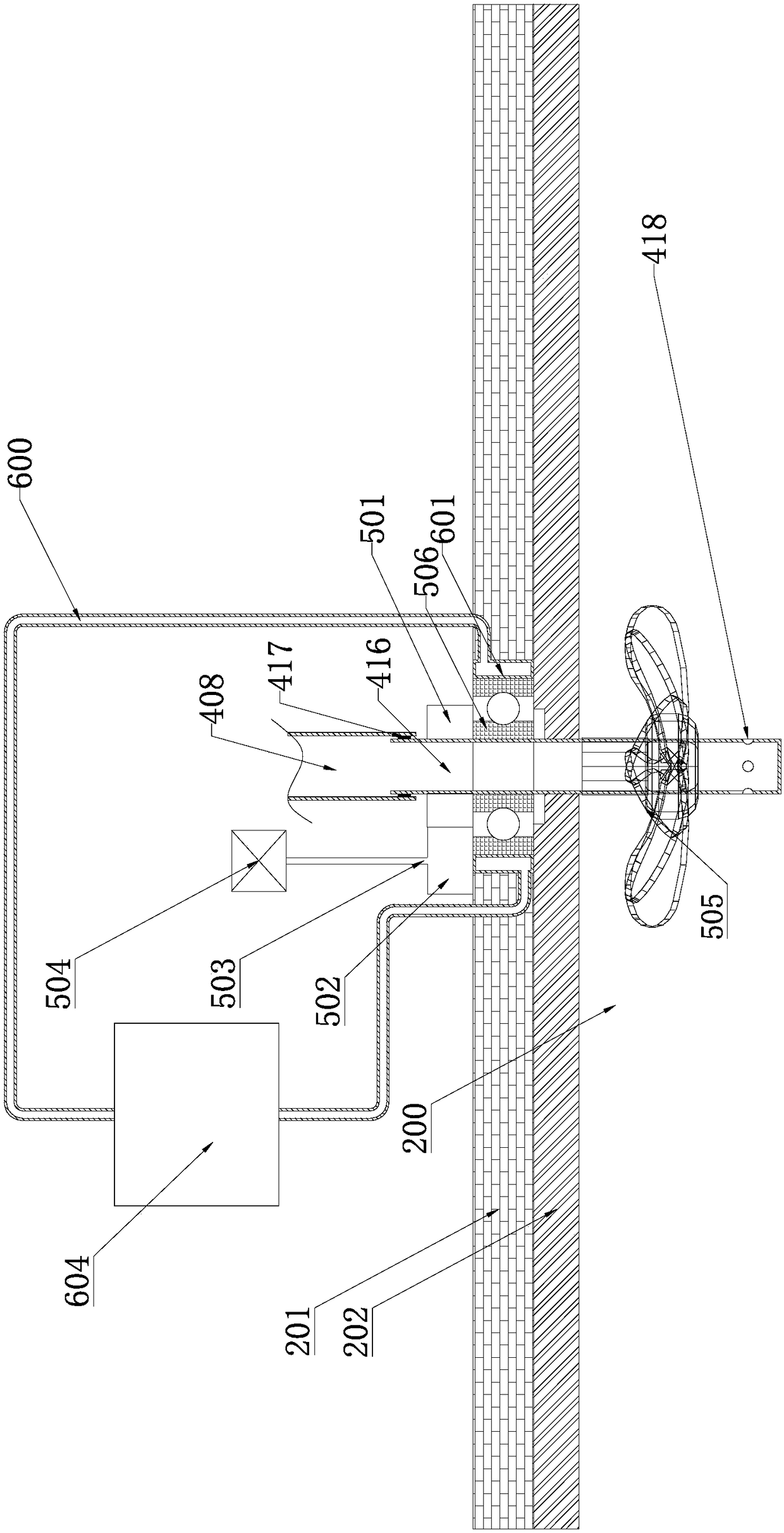

[0018] combine figure 1 and figure 2 , the present invention proposes a box-type multipurpose furnace for metal heat treatment, comprising a front chamber 100, a heating chamber 200, and a material delivery system 300; the heating chamber 200 is connected in series with the front chamber 100, and the two are separated by a middle door 102 The end of the front chamber 100 away from the middle door 102 is provided with a furnace door 101; the lower part of the front chamber 100 is a quenched oil tank 103; the delivery system 300 is used to move the parts to be processed from outside the furnace to the furnace or Move between the heating chamber 200, the front chamber 100, and the oil tank 103 in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com