Composition for cushion rubber, preparation method thereof and cushion rubber

A technology of shock-absorbing rubber and composition, which is applied in the field of shock-absorbing rubber, can solve the problems of low bonding strength between rubber and metal, poor rubber fatigue performance and mechanical strength, and achieve excellent fatigue performance, mechanical strength and good bonding performance , good vulcanization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

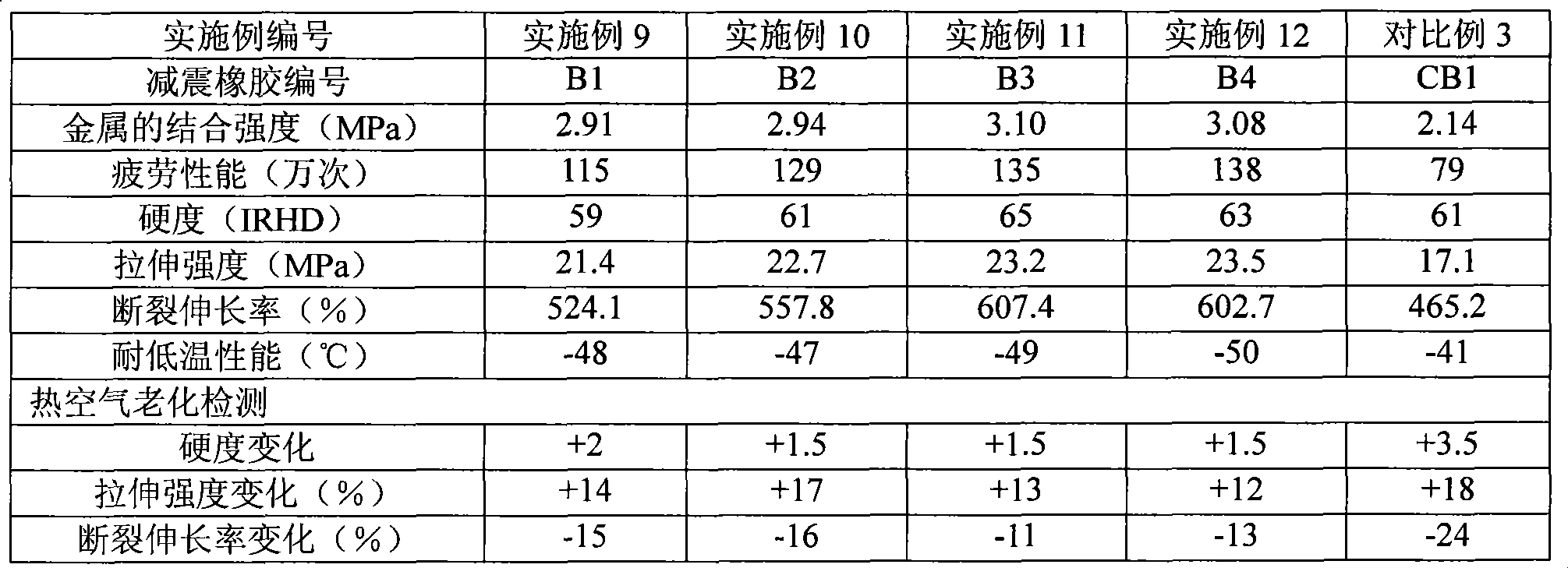

Examples

Embodiment 1

[0033] This example is used to illustrate the composition for shock-absorbing rubber provided by the present invention and its preparation method and shock-absorbing rubber.

[0034] With 80 parts by weight of natural rubber (No. 3 cigarette rubber in Thailand), 20 parts by weight of butadiene rubber (China Petroleum Dushanzi Petrochemical Company, BR9000), 8 parts by weight of phenolic resin (Guangzhou Jinchangsheng Technology Co., Ltd., 203), 8 parts by weight of 2-mercaptobenzothiazole zinc salt (Puyang Weilin Chemical Co., Ltd., MZ), 10 parts by weight of N-isopropyl-N'-phenyl-p-phenylenediamine (produced by Nanjing Chemical Plant 4010NA), 4 parts by weight of stearic acid (Hong Kong Siwen Industrial Co., Ltd., SA1801), 5 parts by weight of zinc oxide (Liuzhou Zinc Products Co., Ltd.), 75 parts by weight of carbon black N774 (Shanghai Cabot), 18 parts by weight The paraffin oil of parts by weight (No. 300 paraffin oil produced by Shanghai Lubricating Oil Factory), joins in...

Embodiment 2

[0038] This example is used to illustrate the composition for shock-absorbing rubber provided by the present invention and its preparation method.

[0039] With 70 parts by weight of natural rubber (No. 3 cigarette rubber in Thailand), 30 parts by weight of butadiene rubber (China Petroleum Dushanzi Petrochemical Company, BR9000), 1.5 parts by weight of phenolic resin (Guangzhou Jinchangsheng Technology Co., Ltd., 203), 5 parts by weight of 2-mercaptobenzothiazole (Puyang Weilin Chemical Co., Ltd., MBT (M)), 7 parts by weight of N-cyclohexyl-N'-phenyl-p-phenylenediamine (produced by Nanjing Chemical Plant 4010), 2 parts by weight of stearic acid (Hong Kong Siwen Industrial Co., Ltd., SA1801), 2 parts by weight of zinc oxide (Liuzhou Zinc Products Co., Ltd.), 40 parts by weight of carbon black N539 (Shanghai Cabot), 15 parts by weight Naphthenic oil (the naphthenic oil produced by Dalian Petroleum No. 7 Plant) in parts by weight was added to a 0.5-liter internal mixer, mixed fo...

Embodiment 3

[0041] This example is used to illustrate the composition for shock-absorbing rubber provided by the present invention and its preparation method.

[0042] With 75 parts by weight of natural rubber (No. 3 cigarette rubber in Thailand), 25 parts by weight of butadiene rubber (China Petroleum Dushanzi Petrochemical Company, BR9000), 1.5 parts by weight of phenolic resin (Guangzhou Jinchangsheng Technology Co., Ltd., 203), 1 part by weight of benzothiazole disulfide (Puyang Weilin Chemical Co., Ltd., DM), 1 part by weight of N-cyclohexyl-2-benzothiazole sulfenamide (Huangyan Donghai Chemical Co., Ltd., CZ), 2 parts by weight Parts of N-(1,3-dimethylbutyl)-N'-phenyl-p-phenylenediamine (4020 produced by Nanjing Chemical Plant), 3 parts by weight of 2,2,4-trimethyl-1, 2-Dihydroquinoline (Huangyan Zhedong Rubber Chemical Co., Ltd., AW), 2 parts by weight of rubber protective wax (Guangzhou Chuangbo Chemical Co., Ltd., RPW-2), 4 parts by weight of stearic acid (Hong Kong Sven Chemica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com