Flame retardant engravable epoxy resin mortar and preparation method thereof

An epoxy resin and mortar technology, applied in the field of artificial landscaping materials, can solve the problems of high price, poor impact resistance, poor plastering and construction, and achieve the effects of reducing pollution, good smoothness, and reducing construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

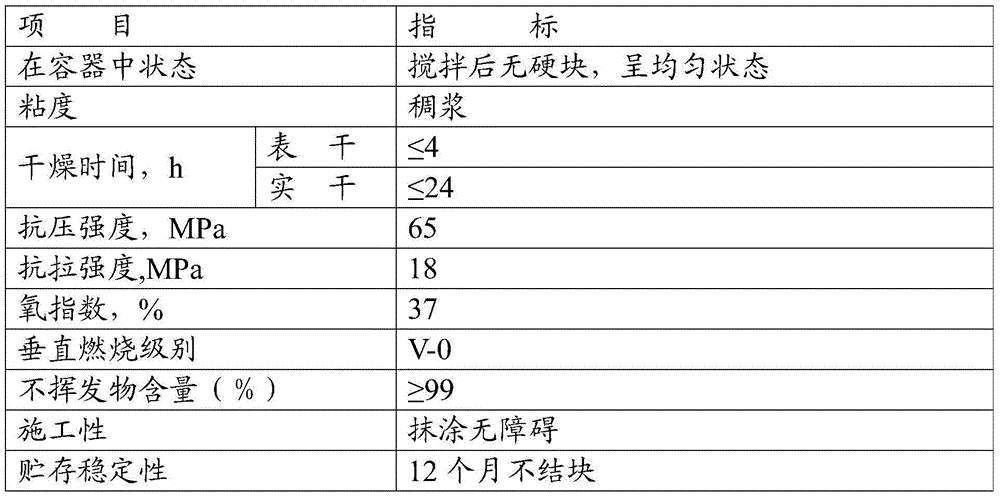

Image

Examples

preparation example Construction

[0033] At the same time, the present invention provides a method for preparing the aforementioned flame-retardant engraved epoxy resin mortar, which includes the following steps:

[0034] a. Modulate the first composition mixture:

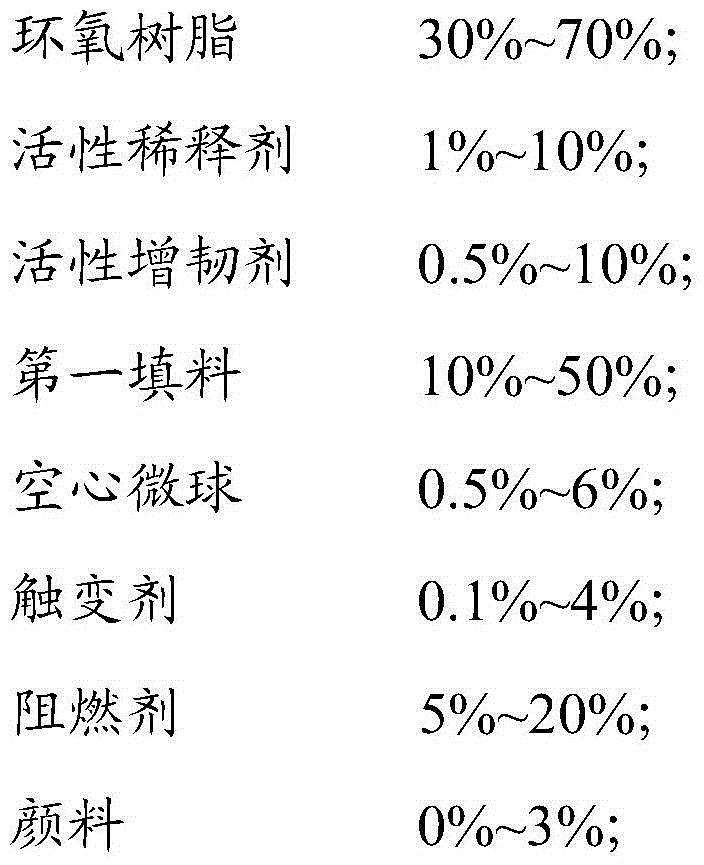

[0035] (1) 30-70 parts by weight of epoxy resin and 2-20 parts by weight of active toughening agent are preheated at 50-60 ° C for 1 hour and then added to the mixer;

[0036] (2) Control the agitator at 400-600r / min, sequentially add 1-10 parts by weight of reactive diluent and 0.1-4 parts by weight of thixotropic agent, and then disperse for 10-15 minutes;

[0037] (3) Increase the speed of the agitator to 800-1000r / min, mix 10-50 parts by weight of filler, 0.5-6 parts by weight of hollow microspheres, 5-20 parts by weight of flame retardant, and 0-15 parts by weight of pigment. Add three times, and after all the additions, increase the speed of the agitator to 1500r / min and continue to disperse for 30 minutes to form the first composition mixtu...

Embodiment 1

[0047] First prepare the first composition mixture: 30 parts by weight of epoxy resin and 3 parts by weight of active toughening agent are preheated at 50-60°C for 1 hour, and then added to the mixer. In this embodiment, the epoxy resin is a hydrogenated ring Oxygen resin, the active toughening agent is polyurethane modified epoxy resin. Start stirring, control the speed of the agitator at 400-600r / min, add 5 parts by weight of active diluent and 1 part by weight of thixotropic agent in sequence, and continue to disperse for 10-15 minutes. Then increase the speed of the agitator to 800-1000r / min, mix 42 parts by weight of filler, 15 parts by weight of flame retardant, and 4 parts by weight of hollow microspheres and add them in 3 times. After each feeding, disperse until no dry powder is seen. Then carry out the next feeding, after all the addition, increase the agitator speed to 1500r / min and continue to disperse for 30 minutes.

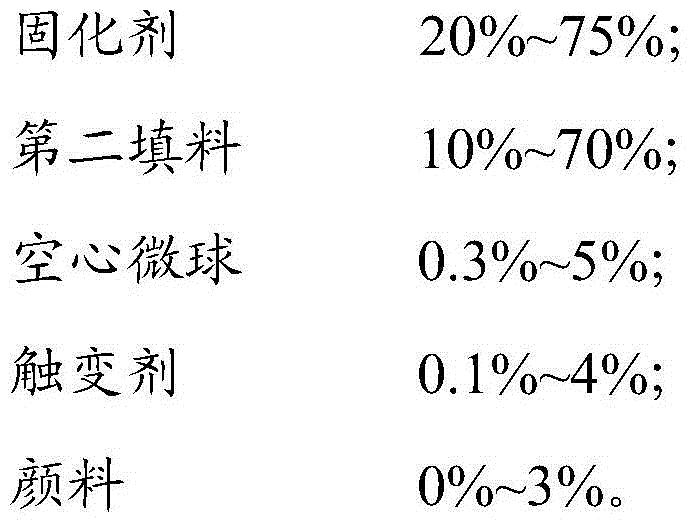

[0048] Then prepare the second component of ...

Embodiment 2

[0051] First prepare the first composition mixture: 45 parts by weight of epoxy resin and 2 parts by weight of active toughening agent are preheated at 50-60°C for 1 hour, and then added to the stirrer for stirring. In this embodiment, the epoxy resin is double Phenol A ring, active toughening agent is polyurethane modified epoxy resin. Next, the rotational speed of the agitator is controlled at 400-600 r / min, 2 parts by weight of butyl glycidyl ether and 0.5 part by weight of bentonite powder are sequentially added, and the dispersion is continued for 10-15 minutes. Then increase the speed of the agitator to 800-1000r / min, then mix 30 parts by weight of heavy calcium, 20 parts by weight of antimony trioxide, and 0.5 parts by weight of organic silicon hollow resin microspheres and add them to the agitator three times. , after dispersing until no dry powder is seen, proceed to the next feeding. After all the powder is added, increase the rotation speed to 1500r / min and continue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com