Impact flow reactor for liquid-phase reaction

A technology of impinging flow reactor and liquid phase reaction, which is applied in chemical methods, chemical instruments and methods, chemical/physical processes, etc. to make liquids react with liquids. The shaft seal structure is easy to be damaged, etc., to achieve the effect of high efficiency mixing reaction uniformity, simplified structural design, and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

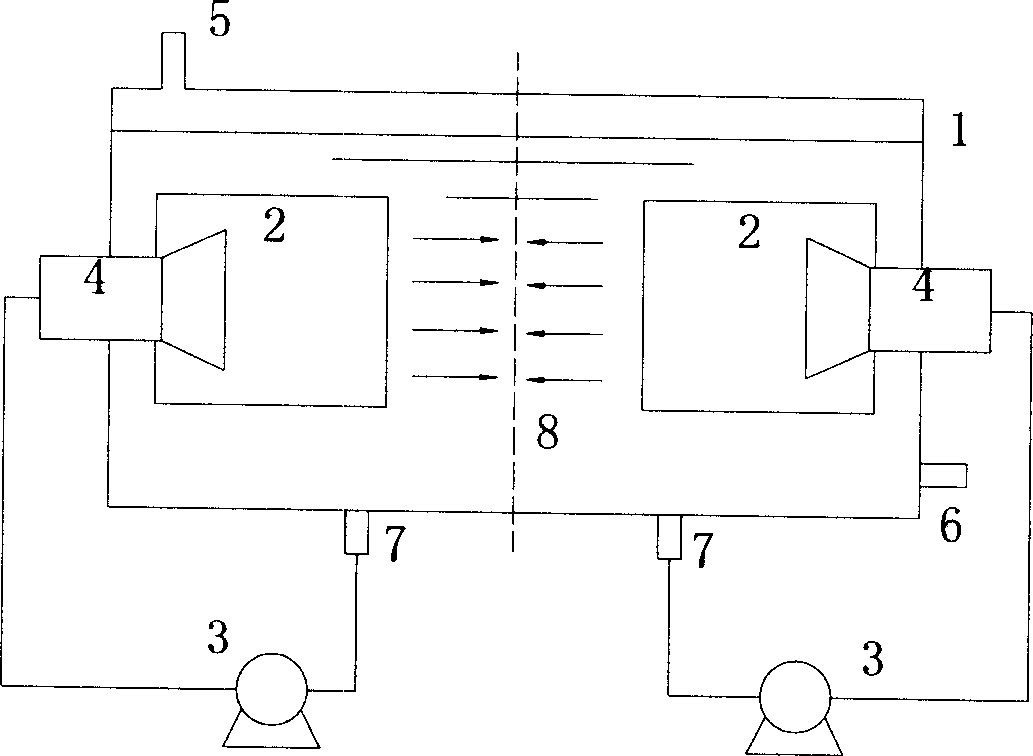

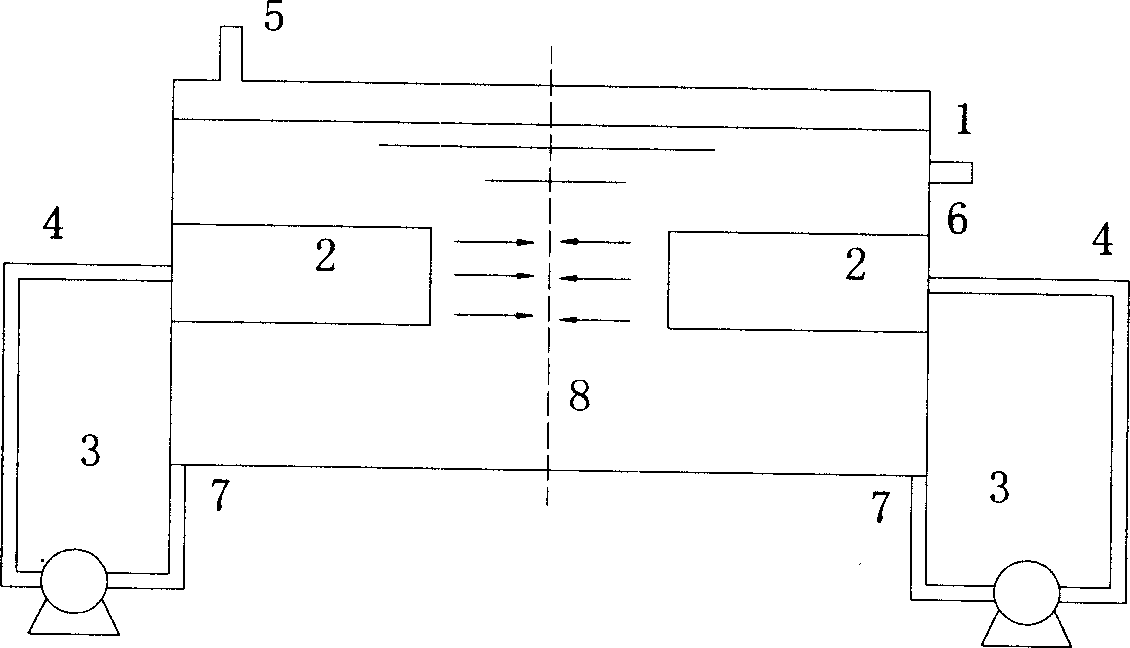

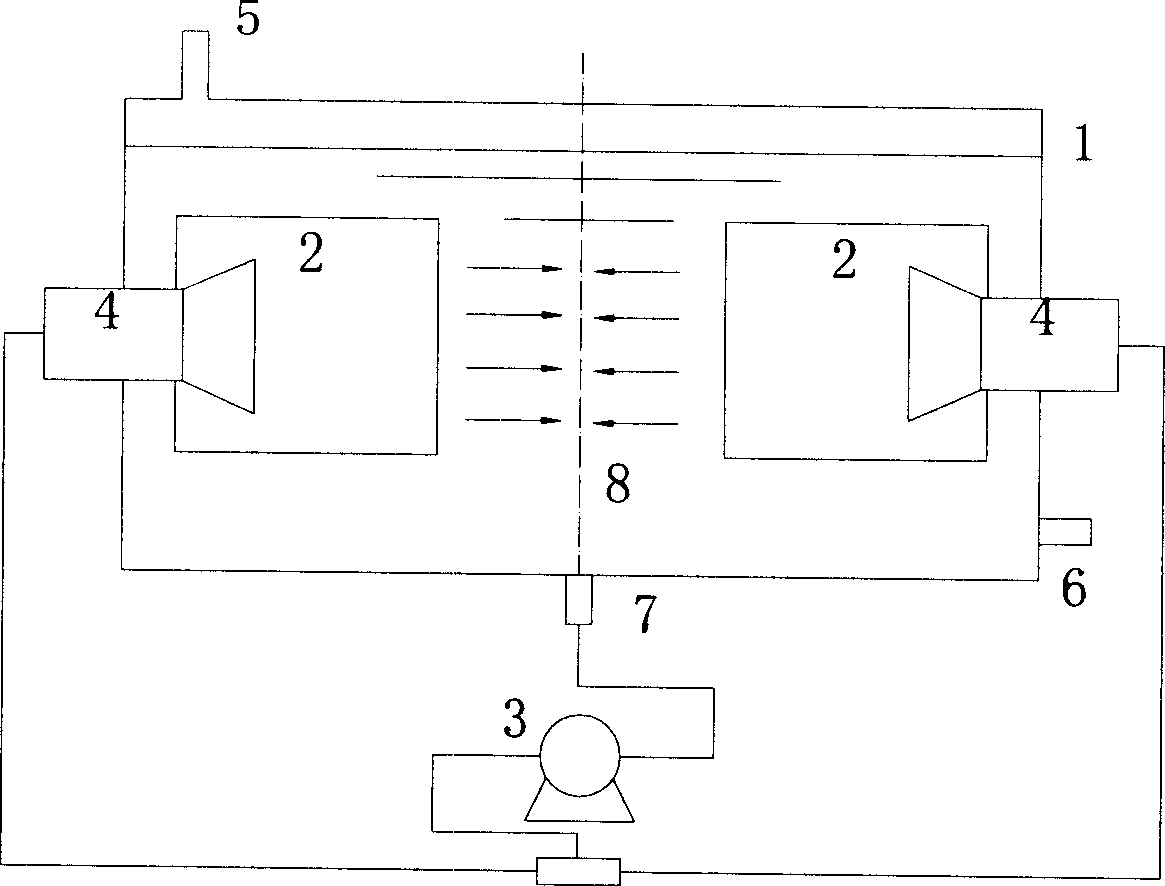

[0010] The structure and function of the impinging flow reactor of the present invention will be further described below in conjunction with the accompanying drawings.

[0011] figure 1 with figure 2 Two material circulation pumps are used in the image 3 with Figure 4 One material circulation conveying pump is used in the pump, and when a material circulation conveying pump is used, the materials at the outlet of the pump can be transported to the inlet of the diversion cylinder with a structure such as a tee. figure 1 with image 3 The connection between the outlet of the medium material delivery pump and the guide tube is designed as a conical tube. The angle of the conical tube can be between 30°C and 60°C. The purpose is to diffuse the reaction raw materials at the outlet of the guide tube to the entire guide tube Cross-section, there may be an annular structure between the guide tube and the tapered pipe, so that the materials in the reactor can form a certain circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com