Method for preparing hydroquinone

A technology for hydroquinone and p-benzoquinone, applied in the field of preparing hydroquinone, can solve the problems such as the limitation of increasing equipment and output, large amount of palladium-carbon catalyst, unfavorable production efficiency and yield, etc., to improve catalytic efficiency and product yields, reduced equipment and yield constraints, strong feasibility and practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

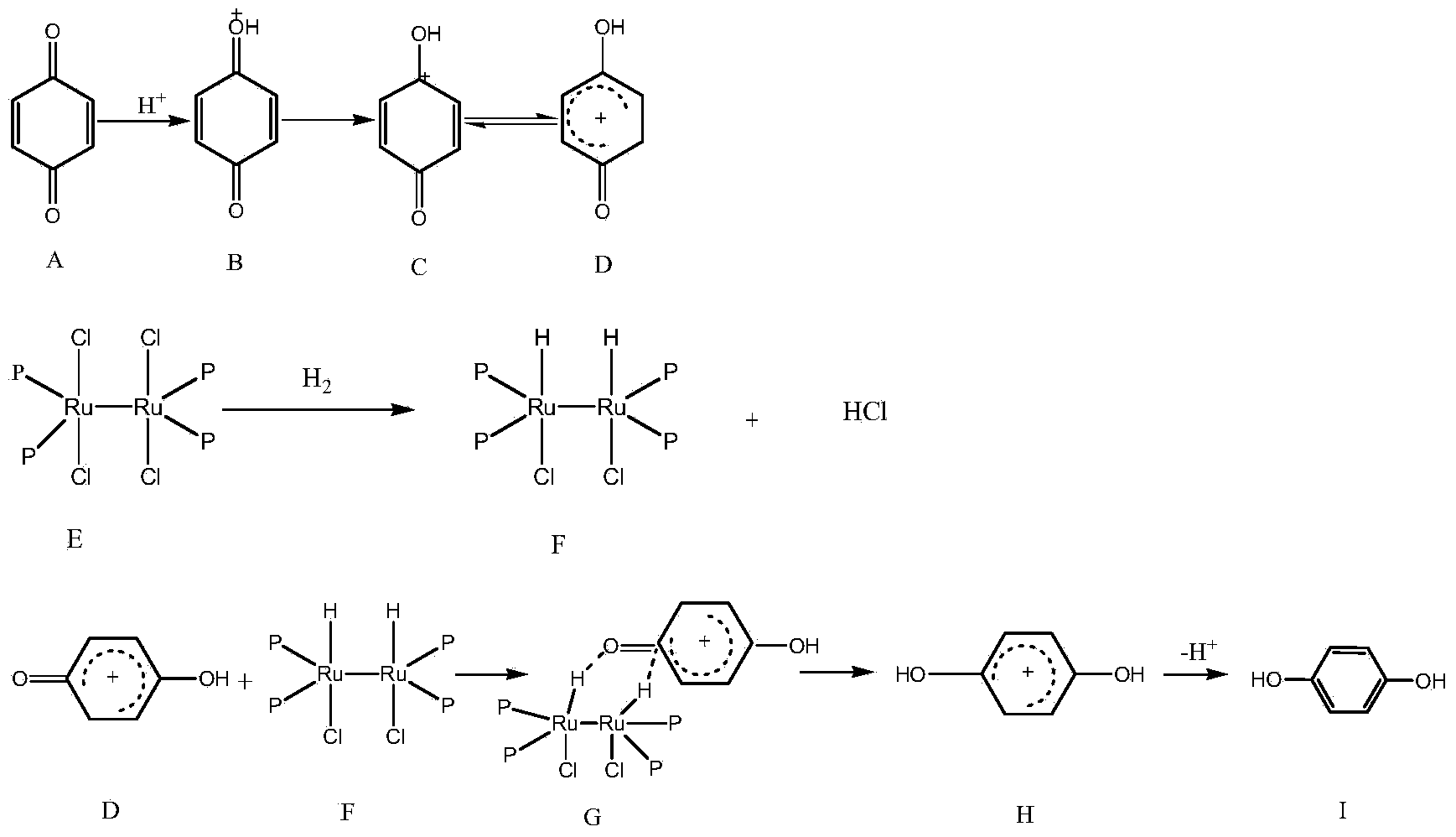

Image

Examples

Embodiment 1

[0036] In autoclave, add 0.050g p-benzoquinone; In autoclave, add catalyst water-soluble ruthenium complex [RuCl 2 (TPPTS) 2 ] 2 , the water-soluble ruthenium complex [RuCl 2 (TPPTS) 2 ] 2 The mol ratio with described p-benzoquinone is 1:400; In autoclave, add 0.1ml sulfuric acid (0.5mol / L), and add distilled water and the pH value of medium solution is controlled to be 1; Pass in autoclave Enter inert gas to replace the air in it; feed hydrogen with a purity greater than 99% into the autoclave, and control the hydrogen pressure in the autoclave to be 1.0MPa; control the reaction temperature to 40°C; at the same time, the solution in the autoclave is For stirring treatment, the stirring speed is controlled to be 120 rpm, and the reaction time is controlled to be 90 minutes. After the reaction was finished, the mixture was allowed to stand and separated, and the hydroquinone product was obtained from the upper organic phase. The yield of hydroquinone obtained by Example 1...

Embodiment 2

[0038] In autoclave, add 0.050g p-benzoquinone; In autoclave, add catalyst water-soluble ruthenium complex [RuCl 2 (TPPTS) 2 ] 2 , the water-soluble ruthenium complex [RuCl 2 (TPPTS) 2 ] 2 The mol ratio with described p-benzoquinone is 1:400; In autoclave, add 0.1ml hydrochloric acid (1.0mol / L), and add distilled water and the pH value of medium solution is controlled to be 1; Pass in autoclave Enter inert gas to replace the air in it; feed hydrogen with a purity greater than 99% into the autoclave, and control the hydrogen pressure in the autoclave to be 1.0MPa; control the reaction temperature to 40°C; at the same time, the solution in the autoclave is For stirring treatment, the stirring speed is controlled to be 120 rpm, and the reaction time is controlled to be 90 minutes. After the reaction was finished, the mixture was allowed to stand and separated, and the hydroquinone product was obtained from the upper organic phase. The yield of hydroquinone obtained by Examp...

Embodiment 3

[0040] In autoclave, add 0.050g p-benzoquinone; In autoclave, add catalyst water-soluble ruthenium complex [RuCl 2 (TPPTS) 2 ] 2 , the water-soluble ruthenium complex [RuCl 2 (TPPTS) 2 ] 2 The mol ratio with described p-benzoquinone is 1:300; In autoclave, add 0.1ml sulfuric acid (0.5mol / L), and add distilled water and the pH value of medium solution is controlled to be 3; Pass in autoclave Enter inert gas to replace the air in it; feed hydrogen with a purity greater than 99% into the autoclave, and control the hydrogen pressure in the autoclave to be 1.0MPa; control the reaction temperature to 40°C; at the same time, the solution in the autoclave is For stirring treatment, the stirring speed is controlled to be 120 rpm, and the reaction time is controlled to be 100 minutes. After the reaction was finished, the mixture was allowed to stand and separated, and the hydroquinone product was obtained from the upper organic phase. The yield of hydroquinone obtained by Example ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com