Multi-element cathode material for lithium ion battery and preparation method for multi-element cathode material

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of low volume energy density of materials, small material tap density, and large environmental pollution, so as to improve cycle performance and vibration The effect of high density and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

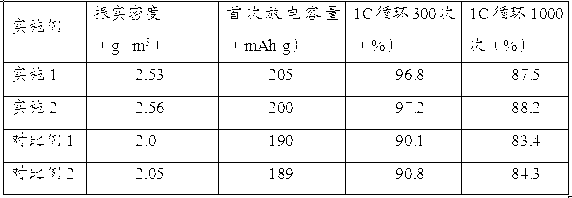

Embodiment 1

[0027] A ternary cathode material for a lithium ion battery, which has a layered structure of α-NaFeO2, and its chemical composition is: Li1.1Ni0.92Co0.05M0.03O2.

[0028] Preparation method: nickel hydroxide with a D50 of 9-12 microns and cobalt hydroxide with a D50 of 3-5 microns , Magnesium hydroxide (Ni:Co:Mg=0.92:0.05:0.03) with D50 of 1-5 microns and lithium hydroxide (content 56.5%) 2000g ((Ni+Co+Mg): Li=1:1.1) and The zirconium balls with a ball-to-material ratio of 1:2 are put into the ball mill together, milled at a speed of 30r / min for 3 hours, taken out and put into a corundum crucible, placed in an atmosphere furnace, under the condition of an oxygen atmosphere (oxygen concentration greater than 50%) , heat up to 800°C at a speed of 3°C / min, keep it warm for 16 hours, then cool down to room temperature at a speed of 3°C / min, pulverize, pass through a 150-mesh sieve, and control the particle size D50 to be about 11 microns. Add deionized water to the pulverized...

Embodiment 2

[0031] A kind of ternary cathode material of lithium ion battery, it has α-NaFeO2 layered structure, and its chemical composition is: Li 1.15 Ni 0.92 co 0.05 m 0.03 o 2 .

[0032] Preparation:

[0033]Mix nickel hydroxide with a D50 of 9-12 microns, cobalt hydroxide with a D50 of 3-5 microns, magnesium hydroxide with a D50 of 1-5 microns (Ni: Co: Mg=0.92:0.05:0.03) and lithium hydroxide (Content 56.5%) 2000g ((Ni+Co+Mn): Li=1:1.15) and zirconium balls with a ball-to-material ratio of 1:3 are added to the ball mill, and the ball is milled at a speed of 30r / min for 3 hours. After taking it out, put it into the corundum Place in a crucible in an atmosphere furnace, under the condition of oxygen atmosphere (oxygen concentration greater than 50%), heat up to 850°C at a rate of 3°C / min, keep it warm for 12 hours, and then cool down to room temperature at a rate of 3°C / min , crushed and passed through a 150-mesh sieve, and the particle size D50 is controlled to be about 11 micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com