Controlling method for wrapping surface of tire

A control method, tire tread technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problems of simulation, time-consuming precision, high machine maintenance rate, etc., achieve good smoothness, improve Vulcanization effect, effect of improving winding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

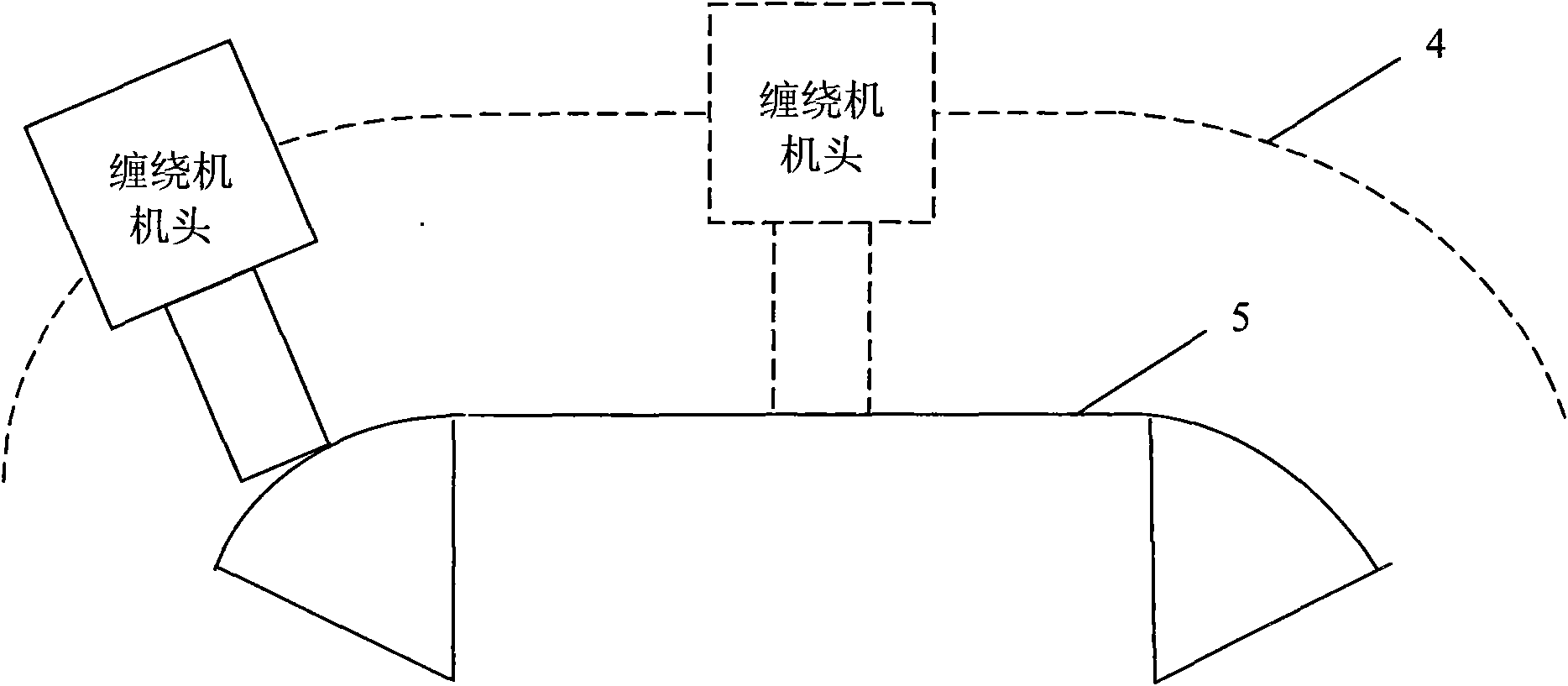

[0047] In this embodiment, a tire tread winding control method comprises the following steps:

[0048] (1) The industrial computer simulates the deformation of the film during the tread helical stacking process;

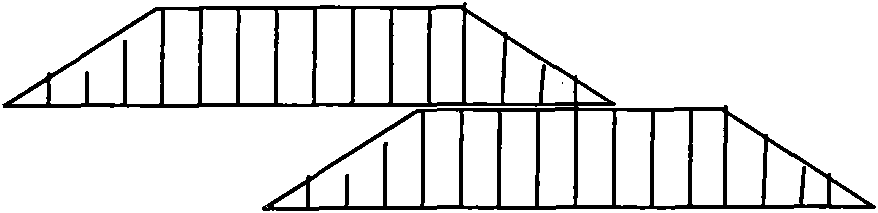

[0049] (2) According to the deformed shape of the film and the set tread effect shape, the industrial computer simulates the arrangement and distribution of each film in the tread during the spiral lamination process, and obtains the pitch between the films;

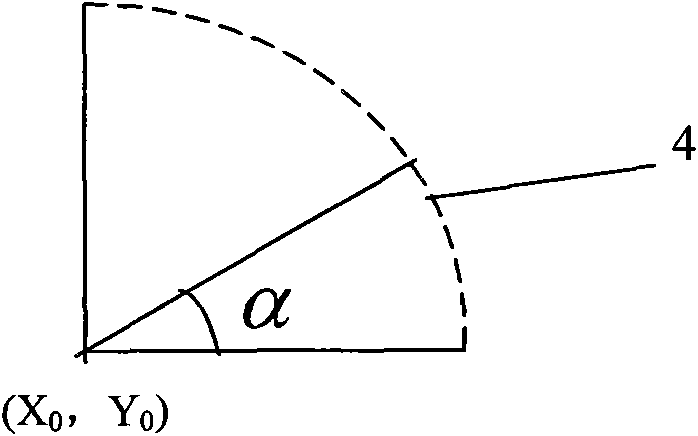

[0050] (3) According to the designed tire surface shape, the industrial computer calculates the virtual circle center coordinates and radius of the winding machine on each circle arc of the tread, and then sends these data to the PLC;

[0051] (4) According to the obtained screw pitches between the films, the industrial computer respectively carries out the corresponding relationship parameters between the circles and radians of the tread arc segment, the corresponding relationship parameters between the circle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com