Patents

Literature

57results about How to "Good smoothness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

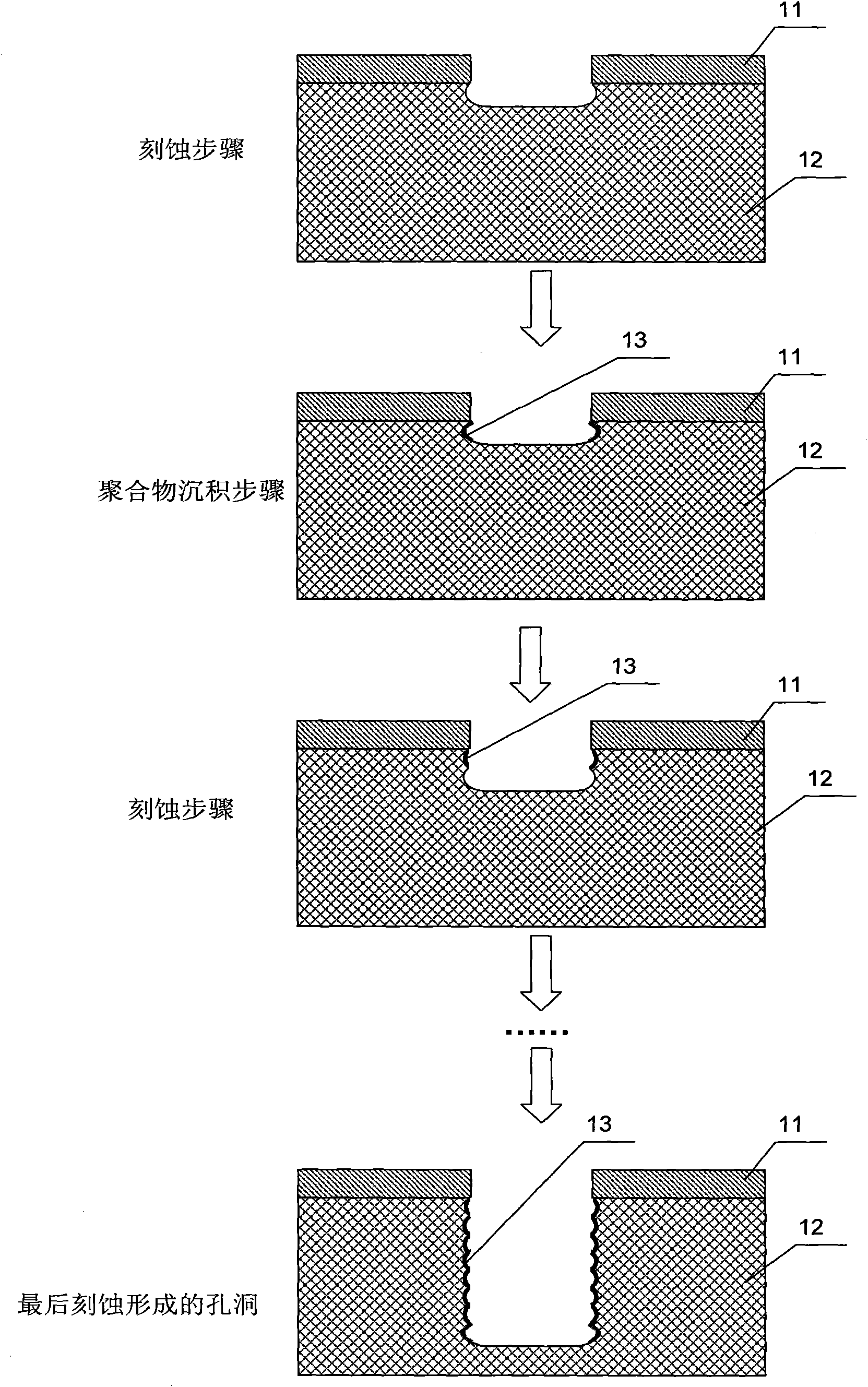

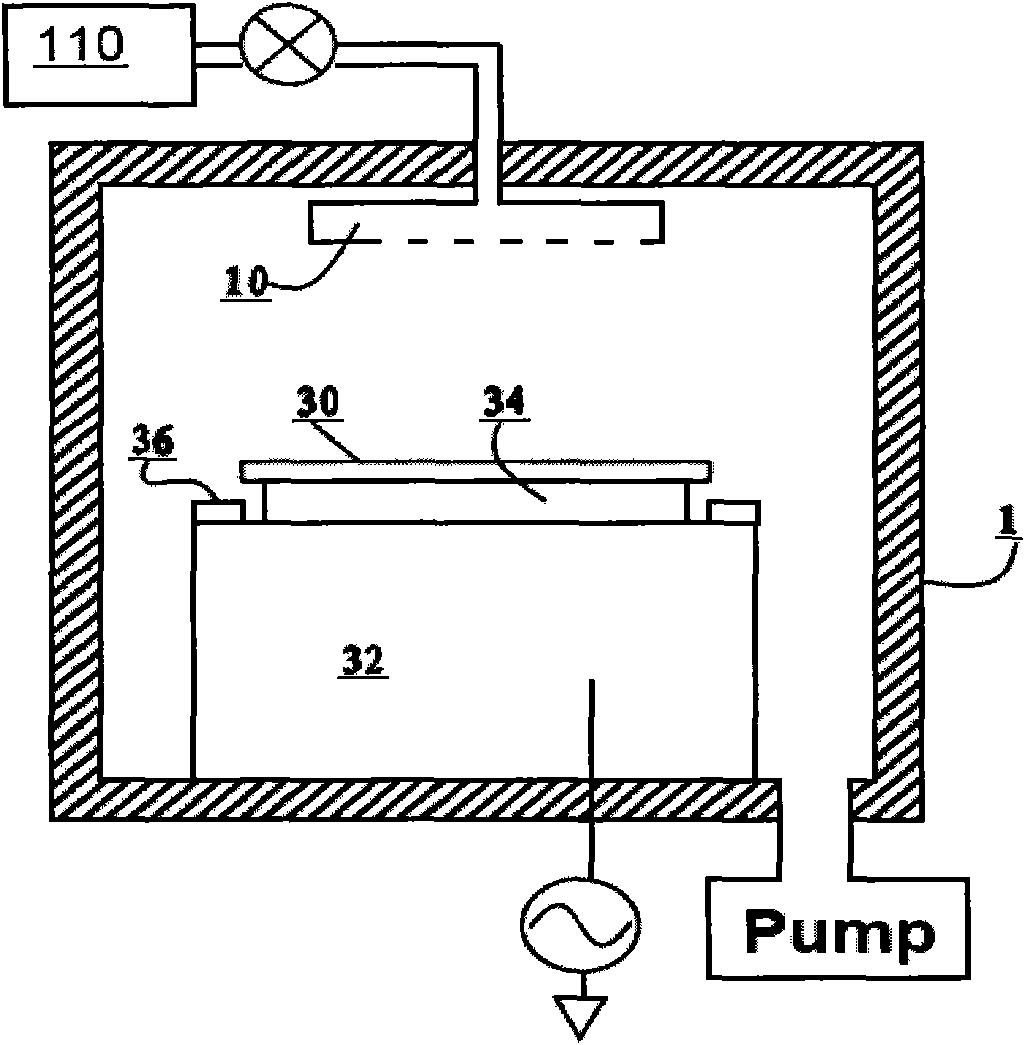

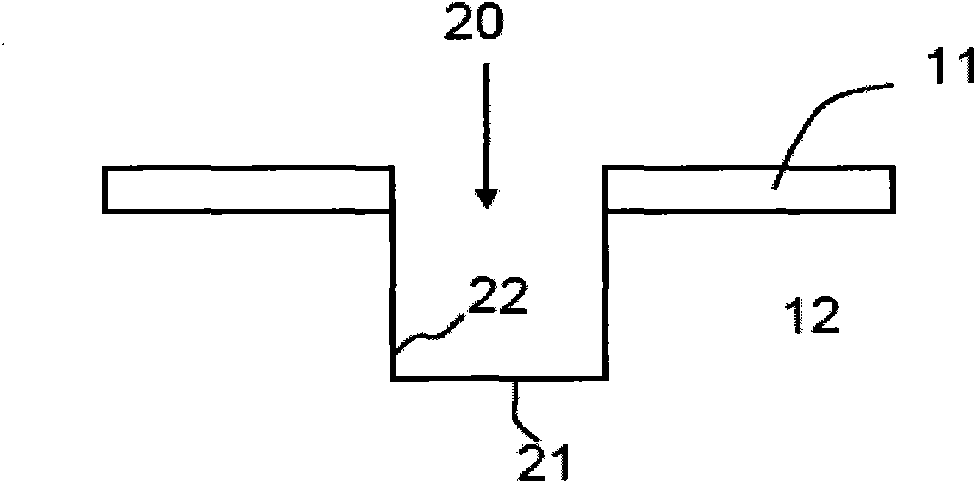

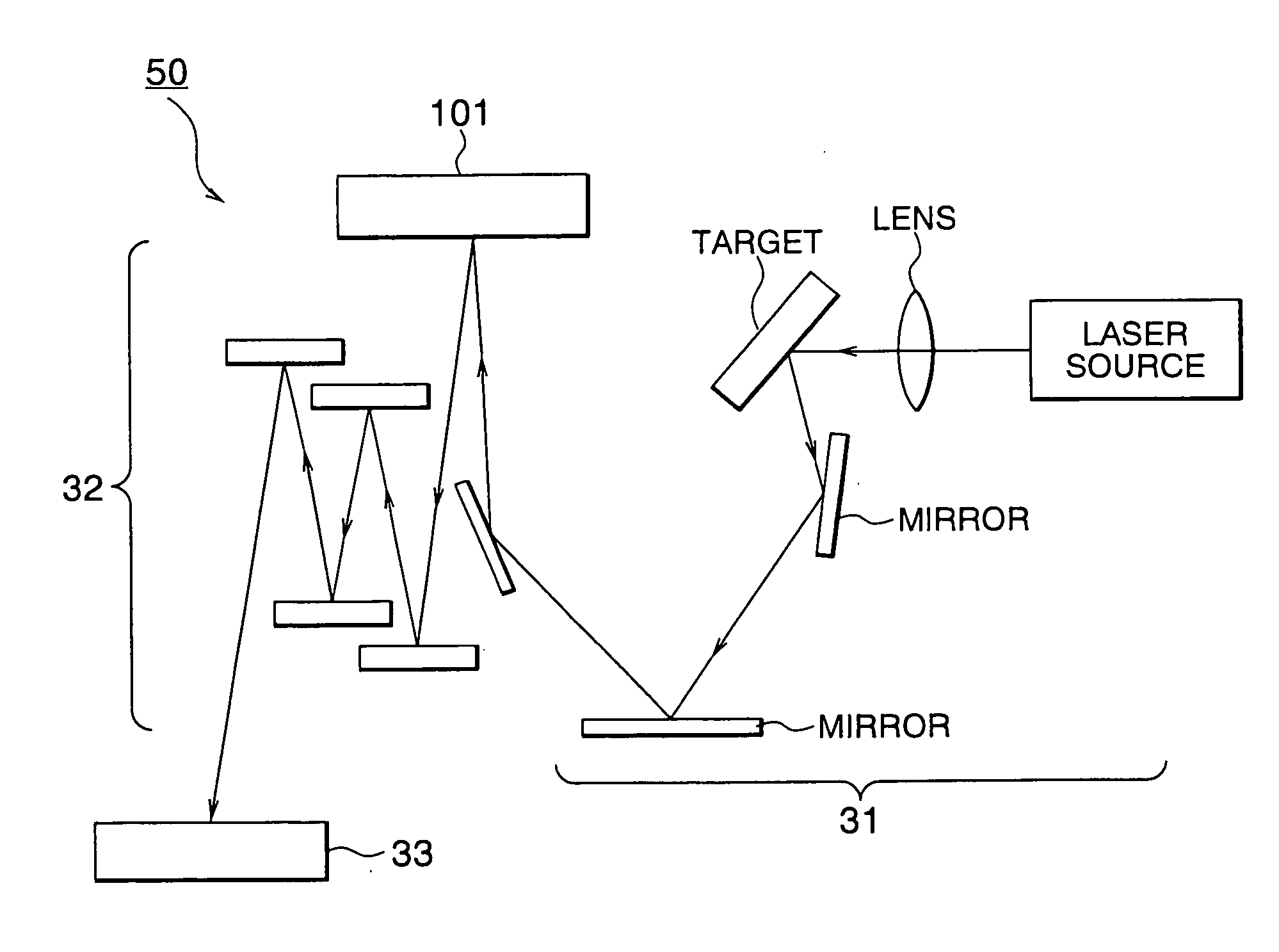

Deep hole silicon etching method

ActiveCN102398887AGood smoothnessShort switching timeDecorative surface effectsChemical vapor deposition coatingPhysicsSilicon chip

The invention provides a deep hole silicon etching method, which belongs to the semiconductor manufacture technical field. The method comprises an etching step and a side wall protective layer deposition step which are alternately carried out, the etching step is capable of supplying etching reaction gas to a reaction chamber used for putting the silicon chip to be etched, a silicon layer is etched to form an opening, the side wall protective step is capable of supplying sidewall protection gas, wherein the sidewall protection gas comprises siliceous gas and oxygen-containing gas, a silicon oxide layer is formed at the sidewall and the bottom of the opening. The deep hold sidewall etched by the method of the invention has higher intensity without extra reinforcement step, so that the etching efficiency of entirety is increased.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

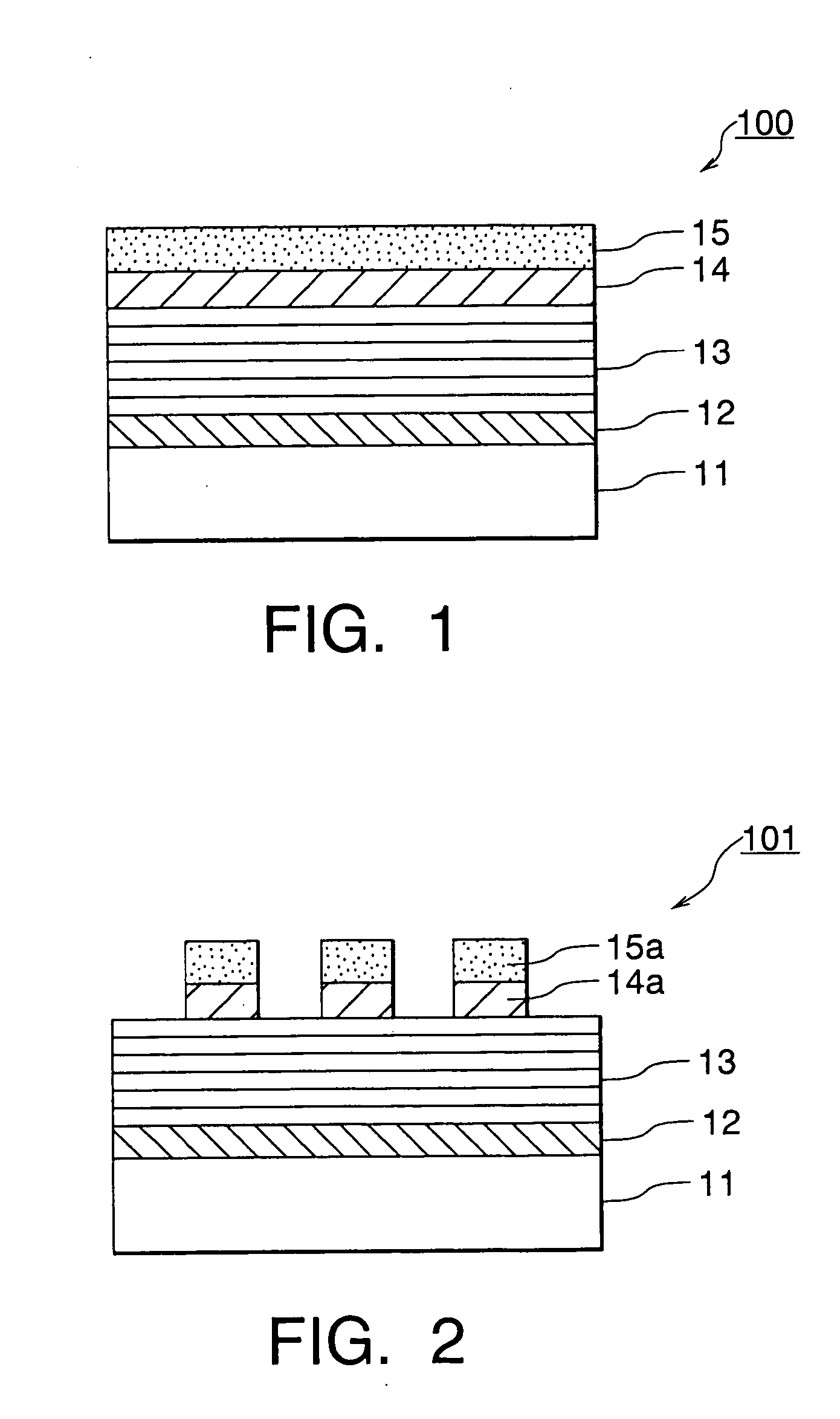

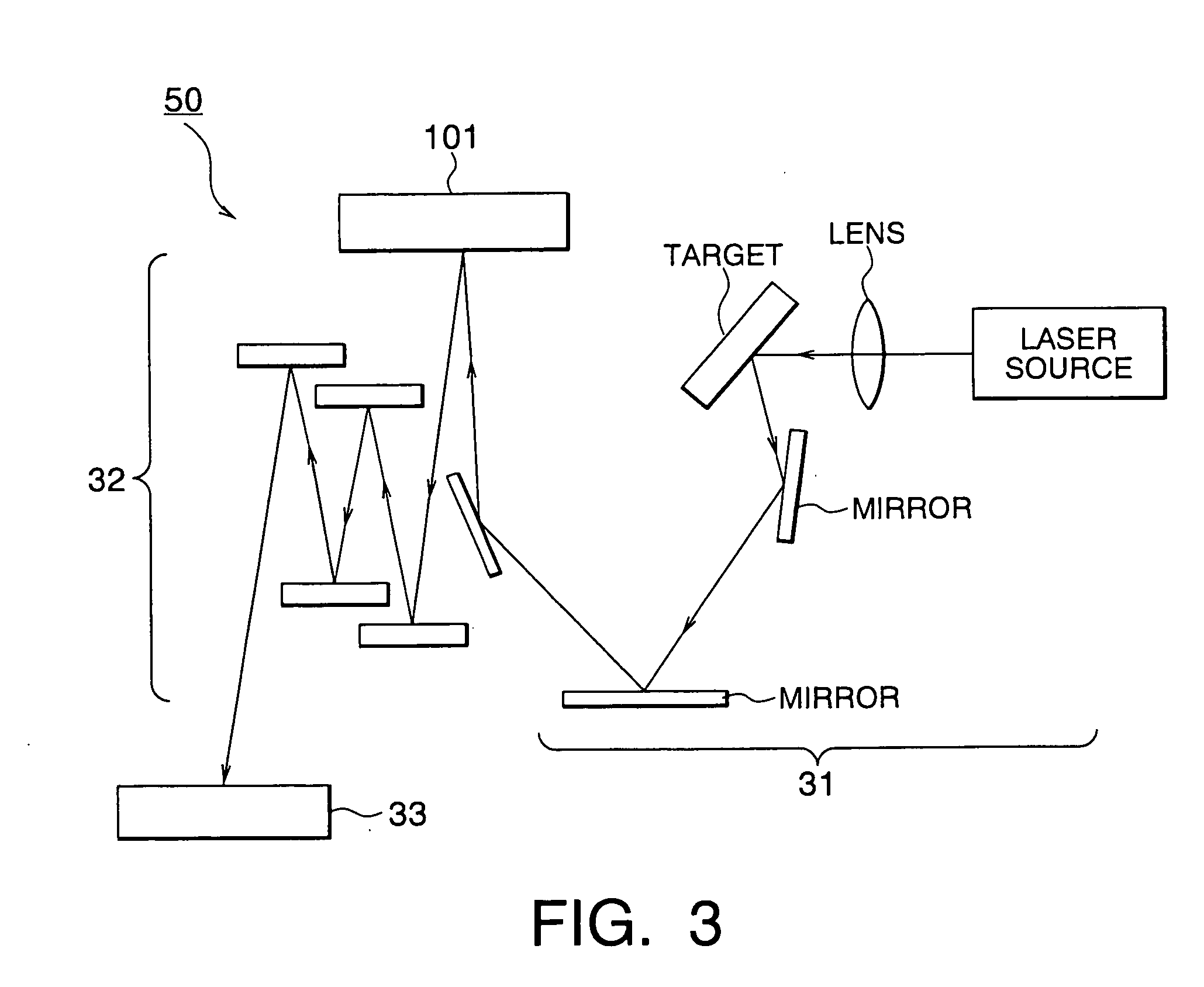

Method of manufacturing a reflection type mask blank and method of manufacturing a reflection type mask

InactiveUS20050100797A1Good smoothnessFacilitate adjustmentNanoinformaticsPhotomechanical apparatusOptoelectronicsHeat treating

A method of manufacturing a reflection type mask blank by forming a multilayer reflection film reflecting exposure light on a substrate and forming an absorber layer absorbing the exposure light on the multilayer reflection film includes a step of forming, between the substrate and the multilayer reflection film, a stress correction film opposite in direction to film stress of the multilayer reflection film and smaller in absolute value than the film stress of the multilayer reflection film, a step of heat-treating the stress correction film, and a step of heat-treating the multilayer reflection film.

Owner:HOYA CORP

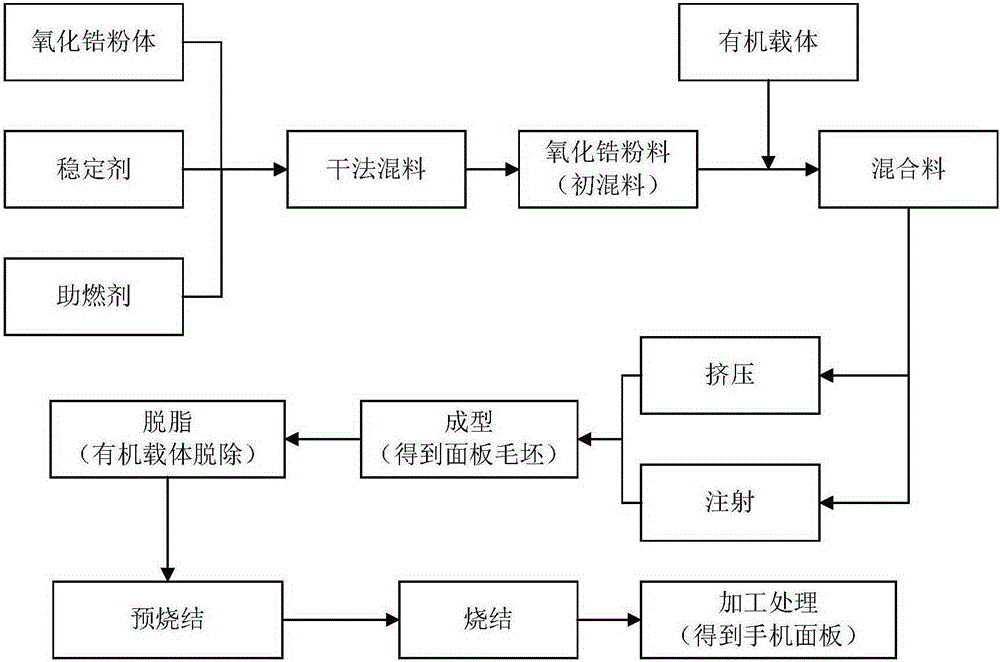

Zirconia ceramic mobile phone panel and preparation method thereof

The invention provides a zirconia ceramic mobile phone panel and a preparation method thereof and belongs to the field of mobile phone panel preparation. The zirconia ceramic mobile phone panel is mainly prepared from, by weight, 80-99.5 parts of a zirconia powder and stabilizer mixture and 0.5-20 parts of organic carriers, wherein molar ratio of stabilizers in the zirconia powder and stabilizer mixture is 4-6%. The preparation method includes mixing the zirconia powder with the stabilizers to obtain a primary mixture; adding the organic carriers into the primary mixture with mixing uniformly so as to obtain a mixture; enabling the mixture to form so as to obtain a panel blank; subjecting the panel blank to organic carrier removal prior to sintering so as to obtain the zirconia ceramic mobile phone panel. The zirconia ceramic mobile phone panel made from special materials is highly smooth in hand feeling, good in colorfulness and light transmission performance, resistant to wear and slip and less prone to breakage.

Owner:王有才

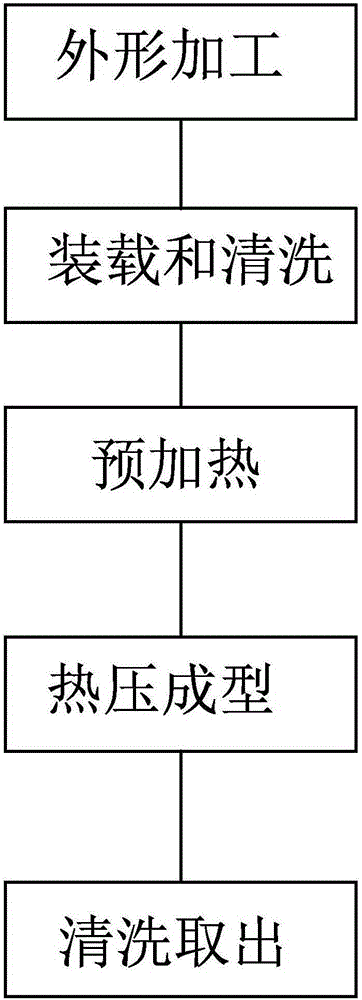

Processing method for three-dimensional glass panel for wearable intelligent devices

InactiveCN105174698AGood smoothnessImprove yield rateGlass reforming apparatusSurface plateHot pressing

The invention provides a processing method for a three-dimensional glass panel for wearable intelligent devices, and belongs to the technical field of glass panel processing techniques. The processing method solves the technical problem of conventional processing methods that surfaces are rough after processing. The processing method comprises the steps of shape machining, loading and cleaning, preheating, hot pressing and cleaning and removal. The processing method can process the high-quality three-dimensional glass panel for one time.

Owner:ZHEJIANG XINGXING TECH CO LTD

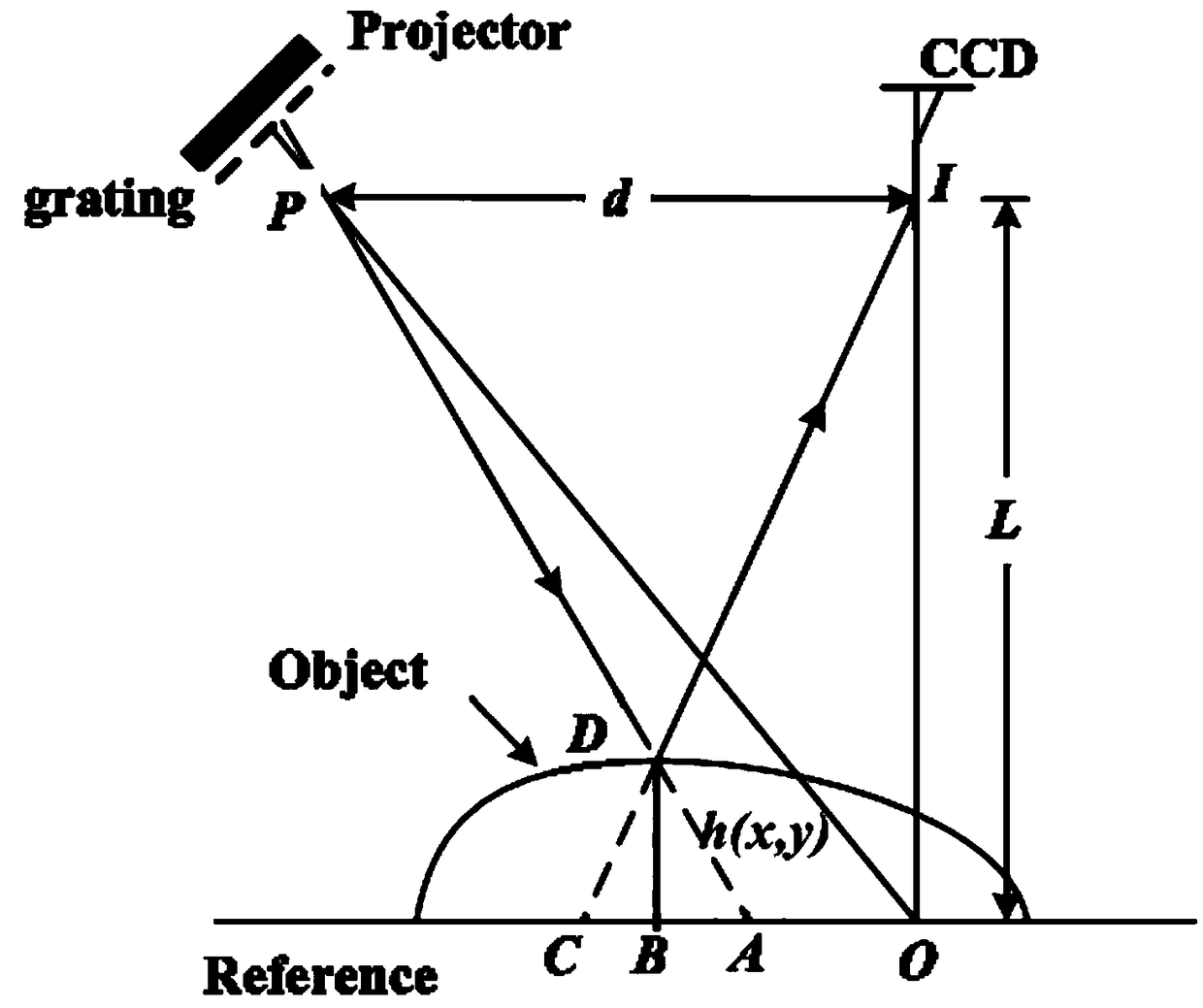

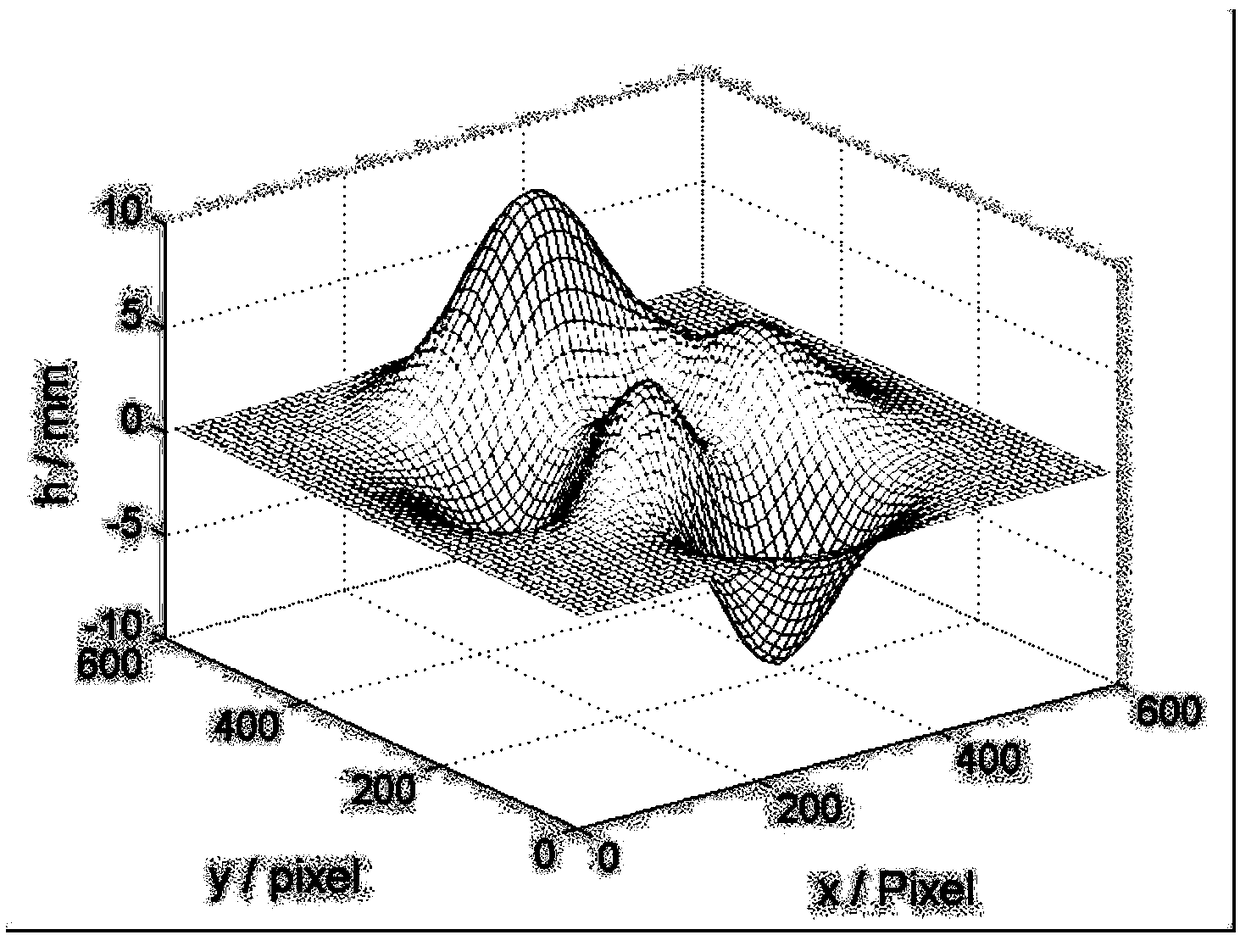

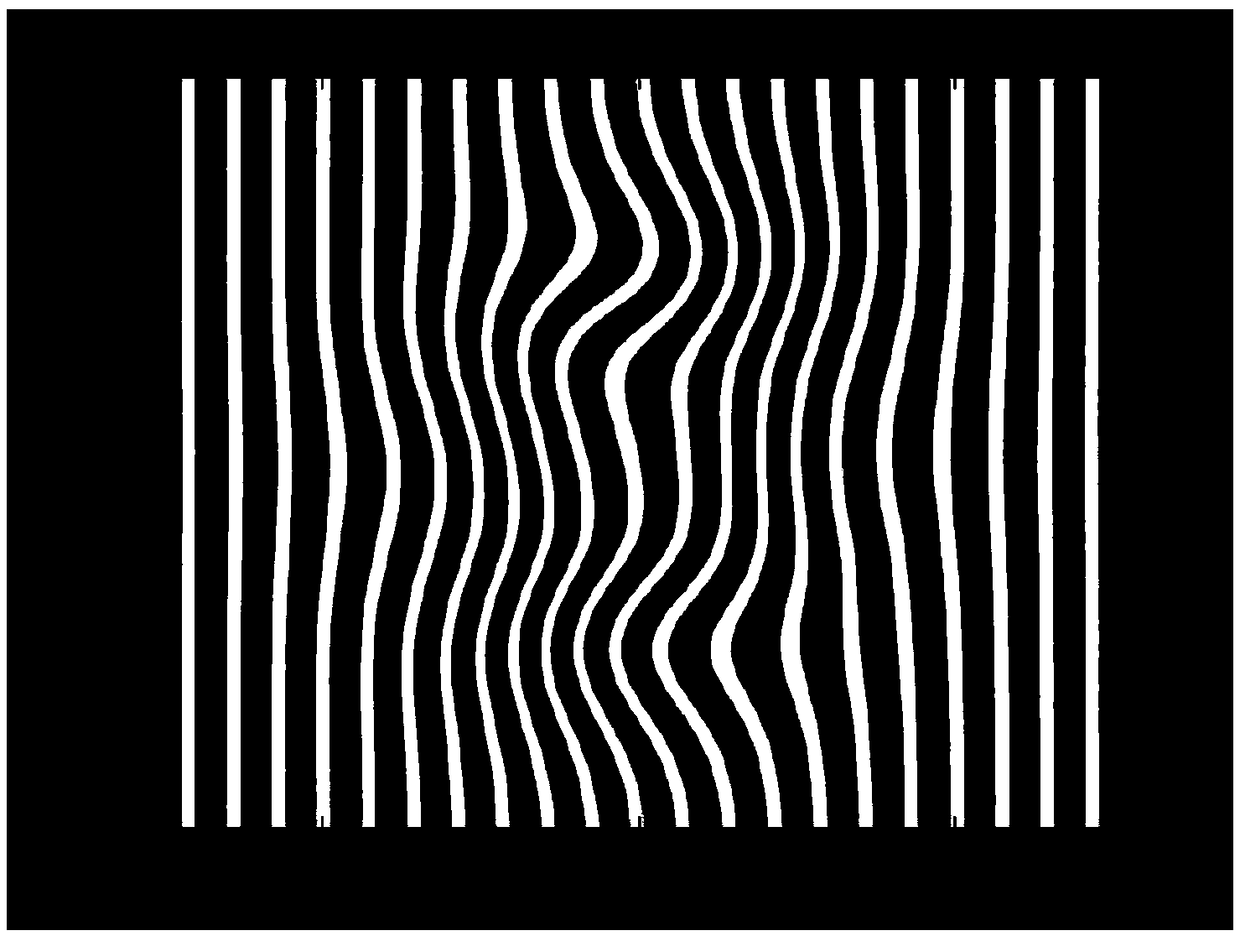

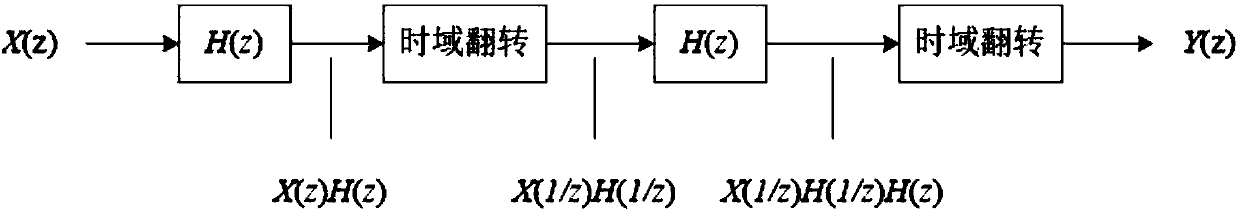

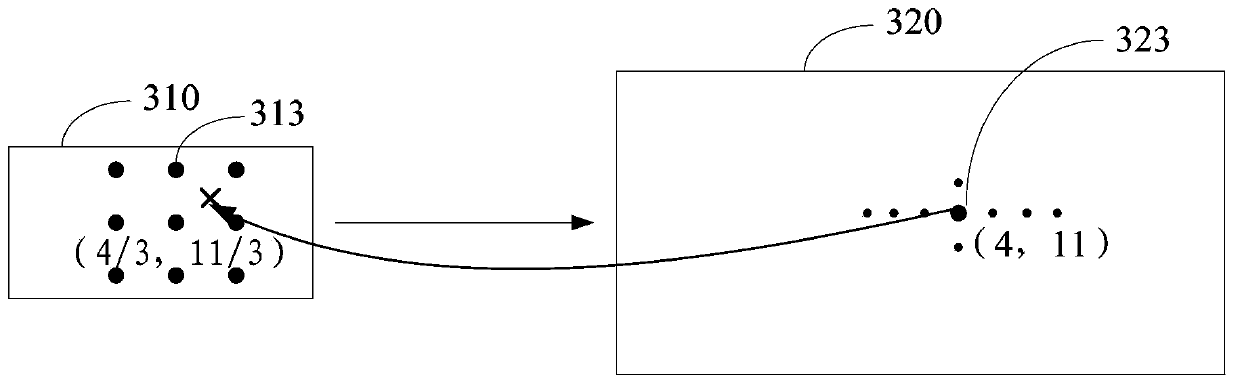

Moving least square method-based three-dimensional surface-shaped measurement method

ActiveCN109186496AHigh accuracy of surface fittingGood smoothnessUsing optical meansPhase shiftedComputer vision

The invention discloses a moving least square method-based three-dimensional surface-shaped measurement method. The moving least square method-based three-dimensional surface-shaped measurement methodcomprises the following steps of building a target function by a moving lead square method, normalizing an expression of a deformation strip, performing regularization on the deformation strip, extracting a phase by Hibert conversion, and solving deformation information of a detected object so as to obtain three-dimensional surface distribution of the detected object. According to the moving least square method-based three-dimensional surface-shaped measurement method, the target function of a deformation strip pattern is obtained by combining the moving least square method, the regularization is performed on the deformation strip, the phase information of the detected object is solved by combining the characteristic that Hibert conversion has 90-degree phase shift, the moving least square method-based three-dimensional surface-shaped measurement method has the advantages of high surface fitting accuracy and good smoothness, the proposed method does not need filtering operation, a zero-frequency component in the strip pattern is eliminated, a phase of the detected object also can be demodulated from a local projection region by a Hibert conversion method, a depth relevant phase isdemodulated from the deformation strip pattern, and the reconstruction accuracy of three-dimensional surface shape is improved.

Owner:HUAIYIN TEACHERS COLLEGE

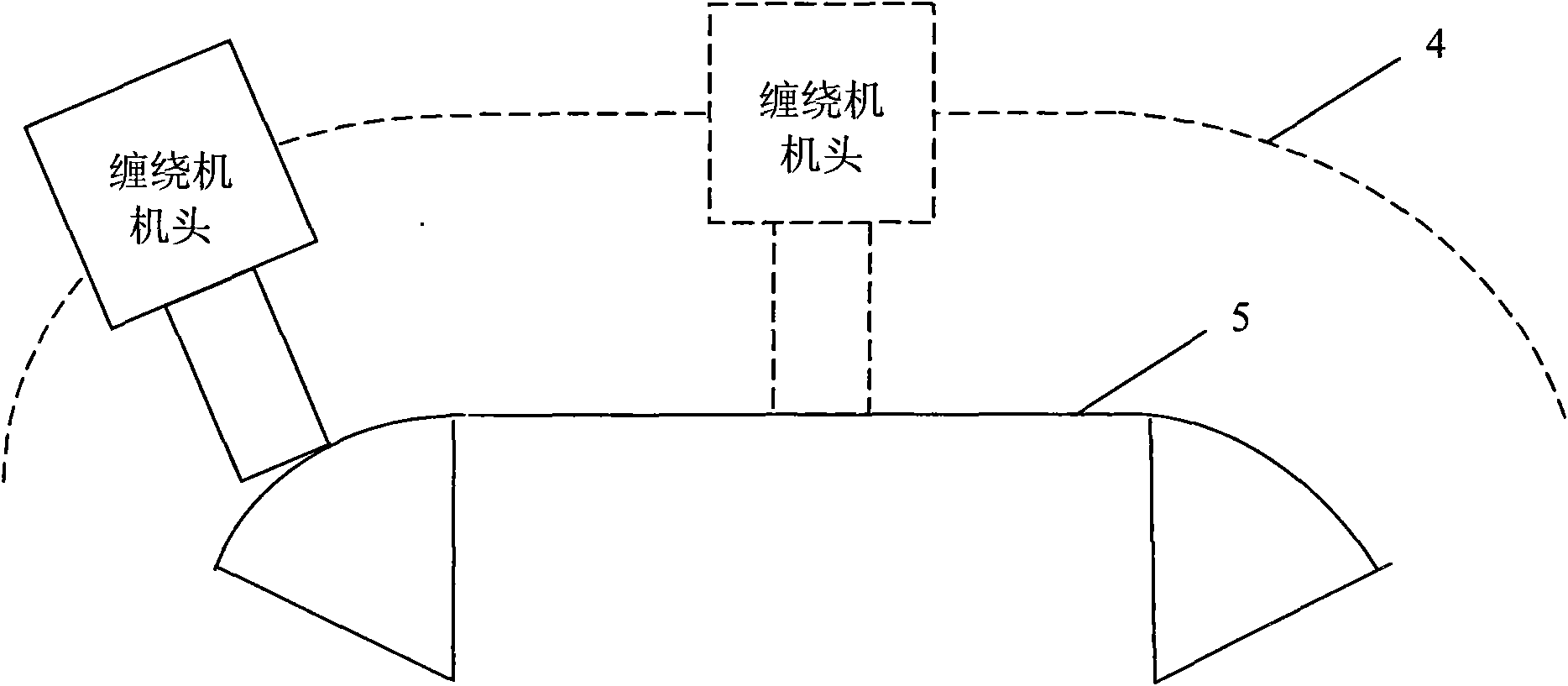

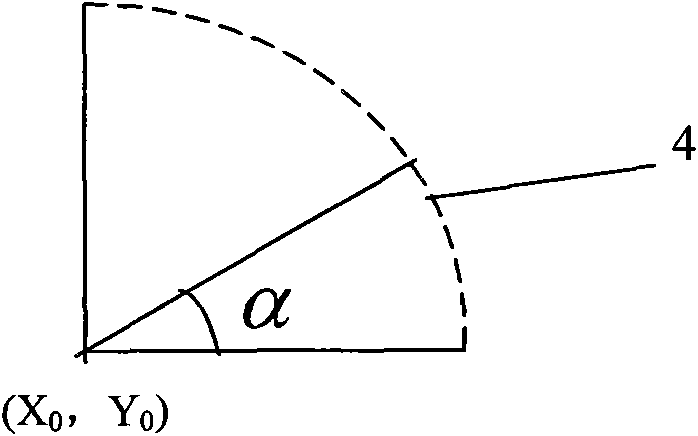

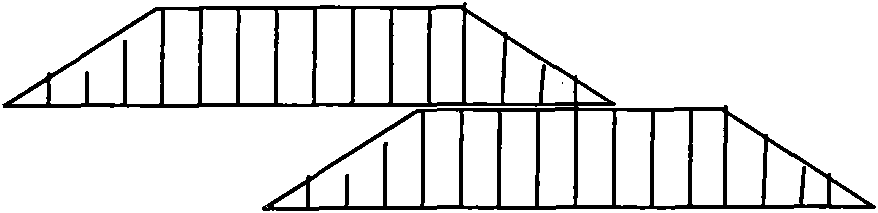

Controlling method for wrapping surface of tire

InactiveCN101625557AGood smoothnessImprove vulcanization effectProgramme control in sequence/logic controllersLine segmentEngineering

The invention provides a controlling method for wrapping the surface of a tire, comprising the following steps: an industrial personal computer (IPC) analog simulates the deformation of rubber pieces in the process of spire piling and the arrangement distribution situation of the each rubber piece in the surface of the tire to obtain spire pitches among each rubber piece; the IPC computes the virtual circle central coordinate and the radius of a wrapper at each loop of the arc of the surface of the tire, and sends a date to a PLC; the IPC respectively computes the arc of the each loop of the arc section of the surface of the tire, the horizontal coordinate of the each loop of the linear section of the surface of the tire and a corresponding theoretical velocity, to form a data table to be sent to the PLC; the PLC computes the real velocity of the wrapper according to the received data table; and the PLC computes to obtain a track coordinate data of the wrapper corresponding at the each loop and finally controls the wrapper to wrap the surface of the tire. The method realizes analog simulation in the process of wrapping the surface of the tire, adjusts the walk track and the walk velocity of the head of the wrapper immediately, and greatly improves the wrapping quality of the surface of the tire.

Owner:柳州市华工百川橡塑科技有限公司

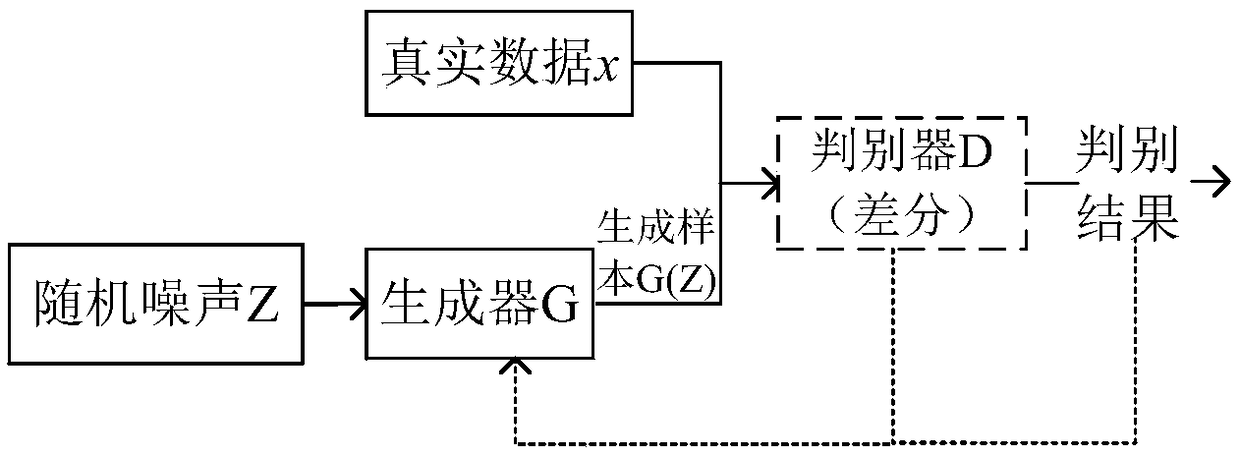

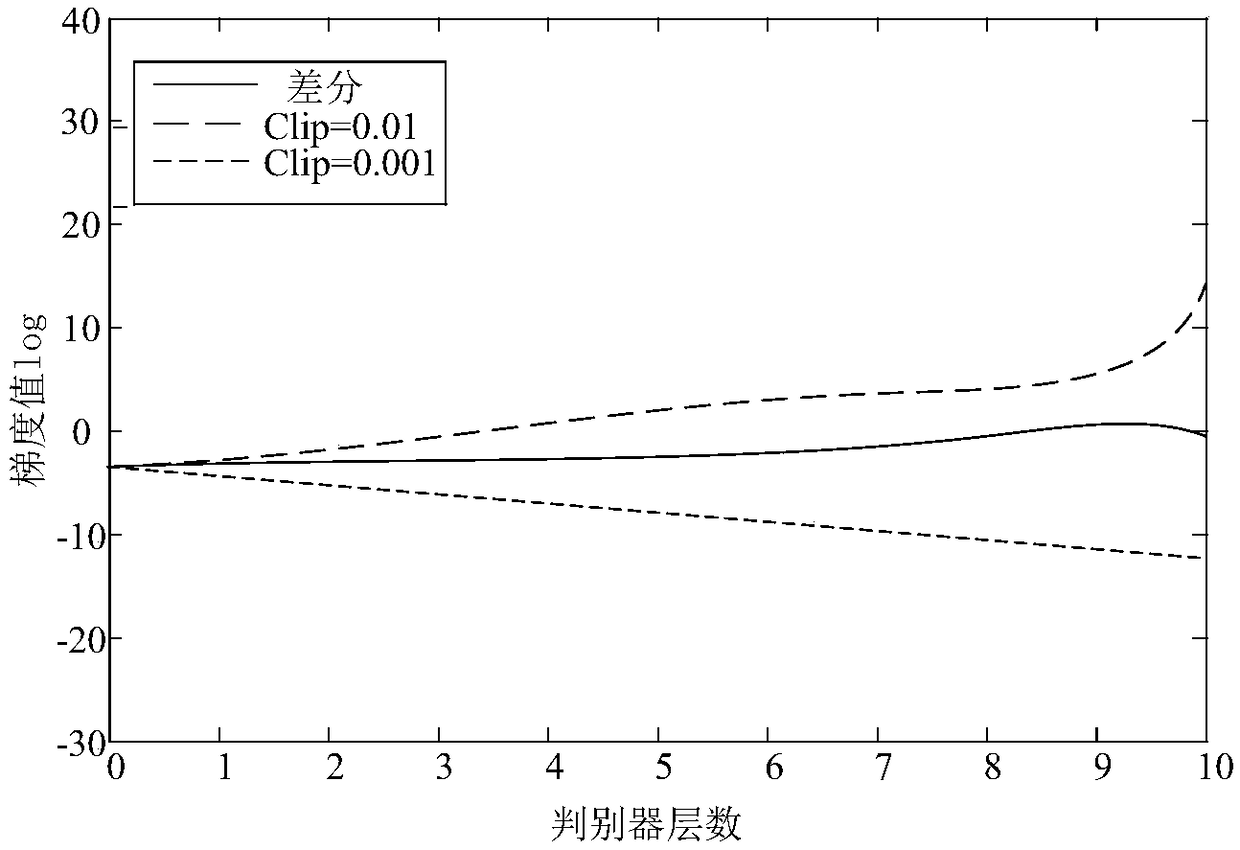

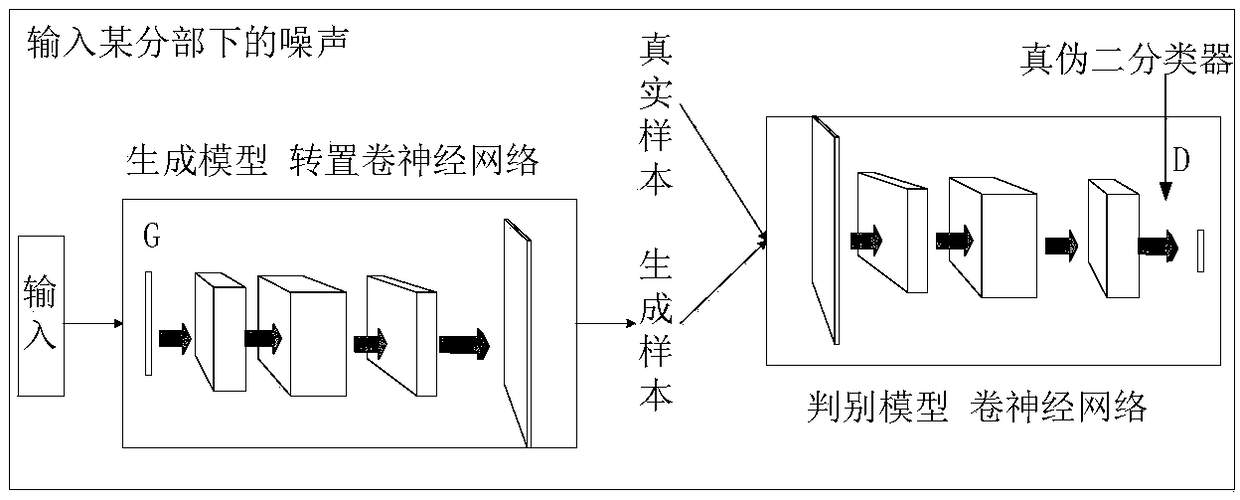

Differential WGAN based network security situation prediction method

InactiveCN109120652AGood smoothnessAvoid vanishing gradientsData switching networksCollapse modeSimulation

The invention provides a differential WGAN based network security situation prediction method. The GAN (Generative adversarial network) is used to simulate the development process of situation, and the situation is predicted in the time dimension. A loss function with the Wasserstein distance as the GAN is used to solve the problem that the GAN is hard to train and instable in collapse mode and gradient, and a differential item is added to the loss function to improve the classification precision of a situation value. The stability of the differential WGAN network is proved. According to experimental results and analysis, the mechanism has advantages in the aspects in convergence, prediction precision and complexity compared with other mechanisms.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

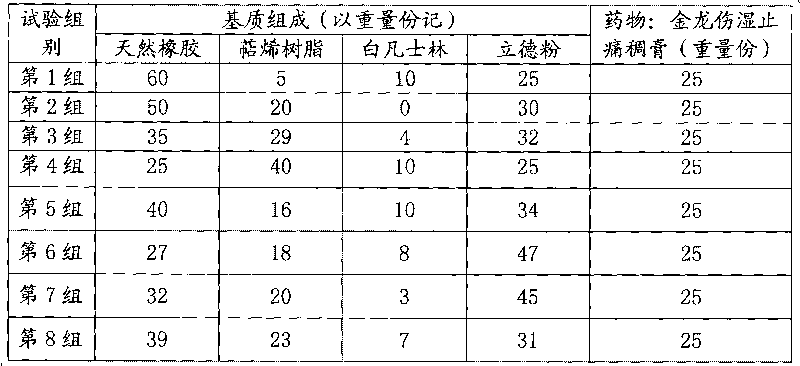

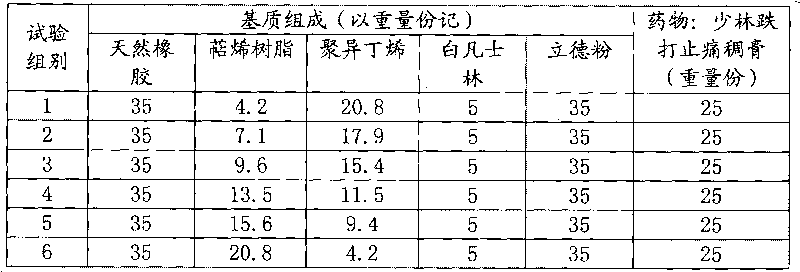

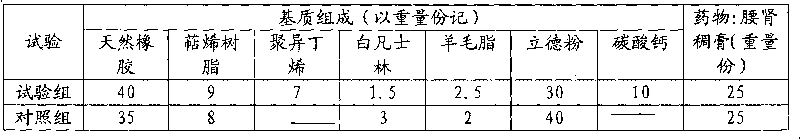

Pharmaceutical plaster substrate, preparation method and applications thereof

ActiveCN101693043AImprove performanceSolve the problem of large drug loading in traditional Chinese medicine plastersOil/fats/waxes non-active ingredientsSheet deliveryInstabilityDrug effect

The invention discloses a pharmaceutical plaster substrate, a preparation method and applications thereof. The pharmaceutical plaster substrate comprises the following components by weight parts: 15 to 65 parts of natural rubber, 5 to 45 parts of viscosifier, 0 to 20 parts of softener and 15 to 70 parts of filling agent. The invention overcomes the defects that the traditional natural rubber plaster has little adhesion, large difference, low smoothness and the like, solves the technical difficulty that the existing preparation technology has poor controllability and instability, has the advantages of smooth production processing, good coating effect, good smoothness of plaster surface (fineness and no blank spot), excellent pasting performance, good stability, proper peeling, strong permeation force, long maintaining time of drug efficacy and drug effect, large drug loading quantity and safe use and the like.

Owner:SINOPHARM GRP DEZHONG (FOSHAN) PHARM CO LTD +1

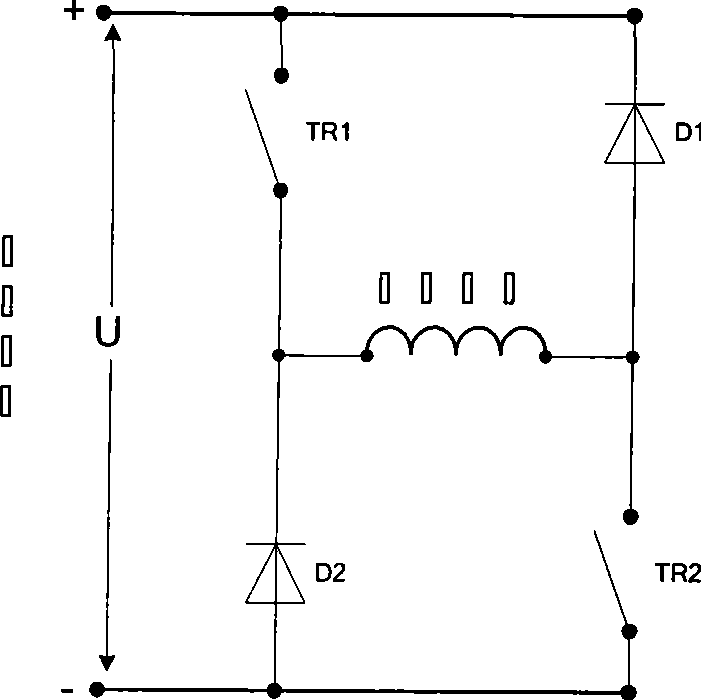

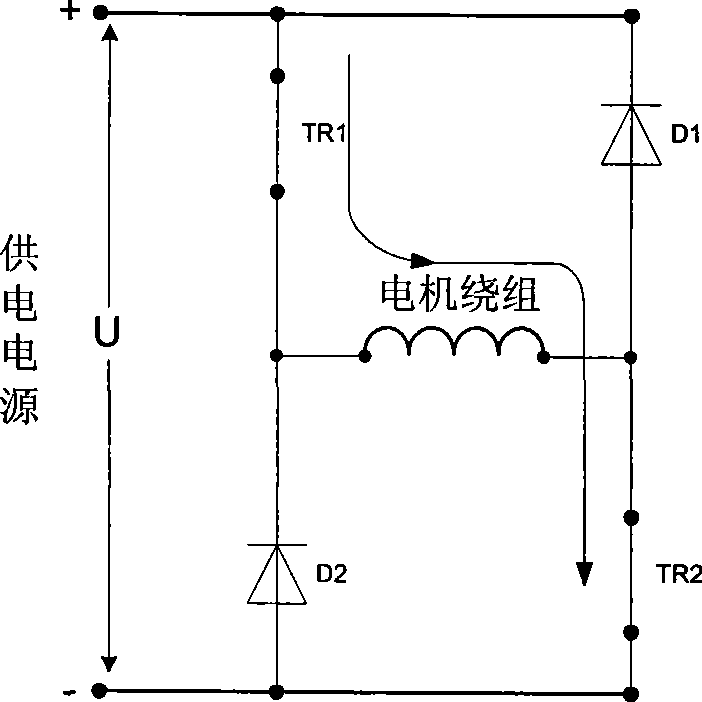

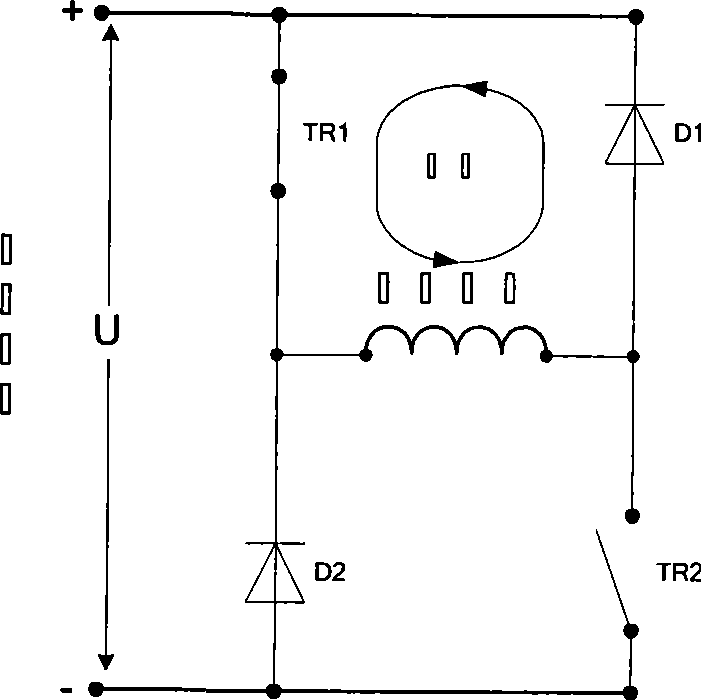

Winding current waveform controlling method for switch reluctance motor braking process

The invention provides a method for controlling the winding current waveform in the braking process of a switch reluctance motor, which comprises: a step of braking operation by the motor, during which the positive voltage is adopted to increase the current in the initial segment of the electrifying interval; a step of adopting negative voltage to reduce the current after the current increases to the specified value and the winding current is larger than the specified current; a step of increasing the winding current by adopting zero voltage when the winding current is less than the specified current; and a step of adopting the positive voltage compensation to increase the current if the winding current is reduced when zero voltage is adopted or the current does not increase to the specified value after the zero voltage with n periods is adopted continuously. The method has the advantages that the braking current waveform of the winding can track the specified waveform well, the current waveform has good smooth property, and the output torque pulse of the motor is effectively reduced.

Owner:BEIJING CHINA TEX MECHANICAL & ELECTRICAL ENG

Vehicle suspension and vehicle

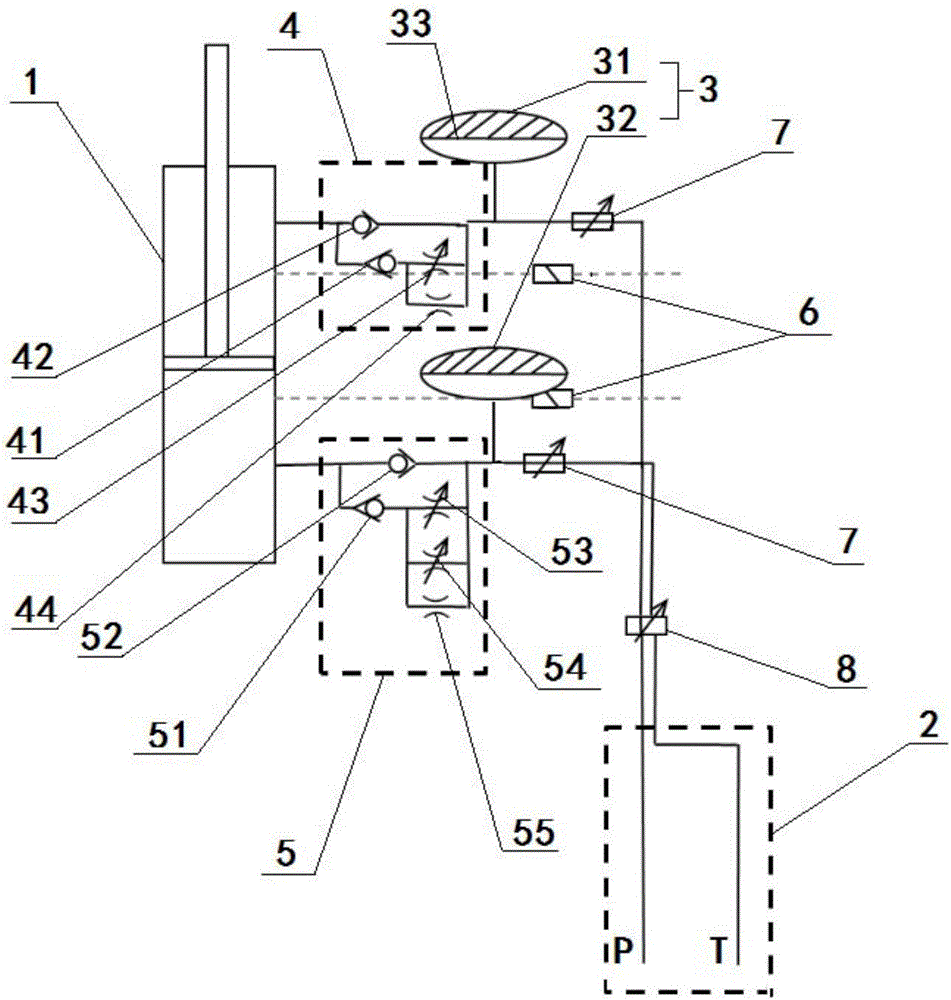

InactiveCN106379128AIncrease the total air chamber volumeThe total air chamber volume is stableResilient suspensionsVehicle springsEngineeringGas chamber

The invention relates a vehicle suspension which comprises an oil cylinder, energy accumulators and damping adjustment units, wherein a rodless cavity of the oil cylinder and a rod cavity of the oil cylinder are respectively connected with one energy accumulator; one damping adjustment unit is arranged between the rodless cavity of the oil cylinder and the corresponding energy accumulator, and the other one damping adjustment unit is arranged between the rod cavity of the oil cylinder and the corresponding energy accumulator. The vehicle suspension has the beneficial effects that the two energy accumulator and corresponding valve banks are arranged, so that rigid and continuous adjustment is realized, the side-tipping resistance and side-turnover resistance of a vehicle are improved, and the comfort, safety and control stability of the vehicle are greatly improved; the capacity of a general gas chamber of the energy accumulator communicated with the rodless cavity of the oil cylinder is increased, so that the rigidity of the suspension is reduced, the suspension is relatively soft, and the vehicle is relatively stable and comfortable in running.

Owner:张家口舒狮汽车科技有限公司

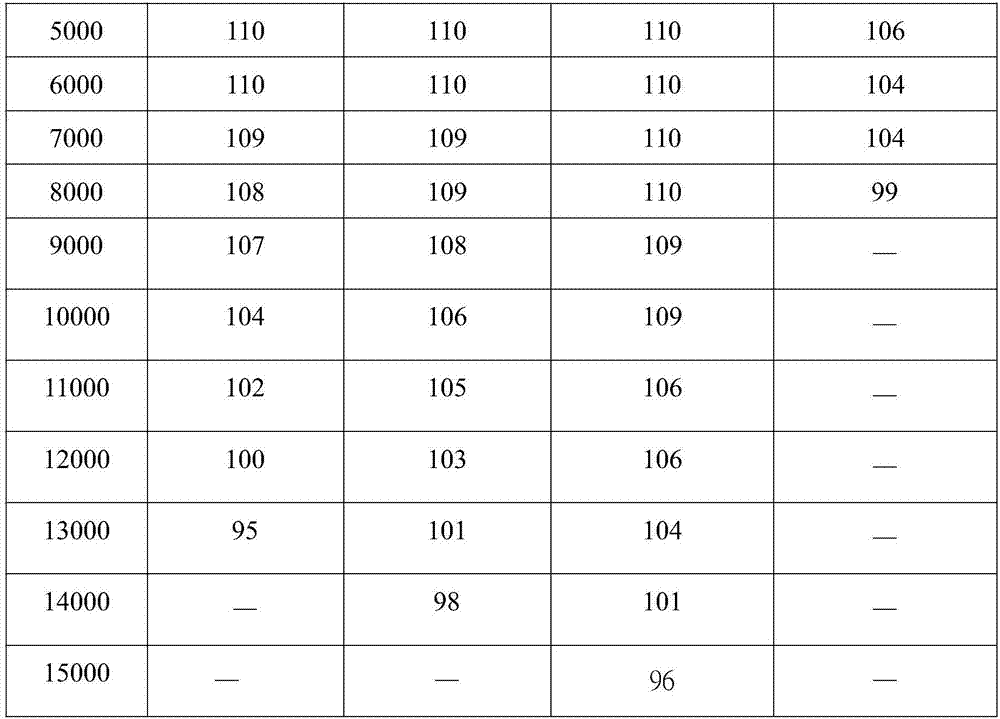

Perfluoropolyether-modified silane compound, surface treatment composition comprising same and thin film

ActiveCN107057056AGood smoothnessExcellent antifoulingAntifouling/underwater paintsPaints with biocidesChemistrySurface finishing

The invention discloses a perfluoropolyether-modified silane compound,a surface treatment composition comprising the same and a thin film. The structure of the perfluoropolyether-modified silane compound is as shown in F(CF2CF2O)m(CF2O)nCF2CH2{CH2}p[O(CH2)3]bSi(CH3)a{(CH2)3Si(OCH3)3}3-a, wherein p and b are independent numbers separately; if p and b are 0 at the same time, a can be 1, or if p and b are 1 at the same time, a is 0; and m and n are independent numbers separately. The perfluoropolyether-modified silane compound has good self-assembled monomolecular coating property, and can be used for forming the thin film which has high durability, relatively good smoothness and excellent antifouling property and scratch resistance.

Owner:龙岩思康新材料有限公司

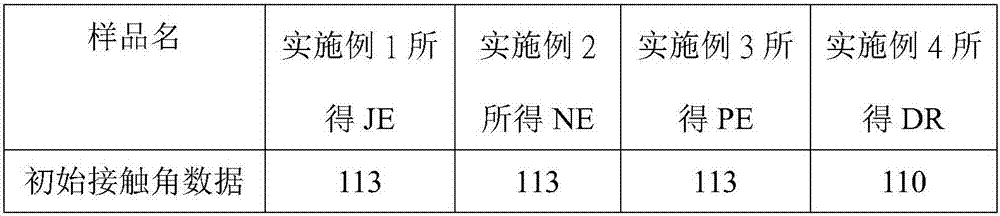

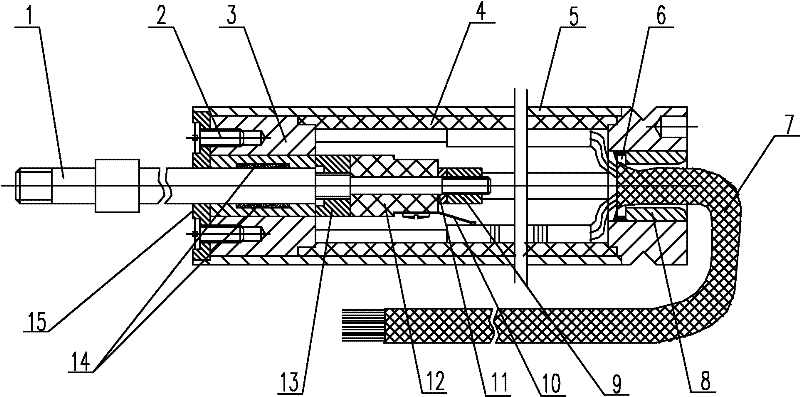

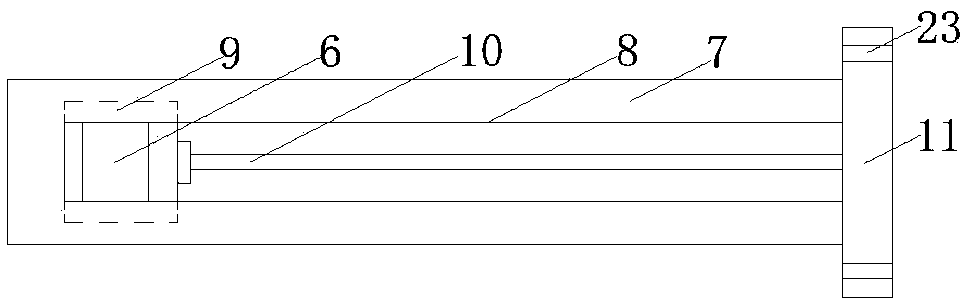

Direct sliding type potentiometer

InactiveCN102456457AIncrease contactImprove contact reliabilityResisitors with sliding contactResistor housing/enclosing/embeddingLinearityMechanical engineering

The invention discloses a direct sliding type potentiometer. The direct sliding type potentiometer comprises a shell, a sliding shaft moving in the shell and an outgoing bus installed on the shell, wherein the shell is internally provided with a resistor body assembly; the resistor body assembly comprises an insulation plate provided with a conductor rail and three mounting lines mounted on the insulation plate, and the three mounting lines are converged at the outgoing bus position; one end of the sliding shaft stretches into the interior of the shell, and one end, stretching into the interior of the shell, of the sliding shaft is provided with an electric brush assembly; the electric brush assembly comprises a sliding block fixed on the sliding shaft; a reed is fixed on the sliding block; the reed is connected with the electric brush; and the electric brush is contacted with the conductor rail on the insulation plate. According to the invention, the effective conversion of linear displacement and an electronic signal can be achieved through the direct sliding type potentiometer; and the direct sliding type potentiometer has the advantages of high linearity, long rotating service life, good smoothness and high reliability, and is convenient for use and popularization.

Owner:SHAANXI HONGXING ELECTRONICS COMPONENTS

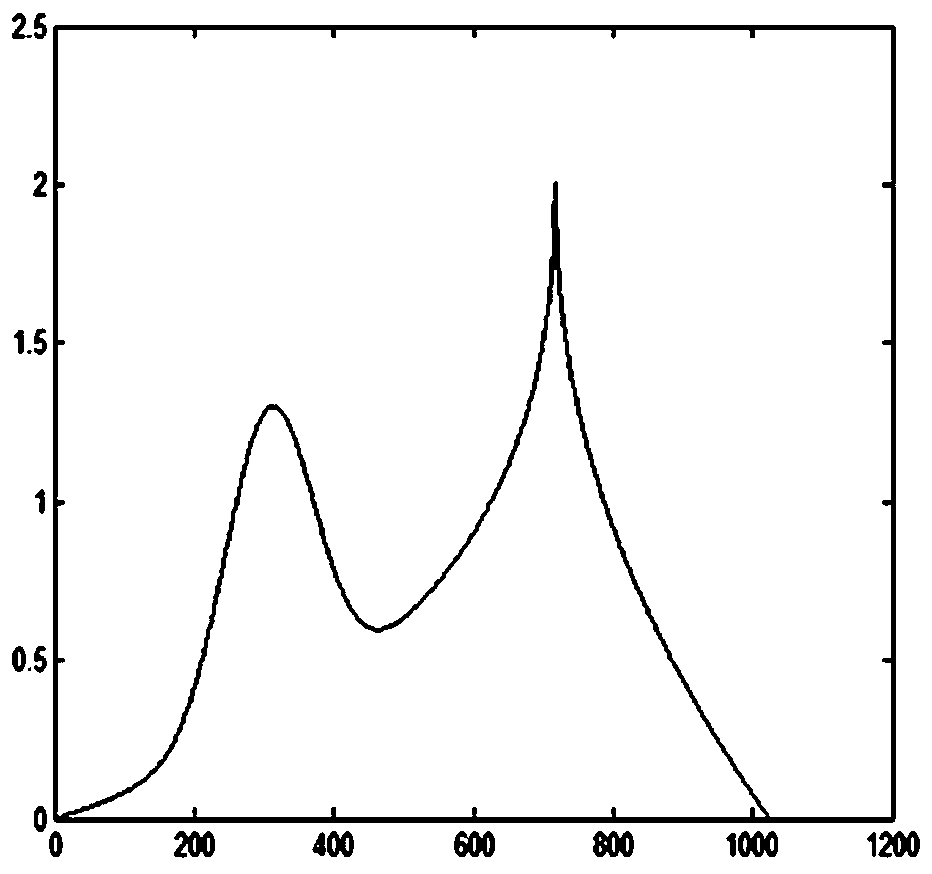

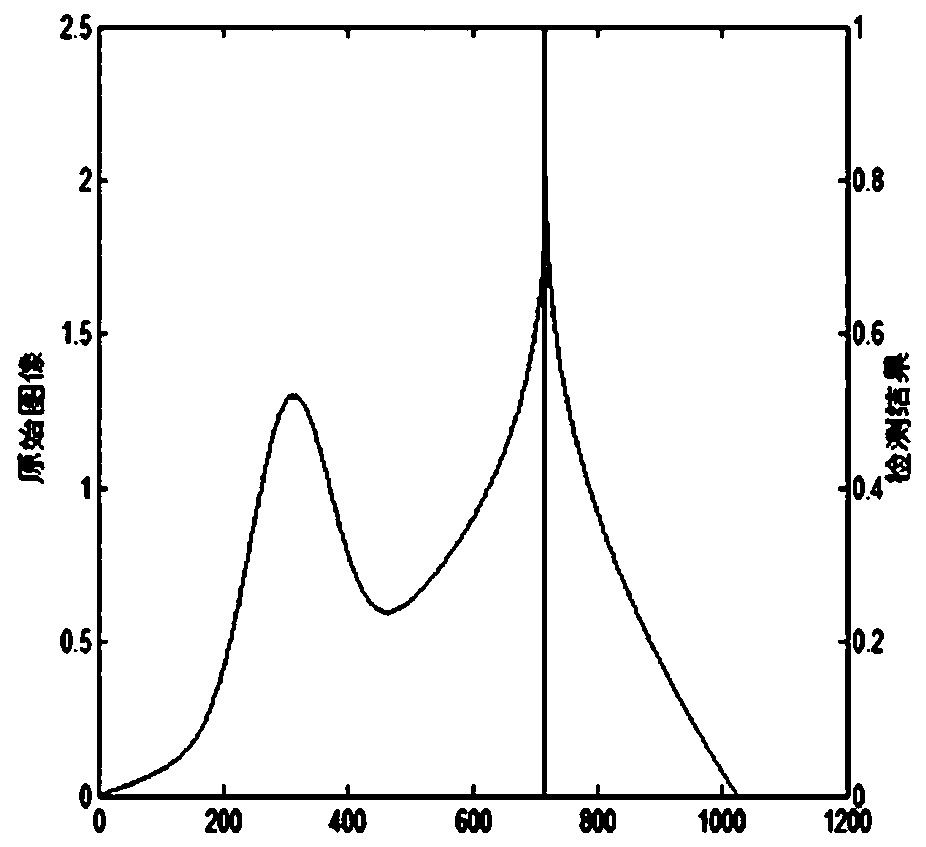

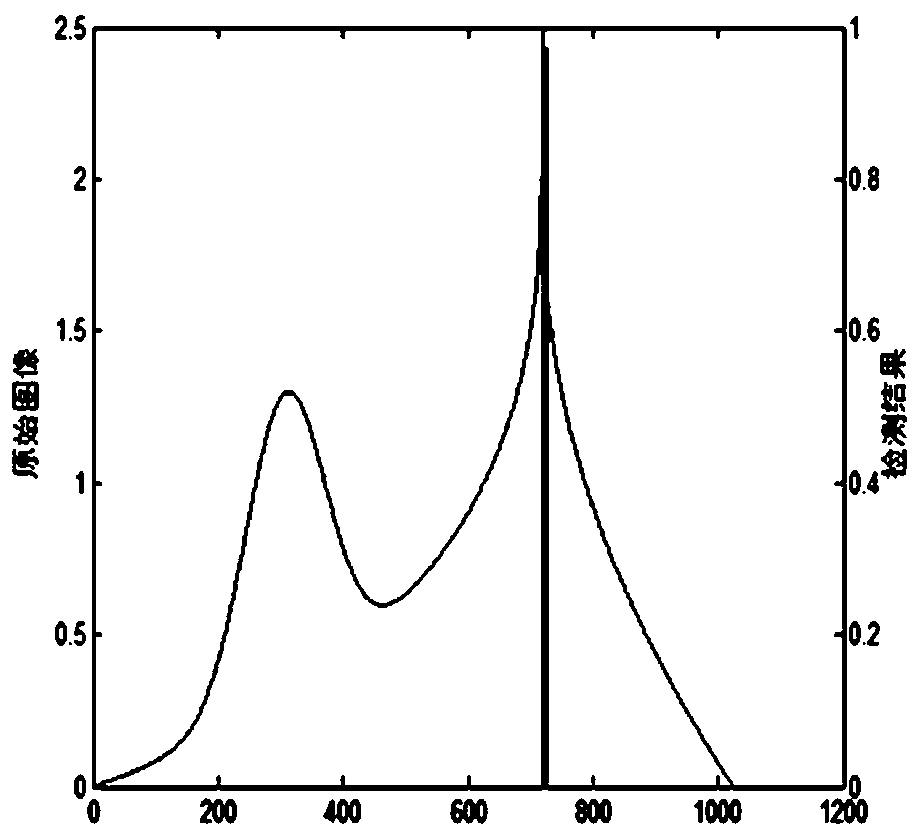

Signal singularity detection method based on sixth-order spline interpolation wavelet

InactiveCN109117816AImprove efficiencyHigh precisionCharacter and pattern recognitionComplex mathematical operationsWavelet decompositionAlgorithm

The invention relates to a signal singularity detection method based on a sixth-order spline interpolation wavelet, which solves the problems of large calculation amount and low detection accuracy ofthe traditional method. The sixth-order spline interpolation wavelet scale function described in the description is obtained from the sixth-order spline wavelet scale function described in the description. The function described in the description yields the low pass filter Ps(omega), a high-pass filter Qs (omega) is obtained from the low-pass filter Ps (omega), a low-pass, high-pass filter Ps (omega), Qs (omega) obtains dual interpolation filters Gs (omega) and Hs (omega), the dual interpolation filter Gs (omega) is obtained, the coefficients of Fourier series of Hs (omega), input the signalto be tested and sample, The interpolation wavelet decomposition coefficients are obtained from the coefficients of the sampling value sequence and the dual interpolation filter Fourier series, The interpolation wavelet decomposition coefficients {an} and {bn} are normalized, and the obtained interpolation wavelet decomposition coefficients are processed by zero interpolation and threshold. The position of the maximum modulus point of the obtained interpolation wavelet decomposition coefficients is the position of the singularity point of the measured signal.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Cup type grinding wheel

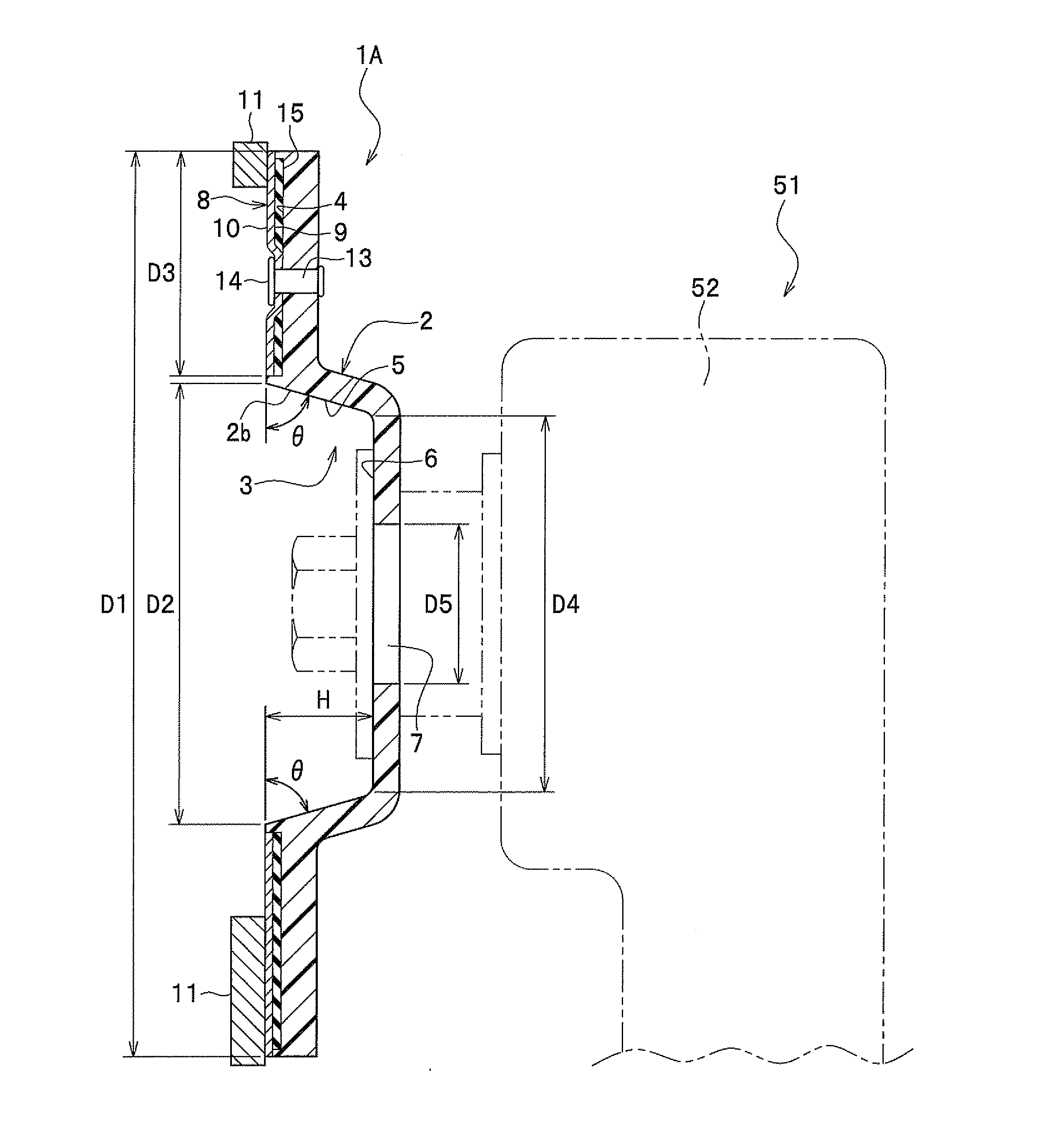

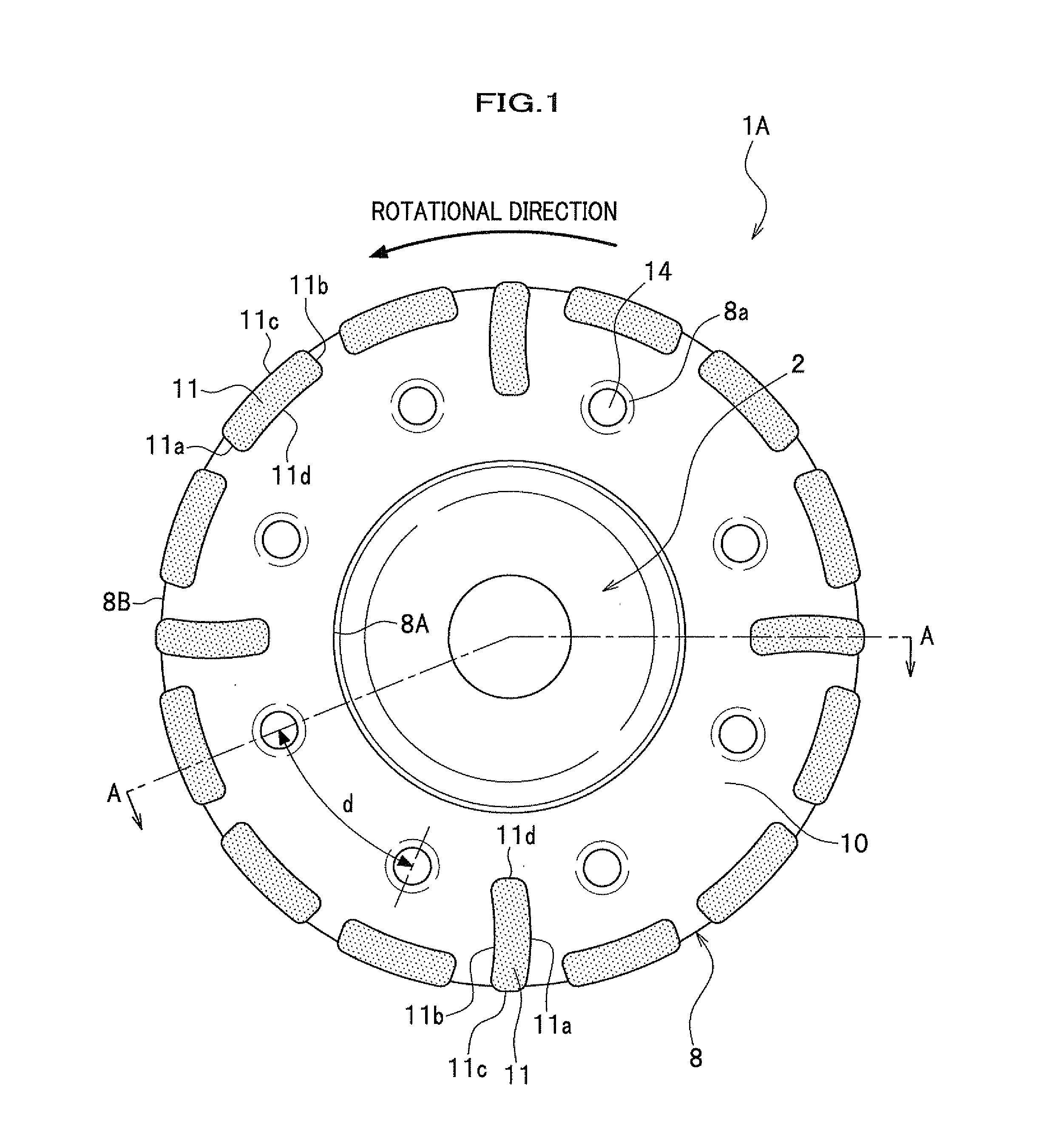

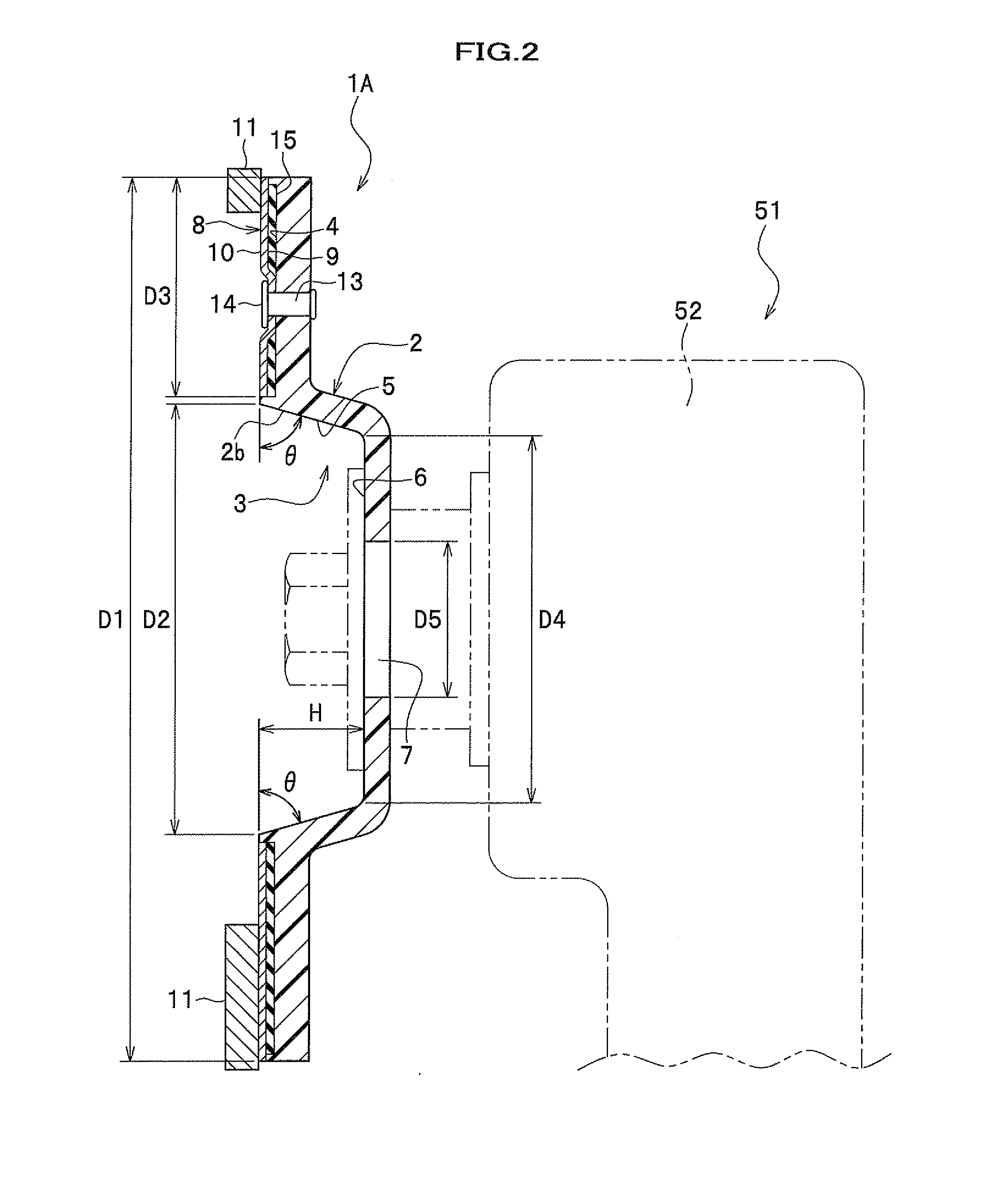

InactiveUS20130331016A1Good smoothnessLight weightRevolution surface grinding machinesBonded abrasive wheelsGrindstoneFastener

Cup type grinding wheel to be attached to a rotary tool includes a plastic base plate made of a glass fiber-reinforced plastic, a metal annular plate with pieces of grindstone or a ring-shaped grindstone on a fixing surface of the metal annular plate, and fasteners for integrating the plastic base plate with the metal annular plate. Heads of fasteners are positioned at the same level as the fixing surface or at a lower level than the fixing surface toward the plastic base plate.

Owner:GOEI

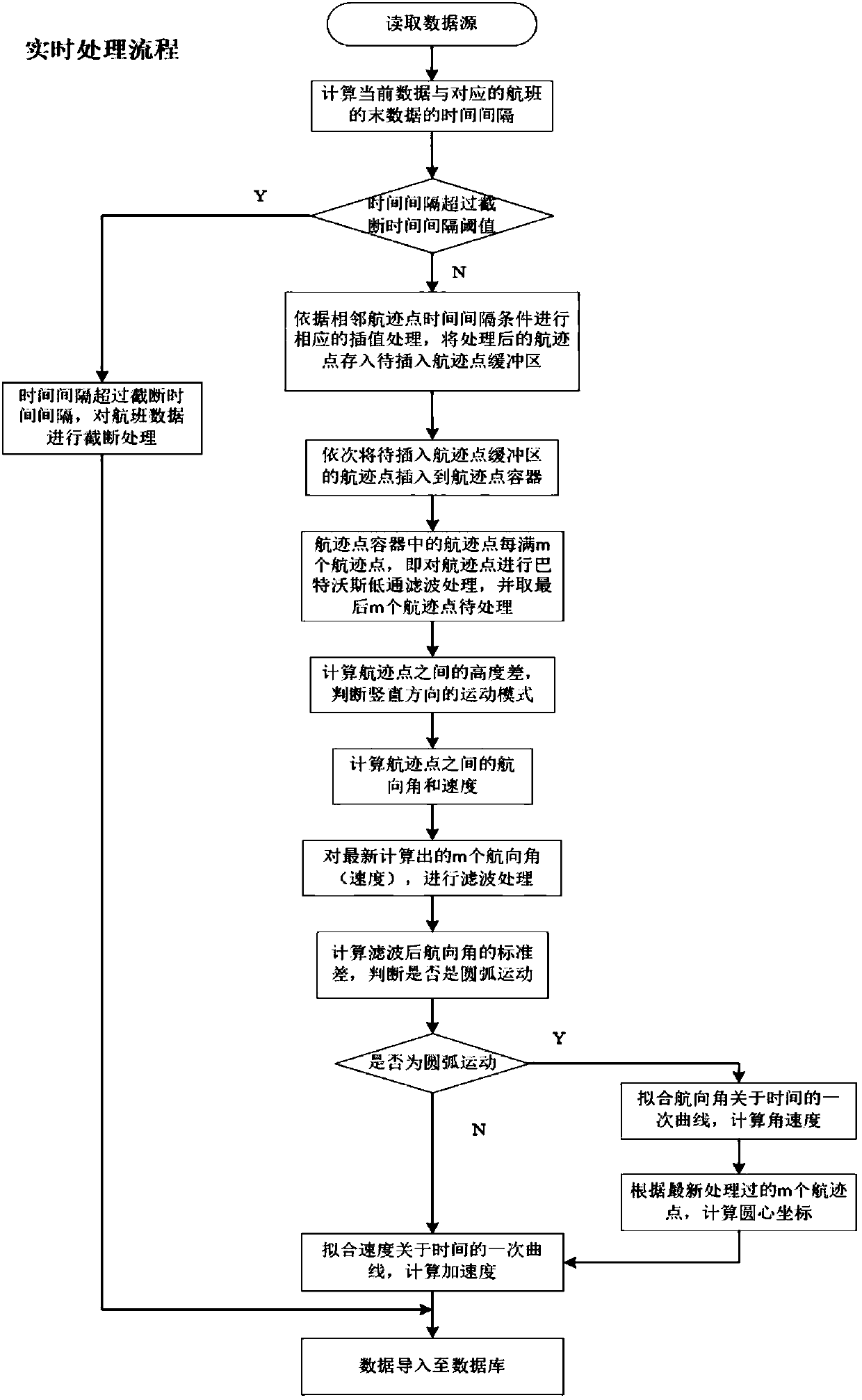

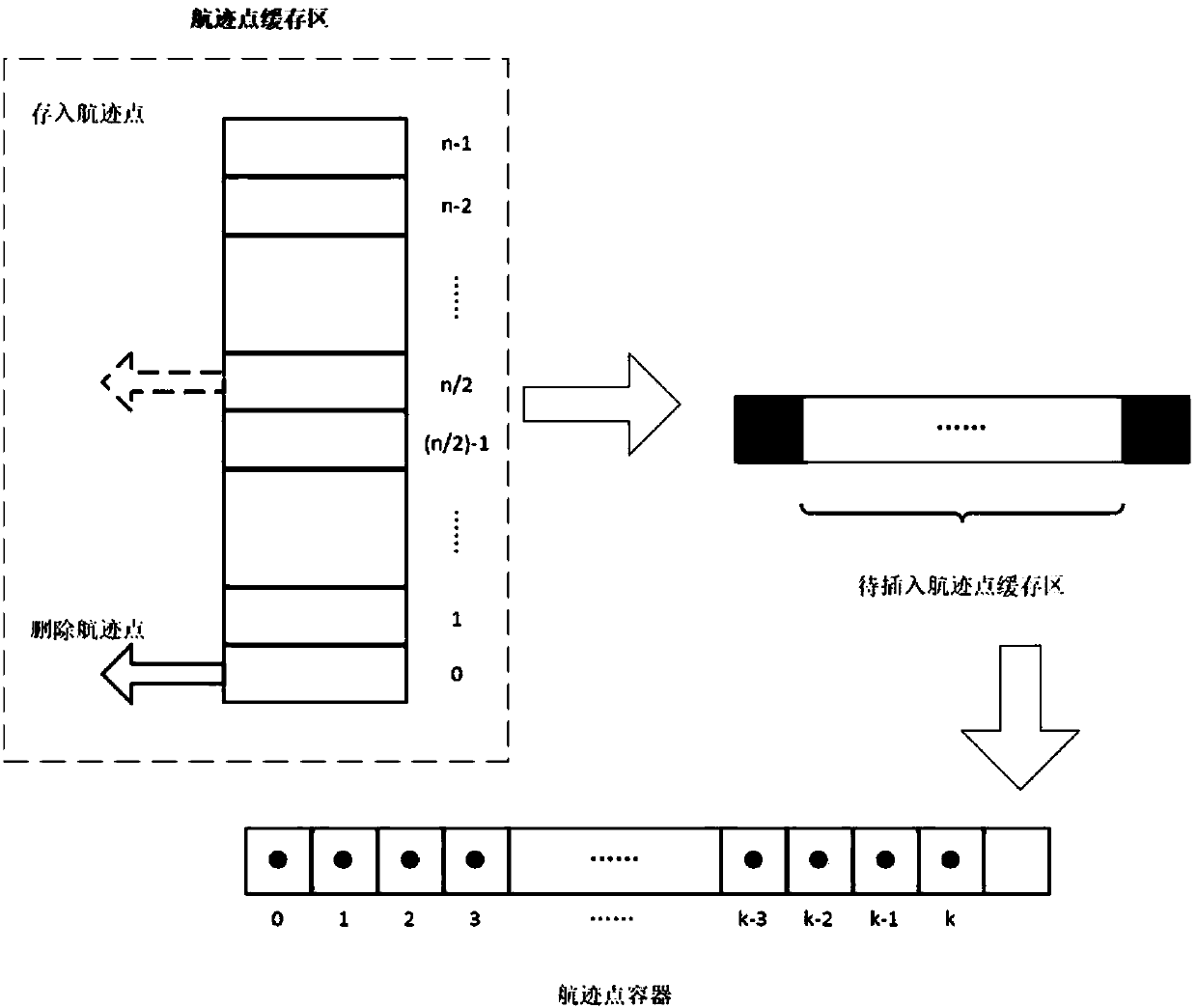

Real-time air target motion pattern recognition and parameter estimation method

ActiveCN108519587ASolve the lossResolve interferenceWave based measurement systemsPoint sequenceEstimation methods

The invention discloses a real-time air target motion pattern recognition and parameter estimation method. A smooth motion track is obtained by conducting interpolation and filtering smoothing processing on a reported position point sequence of an air target, and course angle information obtained through calculation and height information are utilized to judge a motion pattern of the air target inspace. Speed data obtained through calculation is utilized to judge a variation pattern of speed through filtering and smoothing. The least square fitting method is adopted to obtain parameter estimation values such as angular speed and acceleration of motion of the air target through fitting. Moreover, in an arc motion mode, fitting is conducted on a plane equation and a spherical equation on the basis of track points within a specified period of time, and then a circular center coordinates and an arc radius of arc motion can be calculated. The real-time air target motion pattern recognitionand parameter estimation method can well solve the problem of data loss and noise disturbance in original position data.

Owner:SOUTHEAST UNIV

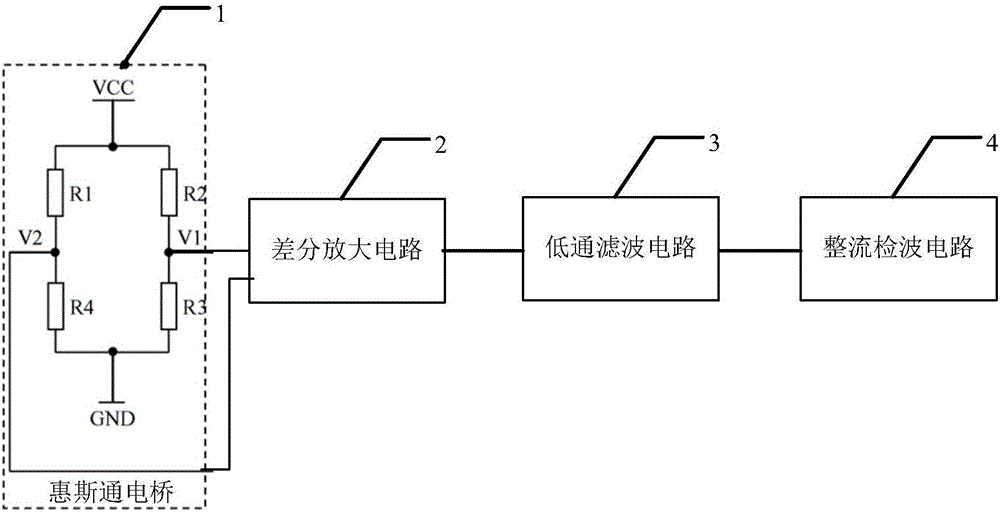

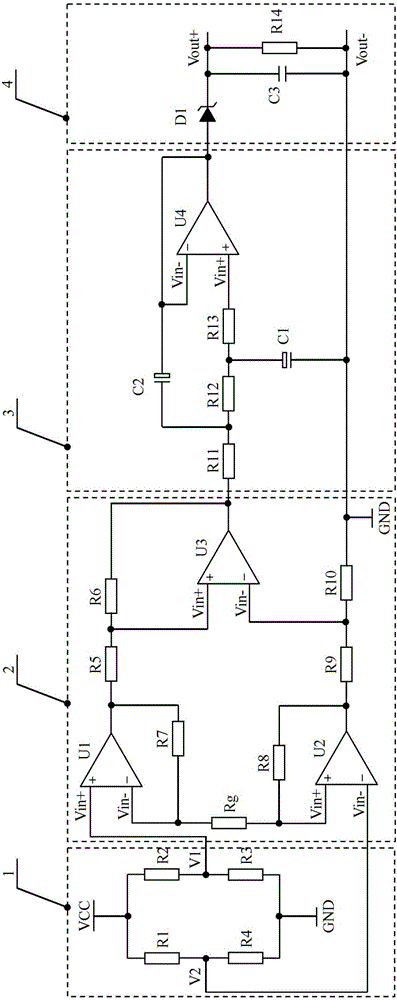

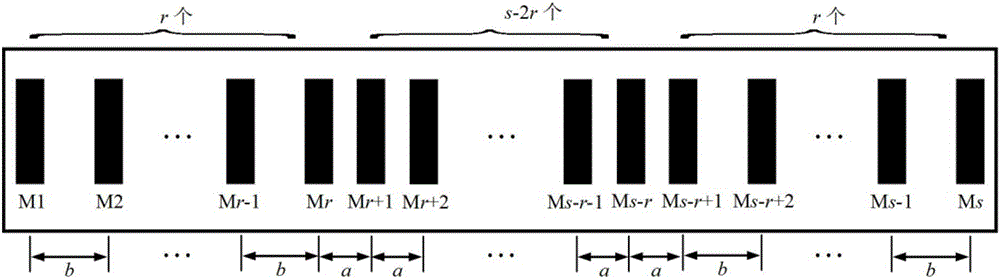

Magnetic field detection circuit, magnetic nail detection device and magnetic nail positioning method

ActiveCN106813658ASimple structureReduce manufacturing costNavigational calculation instrumentsNavigation by terrestrial meansFiltrationLow-pass filter

The invention discloses a magnetic field detection circuit, a magnetic nail detection device and a magnetic nail positioning method. The magnetic field detection circuit comprises a Wheatstone bridge, a differential amplification circuit, a low-pass filter circuit and a rectification detection circuit, wherein the Wheatstone bridge is formed by putting up four metal film magneto-resistors; the magnetic nail detection device comprises s magnetic detection modules packaging the identical magnetic field detection circuits. According to the magnetic field detection circuit and the magnetic nail detection device, a differential voltage signal changed with an external magnetic field can be output via the Wheatstone bridge by virtue of an aeolotropy magnetoresistive effect of the metal film magneto-resistors; the voltage signal is then subjected to amplification, low-pass filtration and rectification detection; the signal acquisition precision is improved; a high frequency noise is removed by the filtration; the signal is output more smoothly; the magnetic nail positioning method achieves precise detection of lateral offset of a magnetic nail relative to the center of the magnetic nail detection device and further contributes to improvement of the navigation precision of the magnetic nail.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

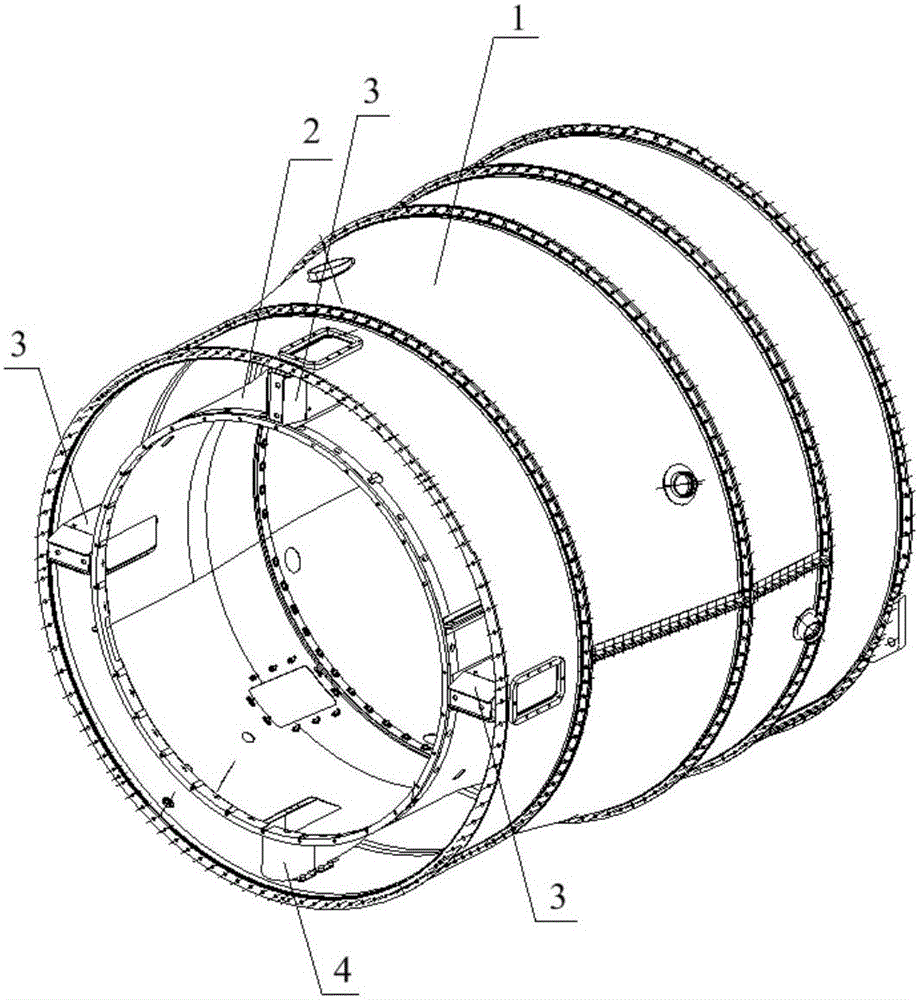

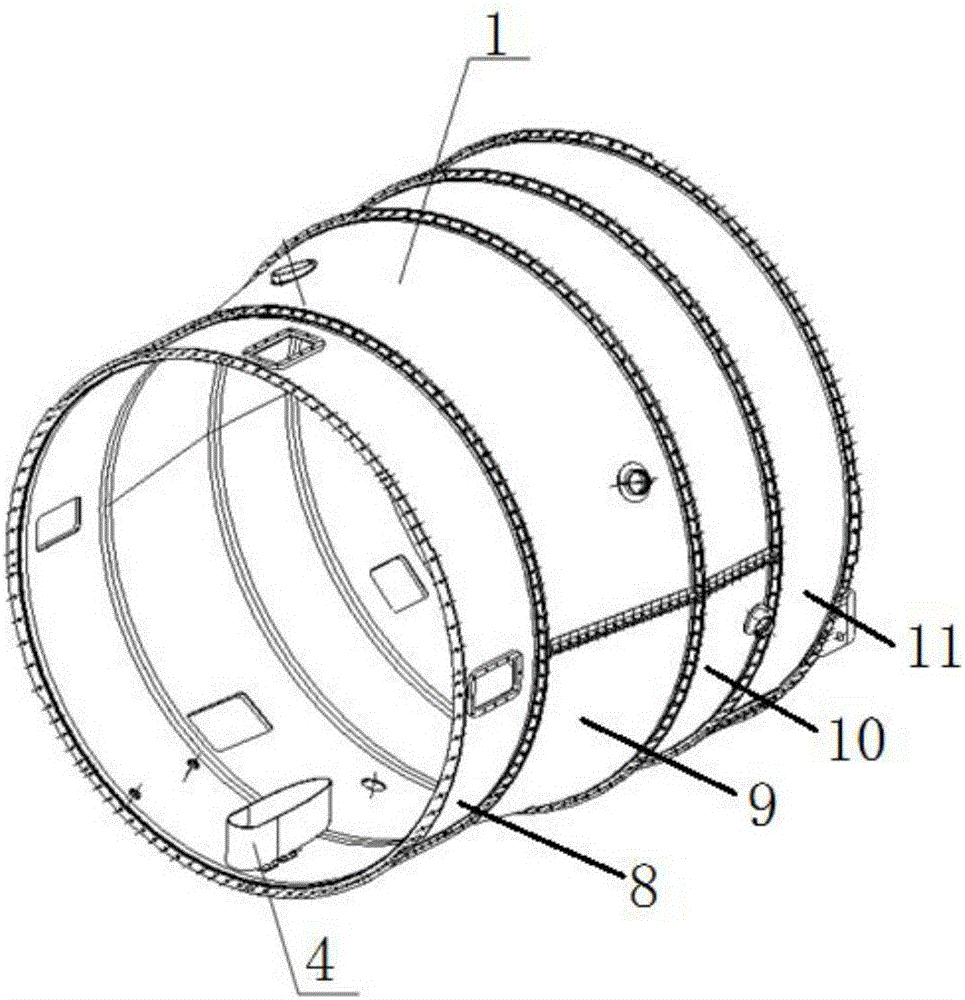

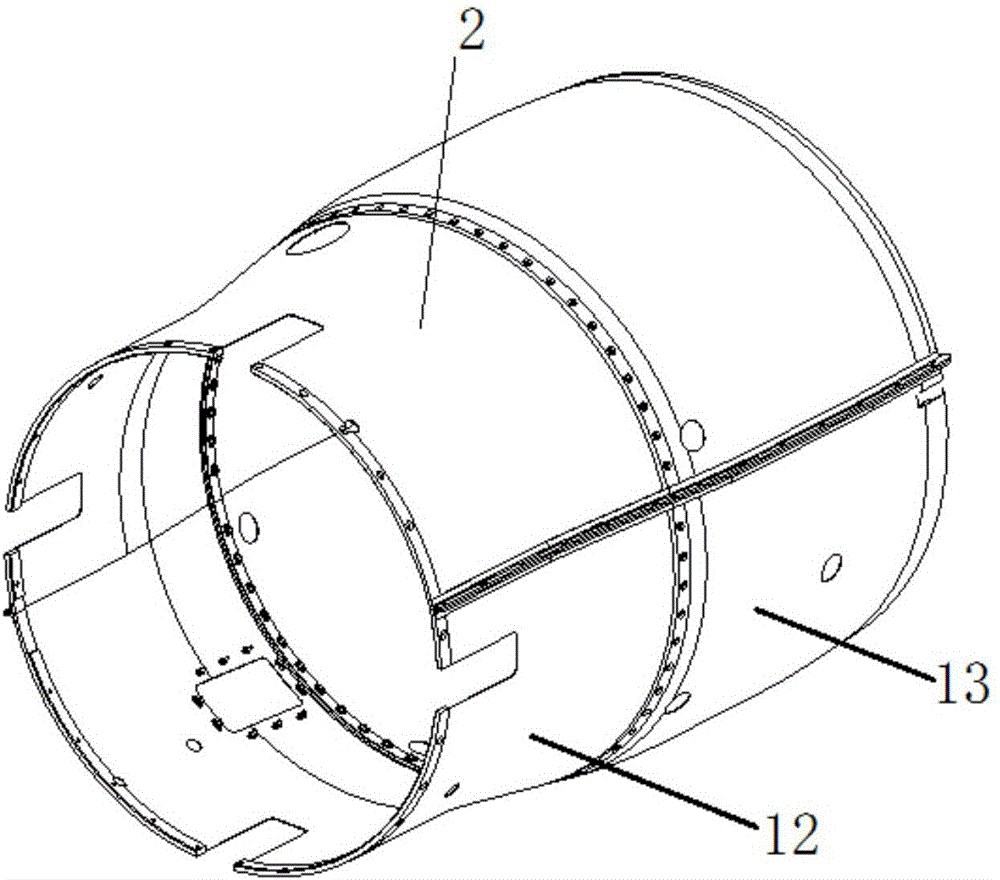

Bypass casing for engine

ActiveCN106812626AGood smoothnessIncrease the total pressure recovery coefficientEngine componentsJet propulsion plantsAirflowEngineering

The invention discloses a bypass casing for an engine and belongs to the field of design of engine casings. The bypass casing comprises an outer casing, an inner casing, junction boxes and a support; a core engine unit body (6) of the engine is sleeved with the inner casing (2); the inner casing (2) is sleeved with the outer casing (1); a flow channel is formed between the outer casing (1) and the inner casing (2); multiple junction boxes are arranged in the flow channel between the outer casing (1) and the inner casing (2) so as to lead out pipelines; the support and the core engine unit body are separately mounted through bolts; and the other end of the support adopts the arc-shaped structure and is glidingly connected with the back section of the inner casing. The outer casing forms an upper wall surface of the bypass flow channel, the inner casing replaces the core engine unit body to form the lower wall surface of the bypass flow channel, the flow channel formed by the outer casing and the inner casing effectively reduces the total pressure loss of the bypass, the total pressure recovery coefficient is increased, the vibration effects caused by air flows on the engine structure and accessories are reduced, and the structural reliability is improved.

Owner:AECC SHENYANG ENGINE RES INST

High temperature resistant nylon fiber for manufacturing wig and preparation method thereof

InactiveCN107805853AGood smoothnessExcellent moisture wicking and breathabilityArtificial filament heat treatmentMelt spinning methodsWaxMoisture

The invention relates to a high temperature resistant nylon fiber for manufacturing wig and a preparation method thereof. The fiber is prepared from the following raw materials in parts by weight: 100parts of PA nylon slice, 1 to 10 parts of additive, 0.1 to 10 parts of pigment, and 0.1 to 5 parts of dispersed wax, wherein the additive is at least one of calcium carbonate, talcum powder, titaniumdioxide, silicon dioxide, diatomite, silica powder, glass bead and mica powder, and the temperature resistant range of the pigment is 180 to 350 DEG C. The preparation method comprises the followingsteps: step a, drying raw materials; step b, carrying out single screw extrusion; step c, cooling nascent fibers; step d, applying oil; and step e, carrying out thermal setting and packaging. The prepared fiber is very smooth and has excellent breathability, good moisture removing performance, and unique and natural luster, which is like the luster of real human hair. Moreover, the environment isnot polluted during the preparation process, and no wastewater or waste is generated.

Owner:XUCHANG HONGYANG BIOCHEM IND DEV

Smooth dough sheet and method for producing the same

InactiveCN101371688AImprove lubricityIncrease moisture contentFood preparationAqueous solutionMechanical engineering

The invention discloses a slip dough cover and a manufacturing method thereof; the slip dough cover comprises elastic slip dough cover bodies and smooth outer layers, and the smooth outer layers are attached on the surfaces of the elastic slip dough cover bodies. The method for manufacturing the slip dough cover comprises: a. emulsifier is melted; b. aqueous solution is formed; c. flour and wheatgluten are mixed to make dough; d. the first rolling is carried out; e. the second rolling is carried out; f. the first rolling to the fifth rolling can be carried out according to the needs, finally, the smooth outer layers can be formed by spreading or sticking smooth powder on the surfaces of the elastic slip dough cover bodies; g. the elastic slip dough cover bodies are cut for moulding. The technique is scientific and reasonable, and the products not only have good smooth mouthfeel, but also have excellent chewiness as well as the advantages of convenience, nutrition, etc.

Owner:童伟雄

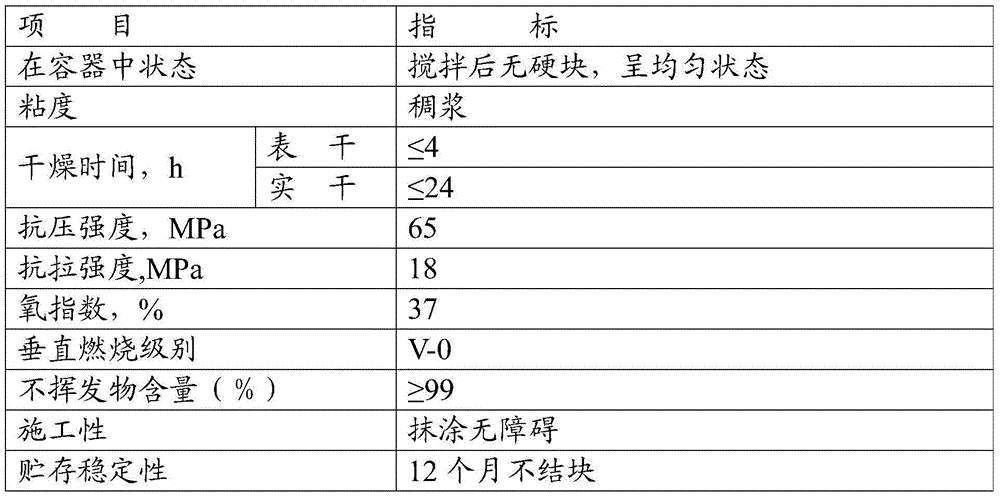

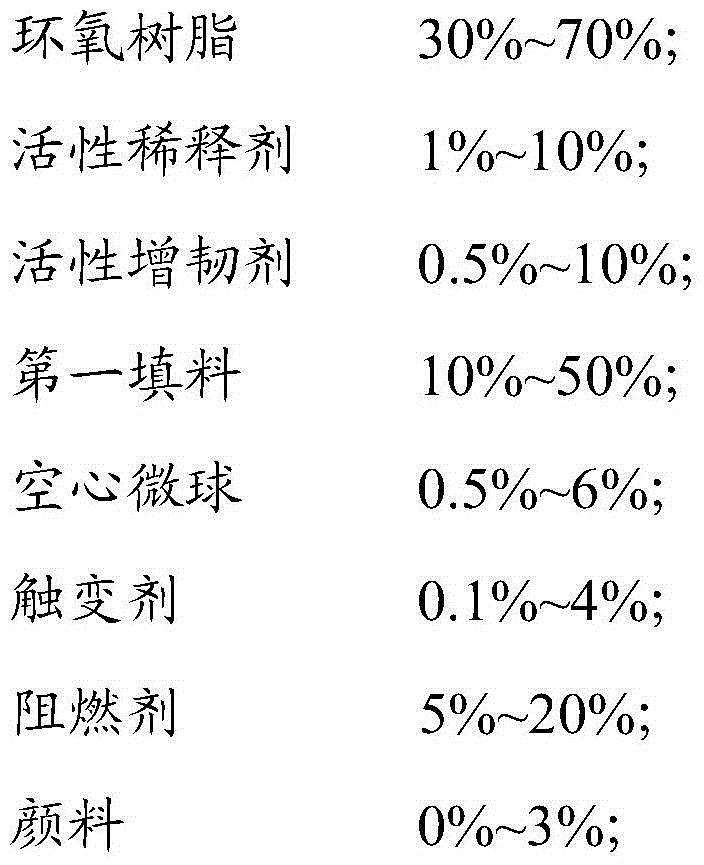

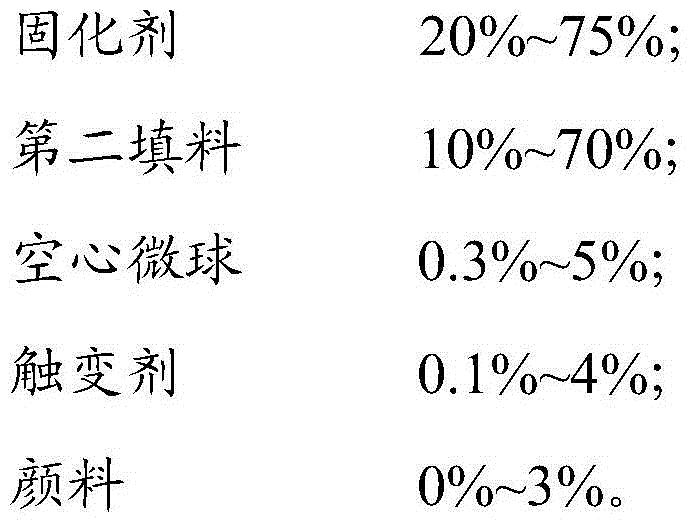

Flame retardant engravable epoxy resin mortar and preparation method thereof

The invention provides flame retardant engravable epoxy resin mortar. The mortar comprises a first composition mixture and a second composition mixture, wherein the first composition mixture comprises epoxy resin, a reactive diluent, a reactive toughening agent, a first filler, a flame retardant, hollow microspheres, a flame retardant, a thixotropic agent and pigments; the second composition mixture comprises a curing agent, a second filler, hollow microspheres, a thixotropic agent and pigments. The invention also provides a preparation method of the flame retardant engravable epoxy resin mortar comprising the above components. The preparation method comprises the following steps: preparing the first composition mixture, preparing the second composition mixture and mixing the first and second composition mixtures according to a specific proportion, thus obtaining the flame retardant engravable epoxy resin mortar.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

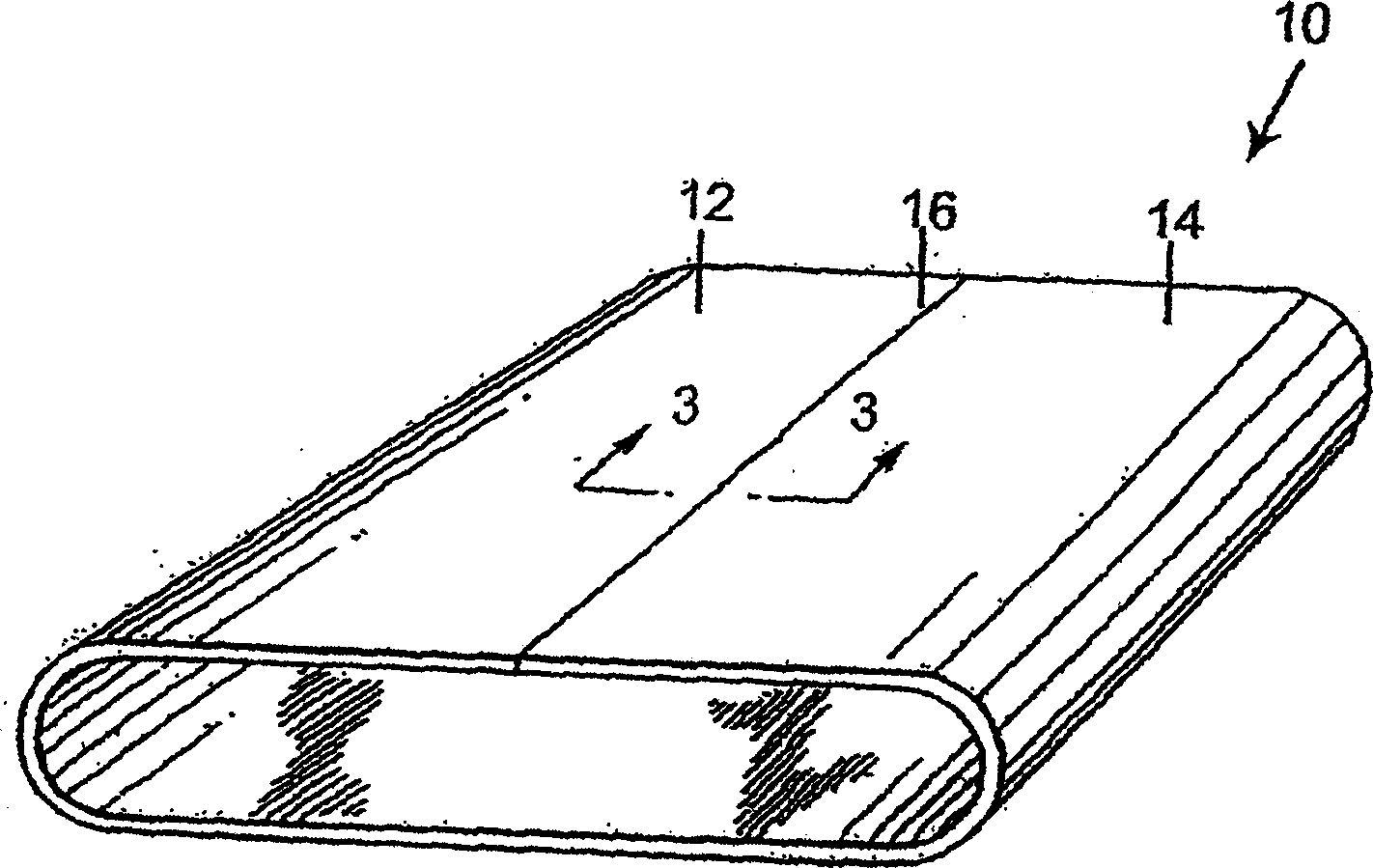

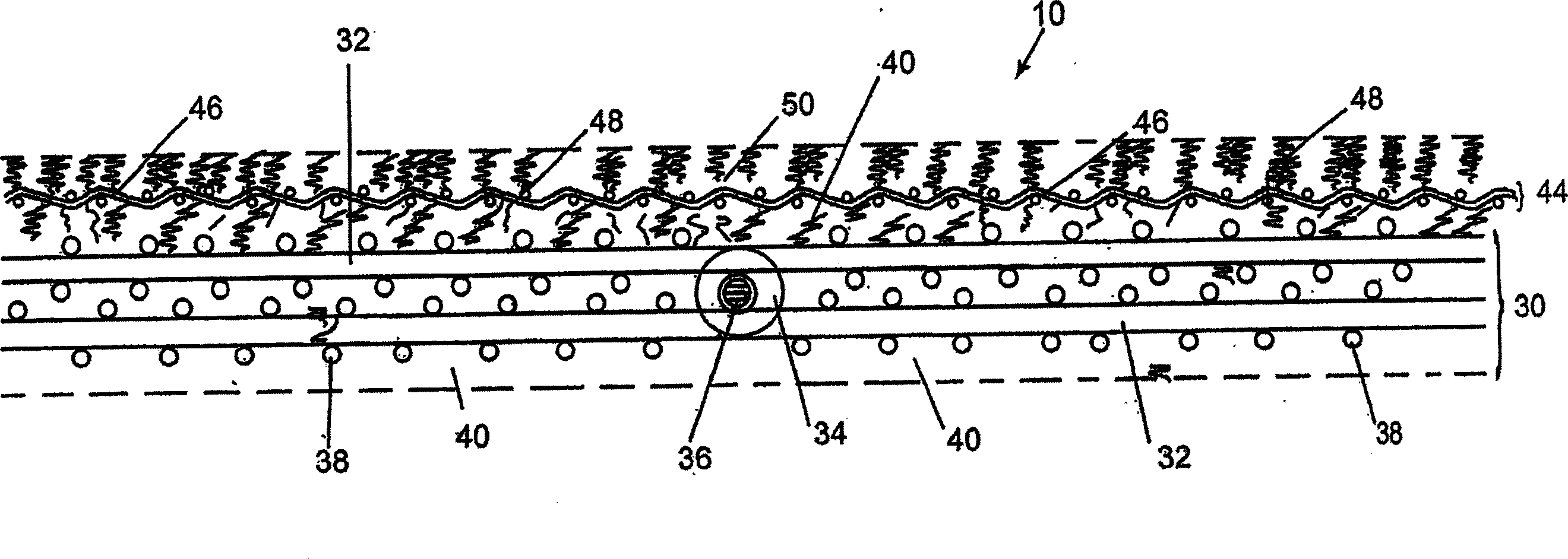

Stratified press fabric

A stratified press fabric for the press section of a paper machine includes a base fabric in the form of an endless loop. A first staple fiber batt material is attached to the outer side of the base fabric by needling. A fine fabric covers the first staple fiber batt material, and a second staple fiber batt material is attached to the fine fabric by needling. The fibers making up the second staple fiber material are finer, that is, of smaller diameter or denier, than the fibers making up the first staple fiber material. The fine fabric prevents the coarser fibers of the first staple fiber batt material from being needled therethrough to mix with the finer fibers of the second fiber batt material.

Owner:ALBANY INT CORP

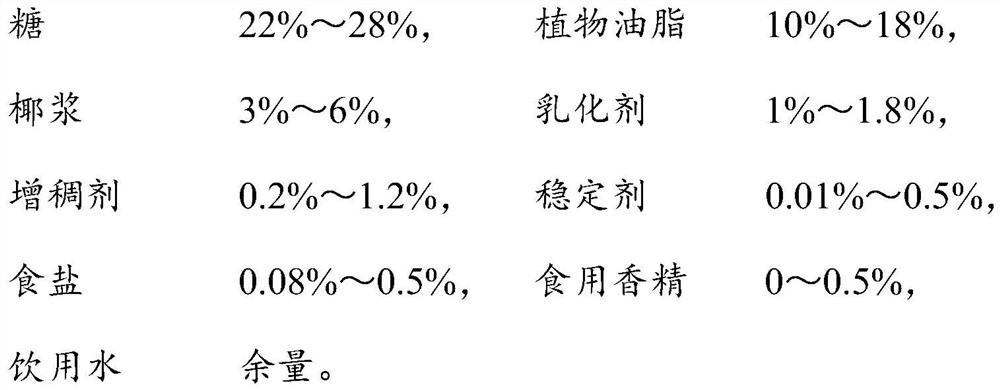

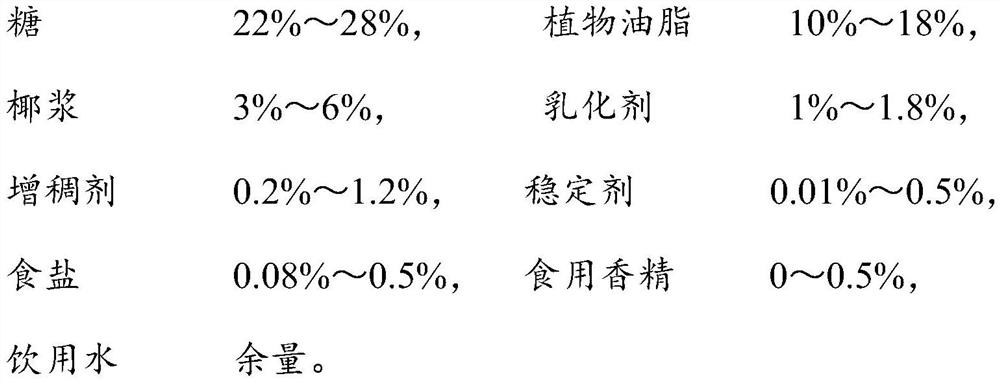

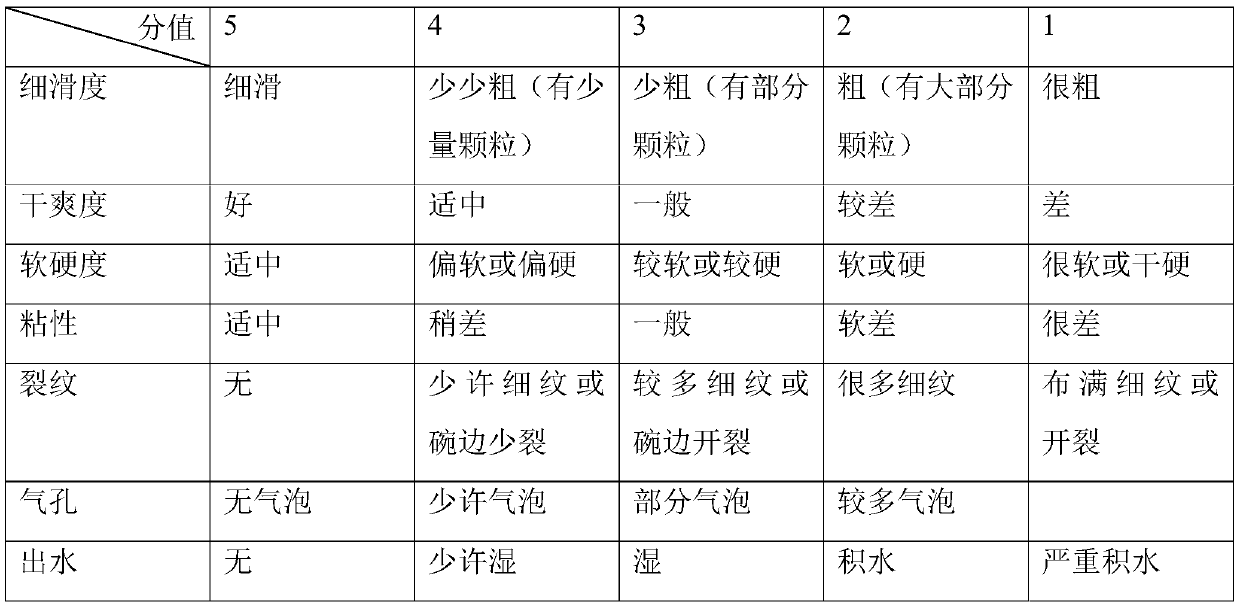

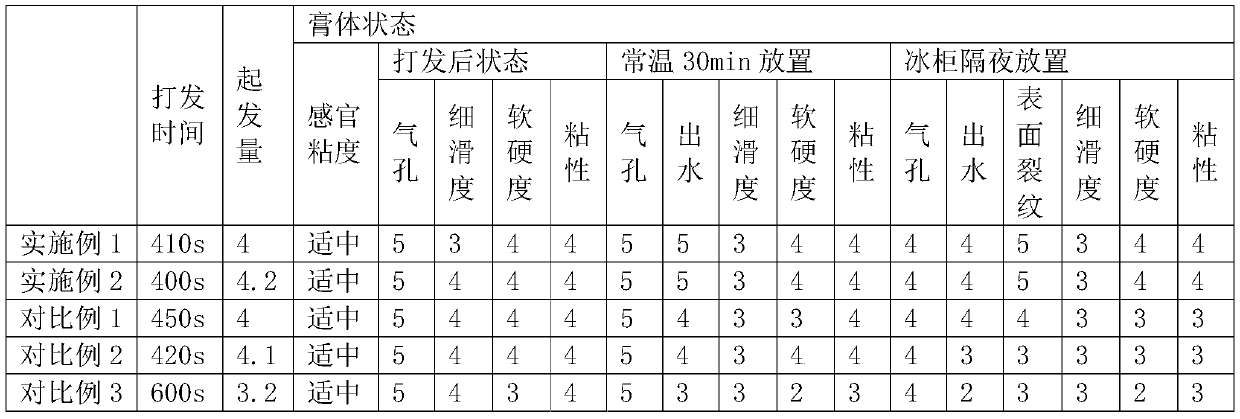

Double-plant-based coconut milk non-dairy cream and preparation method thereof

InactiveCN111616224AStrong natural coconut fragrancePure and soft tasteEdible oils/fats ingredientsEdible oils/fats production/working-upBiotechnologyVegetable oil

The invention discloses double-plant-based coconut milk non-dairy cream and a preparation method thereof. The double-plant-based coconut milk non-dairy cream comprises the following components in percentage by weight: 22%-28% of sugar, 10%-18% of vegetable fat, 3%-6% of coconut milk, 1%-1.8% of an emulsifier, 0.2%-1.2% of a thickener, 0.01%-0.5% of a stabilizer, 0.08%-0.5% of table salt, 0-0.5% ofedible essence and the balance of drinking water. The coconut milk and the vegetable fat are combined to prepare the double-plant-based cream, and the double-plant-based cream has rich natural coconut fragrance, tastes pure and soft, contains a proper amount of fat, a large amount of vegetable proteins and nutrient substances, and meets diversified taste requirements on the market. The double-plant-based coconut milk non-dairy cream prepared by the preparation method has the advantages of strong coconut fragrance, good whipping performance and good stability, and is suitable for industrial production.

Owner:增城市金点食品有限公司

Vehicle suspension and vehicle

InactiveCN106379131AIncrease the total air chamber volumeThe total air chamber volume is stableInterconnection systemsResilient suspensionsPower unitAir chamber

The invention relates to a vehicle suspension and a vehicle. The suspension comprises an oil cylinder, a power unit and at least three accumulators, wherein a rod chamber of the oil cylinder is communicated with the first accumulator and the power unit respectively, and a rodless chamber of the oil cylinder is communicated with the second accumulator and the power unit respectively. The vehicle comprises the suspension which is arranged at the bottom of a vehicle body. The suspension and the vehicle have the beneficial effects that real-time and step adjustment of rigidity is achieved and the side-tipping and rollover resistance of the vehicle is improved, thus greatly improving the comfort, safety and handling stability of the vehicle; and the volume of the total air chamber of the accumulator connected with the rodless chamber of the oil cylinder is increased, thus reducing the rigidity of the suspension, so that the suspension is more flexible and then the vehicle runs more stably and comfortably.

Owner:张家口舒狮汽车科技有限公司

Sea salt-cheese milk-containing non-dairy cream and preparation method thereof

PendingCN110463781AUnique Sea Salt Cheese FlavorMeet the needs of diverse tastesEdible oils/fats ingredientsEdible oils/fats production/working-upVegetable oilAdditive ingredient

The invention discloses a sea salt-cheese milk-containing non-dairy cream and a preparation method thereof, wherein the sea salt-cheese milk-containing non-dairy cream is composed of the following rawmaterials by the weight percentage: 22%-28% of sugar, 12%-18% of vegetable oil, 1%-5% of milk fat, 1%-5% of cheese, 1%-4% of condensed milk, 1.0%-1.8% of an emulsifier, 0.3%-1.2% of a thickener, 0.05%-0.2% of a stabilizer, 0%-0.1% of a coloring agent, 0.08%-0.5% of sea salt, 0%-0.5% of an edible essence, and water added to make the total amount to 100%. The sea salt and cheese ingredients are added on the basis of milk fat-containing non-dairy cream, so that the sea salt-cheese milk-containing non-dairy cream has unique sea salt and cheese flavor, meets the diversified taste demand on the market, has good comprehensive performance and good stability after standing, and is also suitable for industrial production and transportation.

Owner:ZENGCHENG LEGO FOODS CO LTD

Process for preparing a composition using pressurized fluid, composition prepared, and uses thereof

InactiveUS20050169877A1Cosmetic propertyImprove propertiesCosmetic preparationsHair cosmeticsFiberTissue skin

The present invention relates to a process for preparing a composition useful, for example, for the treatment of keratin materials, in particular the skin and human keratin fibres such as the hair, to the composition prepared, and also to a process for treating keratin materials using this composition.

Owner:LOREAL SA

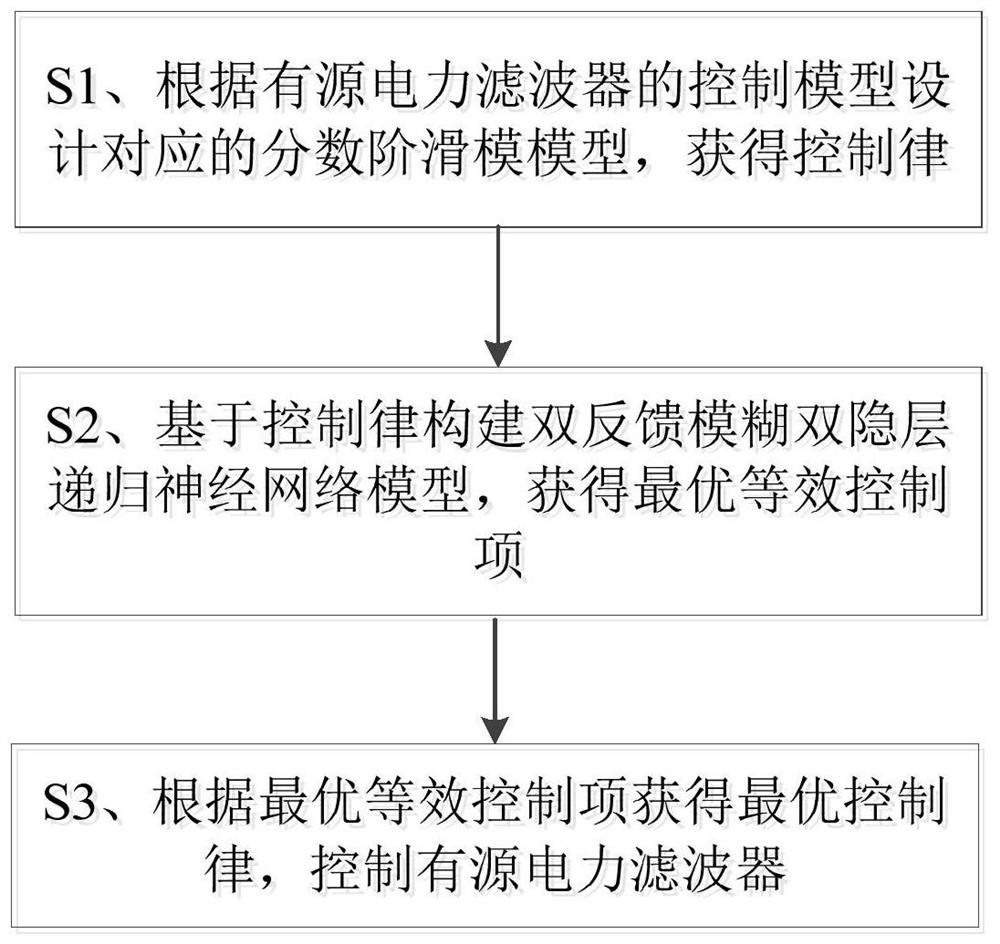

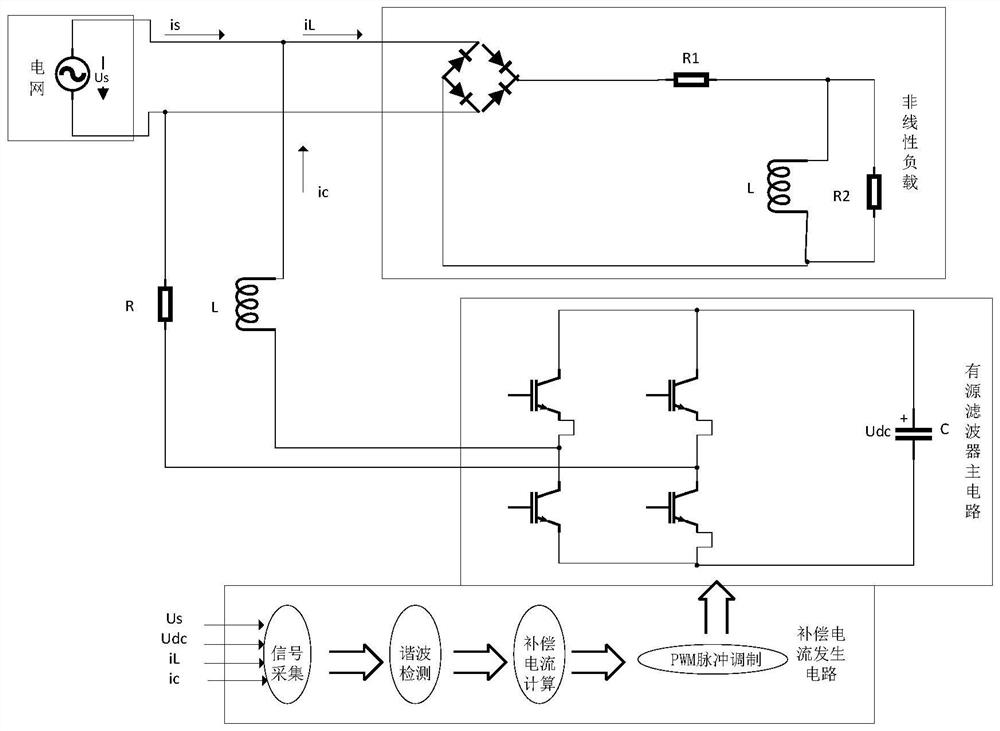

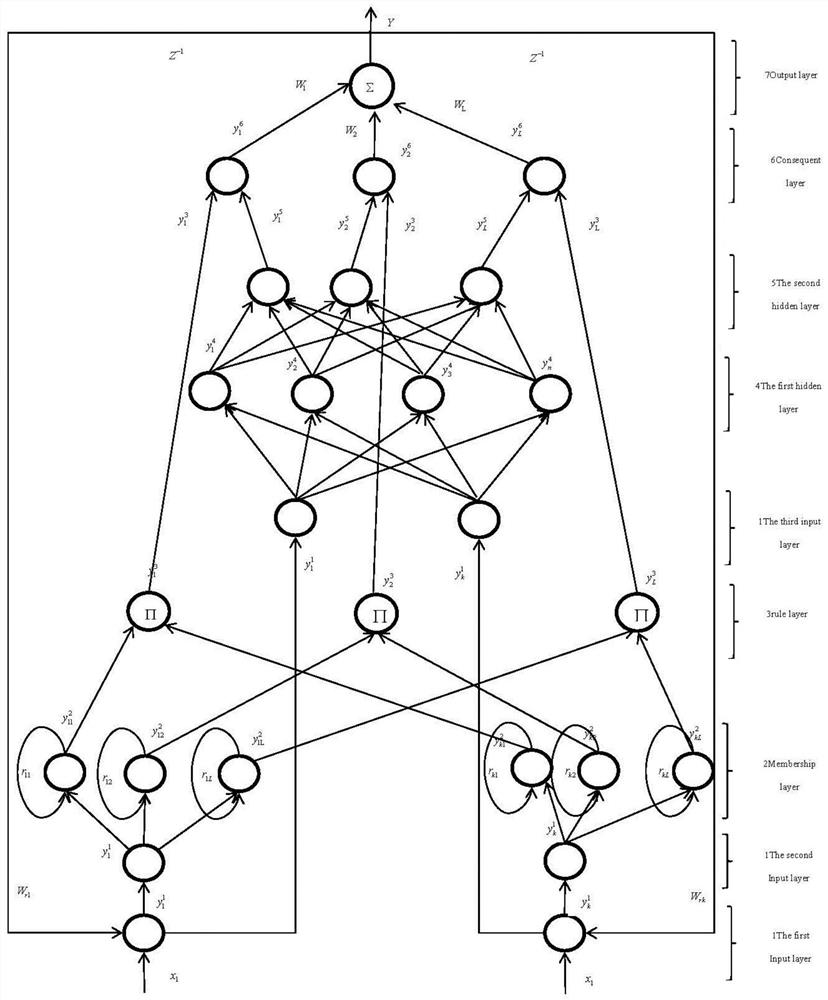

Active power filter fractional order sliding mode control method and system based on neural network and storage medium

ActiveCN112103960AGood smoothnessImprove anti-interference abilityActive power filteringAc network to reduce harmonics/ripplesEquivalent controlControl engineering

The invention discloses an active power filter fractional order sliding mode control method and system based on a neural network, and aims to solve the technical problems of insufficient stability andreliability of active power filter control in the prior art. The method comprises the following steps: designing a corresponding fractional order sliding mode model according to a control model of the active power filter to obtain a control law; constructing a double-feedback fuzzy double-hidden-layer recurrent neural network model based on the control law to obtain an optimal equivalent controlitem; and obtaining an optimal control law according to the optimal equivalent control item, and controlling the active power filter. According to the invention, current compensation can be rapidly and accurately carried out, and the reliability and stability are good.

Owner:HOHAI UNIV CHANGZHOU

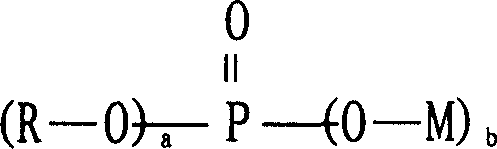

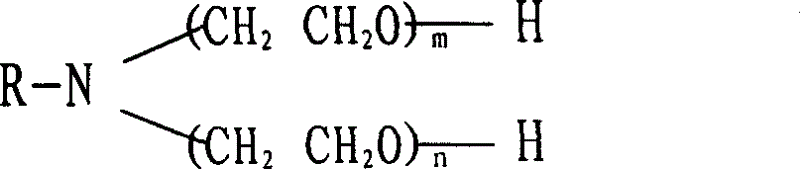

Oil for acrylic acrylic filature

The invention discloses an acrylic fiber oil solution which is an emulsion prepared by active ingredient and pure water, wherein the active ingredient comprises, component A, an alkyl group phosphate sylvite or sodium salt, component B, a polyoxyethylene aliphatic amine, component C, a polyoxyethylene aliphatic acid single (double) ester mixture, component D, white oil. Compared with the prior art, the acrylic fiber oil solution provided by the present invention can not only produce fine fabric smoothness, but also bring better beaming property simultaneously, thus is especially fitted for acrylic fiber production of complex manufacturing process.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

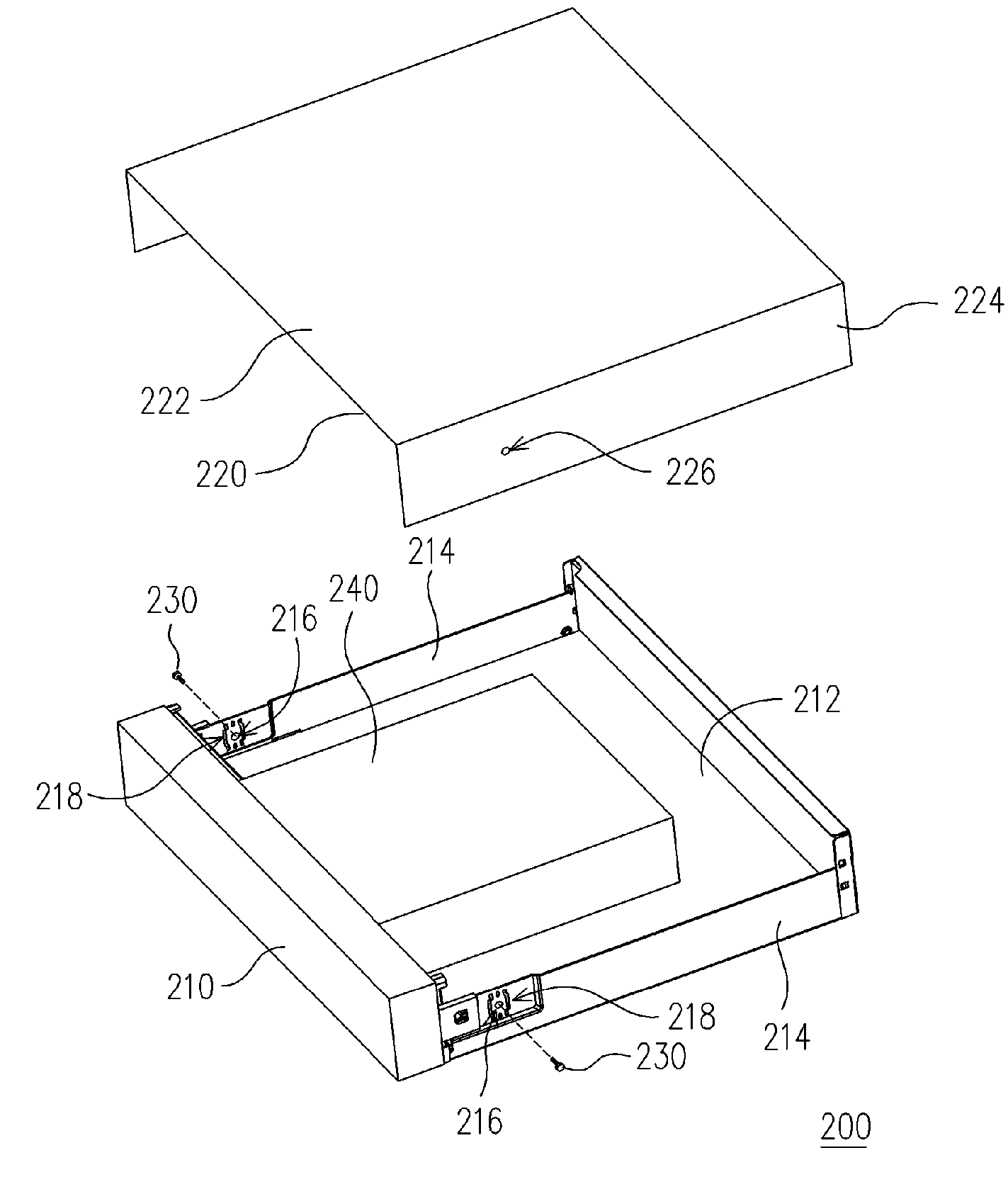

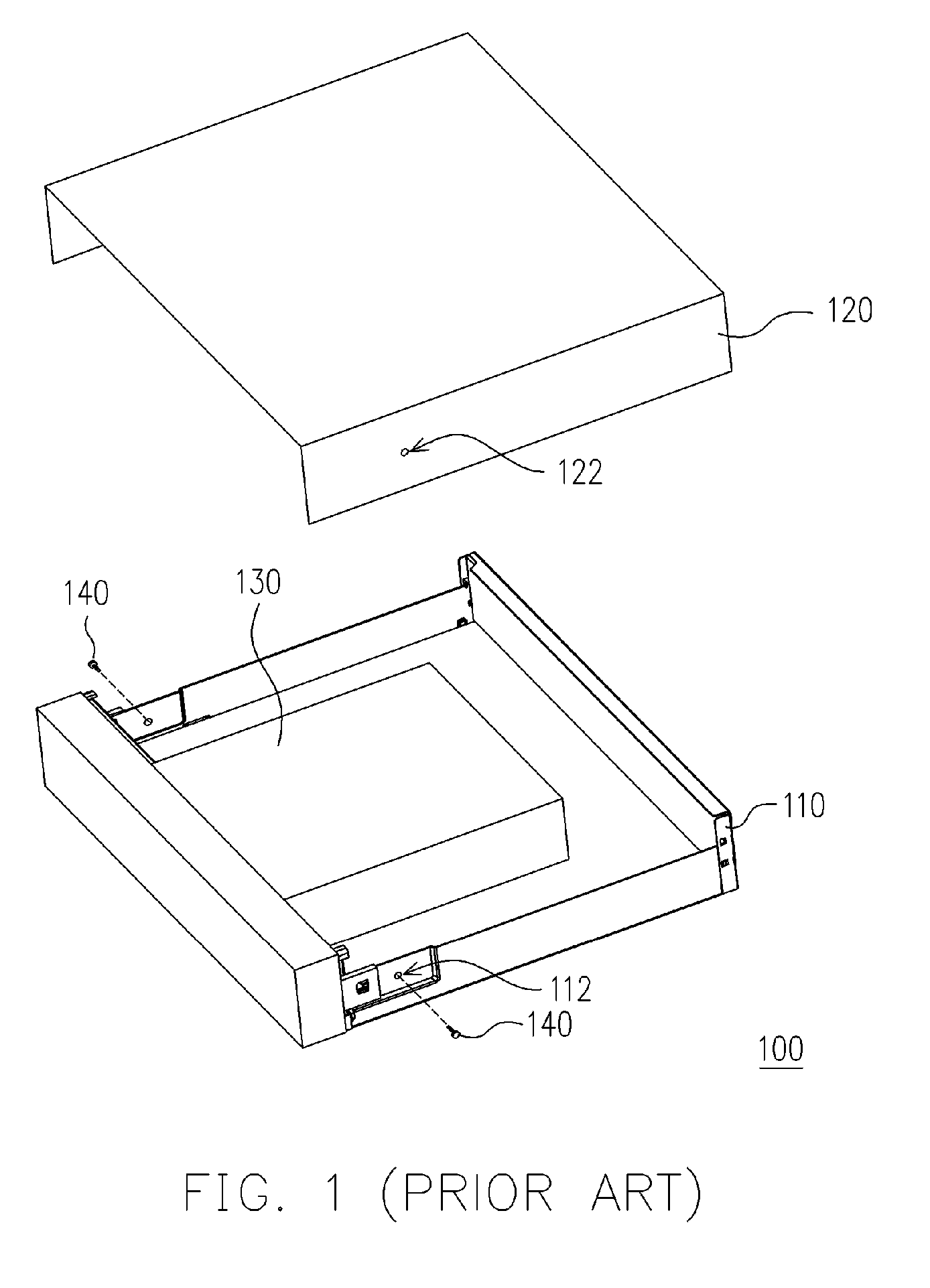

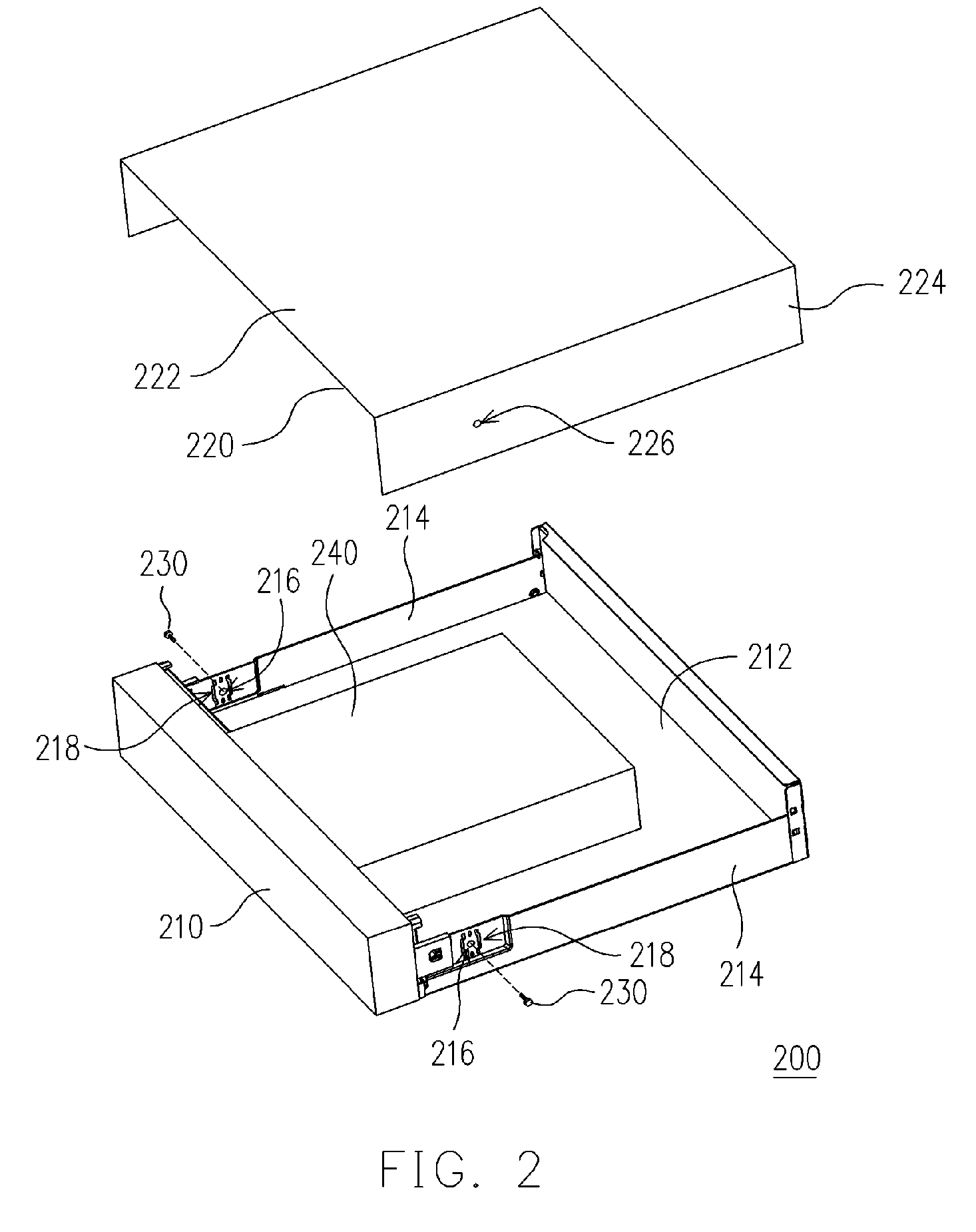

Optical disc drive and housing of an electronic device

InactiveUS7447012B2Good smoothnessImprove smoothnessDigital data processing detailsRecord information storageEngineeringOptical disc drive

A housing adapted for use in an electronic device is provided. The housing includes a first member, a second member, and a fastener. The first member has a first fastening hole and a weakening structure disposed around the first fastening hole. The second member has a second fastening hole. The fastener passes through the first fastening hole and the second fastening hole to fix the first member and the second member to each other.

Owner:INT BUSINESS MASCH CORP +1

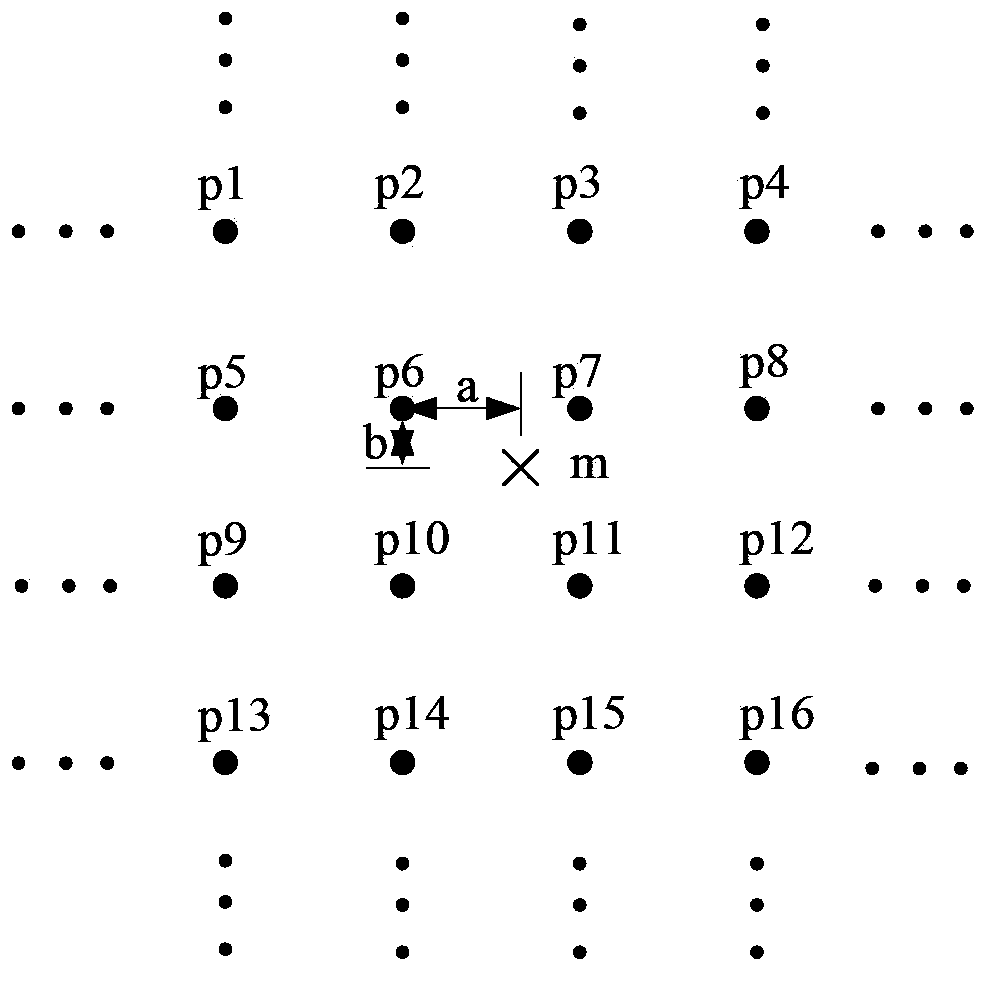

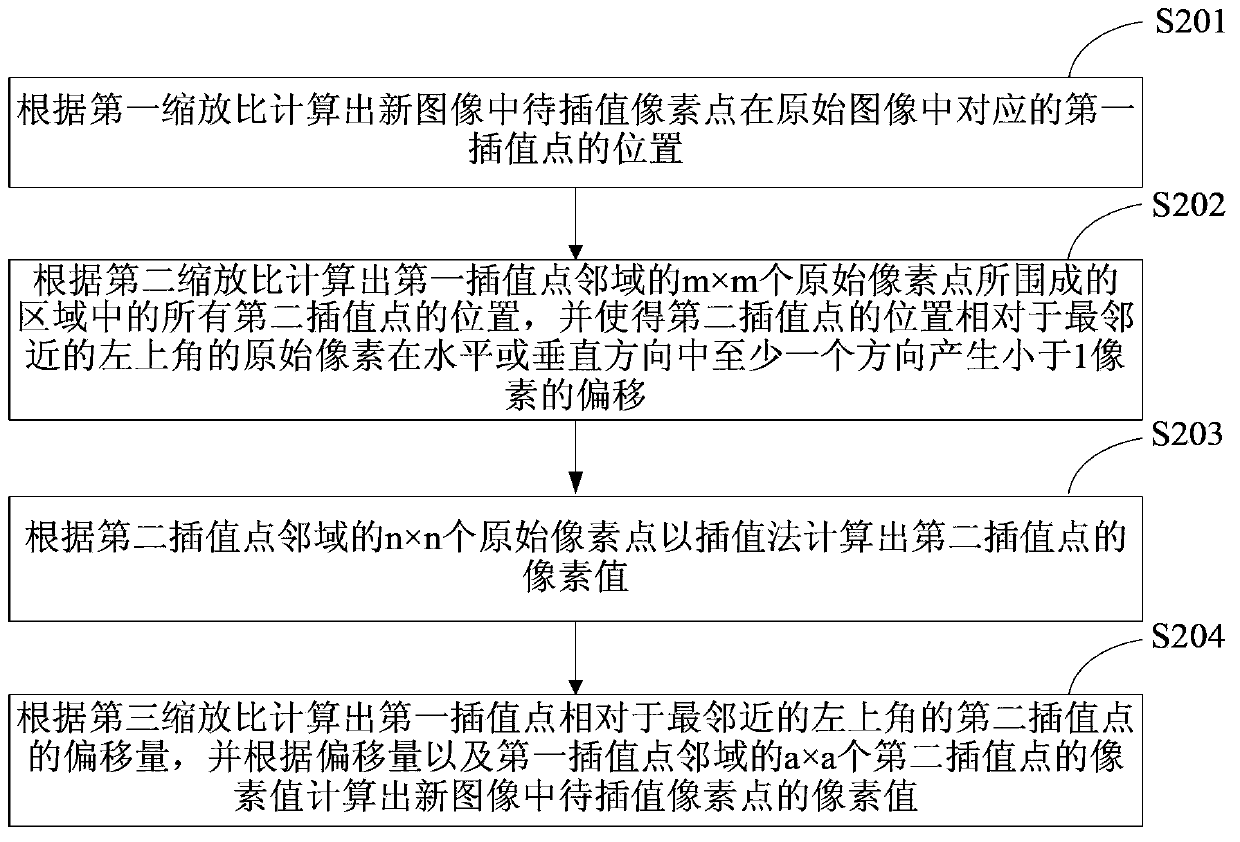

Image magnification method and device

ActiveCN103500434AMaintain image clarityGood smoothnessGeometric image transformationPantographAlgorithm

The invention discloses an image magnification method and device. The method comprises the steps of calculating the positions, corresponding to first interpolating points in an original image, of pixel points to be interpolated in a new image according to a first pantograph ratio; calculating the positions of all second interpolating points in a region surrounded by m*m original pixel points in an adjacent region of the first interpolating points according to a second pantograph ratio, and enabling the positions, relative to the original pixels at the nearest upper left corner, of the second interpolating points to generate offset smaller than one pixel in the at least one direction of the horizontal or perpendicular directions, wherein the second pantograph ratio is two; calculating the pixel values of the second interpolating points according to n*n original pixel points in the adjacent region of the second interpolating points; calculating the offset amount, relative to the second interpolating points at the nearest upper left corner, of the first interpolating points according to a third pantograph ratio, and calculating the pixel values of the pixel points to be interpolated according to the offset amount and the pixel values of the a*a second interpolating points in the adjacent region of the first interpolating points, wherein the third pantograph ratio is equal to the result that the first pantograph ratio is divided by the second pantograph ratio.

Owner:HUAWEI TECH CO LTD

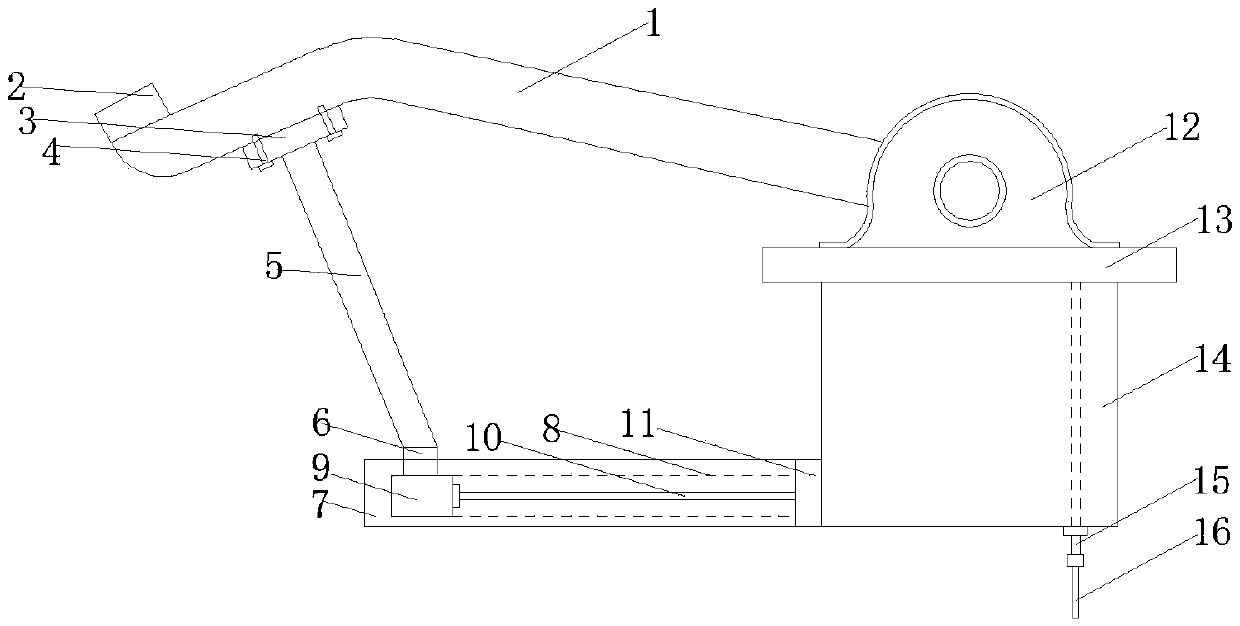

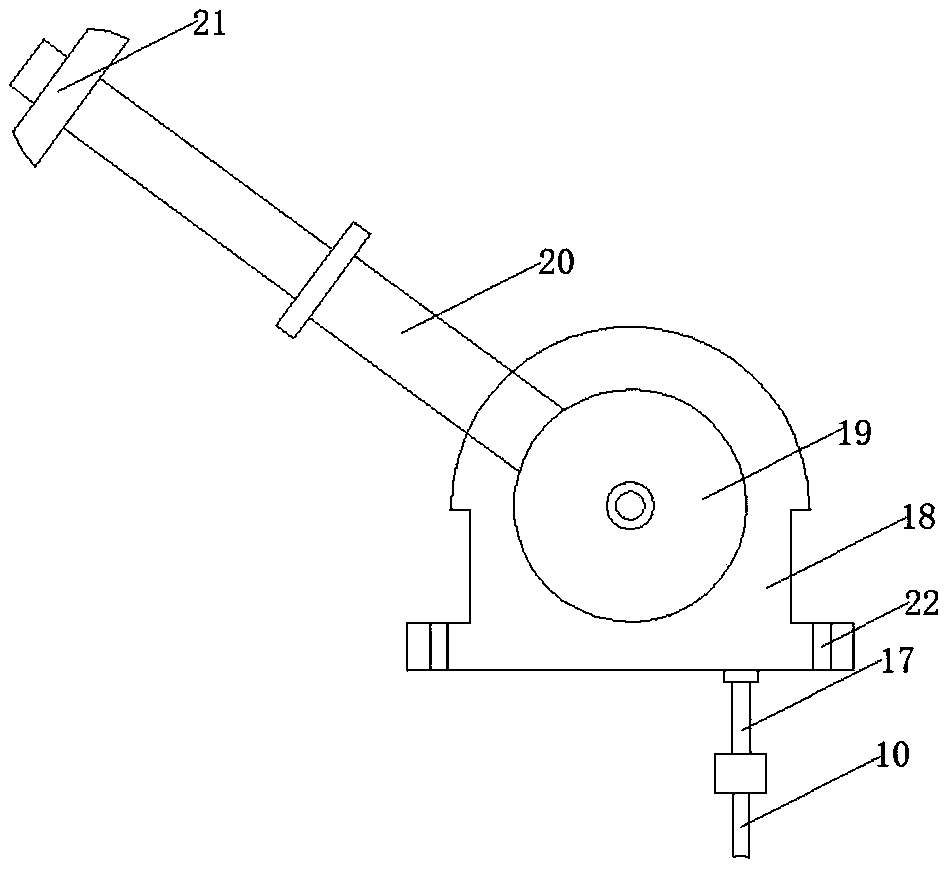

A manual throttle control of an automobile

InactiveCN109094366AGood smoothnessImprove securityPropulsion unit arrangementsDriving safetyThrottle control

A manual throttle control for automobile Including throttle swing arm, one end of the throttle swing arm is fixedly provided with a throttle control assembly, the lower end of the connecting plate isfixedly provided with a moving rod, A sliding seat is arranged below the connecting rod, the sliding seat is fixedly provided with a sliding groove inside the sliding seat, A slide block is slidably connected in the sliding groove, the upper end of the slider is fixedly connected with the connecting rod, The slider is fixedly connected with an iron cable on the inner side of the sliding groove, and an end of the iron cable far away from the slider is fixedly connected with a connecting cable; a manual control assembly is fixedly arranged inside the fixed outer shell, and the manual control assembly is provided with an accelerator rotation adjusting lever. The invention relates to the field of automobile accessories. A manual accelerator control for automobile can ensure good smoothness when a driver step on that accelerator pedal, and at the same time, the driver does not need to continuously step on the right foot on the accelerator pedal when driving for a long distance, which is favorable for improving driving safety of the driver.

Owner:ANHUI TIANYU AUTO PARTS MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com