Method for reducing surface tension of molten-state lithium source so as to improve high-temperature solid phase sintering process of cathode material of lithium ion battery

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of uneven distribution of lithium sources, insufficient reaction, unbalanced reaction, etc., and achieve low lithium-nickel mixing degree, Improving the effect of wetting and the effect of complete solid-state reaction at high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

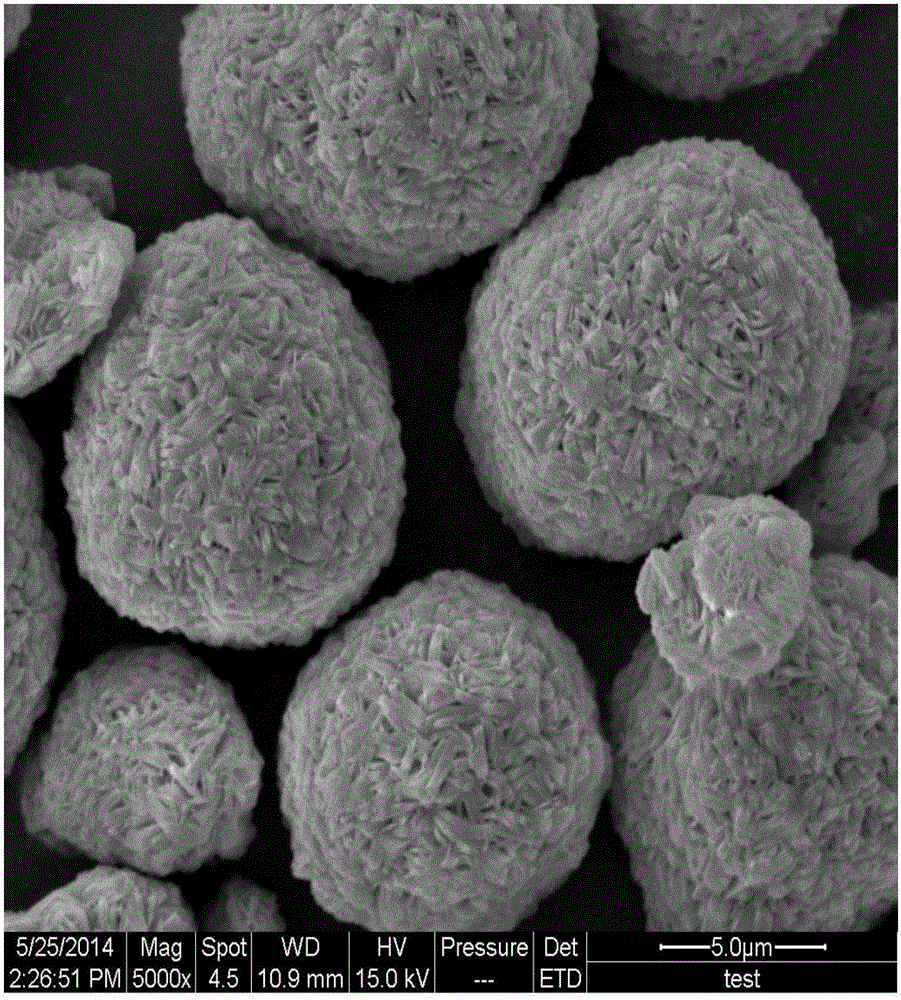

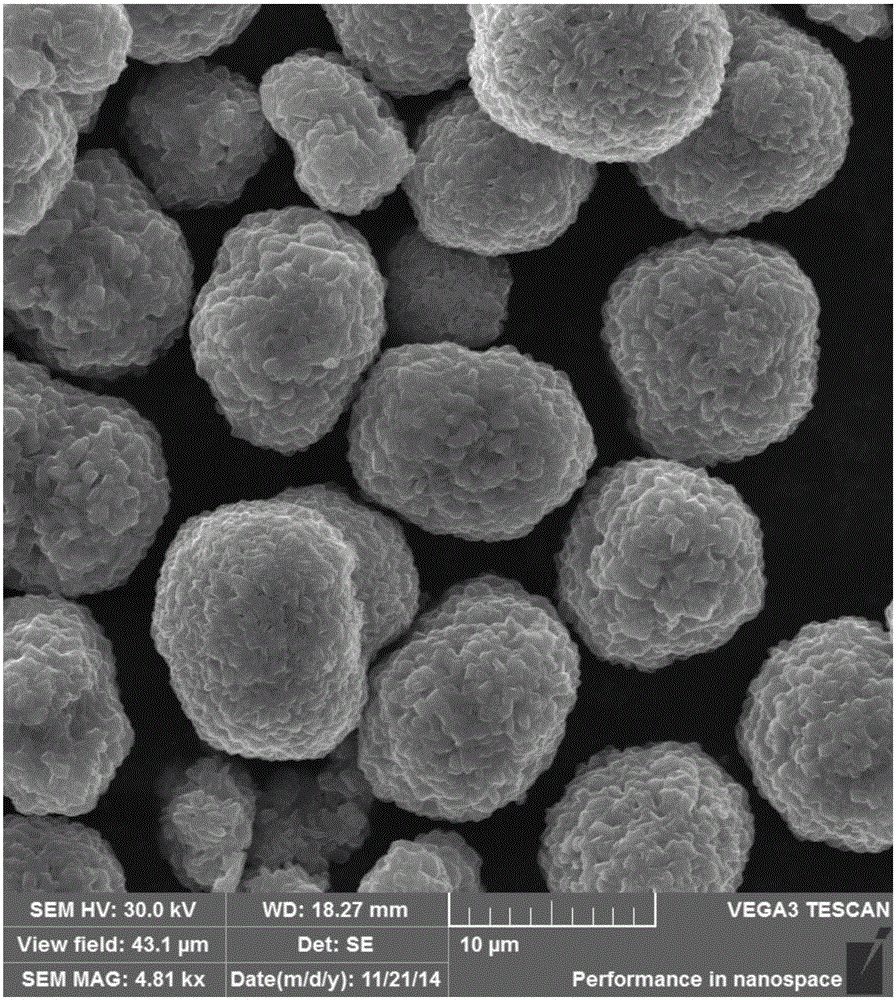

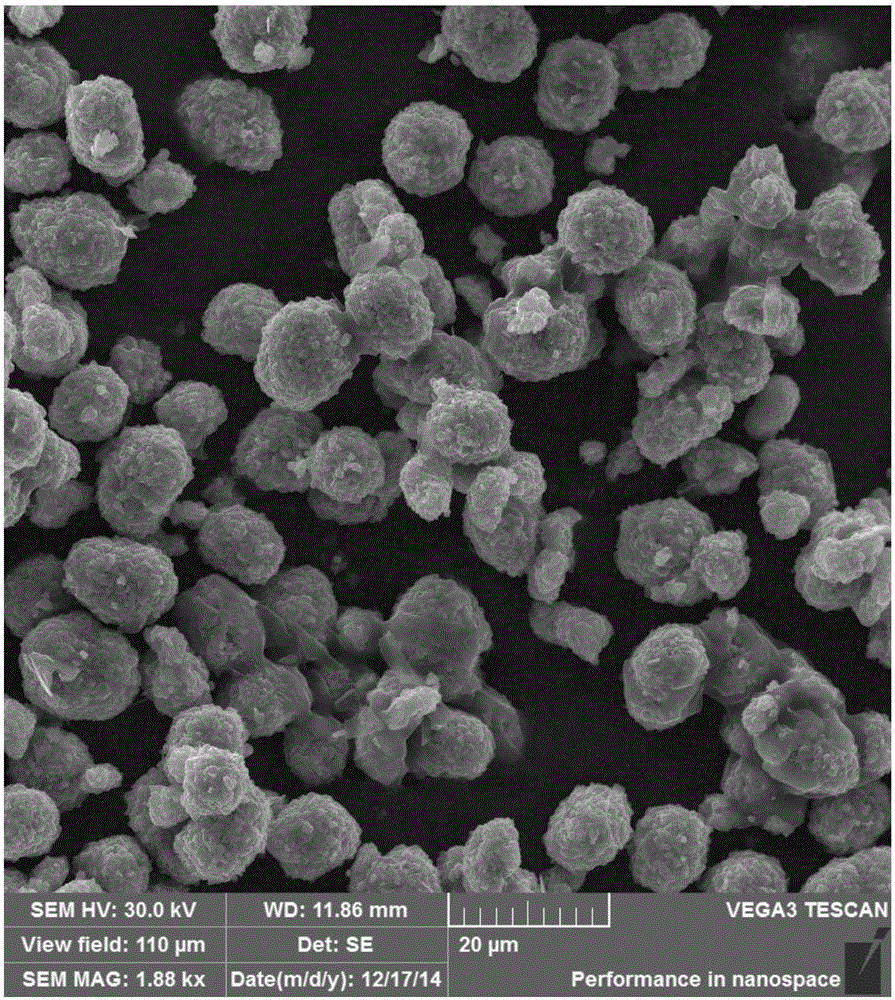

Image

Examples

specific Embodiment approach 1

[0027] Embodiment 1: A method of reducing the surface tension of the molten lithium source in this embodiment to improve the high-temperature solid-state sintering process of the positive electrode material of the lithium-ion battery is carried out according to the following steps:

[0028] 1. Lithium source pretreatment: mix lithium source and phosphate according to the molar ratio of 1:(0.005~0.2) and stir for 10min~120min to obtain solid mixture 1; transfer solid mixture 1 to a ball mill tank and ball mill for 1h~20h to obtain solid mixture 2;

[0029] 2. Mix the lithium source and the precursor material of the positive electrode material of the lithium ion battery: mix the solid mixture 2 obtained in step 1 with the precursor material of the positive electrode material of the lithium ion battery at a molar ratio of 1: (1 to 1.2) and stir for 10 minutes ~60min to obtain solid mixture 3;

[0030] 3. Fully infiltrate the lithium source and the precursor material: transfer the ...

specific Embodiment approach 2

[0032] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the phosphate described in step one is potassium dihydrogen phosphate phosphate, dipotassium hydrogen phosphate phosphate, sodium dihydrogen phosphate phosphate, disodium hydrogen phosphate phosphoric acid Salt, Sodium Phosphate Phosphate, Sodium Pyrophosphate Phosphate, Sodium Pyrophosphate Phosphate, Diammonium Phosphate Phosphate, Monoammonium Phosphate Phosphate, Calcium Phosphate Phosphate, Calcium Phosphate Phosphate, Calcium Pyrophosphate Phosphate Salt, sodium aluminum phosphate phosphate, iron phosphate phosphate, iron pyrophosphate phosphate, magnesium hydrogen phosphate phosphate, magnesium phosphate phosphate, manganese hypophosphite phosphate or a mixture of more. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0033] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the lithium source described in step one is lithium hydroxide, lithium carbonate, lithium nitrate, lithium acetate, lithium sulfate, lithium chloride, lithium fluoride, lithium oxalate , lithium phosphate, lithium hydrogen phosphate or a mixture of one or more. Other steps and parameters are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com