Zirconia ceramic mobile phone panel and preparation method thereof

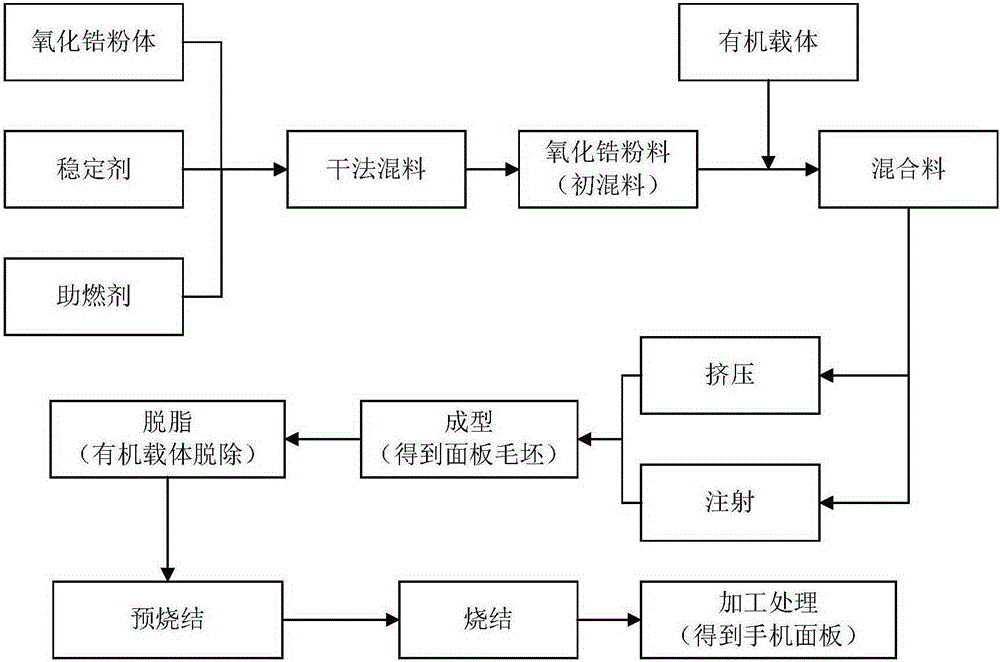

A technology of zirconia ceramics and zirconia powder is applied in the field of zirconia ceramic mobile phone panels and their preparation, which can solve the problems of complex processing operations, poor color, light transmittance and touch feeling, and high machine cost, and achieve user experience. High, smooth hand feel, light transmittance and color enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The present invention provides such a zirconia ceramic mobile phone panel, which is mainly made of the following components in terms of parts by weight: 80 parts of a mixture of zirconia powder and stabilizer, and 20 parts of an organic carrier; among them, in the zirconia powder and In the stabilizer mixture, the mole ratio of the stabilizer is 5% (the ratio of the stabilizer is added according to 5% mol of the overall ratio of the mixture). More specifically, the particle size of the zirconia powder is 1-100μm, and the specific surface area is 1-40m. 2 / g; The stabilizer is yttrium oxide. In addition, in terms of weight percentage, the organic vehicle includes: 50% paraffin wax, 9% polyethylene, 8% random polypropylene, 4% polystyrene, 3% polymethacrylate, 25% ethylene ethyl acrylate copolymer , Dibutyl phthalate 1%.

[0056] Preparation:

[0057] The zirconia powder and stabilizer are mixed with a mixer to obtain an initial mixture; the organic carrier is added to the i...

Embodiment 2

[0059] The present invention provides such a zirconia ceramic mobile phone panel, which, in parts by weight, is mainly made of the following components: 99.5 parts of zirconia powder and stabilizer mixture, and 0.5 parts of organic carrier; among them, the zirconia powder and In the stabilizer mixture, the mol proportion of the stabilizer is 5% (the proportion of the stabilizer is added according to 5% mol of the total proportion of the mixture), and also includes the combustion promoter (alumina); the combustion promoter accounts for 3% of the weight of the zirconia powder %. The particle size of zirconia powder is 30-100μm, and the specific surface area is 10-40m 2 / g; The stabilizer is magnesium oxide. More specifically, in terms of weight percentage, the organic carrier includes: paraffin 50%, polyethylene 9%, random polypropylene 8%, polystyrene 4%, polymethacrylate 3%, and vinyl ethyl acrylate copolymer 25%, 1% dibutyl phthalate.

[0060] Preparation:

[0061] The zirconia...

Embodiment 3

[0065] The present invention provides such a zirconia ceramic mobile phone panel, which is mainly made of the following components in terms of parts by weight: 90 parts of a mixture of zirconia powder and stabilizer, and 10 parts of an organic carrier; among them, the zirconia powder and In the stabilizer mixture, the mol ratio of the stabilizer is 5% (the ratio of the stabilizer is added according to the 5% mol of the total proportion of the mixture), and also includes the combustion promoter; the combustion promoter is alumina; the combustion promoter accounts for the weight of the zirconia powder Of 1.5%. Among them, the particle size of zirconia powder is 50-100μm, and the specific surface area is 30-40m 2 / g; The stabilizer is calcium oxide. Among them, in terms of weight percentage, the organic vehicle includes: paraffin wax 48%, polyethylene 9%, random polypropylene 8%, polystyrene 4%, polymethacrylate 3%, and ethylene ethyl acrylate copolymer 27% , Dibutyl phthalate 1%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com