Pharmaceutical plaster substrate, preparation method and applications thereof

A matrix and plaster technology, which is applied in the direction of pharmaceutical formula, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve the problem that the adhesion performance, uniformity and smoothness of the finished product are not as good as those of the solvent method, and the volatility Composition loss, inconvenient use, etc., to achieve the effect of long-lasting drug efficacy, comfortable use, and reduced loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

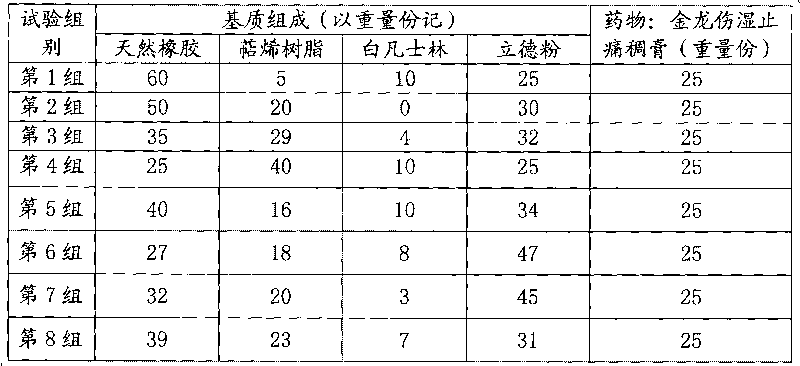

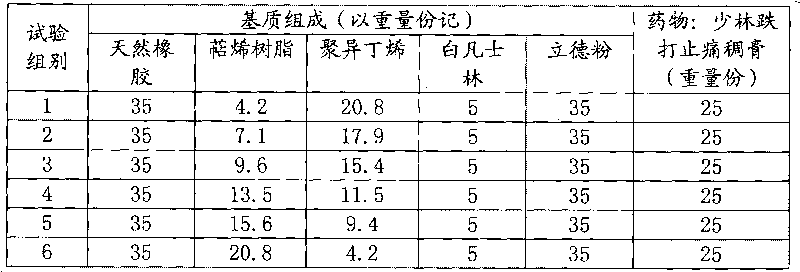

Examples

Embodiment 1

[0028] Weigh the following raw materials (parts by weight):

[0029] Matrix component: 30 parts of natural rubber (Mooney viscosity value is 75)

[0030] Rosin 15 parts

[0031] Yellow Vaseline 2.5 parts

[0033] Traditional Chinese Medicine Extract: Waist Kidney Thick Cream 25 parts

[0034] The preparation method: weigh each matrix component according to the ratio, and masticate the natural rubber into a sheet; mix and grind the filler zinc oxide and the solid tackifier rosin into a coarse powder; add natural rubber and softener yellow vaseline and mix to obtain the Invent the matrix; add Chinese medicine extract to the matrix, mix and refine, make plaster, pack, and obtain the Chinese medicine plaster of the present invention.

Embodiment 2

[0036] Weigh the following raw materials (parts by weight):

[0037] Matrix component: 35 parts of natural rubber (Mooney viscosity value is 75)

[0038] Terpene resin 29 parts

[0039] 4 parts white petroleum jelly

[0040] Lithopone 32 parts

[0041] Traditional Chinese medicine extract: Shaolin Dieda Pain Relief Thick Cream 25 parts

[0042] Preparation method: weighing each matrix component according to the ratio, masticating natural rubber into flakes; mixing filler lithopone with solid tackifier terpene resin and pulverizing into coarse powder; adding natural rubber and softener white vaseline Mix to obtain the matrix of the present invention; then add traditional Chinese medicine extract to the matrix, mix and refine, make plaster, pack, and obtain the traditional Chinese medicine plaster of the present invention.

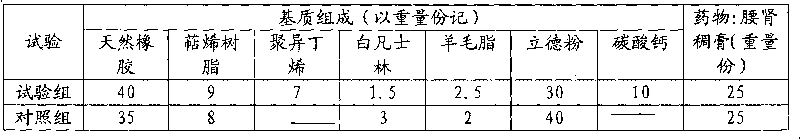

Embodiment 3

[0044] Weigh the following raw materials (parts by weight):

[0045] Matrix component: 35 parts of natural rubber (Mooney viscosity value is 53)

[0046] 10 parts hydrogenated rosin

[0047] 7.5 parts of liquid paraffin

[0048] White carbon black 35 parts

[0049] Traditional Chinese Medicine Extract: Jinlong Shangshi Pain Relief Extract 35 parts

[0050] Preparation method: Weigh each matrix component according to the ratio, masticate the natural rubber into a sheet; mix the filler white carbon black and the solid tackifier hydrogenated rosin and pulverize it into a coarse powder; add natural rubber and softener liquid paraffin to mix Obtain the matrix of the present invention; add Chinese medicine extract to the matrix, mix and refine, make plaster, pack, and obtain the Chinese medicine plaster of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com