Cup type grinding wheel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

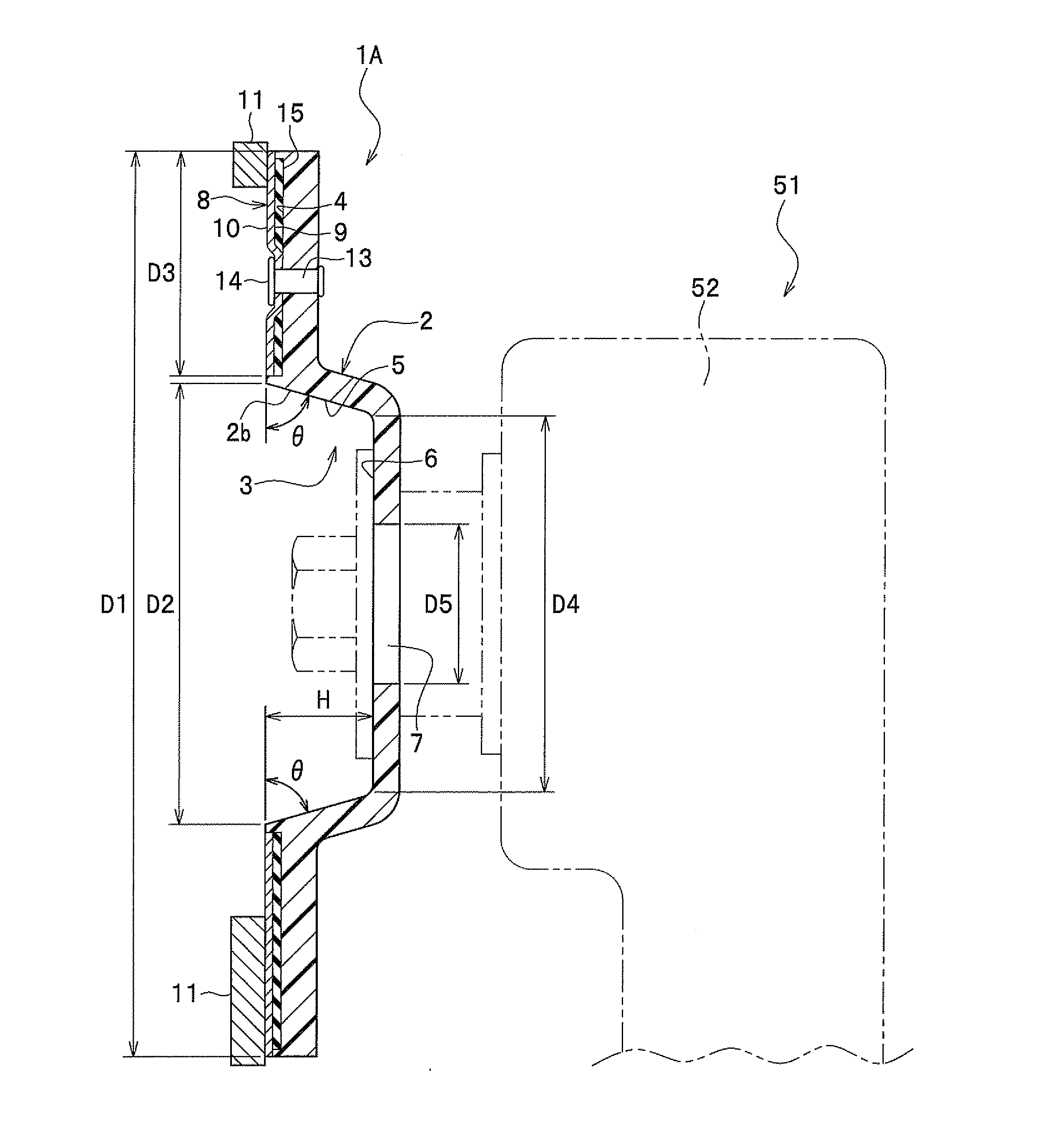

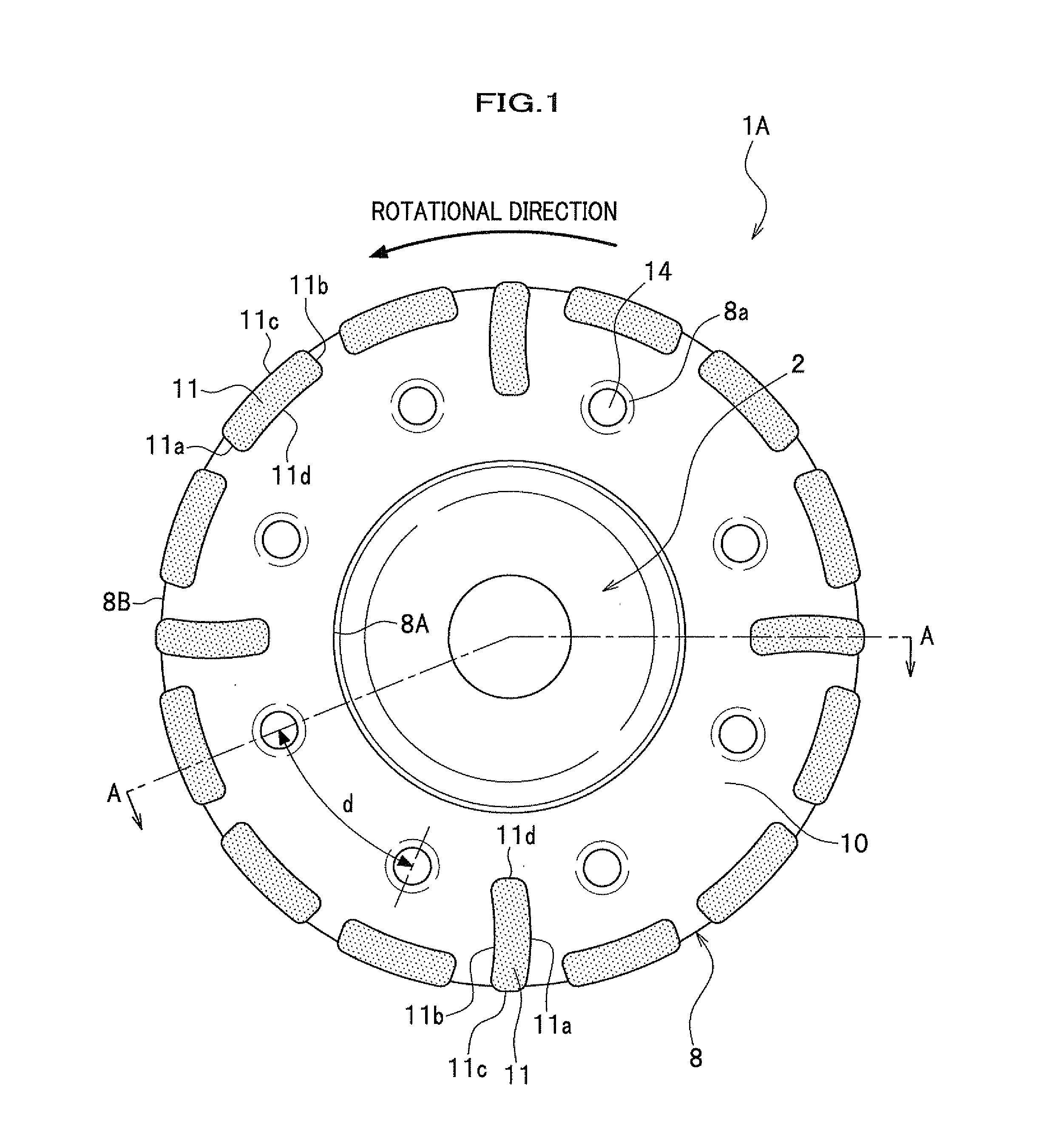

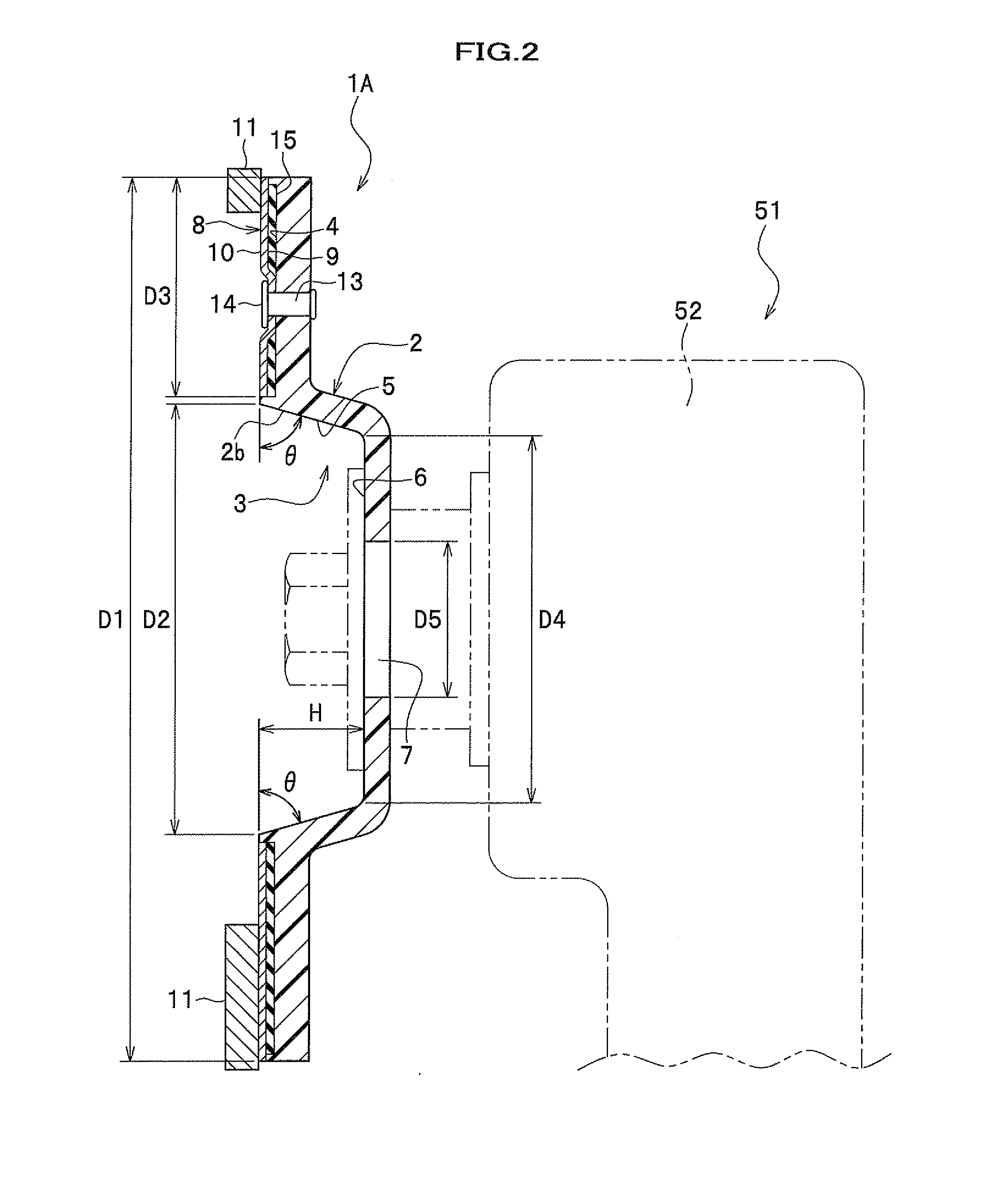

[0087]The example of the grinding wheel according to the present invention will be explained in the following.

[0088]The grinding wheel as shown in FIGS. 1 and 2 is made by using the following members.

[0089](Plastic Base Plate)

[0090]A base plate made of a glass fiber-reinforced plastic (The brand name is TECAMID 66 GF 30) made by Ensinger Co., Ltd. whose outer diameter D1 is 123 mm, thickness is 3.5 mm, inner diameter D2 of the recessed portion 3 is 60 mm, height H of the recessed portion 3 is 13 mm, and the slant angle θ of the recessed portion 3 is 73 degrees is used.

[0091](Metal Annular Plate)

[0092]A metal annular plate made of SK5 (carbon tool steel) whose width is 30.5 mm and thickness is 1.0 mm is used.

[0093](Fastener)

[0094]A rivet made of stainless steel having a diameter of 4.0 mm is used.

[0095](Piece of Grindstone)

[0096]A piece of grindstone made of diamond abrasive grains whose size is 6 mm×20 mm×4.5 mm is used. Each piece of grindstone is fixed to the outer peripheral port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com