Melt polymer body photochemical reaction device

A photochemical reaction and melting polymer technology, which is applied in the field of photochemical reaction devices in the molten state of polymers, can solve the problems of low uniformity and low utilization rate of ultraviolet light energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

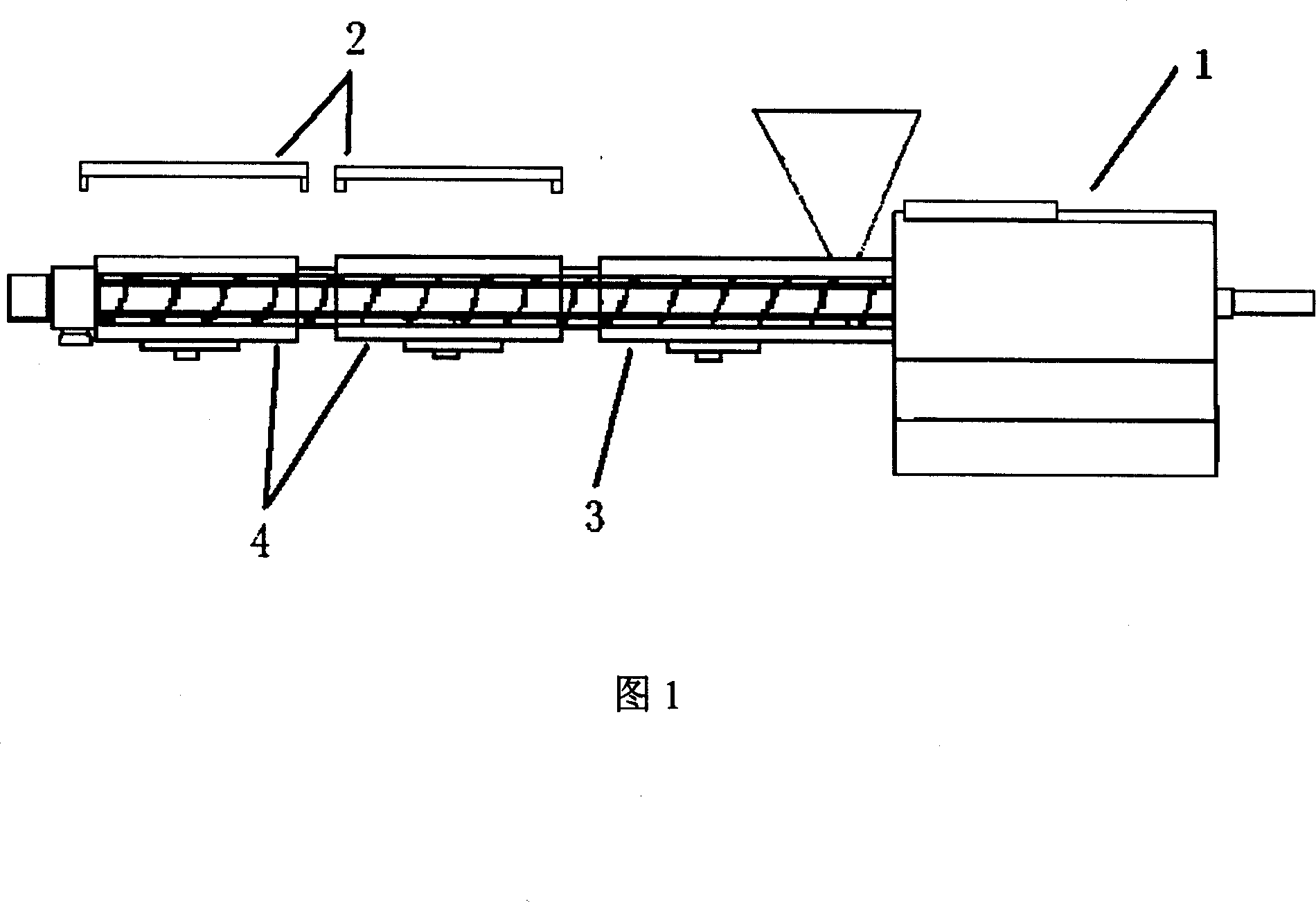

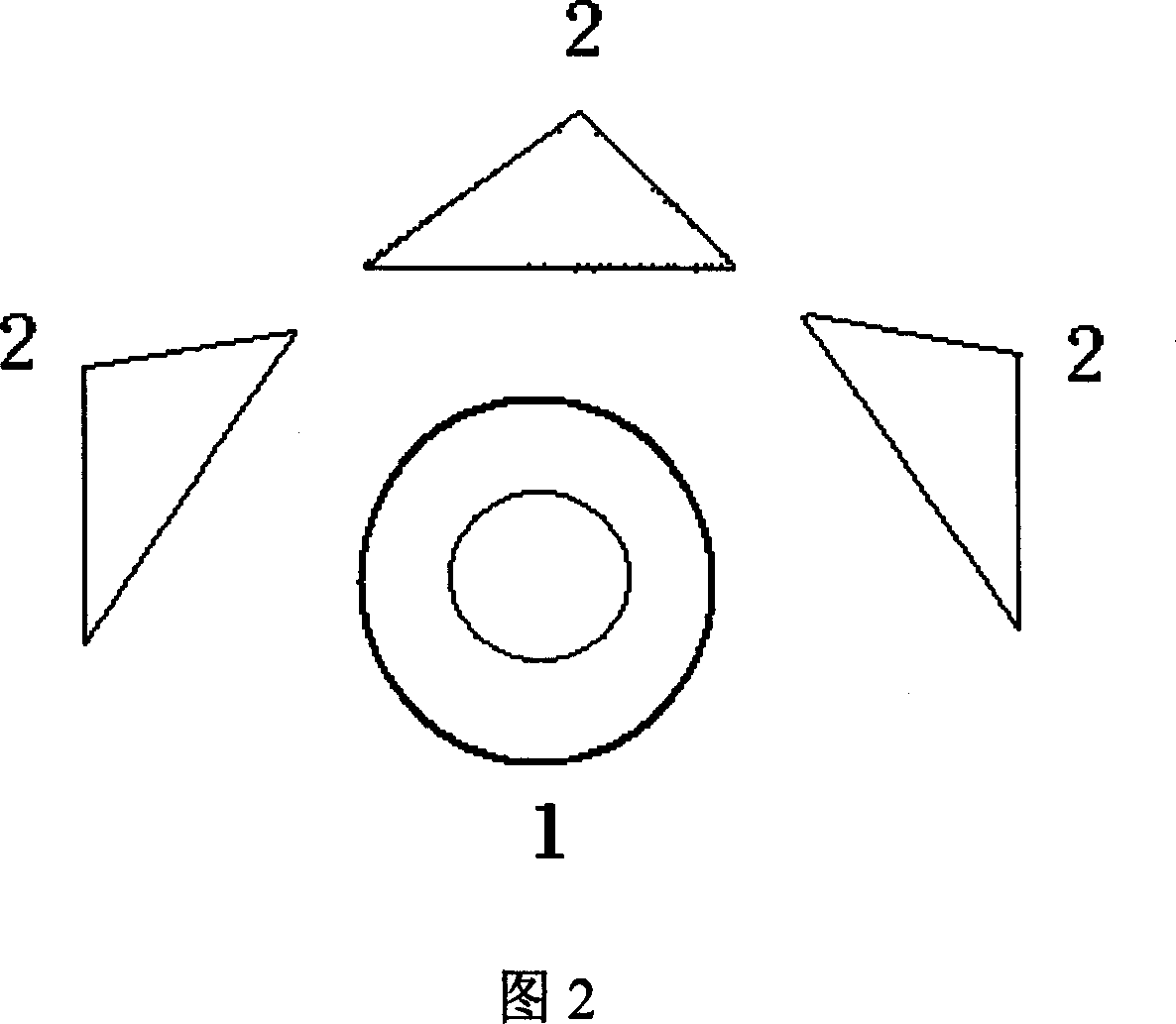

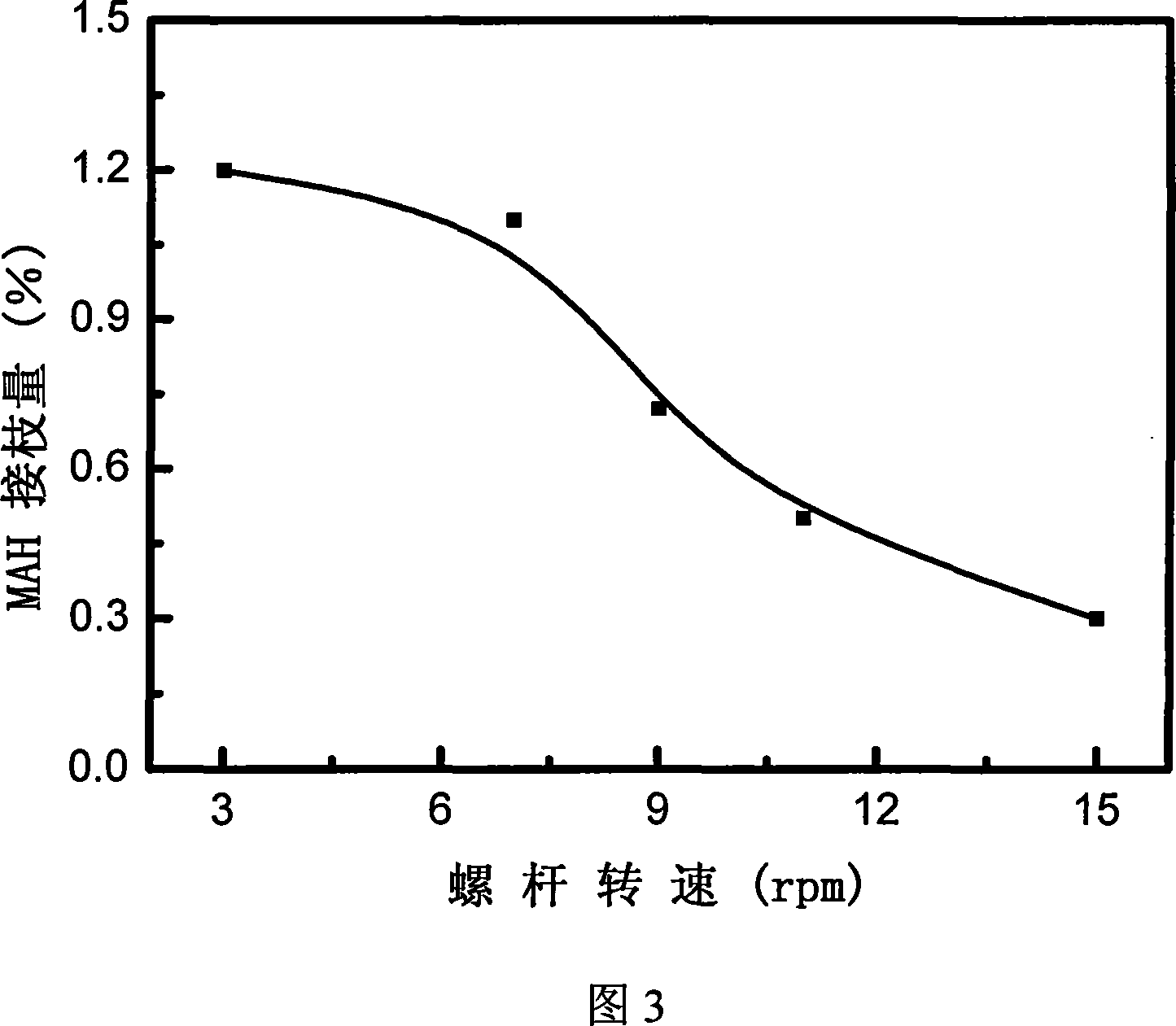

[0022] Embodiment 1: ultraviolet light triggers molten polypropylene mass grafting maleic anhydride

[0023] Required materials: polypropylene, photosensitizer benzophenone, maleic anhydride

[0024] The temperature settings of the solid conveying section, melt conveying section and metering section of the barrel of the single-screw extruder: 185°C, 195°C, 200°C, heating by cast aluminum heaters, temperature detection by infrared thermometers, cooling methods Adopt forced air cooling.

[0025] 1. After selecting the experimental materials, weigh the dried polypropylene, photosensitizer benzophenone and maleic anhydride. The amount of photosensitizer benzophenone is 0.5% of the amount of polypropylene, and the amount of maleic anhydride is the amount of polypropylene 5% of the mixture, mixed evenly and added to the hopper of the single-screw extruder;

[0026] 2. Preheat the single-screw extruder for 30 minutes according to the temperature set by the single-screw extruder;

...

Embodiment 2

[0029] Embodiment 2: Ultraviolet light triggers molten polyethylene bulk crosslinking reaction

[0030] Required materials: polyethylene, photosensitizer, cross-linking assistant

[0031] The temperature settings of the solid conveying section, melt conveying section and metering section of the barrel of the single-screw extruder: 175°C, 180°C, 190°C, heating by cast aluminum heaters, temperature detection by infrared thermometers, cooling methods Adopt forced air cooling.

[0032] 1. After selecting the experimental materials, weigh the dried polyethylene, photosensitizer benzophenone and cross-linking auxiliary agent. The amount of photosensitizer benzophenone is 0.5% of the amount of polypropylene, and the amount of cross-linking auxiliary agent is 0.3% of propylene consumption, after mixing evenly, join in the single-screw extruder hopper;

[0033] 2. Preheat the single-screw extruder for 30 minutes according to the temperature set by the single-screw extruder;

[0034]...

Embodiment 3

[0036] Example 3: Preparation of Polypropylene with Controllable Rheological Behavior by Degrading Polypropylene by Ultraviolet Light Irradiation

[0037] Required materials: polypropylene (melt index 3), photosensitizer benzoin alkyl ether

[0038] The temperature settings of the solid conveying section, melt conveying section and metering section of the barrel of the single-screw extruder: 185°C, 195°C, 200°C, heating by cast aluminum heaters, temperature detection by infrared thermometers, cooling methods Adopt forced air cooling.

[0039] 1. After selecting the experimental materials, weigh the dried polypropylene and photosensitizer benzoin alkyl ether. The dosage of photosensitizer benzoin alkyl ether is 0.5% of the polypropylene dosage, mix them evenly and add them to the hopper of the single-screw extruder ;

[0040] 2. Preheat the single-screw extruder for 30 minutes according to the temperature set by the single-screw extruder;

[0041] 3. Turn on the ultraviolet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com