Patents

Literature

52results about How to "Increase the total pressure recovery coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

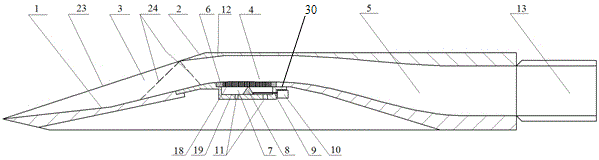

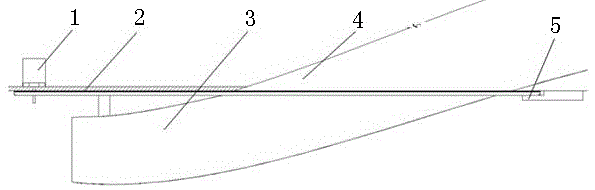

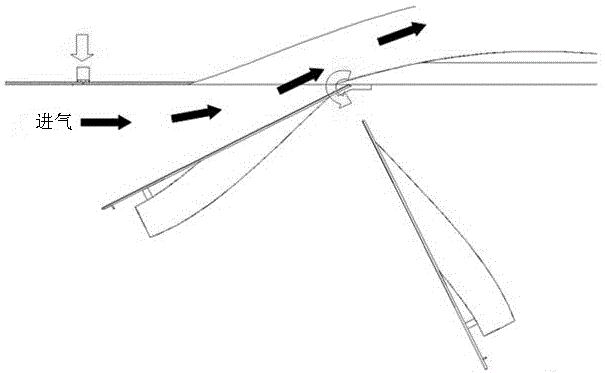

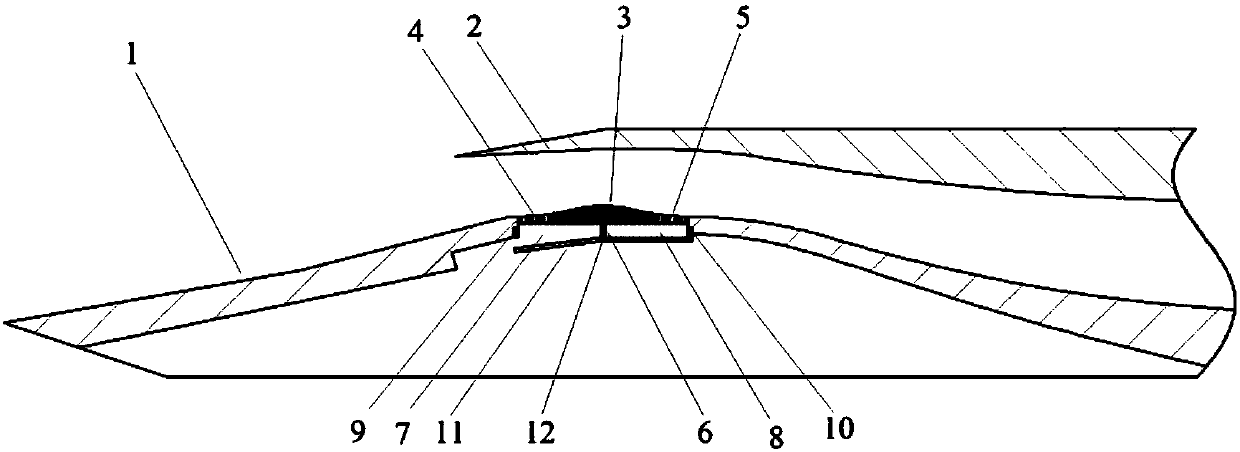

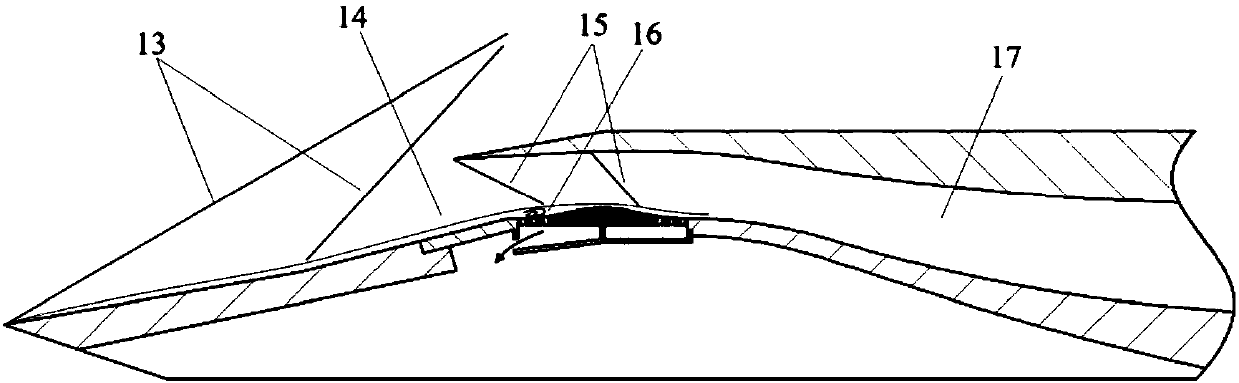

Aircraft supersonic air inlet channel with variable deflation system

ActiveCN103950543ASuppress interference phenomenonBroaden the scope of the work envelopePower plant air intake arrangementsShock waveInlet channel

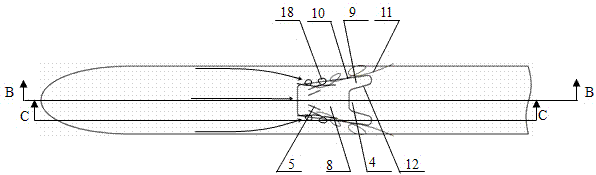

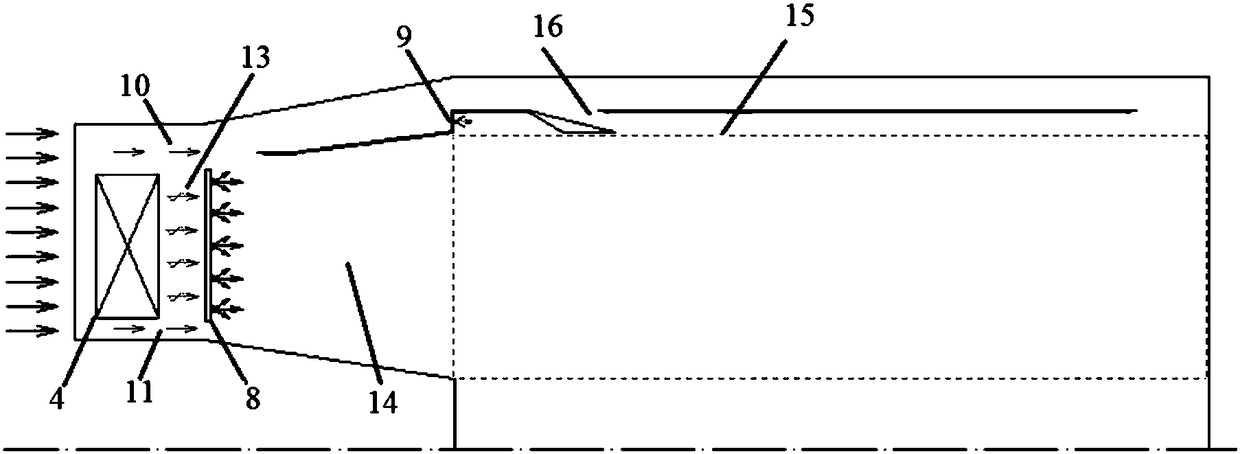

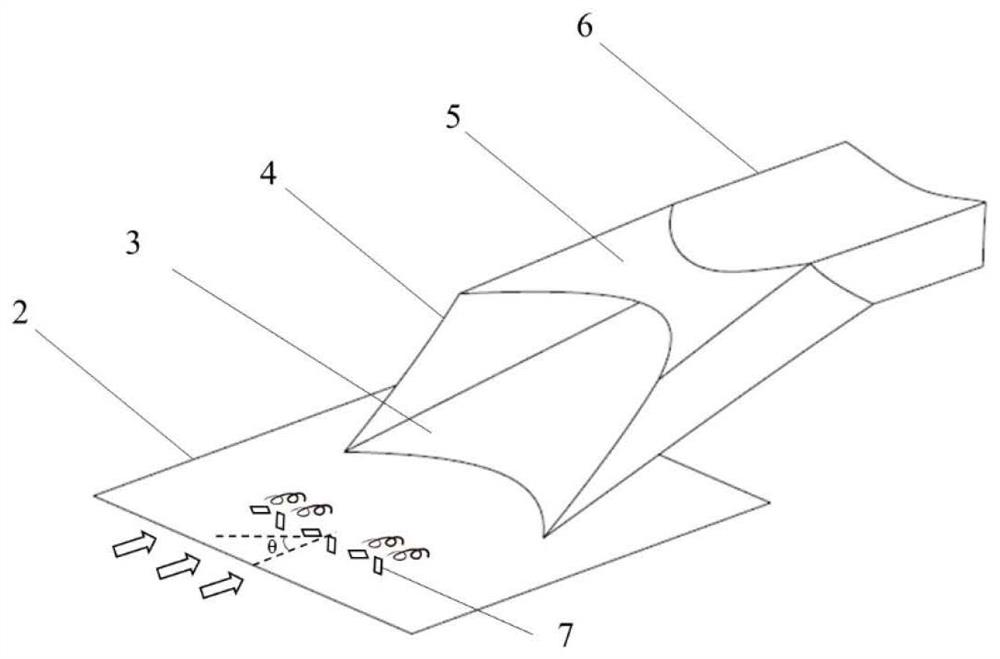

The invention provides an aircraft supersonic air inlet channel with a variable deflation system. The aircraft supersonic air inlet channel with the variable deflation system comprises a supersonic front body compression surface, an air inlet channel lip cover, an air inlet channel side plate, an inner plate which extends inwards from the supersonic front body compression surface; a deflation chamber, a multi-seam or porous cover plate, a deflation chamber partition plate and flow limiting openings are arranged in the inner plate, wherein the multi-seam or porous cover plate covers the deflation chamber; the deflation chamber partition plate is positioned in the deflation chamber; the flow limiting openings are formed in the lower surface of the deflation chamber; the deflation chamber is partitioned into independent sub-chambers by the deflation chamber partition plate. The size of each sub-chamber, the number of the seams / pores of the multi-seam or porous cover plate corresponding to each sub-chamber and the opening and the closing of the flow limiting openings are adjusted by moving the deflation partition chamber according to the working Mach number and the attitude angle change of the supersonic air inlet channel, so that the deflation characteristics interfered by a lip cover shock wave / boundary layer are adjusted; therefore a good boundary layer control effect can be achieved in a wider work envelope range; the air emission amount is saved; a deflation flow channel in a certain area can even be closed when necessary.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

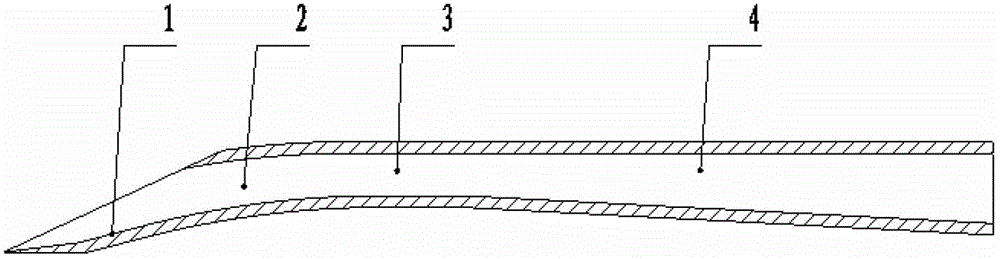

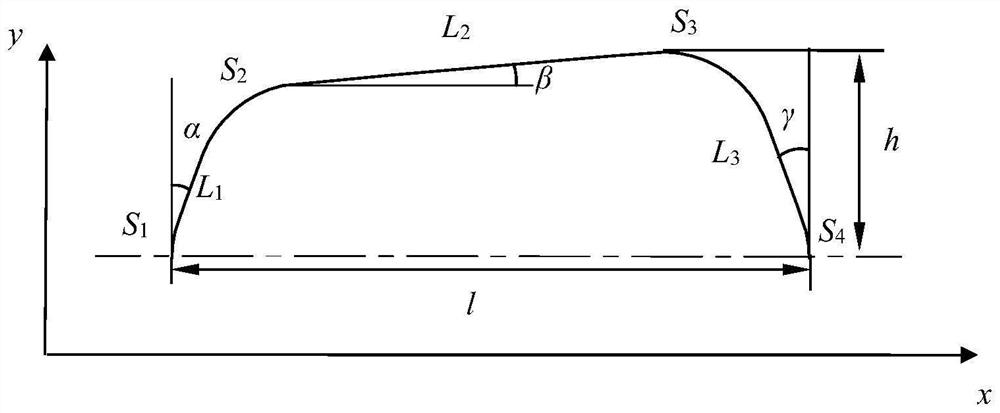

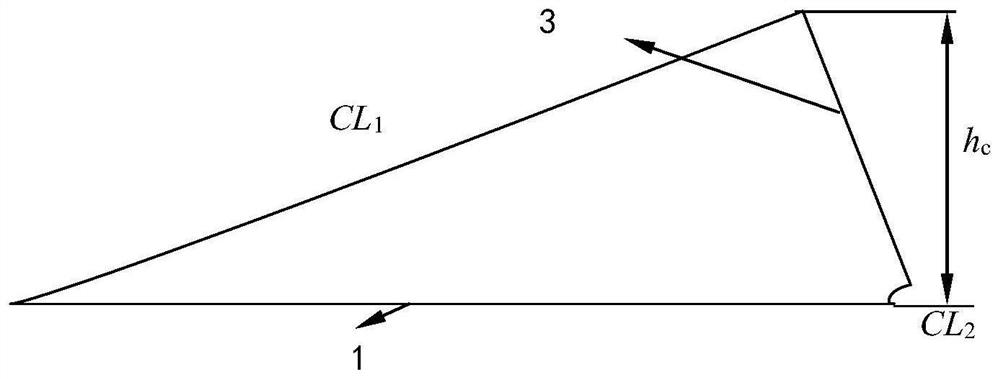

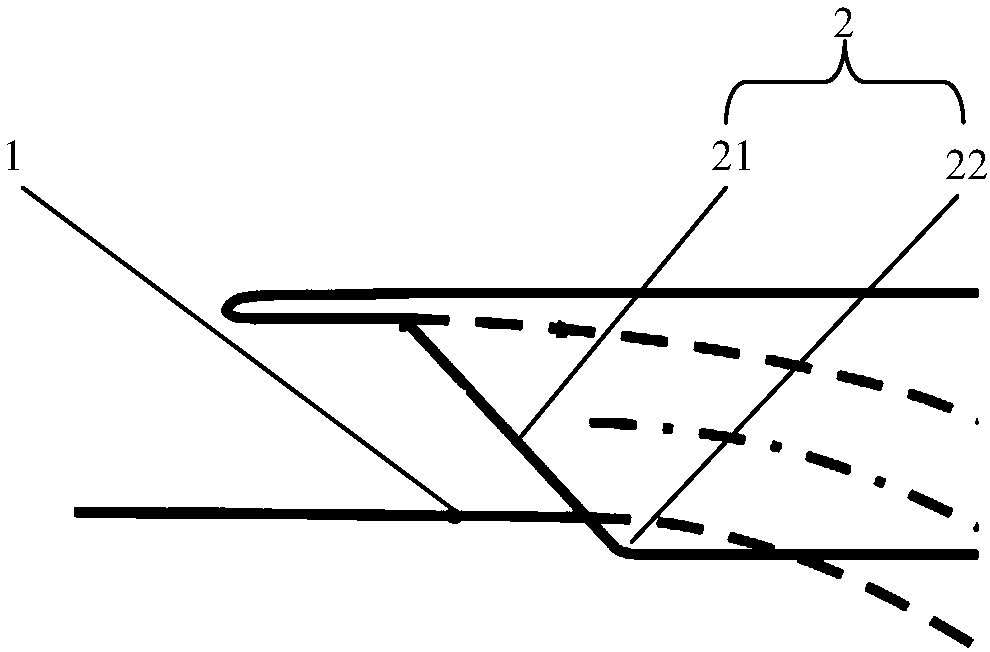

Method for designing fixed-geometry two-dimensional mixed-compression type supersonic velocity air inlet channel

InactiveCN102748135ASatisfy the starting ability requirementReduce the starting Mach numberTurbine/propulsion air intakesWedge angleInlet channel

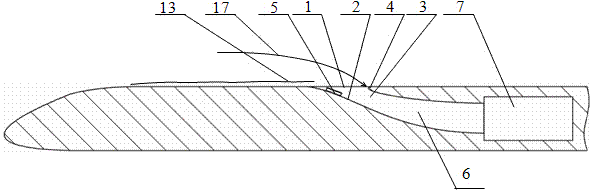

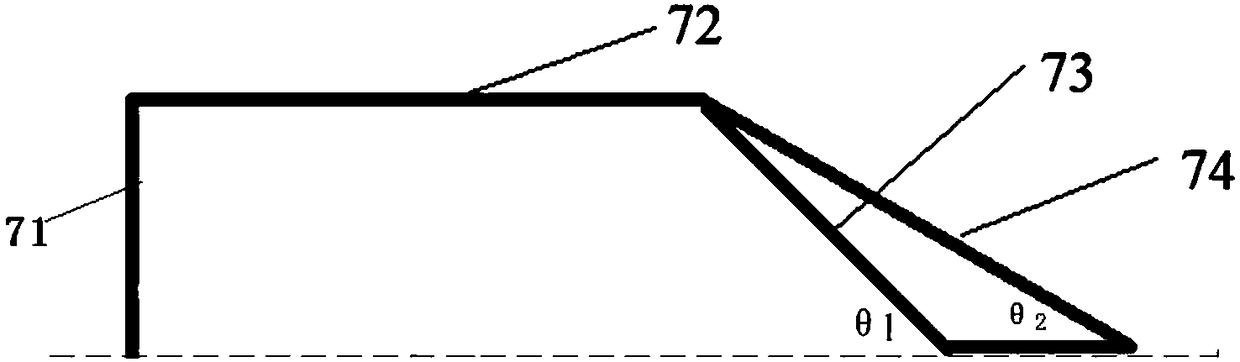

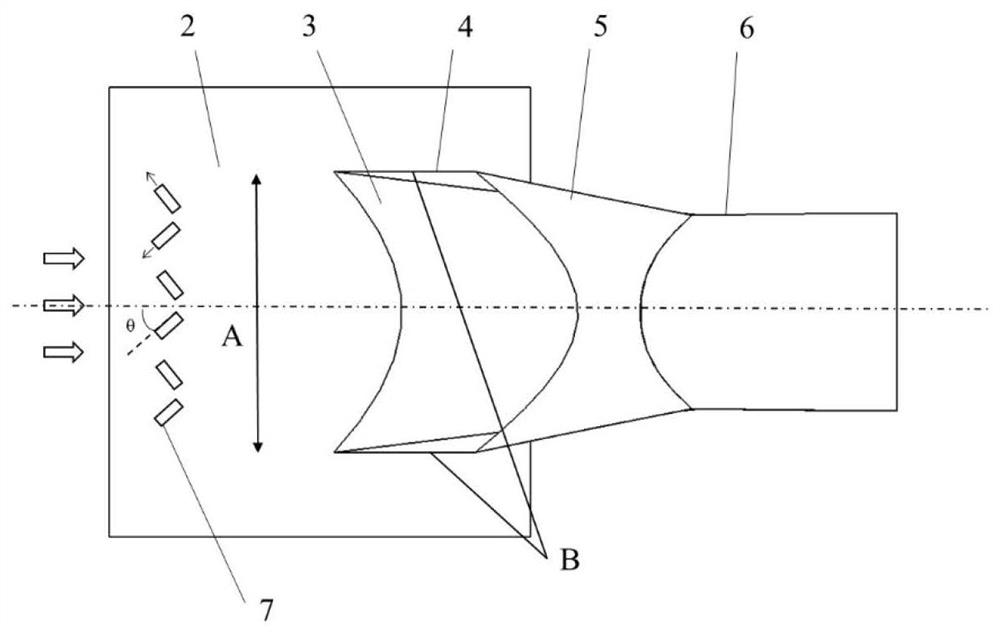

The invention discloses a method for designing a fixed-geometry two-dimensional mixed-compression type supersonic velocity air inlet channel. A basic structure of the adopted two-dimensional mixed-compression type air inlet channel comprises an outer pressing section, an inner pressing section, a throat section, an expanding section and a lip. The lip is of a sharp plate structure with a certain wedge angle. When the air inlet channel is designed, designed starting Mach number is improved appropriately, the lip shape is changed, and the starting mach number is effectively reduced to be lower than a requested value through a certain flow on the premise that the flow requirement of the air inlet channel is met. By means of the method, the requirement for starting performance can be met, contraction ratio of the air inlet channel can be increased in design, and accordingly high back pressure resisting capability and low outlet Mach number are obtained in a wide working range to facilitate efficiently combusted organizations in a combustion chamber. Furthermore, small total pressure loss in the working process of the air inlet channel can be achieved through the change of the lip shape. The method for designing the fixed-geometry two-dimensional mixed-compression type supersonic velocity air inlet channel has good actual application value.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Aircraft using submerged intake

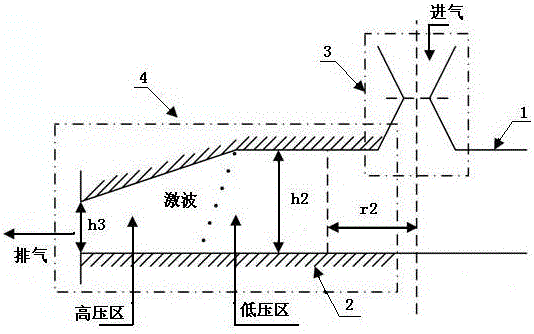

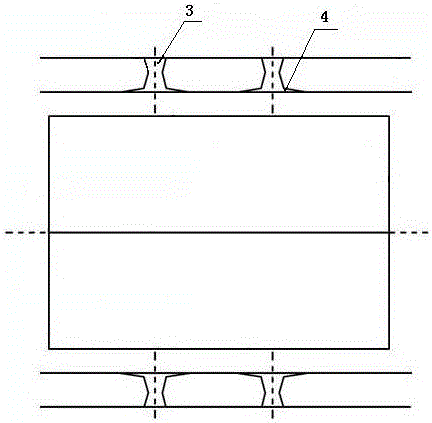

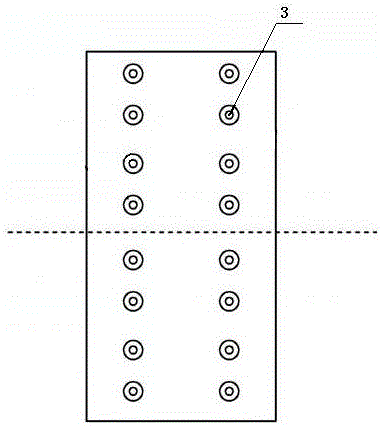

InactiveCN102249004AIncrease the total pressure recovery coefficientReduce flow field distortionPower plant air intake arrangementsEngineeringHigh pressure

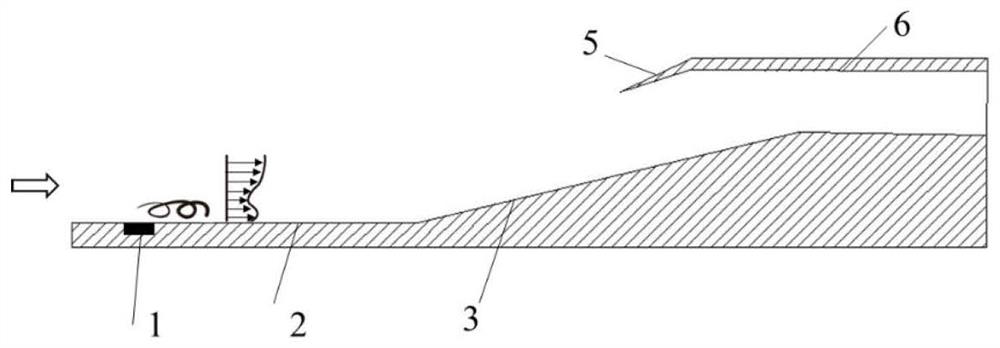

The invention provides an aircraft using a submerged intake. In the invention, a plurality of pairs of air-blowing tanks are arranged on the surface of a projectile body using the submerged intake so as to blow off a boundary layer on the surface of the projectile body through high-pressure jet, which effectively improves the characteristic of the boundary layer in front of the entrance of the submerged intake and enhances quality of air flow entering the submerged intake so as to greatly improve total pressure recovery coefficient and lower flow field distortion index at the exit of the submerged intake.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

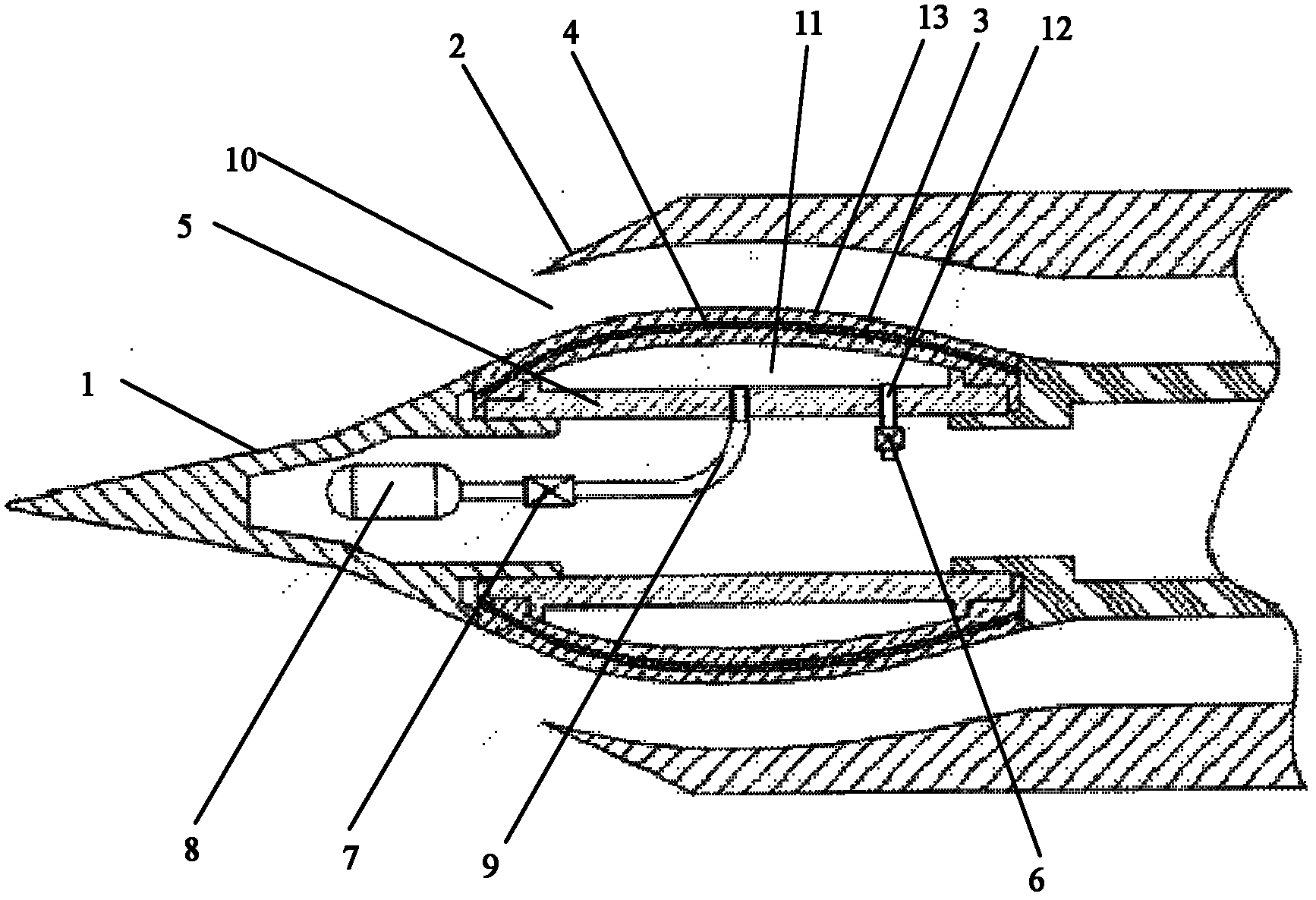

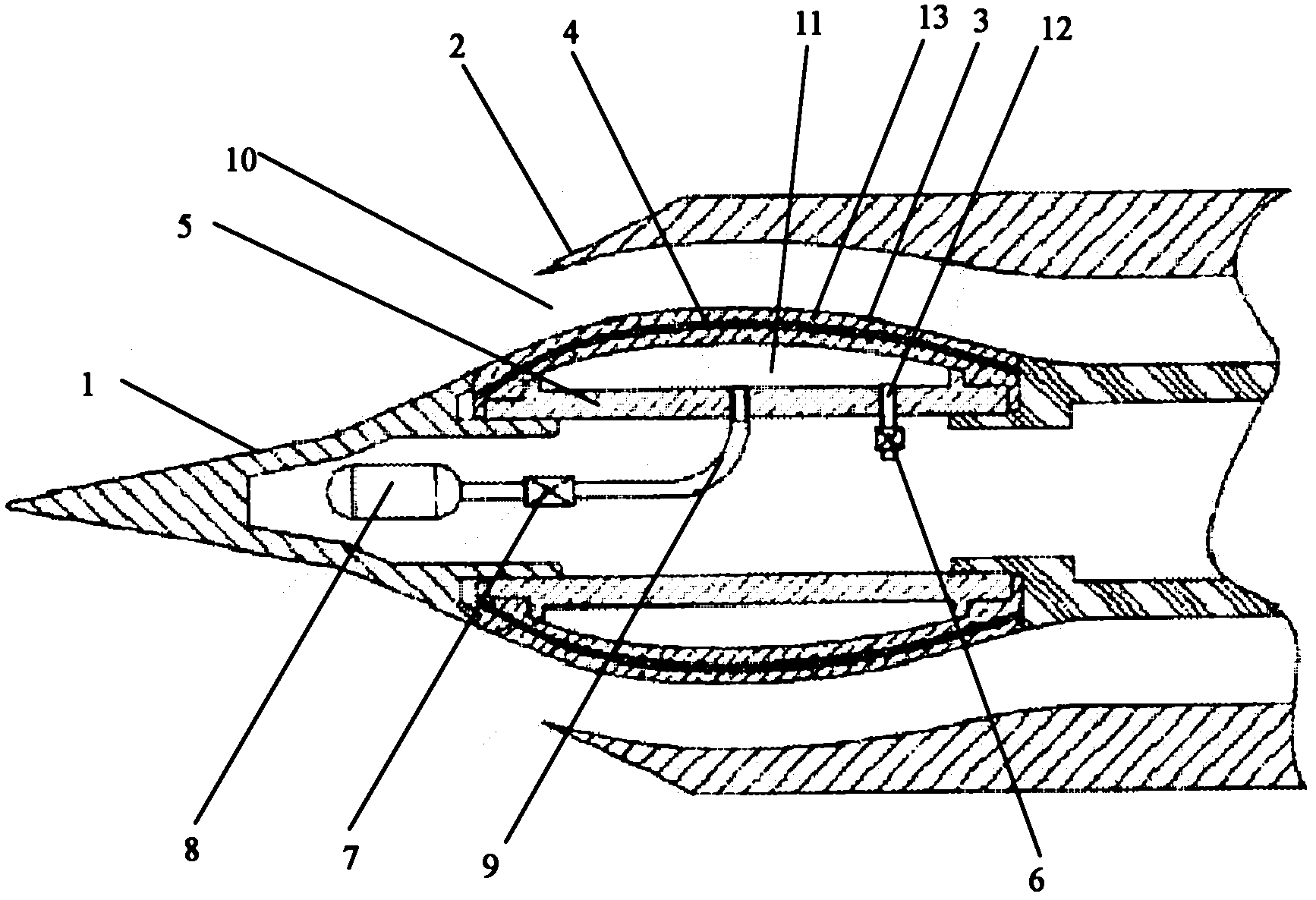

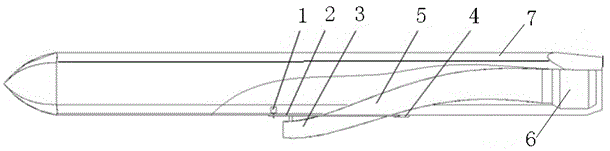

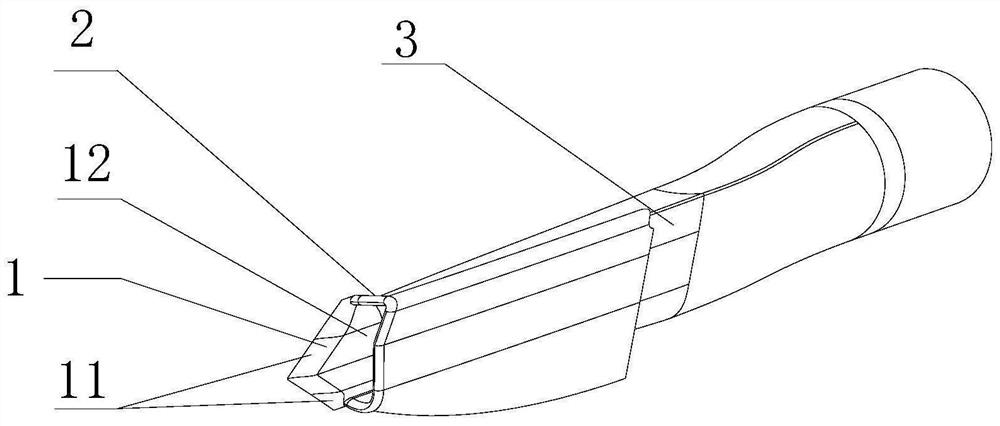

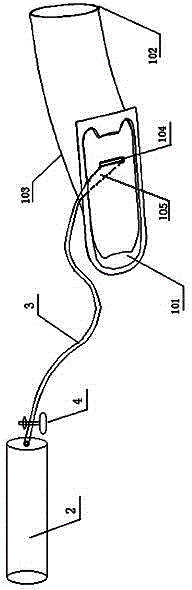

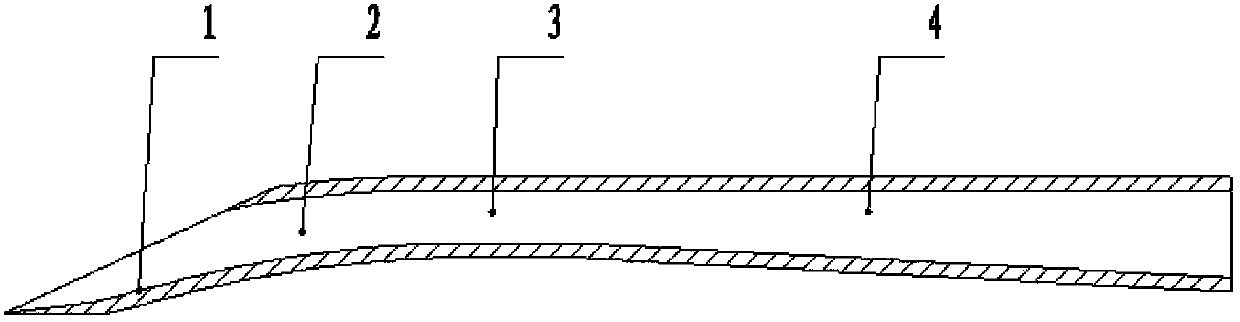

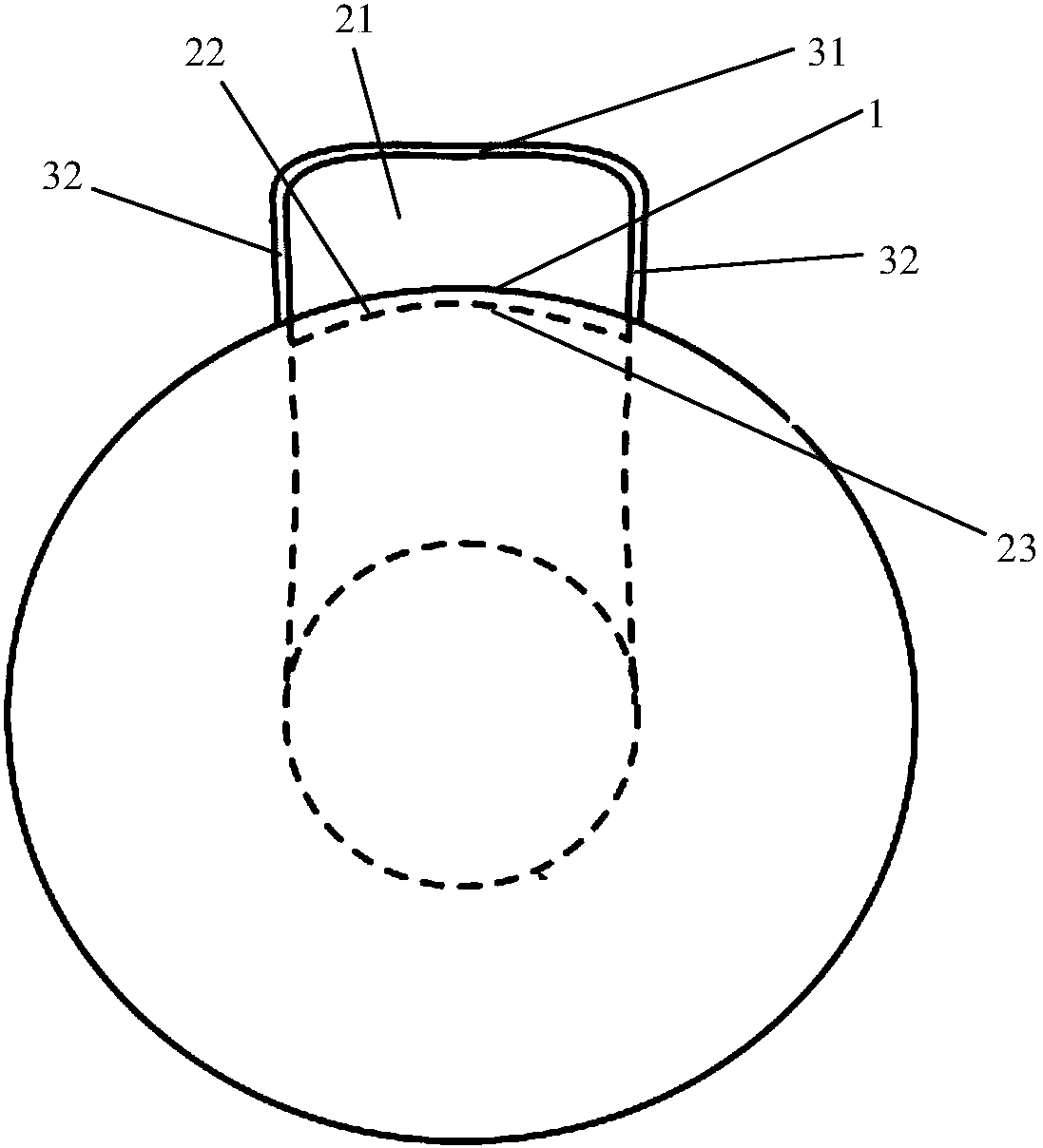

Special air bag-based axially-symmetrical deformable air inlet channel

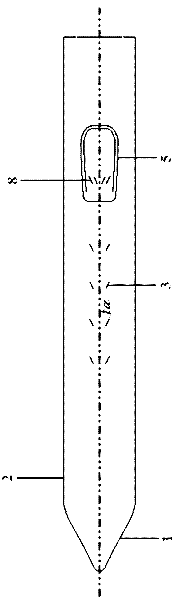

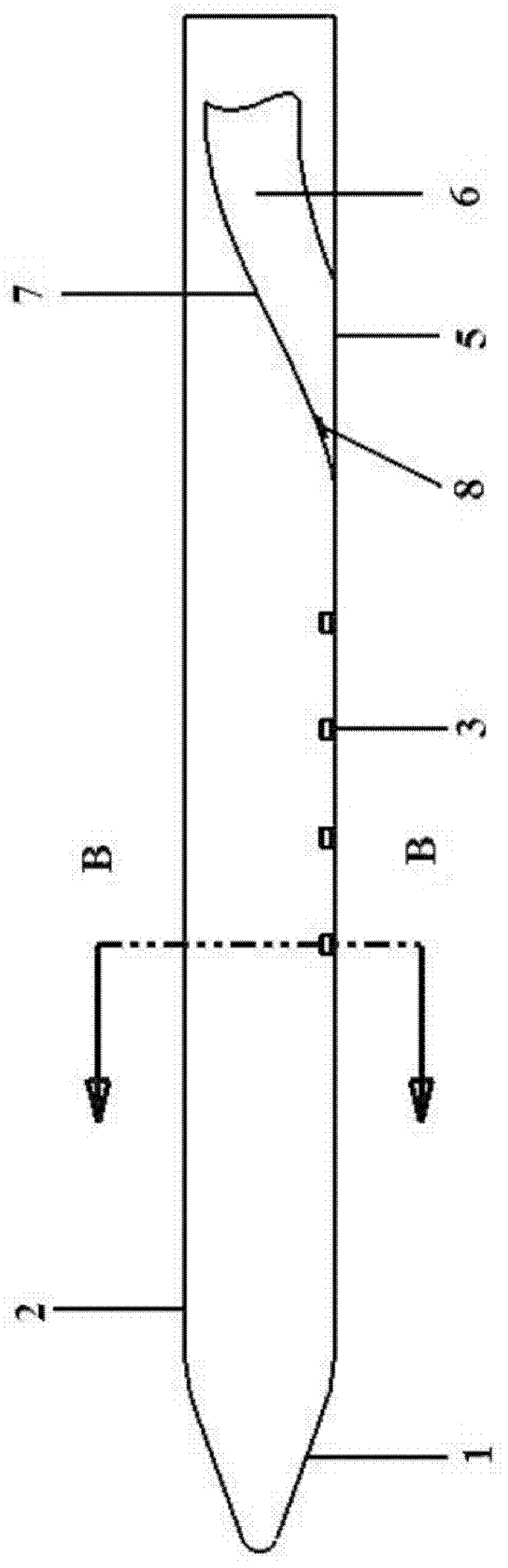

InactiveCN102434285AThe size is simple and convenientIncrease the total pressure recovery coefficientGas turbine plantsTurbine/propulsion air intakesHigh pressureInlet channel

The invention provides a special air bag-based axially-symmetrical deformable air inlet channel, which comprises a front conical tip, an air inlet channel lip cover, a special air bag, a high-pressure air source and an air inlet pipe, wherein the air inlet channel lip cover is positioned on the outer side of the front conical tip; the special air bag is connected with the front conical tip; the air inlet pipe is connected with the high-pressure air source and the special air sag; and an air inlet channel throat is formed between the special air bag and the air inlet channel lip cover. According to the invention, the throat area of the air inlet channel throat can be adjusted by adjusting the size of the special air bag, so that high total pressure recovering coefficient of the air inlet channel can be ensured, the improvement on the cruising performance of an aerocraft is facilitated, the size of the special air bag is convenient and easy to adjust, the additional adjusting cost is low, the internal space of the aerocraft is utilized fully, and the deformable air inlet channel is easy to realize.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

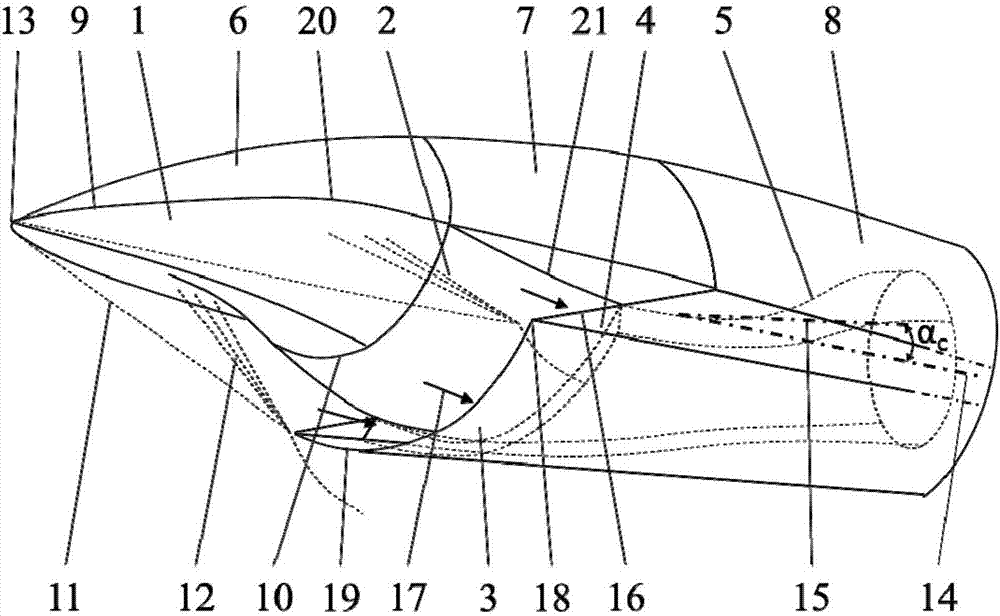

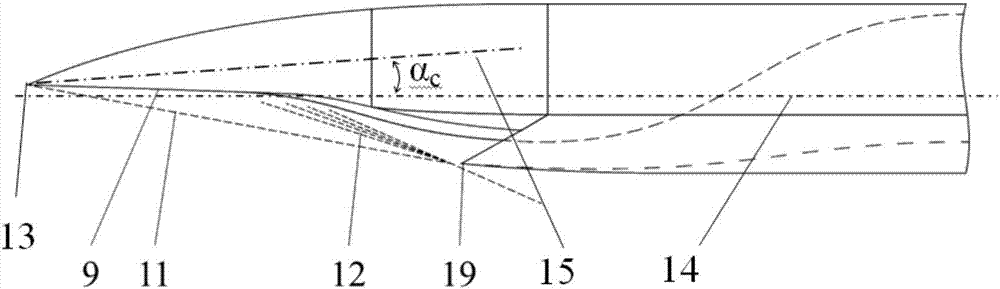

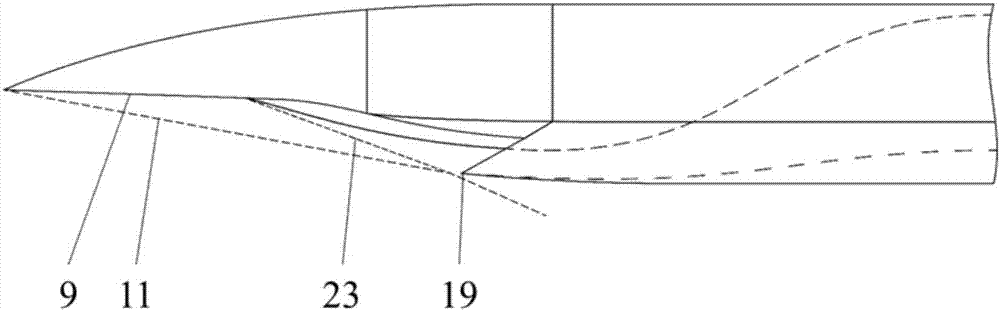

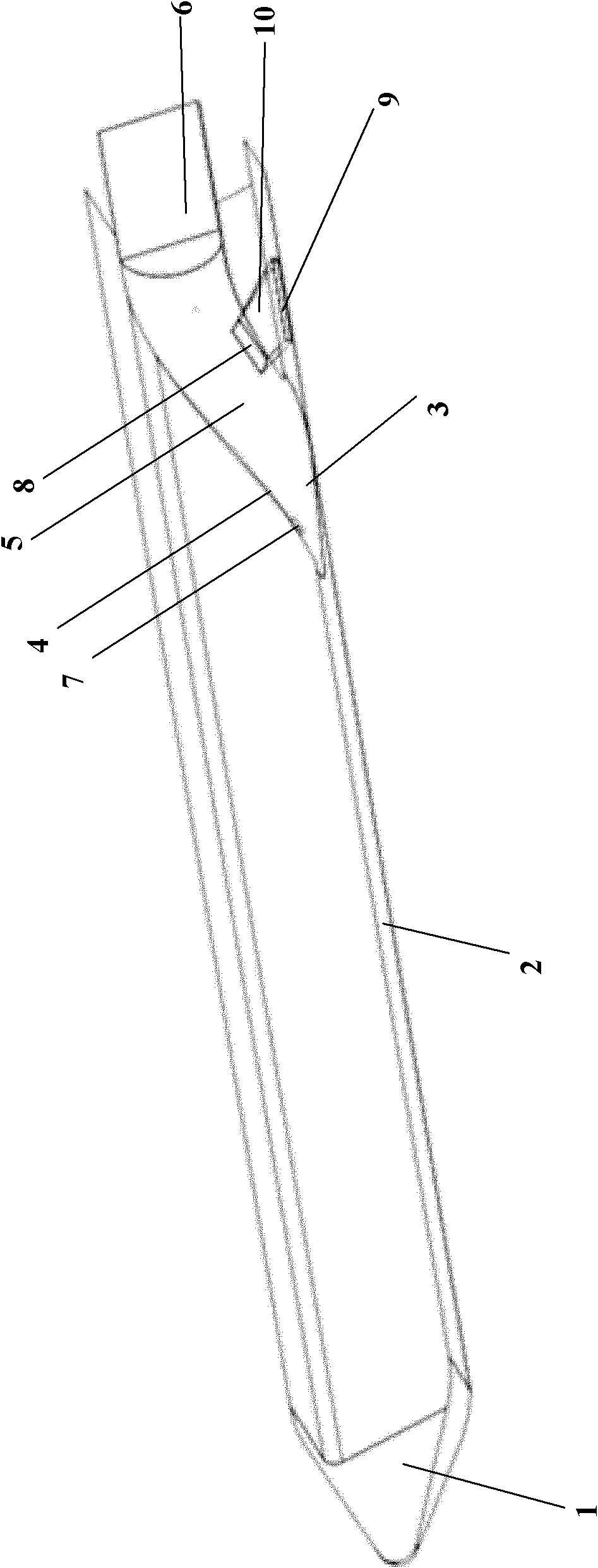

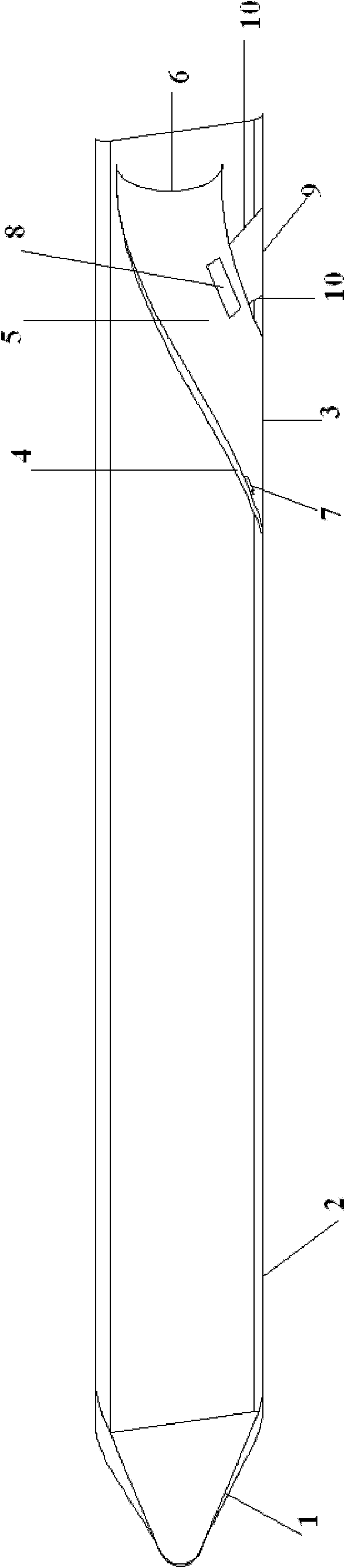

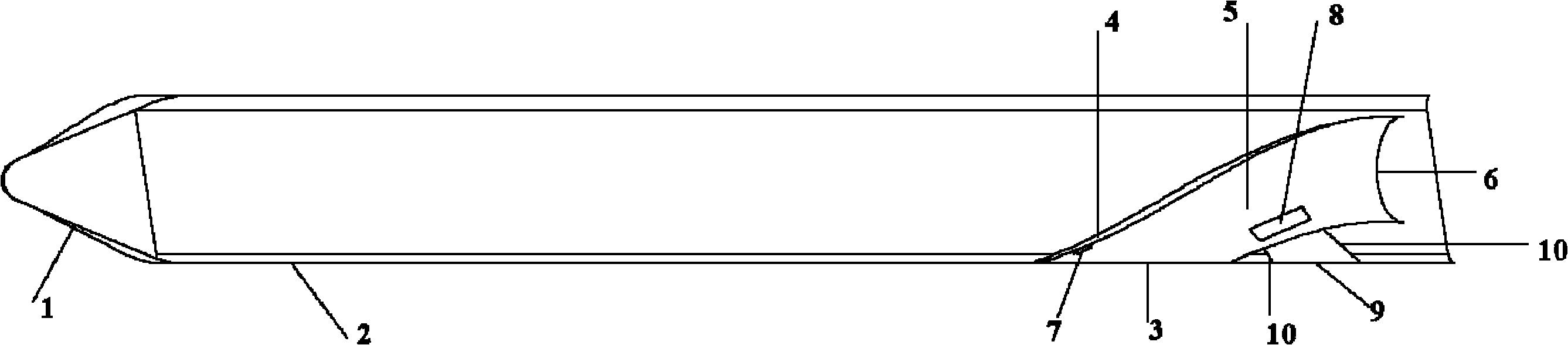

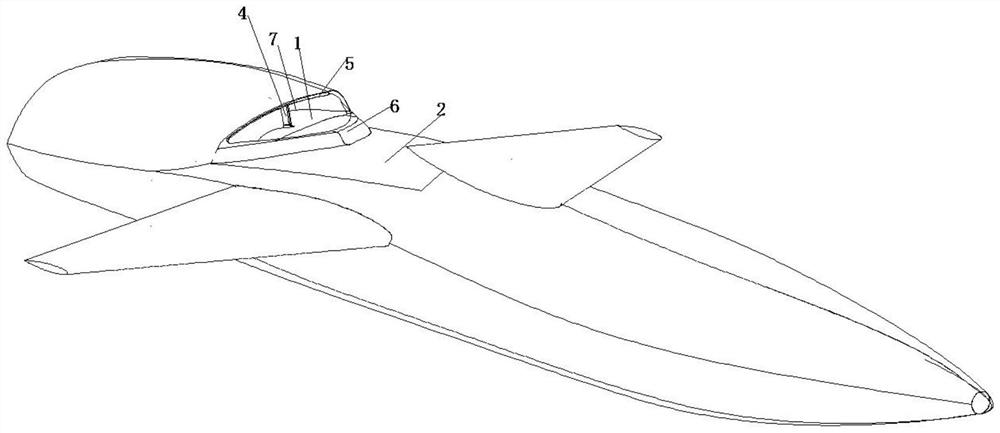

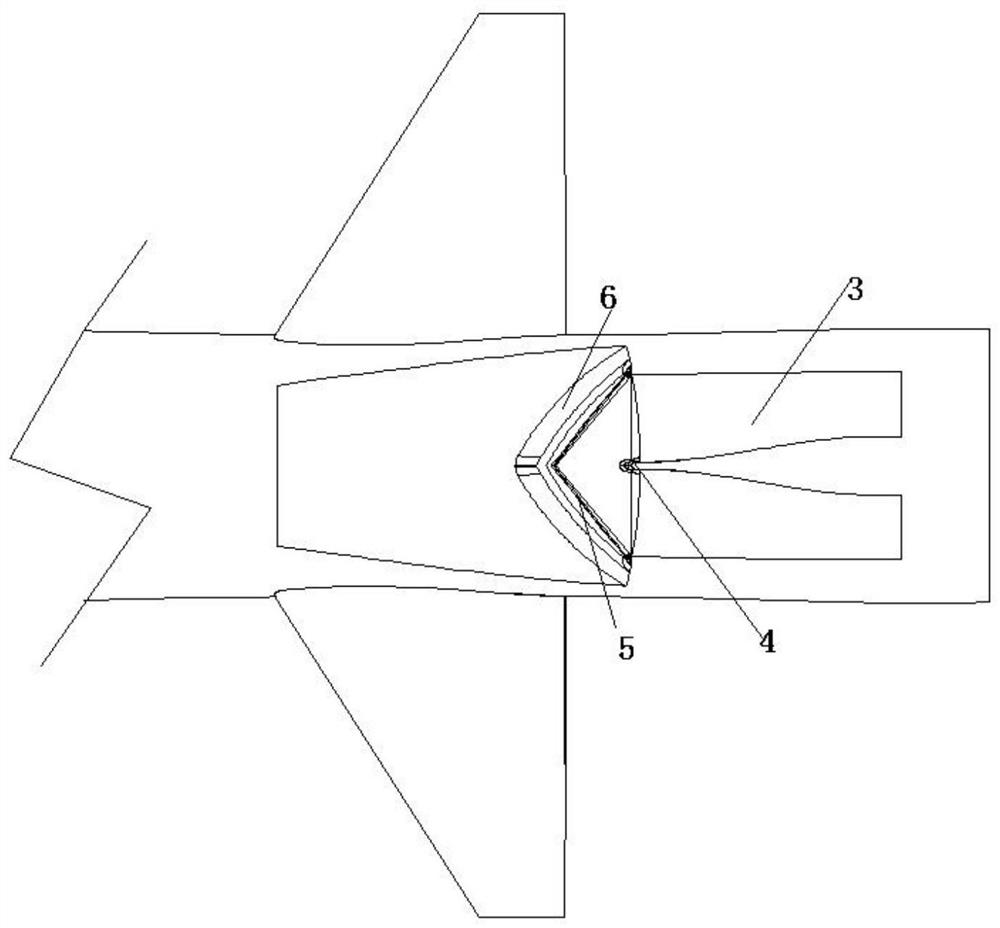

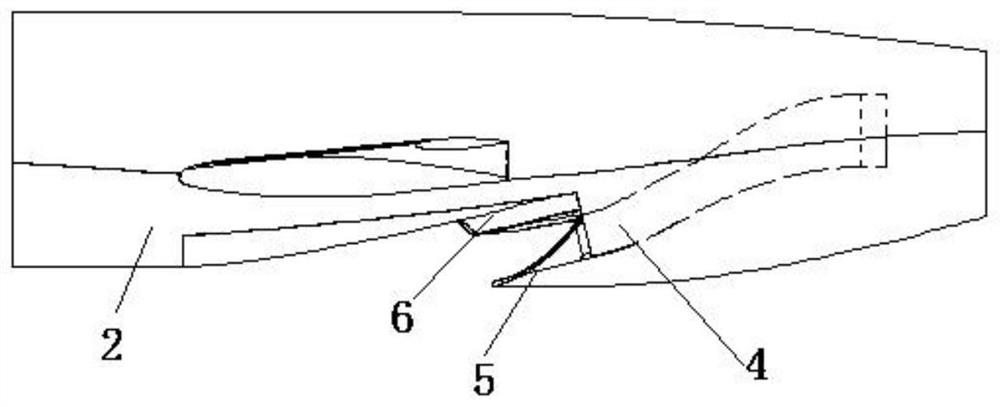

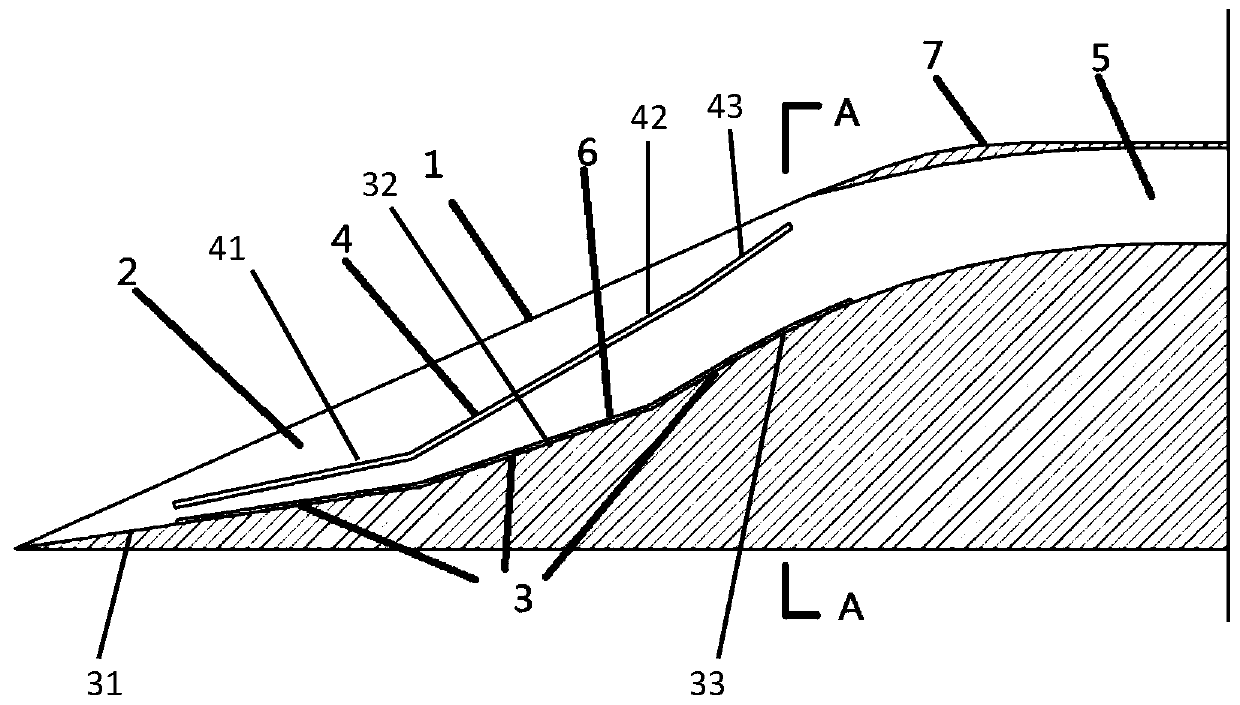

Lower-jaw type supersonic/hypersonic inlet integrated with forebody and design method of lower-jaw type supersonic/hypersonic inlet

ActiveCN107089340AImprove traffic capture capabilitiesReduce aerodynamic dragGround installationsPower plant air intake arrangementsShock waveEngineering

The invention provides a lower-jaw type supersonic / hypersonic inlet integrated with a forebody of an air vehicle and a design method of the lower-jaw type supersonic / hypersonic inlet. The lower-jaw type supersonic / hypersonic inlet comprises a local waverider compression surface, a rotation-formed axially symmetric compression surface, a rotation-formed axially symmetric lip cover, backswept side plates, an annular rotating round bent expanding pipeline, a forebody head upper surface, a forebody head transition surface and an aircraft fuselage profile. The forebody head of the air vehicle is designed asymmetrically, a non-regular capture surface is designed, accordingly, the theoretical capture area of the inlet and the utilization efficiency of the windward side of the air vehicle can be increased remarkably, and the shock wave intensity and the windward area above the forebody head of the air vehicle are reduced. The forebody of the air vehicle and the shock wave system of the lower-jaw type inlet are designed integrally, so that loss of strong shock waves and local reaccelerating areas can be avoided. Accordingly, the design method has a remarkable effect on improvement of the flow capture capacity and the total-pressure recovery capacity of the inlet as well as reduction of aerodynamic resistance of the air vehicle.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

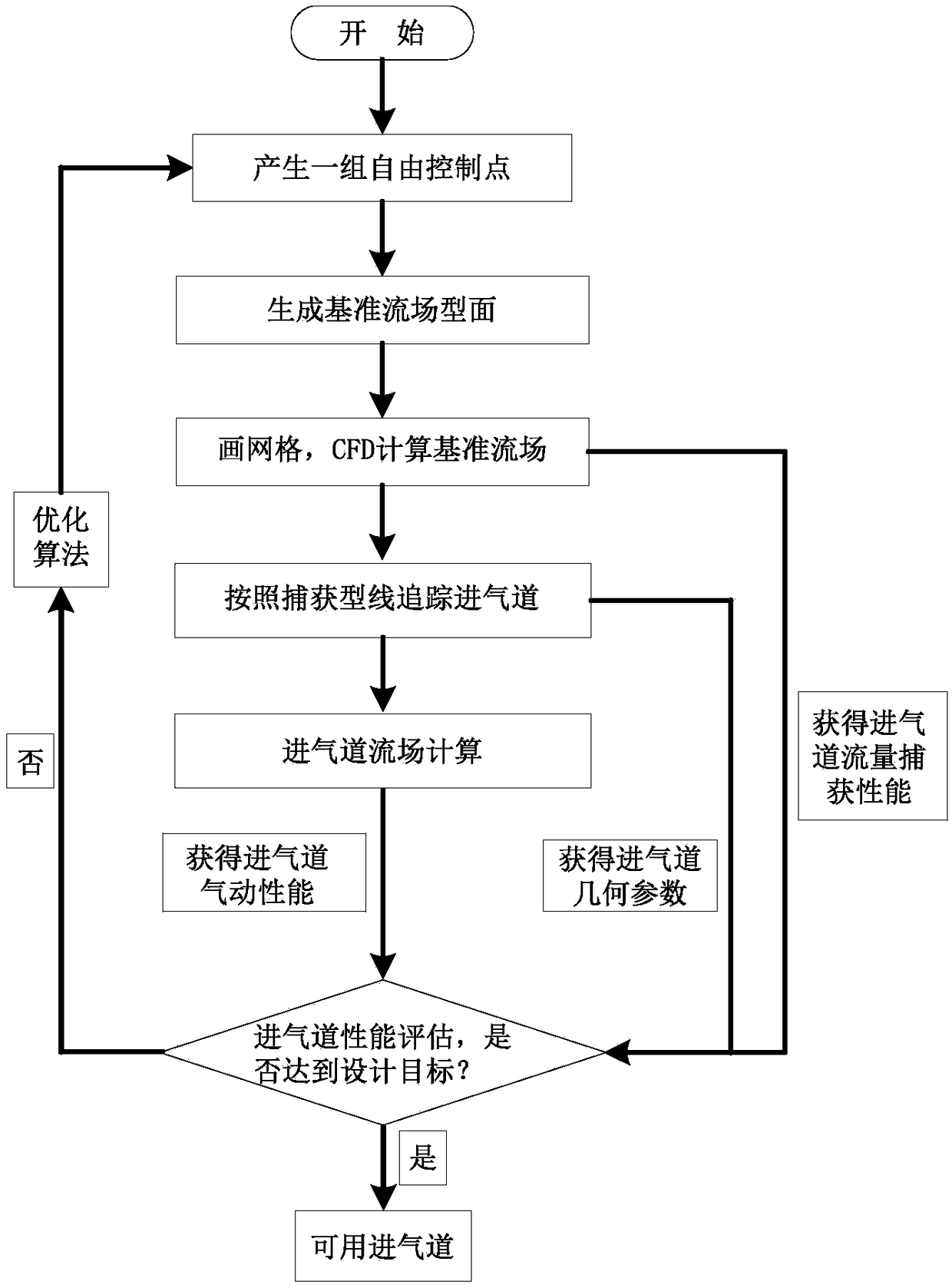

Supersonic flow channel design method and apparatus

ActiveCN108846224AMeet pre-determined requirementsImprove aerodynamicsGeometric CADDesign optimisation/simulationInlet channelEngineering

The invention relates to a supersonic flow channel design method and apparatus. The method comprises the following steps: step S1, generating a reference flow field molded surface; step S2, calculating the reference flow field obtained in the step S1; step S3, generating a three-dimensional internal steering air inlet channel by using a streamline tracing method; step S4, calculating the flow field of the three-dimensional internal steering air inlet channel obtained in the step S3; and step S5, repeatedly iterating step S1 to step S5 by using an optimization algorithm to obtain a three-dimensional internal steering air inlet channel meeting traffic capture performance, geometric parameters and aerodynamic performance. Compared with the prior art, the method has the advantages of being able to solve the problems that the traditional air inlet channel design does not directly aim at the aerodynamic performance of the air inlet channel and starts from the reference flow field performance, such that it is difficult to ensure the same performance of the air inlet channel, the experience is too high to ensure the optimal value of the performance of the air inlet channel and that the total shrinkage ratio and the internal shrinkage ratio of the internal steering air inlet channel are uncontrollable.

Owner:NAT UNIV OF DEFENSE TECH

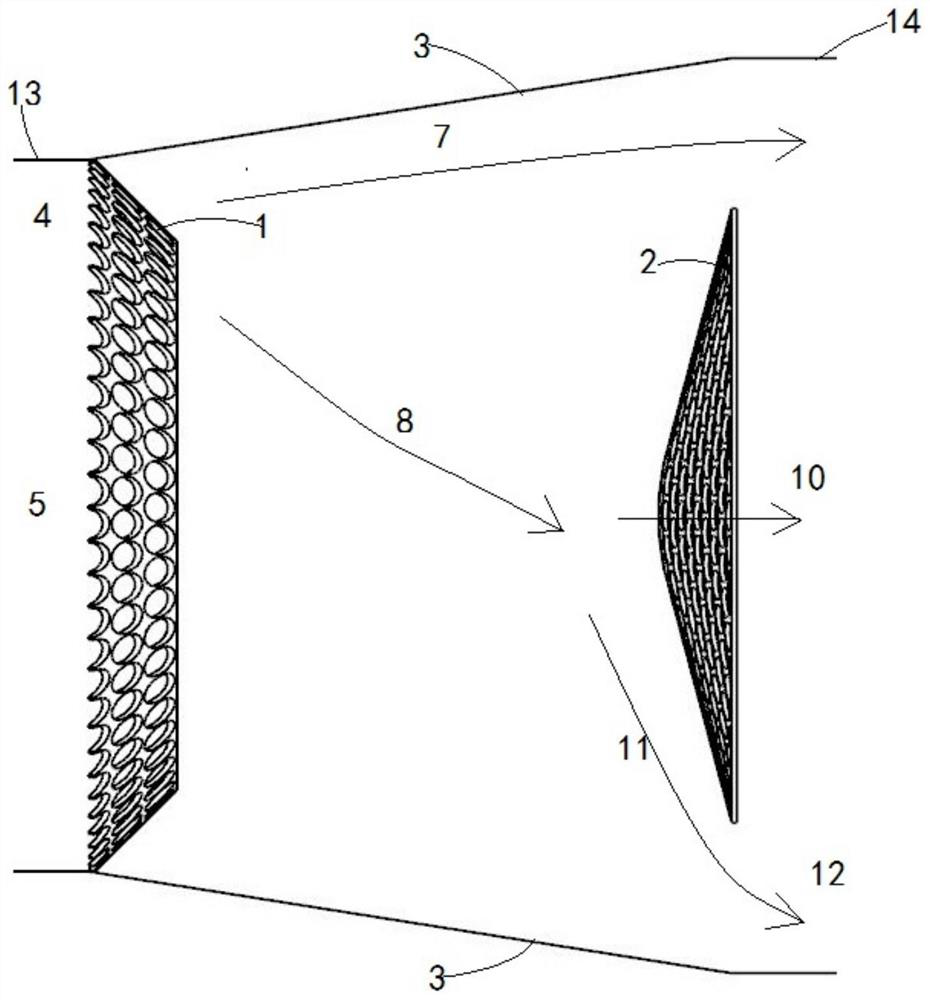

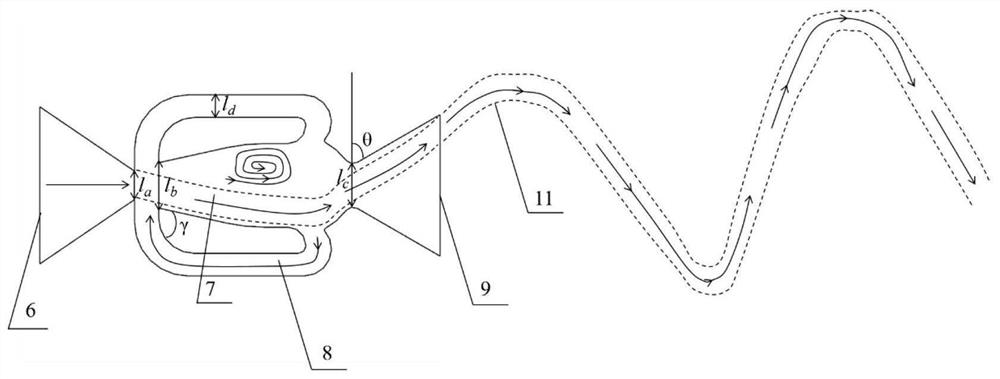

Embedded air inlet based on vortex excretion and aircraft using embedded air inlet

InactiveCN101994570AIncrease the total pressure recovery coefficientReduce flow field distortionTurbine/propulsion air intakesFlight vehicleEngineering

The invention provides an embedded air inlet based on vortex excretion and an aircraft using the embedded air inlet. The side wall of the inner path of the embedded air inlet is provided with a pair of air bleeding grooves, vortex generated by an inlet chamfered edge and boundary layer low-energy flow entrained by the vortex are discharged out of the inner path via the air bleeding grooves so as to avoid high pitot loss and distortion caused by vortex self and entrainment projectile body boundary layer while fully utilizing actinal surface vortex for air entrainment. Thus, in the invention, the total pressure restitution coefficient of the embedded air inlet is greatly improved and the outlet flow field distortion is lowered.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

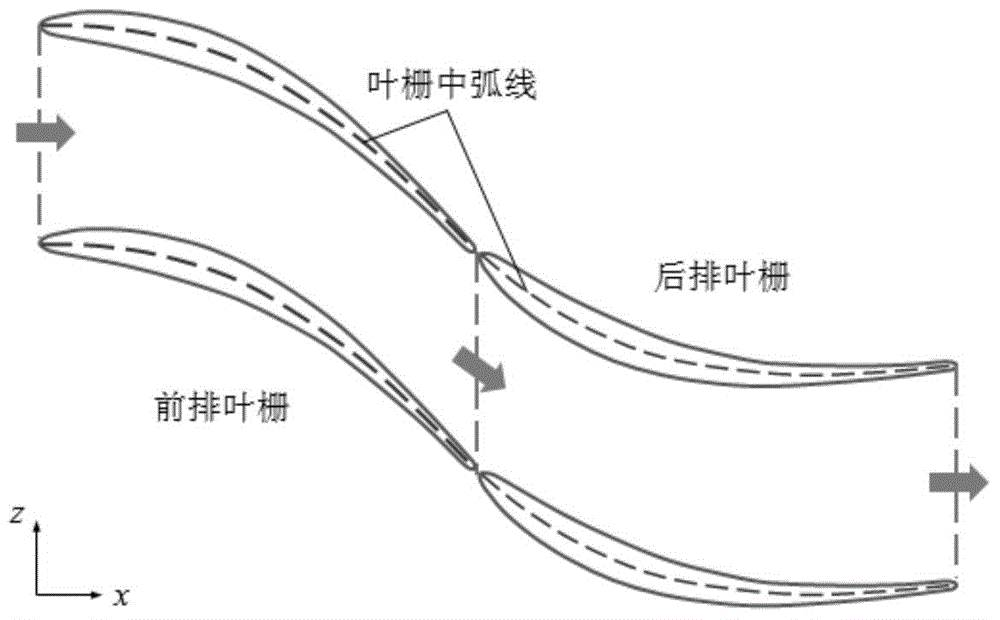

Half split hierarchical S-shaped air inlet channel design method

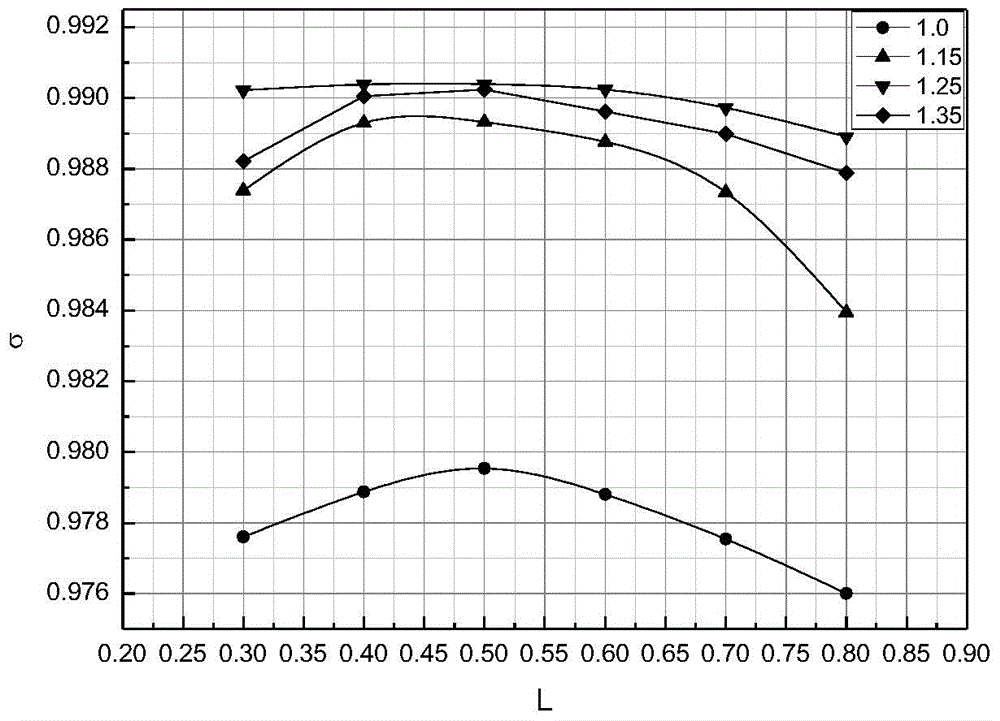

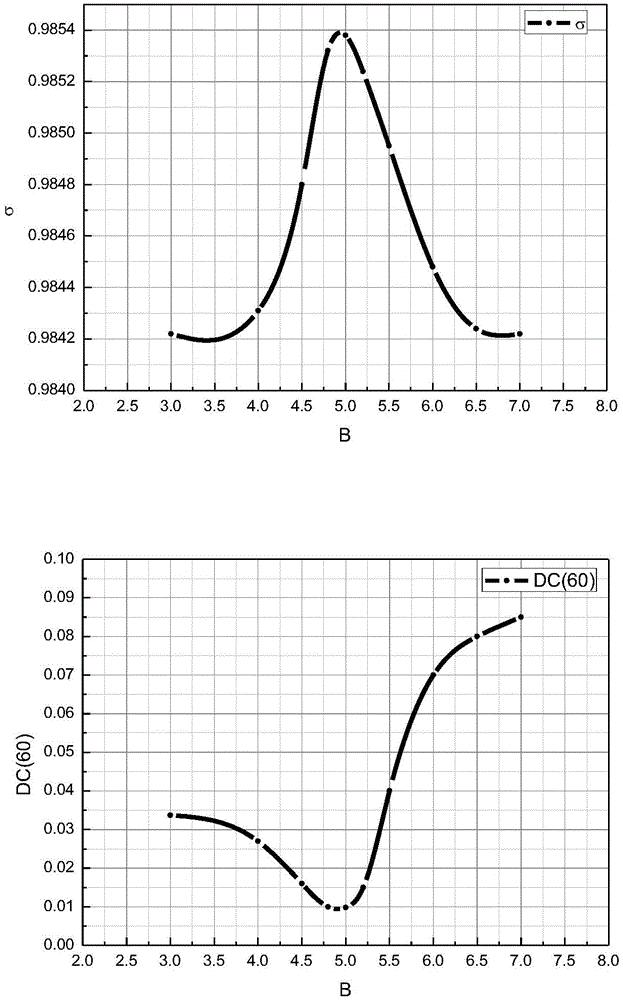

InactiveCN104832291AIncrease the total pressure recovery coefficientSmall Distortion IndexTurbine/propulsion air intakesSpecial data processing applicationsInlet channelAxial pressure

The invention discloses a half split hierarchical S-shaped air inlet channel design method. First, by use of two stationary blade row mean camber line design for reference, two-dimensional half split design idea is used, dimensionless parameter ''load coefficient'' ''expansion coefficient'' control of air inlet channel normal and axial pressure distribution is proposed, a two-dimensional wall surface molded line of an S-shaped air inlet channel is designed, and a two-dimensional wall surface geometric parameterized model is established; total pressure recovery coefficient is used as an optimization objective, and by combination of genetic algorithm and an S-shaped air inlet channel modelling program, the two-dimensional parameterized model is optimized; by use of three-dimensional hierarchy design idea and by introduction of dimensionless parameter ''distribution coefficient'', an S-shaped air inlet channel three-dimensional geometric model is further obtained by determination of center line along the distance; and finally, the total pressure recovery coefficient and outlet distortion are used as an optimization objective, the genetic algorithm is used for multi-objective optimization of the model, and by discuss of physical relationship of the parameters and the air inlet total channel pressure loss and the outlet distortion, an S-shaped air inlet channel with better aerodynamic performance can be obtained.

Owner:BEIHANG UNIV

Embedded type air inlet channel using combined opening surface vortex control method

ActiveCN103939216AIncrease the total pressure recovery coefficientDoes not take up spaceTurbine/propulsion air intakesInlet channelEngineering

The invention discloses an embedded type air inlet channel using a combined opening surface vortex control method. The embedded type air inlet channel comprises an air inlet channel inlet, a flow guide surface, a side wall, a rear lip opening and multiple micro vortex generators, wherein the micro vortex generators are arranged on the flow guide surface; the air inlet channel inlet comprises a main inlet and a pair of overflow grooves; and the main inlet is arranged at the front part of the air inlet channel inlet and the overflow grooves extend backwards from two sides of the rear of the main inlet. The air intake strengthening function of the opening surface main vortex of the embedded type air inlet channel is used; directly flowed secondary vortexes, which continuously expand to two sides of the air inlet channel inlet, are generated by the vortex generators, and main vortexes at two sides of the air inlet channel inlet are thrust to the outside of the inlet, so that most of vortex air flow is exhausted to the outside of the air inlet channel through the pair of overflow grooves at the rear end of the inlet; and besides, at the time, the advantage of the embedded type air inlet channel is realized, the adverse pneumatic impact caused by the main vortex is ingeniously avoided, so that the purposes of increasing the total pressure recovery coefficient of the embedded air inlet channel, reducing the distortion index and improving air intake capability are achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Contrarotating rotary spraying engine

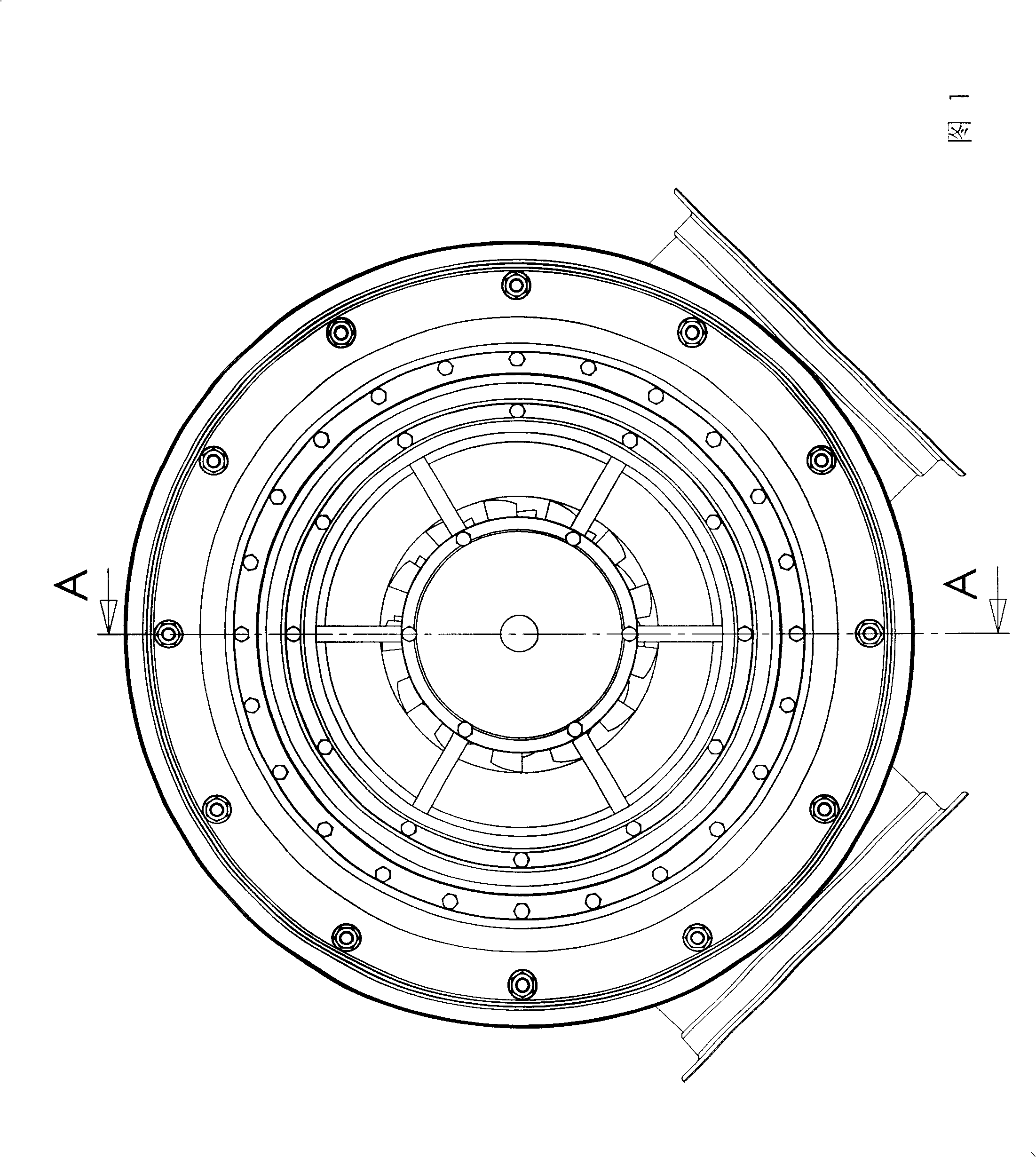

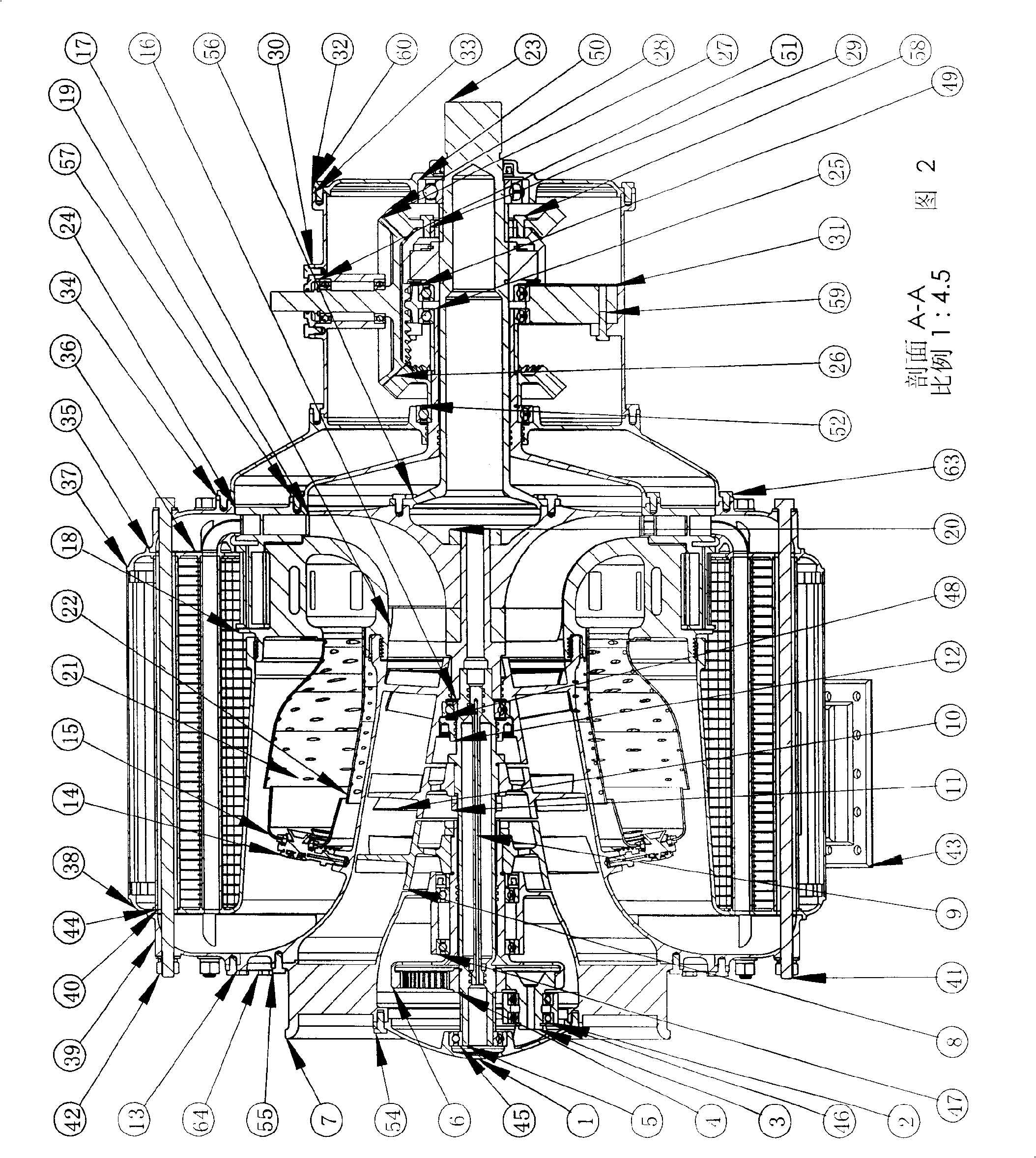

InactiveCN101349197AShort axial distanceShort thermal stressContinuous combustion chamberGas turbine plantsHigh energyMechanical energy

The invention provides a contra-rotating rotary-jetting engine which can remarkably raise heat efficiency and reduce pollutant emission, manufacturing cost as well as maintenance cost. The engine works by utilizing a principle that a rotary jet turbine of the engine ejects fuel gas at high speed from a tangential spout to allow the self of the rotary jet turbine to rotate reversely so as to convert fuel gas internal energy into mechanical energy; meanwhile, the engine also utilizes a tangential impact turbine to recycle the kinetic energy of the fuel gas ejected from the rotary jet turbine, utilizes a heat regenerator to realize regenerative cycle, adopts a contra-rotating axial flow and contra-rotating centrifugal pressure gas technique to obtain high total pressure ratio, adopts a rotary flame tube technique to obtain high fuel gas temperature in front of the turbine, adopts the novel structural design to greatly reduce the number of components and the consumption of precious materials, and adopts a power confluence mechanism of a cone gear and an overrunning clutch to realize the power confluent output of the mechanical energy of the rotary jet turbine and the tangential impact turbine. Therefore, the engine has high energy conversion efficiency, low manufacturing cost and pollutant emission.

Owner:蔡盛龙

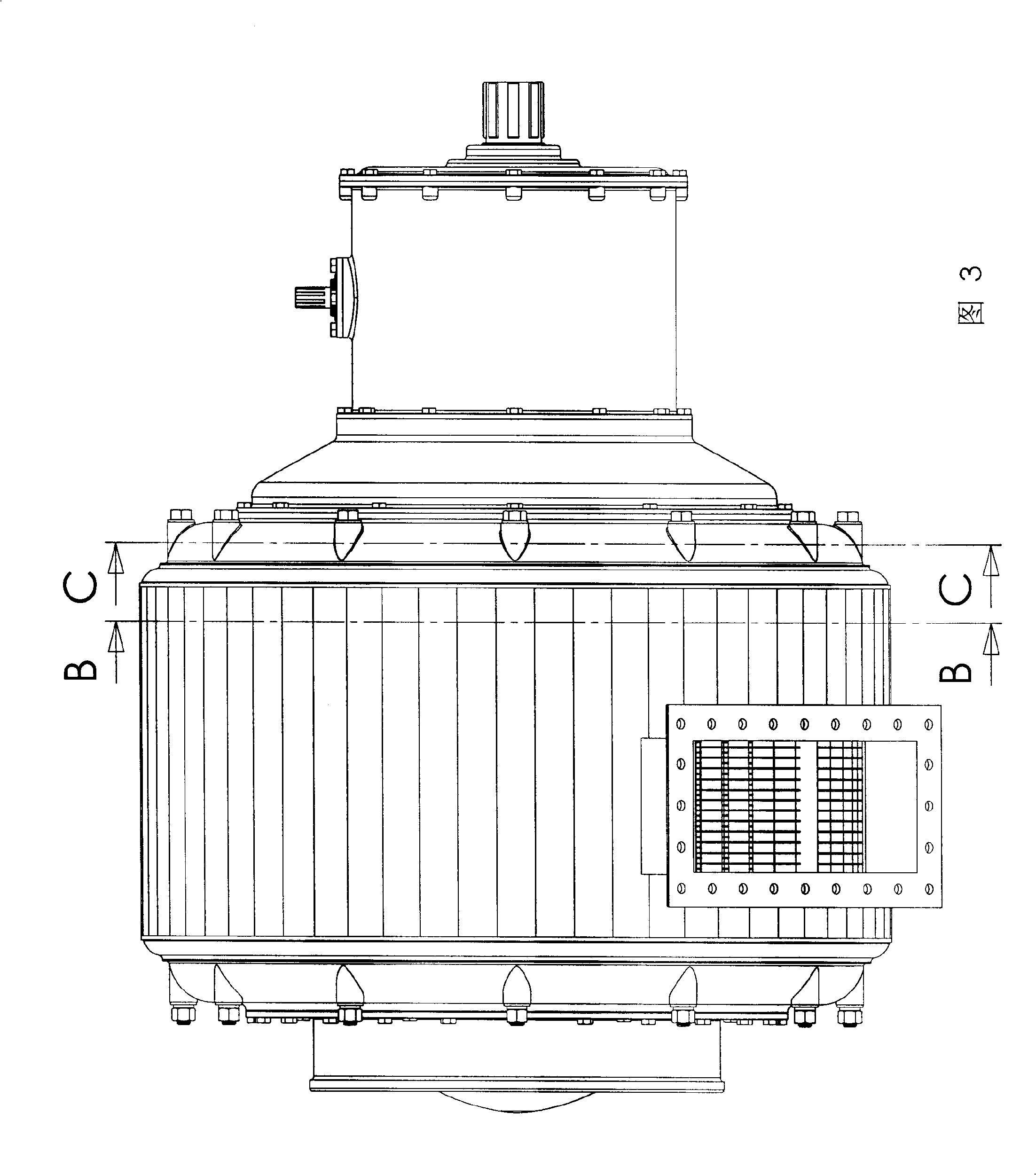

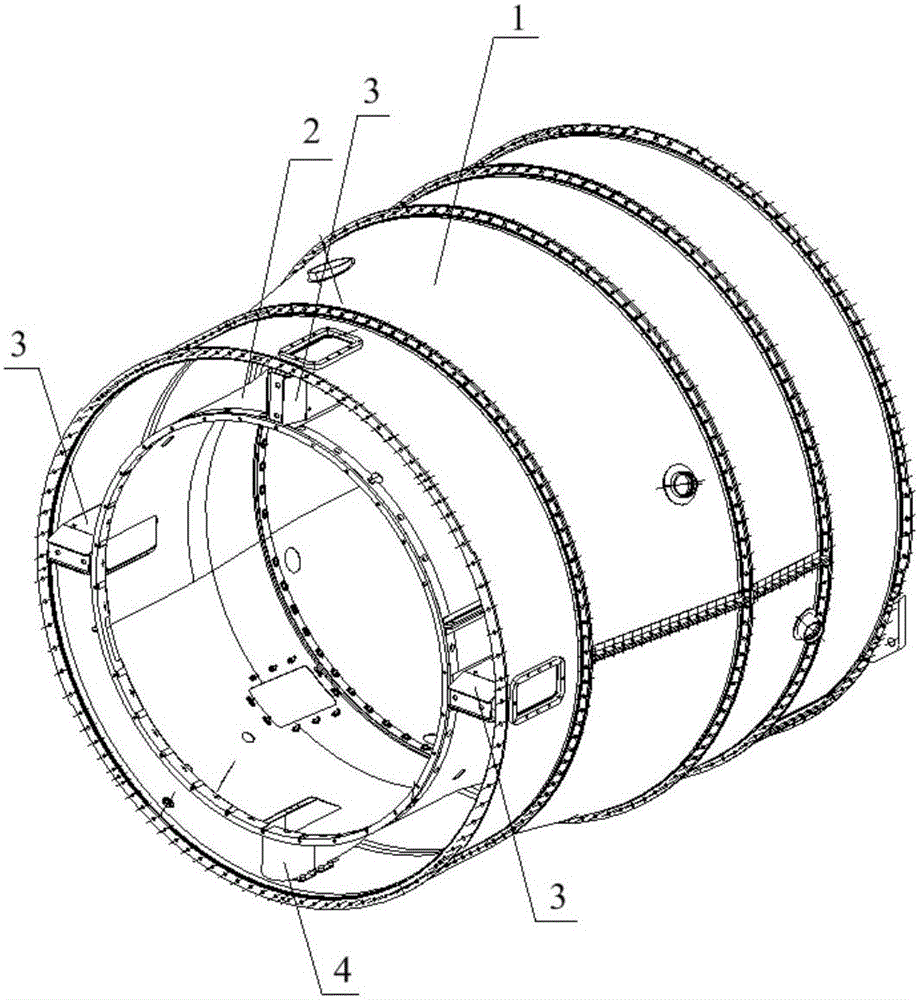

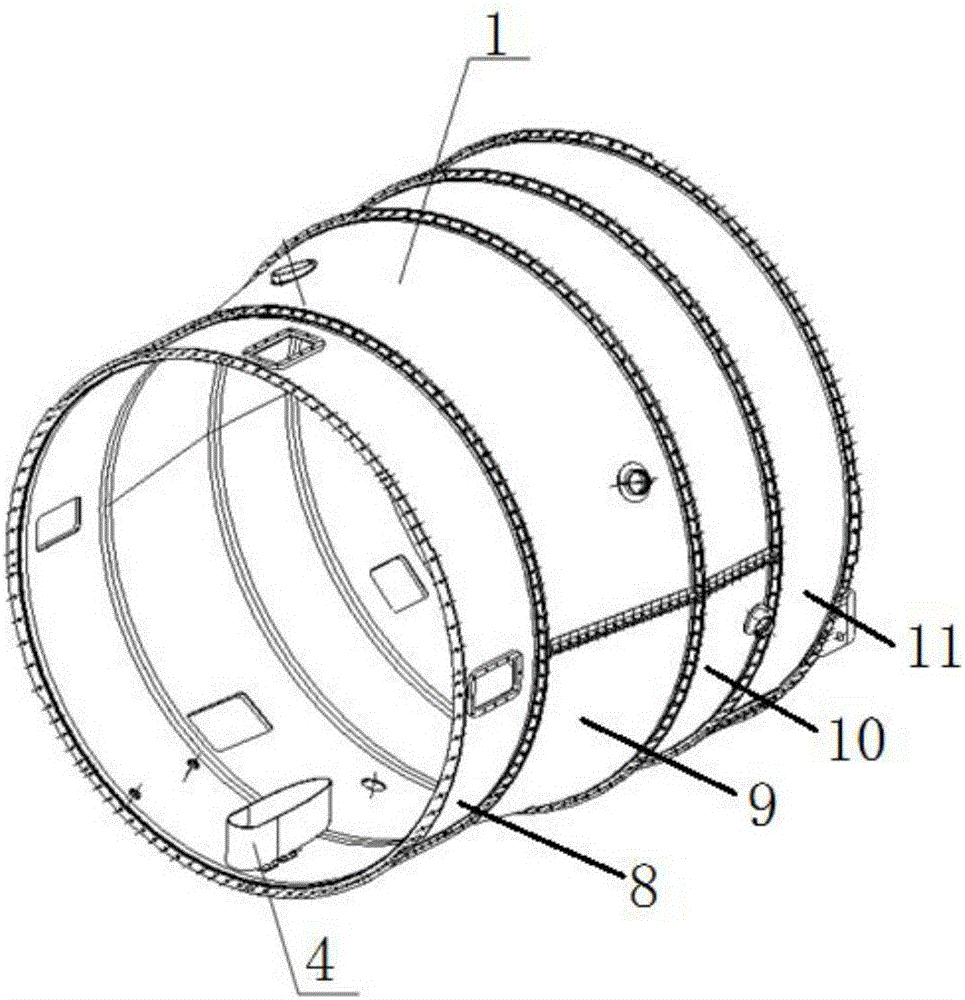

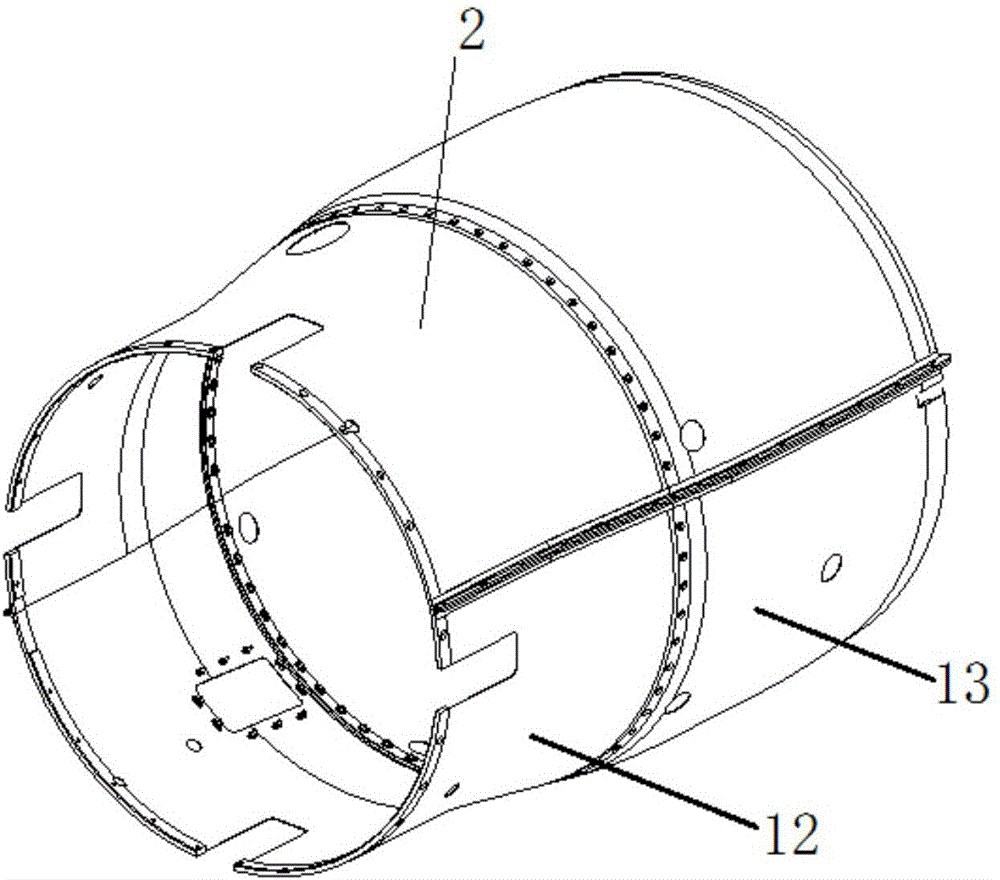

Bypass casing for engine

ActiveCN106812626AGood smoothnessIncrease the total pressure recovery coefficientEngine componentsJet propulsion plantsAirflowEngineering

The invention discloses a bypass casing for an engine and belongs to the field of design of engine casings. The bypass casing comprises an outer casing, an inner casing, junction boxes and a support; a core engine unit body (6) of the engine is sleeved with the inner casing (2); the inner casing (2) is sleeved with the outer casing (1); a flow channel is formed between the outer casing (1) and the inner casing (2); multiple junction boxes are arranged in the flow channel between the outer casing (1) and the inner casing (2) so as to lead out pipelines; the support and the core engine unit body are separately mounted through bolts; and the other end of the support adopts the arc-shaped structure and is glidingly connected with the back section of the inner casing. The outer casing forms an upper wall surface of the bypass flow channel, the inner casing replaces the core engine unit body to form the lower wall surface of the bypass flow channel, the flow channel formed by the outer casing and the inner casing effectively reduces the total pressure loss of the bypass, the total pressure recovery coefficient is increased, the vibration effects caused by air flows on the engine structure and accessories are reduced, and the structural reliability is improved.

Owner:AECC SHENYANG ENGINE RES INST

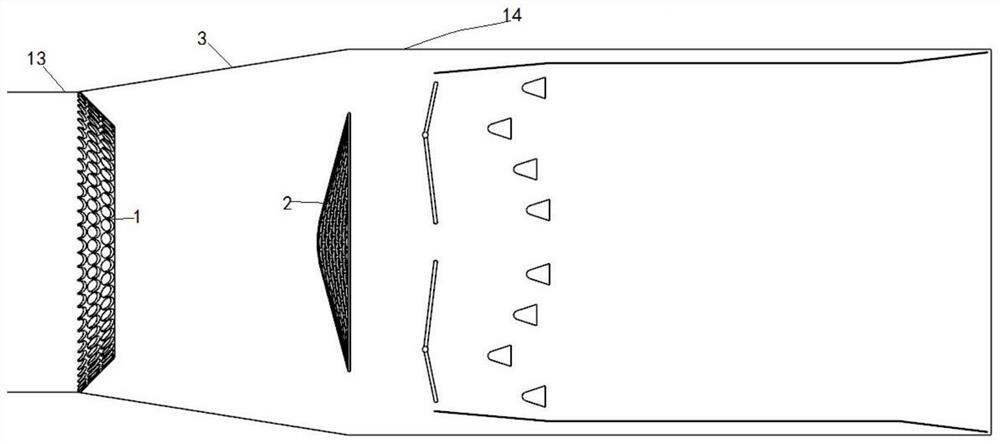

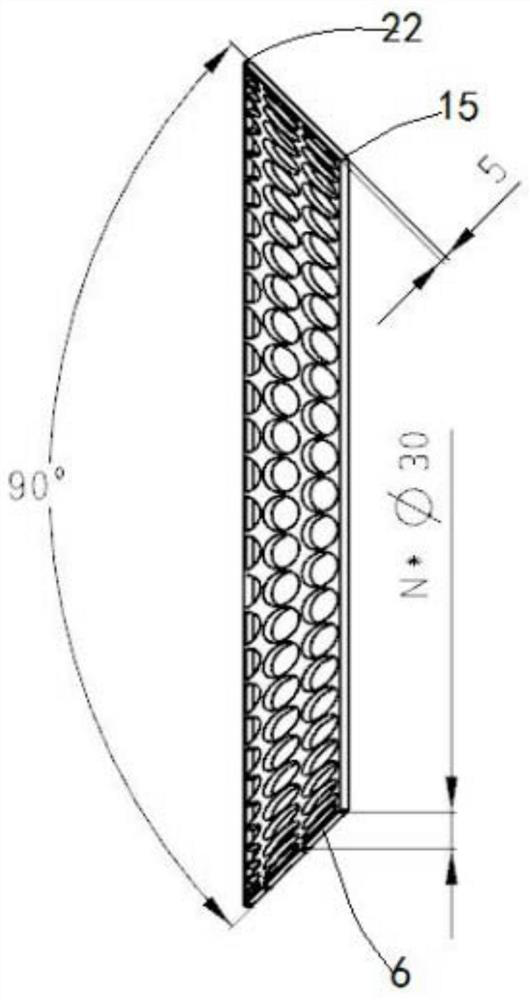

Ramjet combustor rectification grille

ActiveCN112113241AIncrease the total pressure recovery coefficientGuaranteed to workContinuous combustion chamberEfficient propulsion technologiesRamjetCombustion chamber

The invention belongs to the technical field of aero-engines, and particularly relates to a ramjet combustor rectification grille. The ramjet combustor rectification grille comprises a front grille body and a rear grille body, the front grille body is arranged at a diffuser inlet of a ramjet combustor and used for buffering high-speed airflow of the diffuser inlet and guiding part of the bufferedhigh-speed airflow to a center area of a diffuser, and the rear grille body is arranged at a diffuser outlet of the ramjet combustor and used for buffering the air flow in the center area of the diffuser and evenly diffusing the buffered air flow in the center area of the diffuser outwards along the center area. According to the ramjet combustor rectification grille, through the design scheme thatthe front and rear rectification grille bodies are arranged at the inlet and outlet of the diffuser for combined rectification, the defects of an existing ramjet combustor rectification grille are overcome; and compared with a traditional single-layer grille, the rectification capacity of the ramjet combustor rectification grille can be obviously improved, the unevenness of distorted airflow is reduced, and the total pressure loss of the grille can be effectively reduced.

Owner:AECC SICHUAN GAS TURBINE RES INST

Swirling afterburner chamber based on outer concave cavity

ActiveCN108253456AIncrease the total pressure recovery coefficientImprove performanceContinuous combustion chamberFriction lossAirflow

The invention discloses a swirling afterburner chamber based on an outer concave cavity. The swirling afterburner chamber based on the outer concave cavity comprises an outer cylinder assembly, a central body assembly and an oil passage assembly; the outer cylinder assembly comprises an outer cartridge receiver and a shock-proof insulation screen; and the central body assembly comprises a swirlingdevice, an inner cartridge receiver, a frustum, a spreader plate and an outer concave cavity flame stabilizer. Through the cooperation among the outer concave cavity flame stabilizer, the swirling device and the frustum, the stability and rapid propagation of the flame in high speed airflow can be achieved by the relatively low resistance loss, so that the high-efficiency and low resistance combustion is achieved, the effective thermal protection to a hot end part is achieved, the uniform and reasonable distribution of the outlet temperature of the combustion chamber is met.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

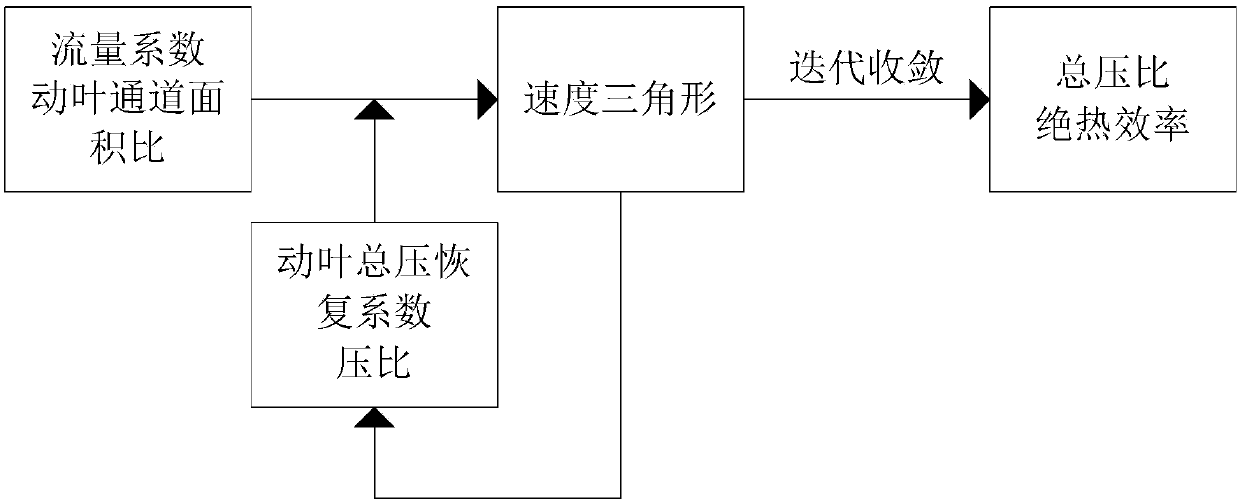

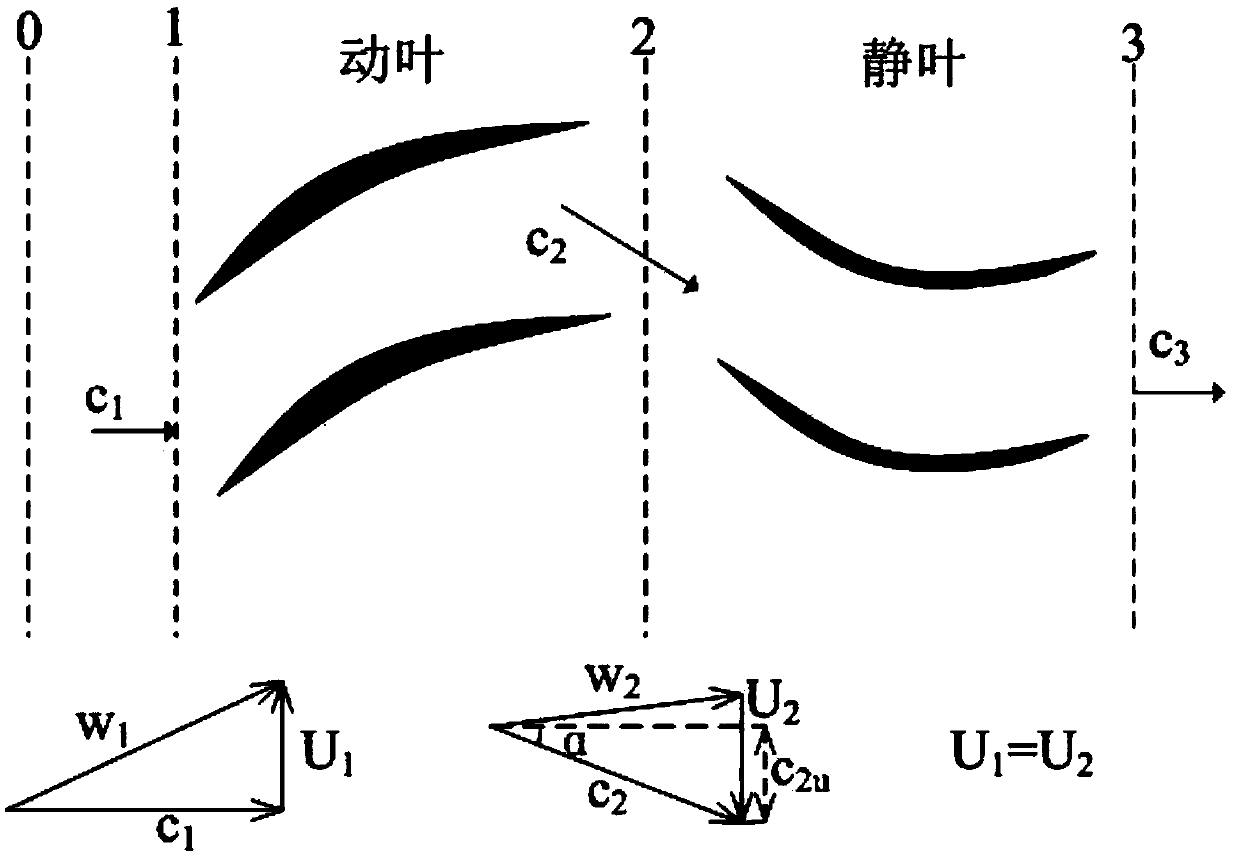

Axial supersonic inflow shock-in-stator fan

ActiveCN108131325AIncrease the total pressure recovery coefficientHigh strengthPump componentsPumpsShock waveStator

The invention relates to an axial supersonic inflow shock-in-stator fan (SSSF), and belongs to the technical field of mechanical devices and transportation. The SSSF provides a thermodynamic layout fan in a new form, and the thermodynamic layout fan includes axial supersonic inflow rotating vanes and shock stator vanes; the SSSF can directly face axial supersonic inflow, the interior of a rotatingvane channel stays in a fully-unfolded highly-axial supersonic flow state, and a stator vane channel decelerates flow into a subsonic speed through a shock wave system. The design process of the SSSFincludes one-dimensional scheme design, two-dimensional flow design, three-dimensional appearance design, intensity check and machining and testing of test pieces. Compared with a traditional subsonic or transonic fan, the SSSF has the advantages that the length and weight of an air inlet passage are greatly reduced; meanwhile, due to excellent load capacity of the supersonic inflow rotating vanes, the SSSF in a supersonic flight state has the advantages of being high in load and efficiency and light in weight.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Fluid-solid coupled gas shock wave adjusting bearing

ActiveCN106545576AImprove carrying capacityImproved aerodynamic stabilityBearingsShock waveCarrying capacity

The invention relates to a fluid-solid coupled gas shock wave adjusting bearing. At present, a widely used dynamic pressure foil-bearing is limited in carrying capacity and lacks of stability and the coating process requirements on the surface of a foil are high, and a static pressure-dynamic pressure mixed bearing is insufficient in carrying capacity at a slow rotating speed while is pneumatically unstable at a high rotating speed. The bearing provided by the invention comprises a bearing bush (1) which is provided with air supply throttling orifices (3), damping cavities (4) are arranged in the outlet positions of the air supply throttling orifices, one or more than one row of air supply throttling orifices and the damping cavities is uniformly distributed circumferentially on the inner surface of the bearing bush, and foil structures (7) are arranged between the outlets of the damping cavities and a rotor (2); the foil structures comprises bump foils (6) and flat foils (5). By changing the air supply pressure of the bearing, the throttling orifice structures and the damping cavity structures, the fluid-solid coupled gas shock wave adjusting bearing can be matched with a large-gap high-load bearing working condition. The invention is the fluid-solid coupled gas shock wave adjusting bearing.

Owner:HARBIN INST OF TECH +1

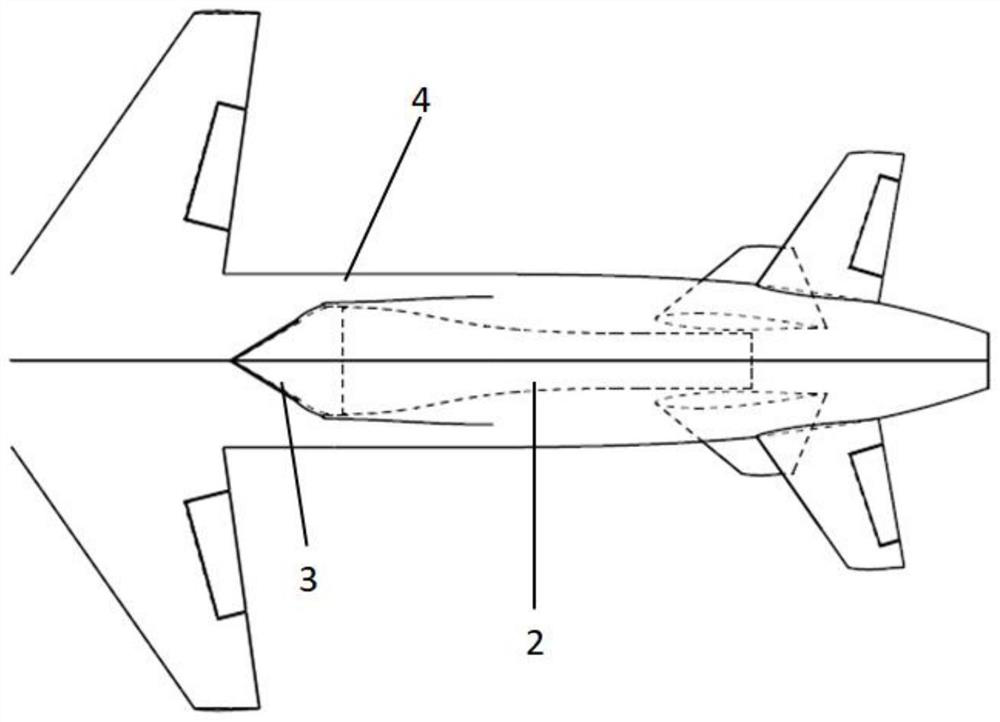

Aircraft S bend and embedded type combination air inlet channel

InactiveCN105129098AImprove stealth performanceImprove battlefield survivabilityPower plant air intake arrangementsInlet channelSurvivability

The invention aims to provide an aircraft S bend and embedded type combination air inlet channel. The combination air inlet channel comprises an actuating device, a sealing gasket, an air inlet channel jettison section, a breakable connecting device, an embedded type air inlet channel, an engine and an aircraft body. The air inlet channel jettison section is fixed on the outer portion of the aircraft body through the actuating device and the breakable connecting device and is in sealed butt joint combination with the embedded type air inlet channel through the sealing gasket on an air inlet channel jettison section flange to form an S bend air inlet channel. At a small flow starting period and a cruising period, an aircraft supplies gas to the engine through the S bend air inlet channel formed by combining the air inlet channel jettison section and the embedded type air inlet channel. When the aircraft is at a penetration period, the air inlet channel jettison section is discarded, and gas is supplied to the engine through the embedded type air inlet channel. The aircraft S bend and embedded type combination air inlet channel is simple in structure and convenient to use and has the advantages that the air inlet channel is good in reliability at the small flow starting period, high in total pressure recovery coefficient at the cruising period, good in stealth capability at the penetration period and high in battlefield survivability.

Owner:JIANGXI HONGDU AVIATION IND GRP

Boundary-layer-free separation air inlet channel

ActiveCN111942600AIncrease the total pressure recovery coefficientImprove stealth performancePower plant air intake arrangementsAviationInlet channel

The invention relates to the technical field of aviation air inlet channels, in particular to a boundary-layer-free separation channel air inlet channel which is used for solving the problems that inthe prior art, a boundary layer separation channel of an air inlet channel increases the windward area of an airplane, so that the aerodynamic resistance of the airplane is increased, the radar stealth performance is reduced, and the air inlet channel is difficult to manufacture. The boundary-layer-free separation channel air inlet channel comprises an air inlet pipeline, a lip and a bulge which are sequentially formed into a whole, the bulge comprises a step face and a bulge main face which are mutually formed into a whole, the step face comprises an upper step face body and a lower step facebody, and a sweepback angle is arranged on the edge of the lip. A boundary layer separation channel is omitted, the angle emitter effect of boundary layer separation channel electromagnetic waves iseliminated, the windward area and resistance of an airplane are reduced, and manufacturing is easier; the sweepback angle design is adopted for the lip and the bulge, the electromagnetic wave mirror surface effect under the main use posture of an airplane is reduced, and therefore the stealth effect of the lip is improved.

Owner:SICHUAN AEROSPACE ZHONGTIAN POWER EQUIP CO LTD

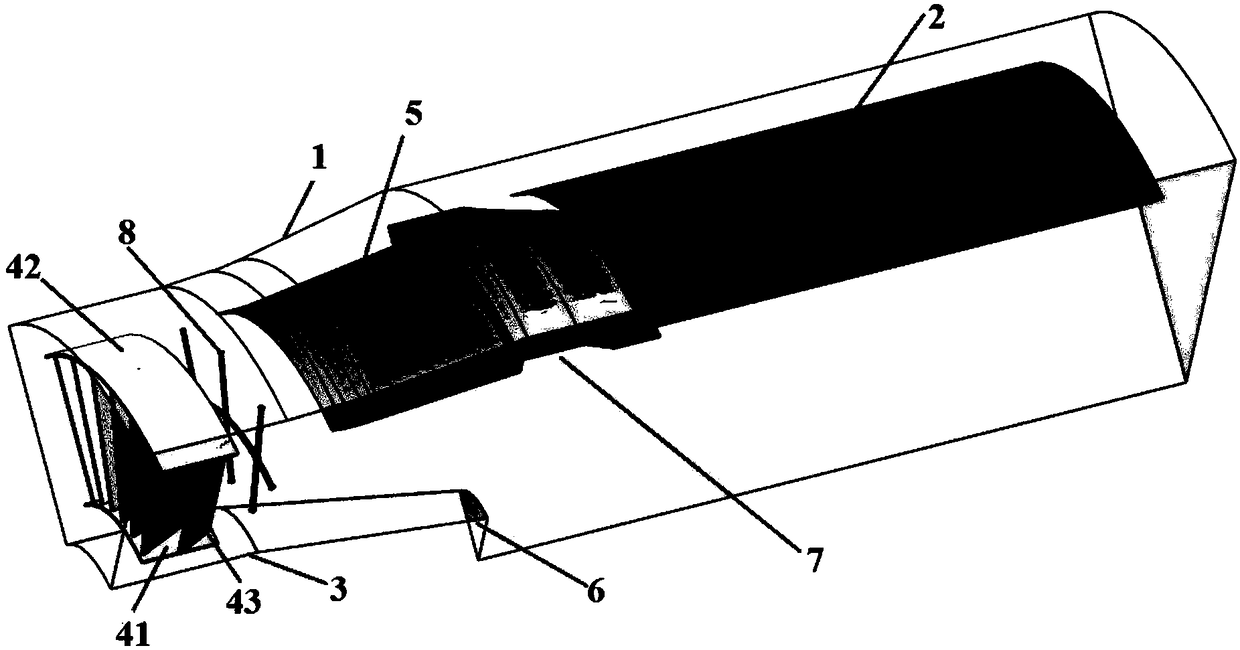

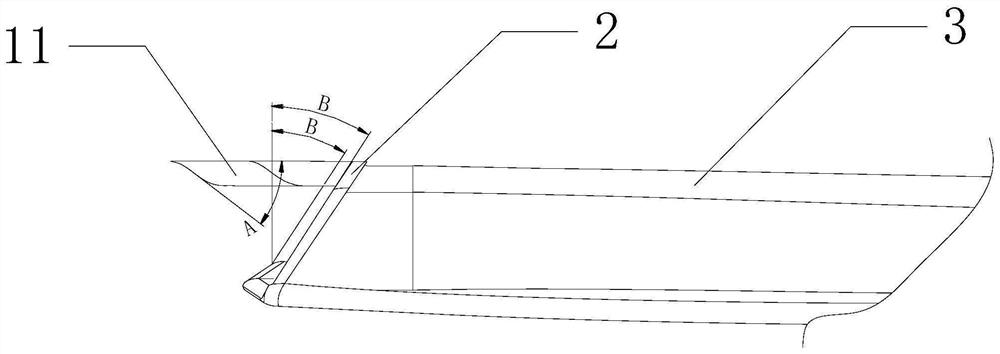

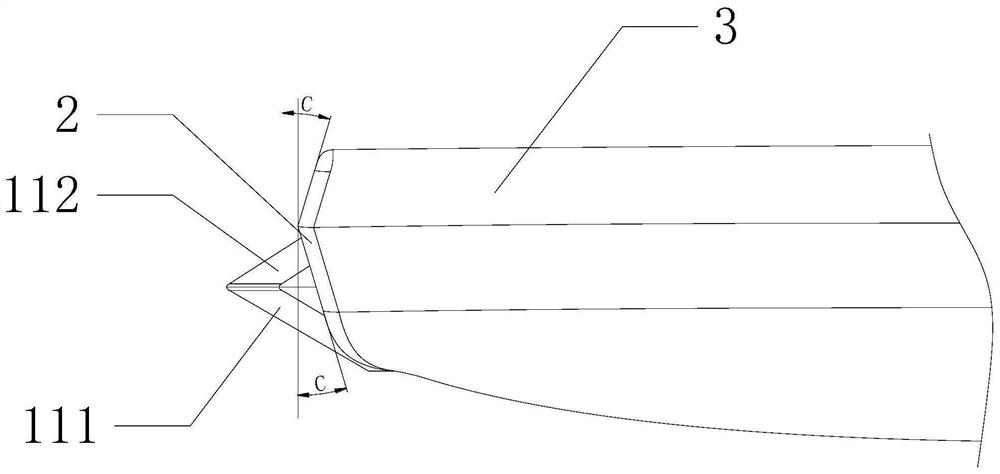

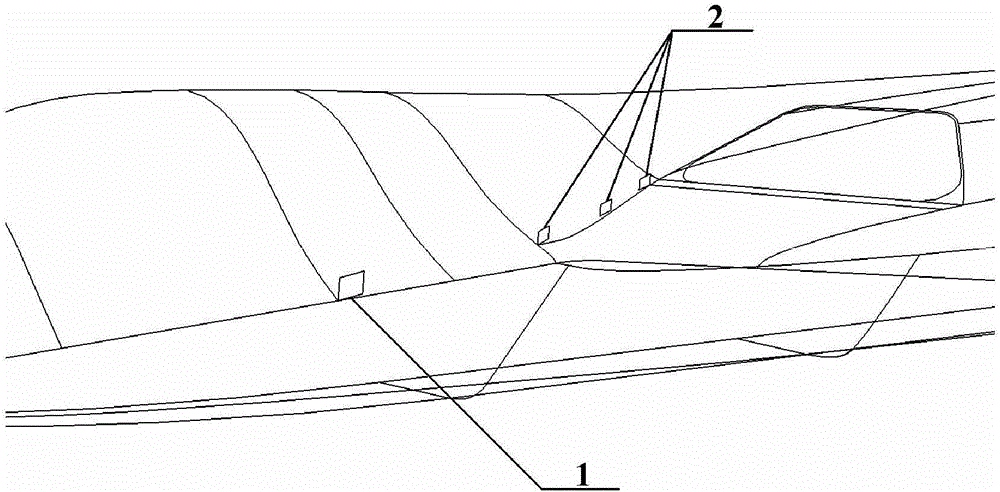

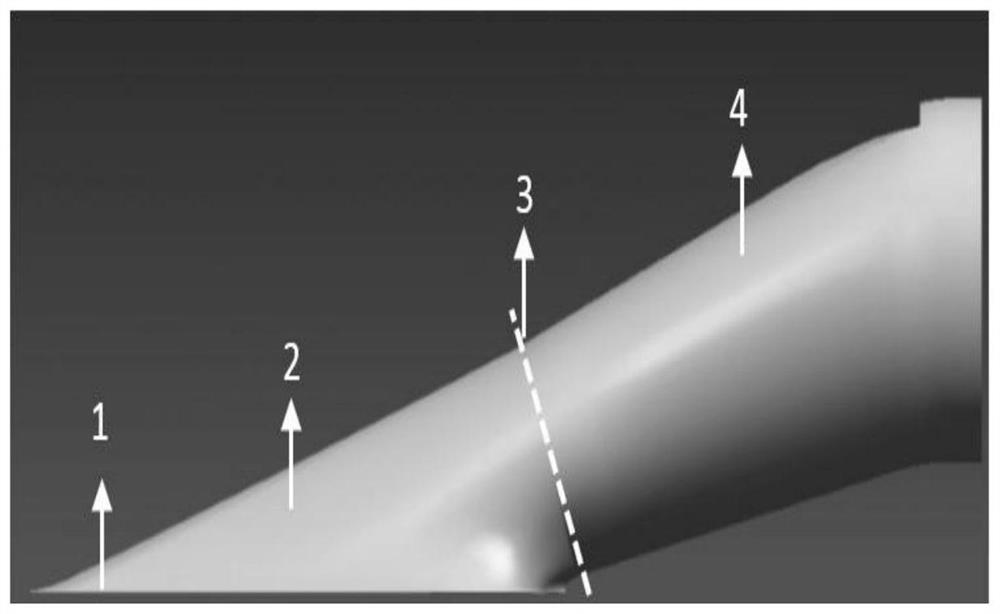

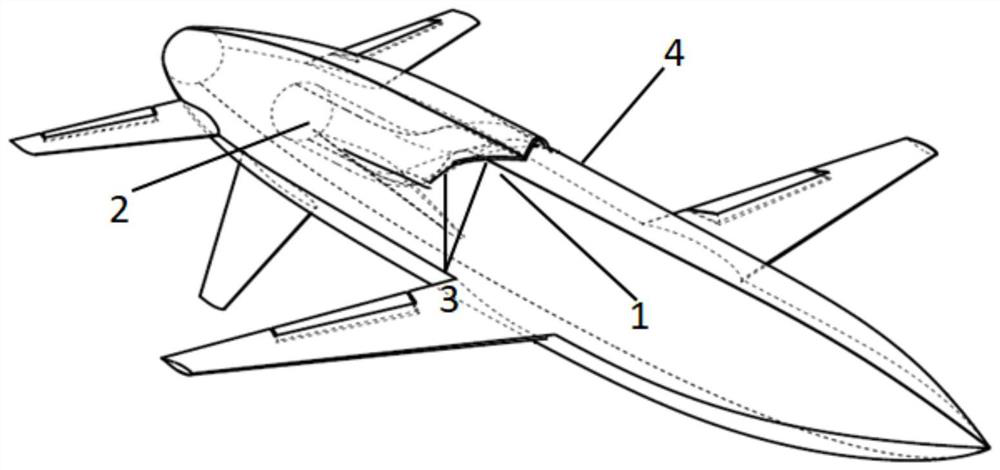

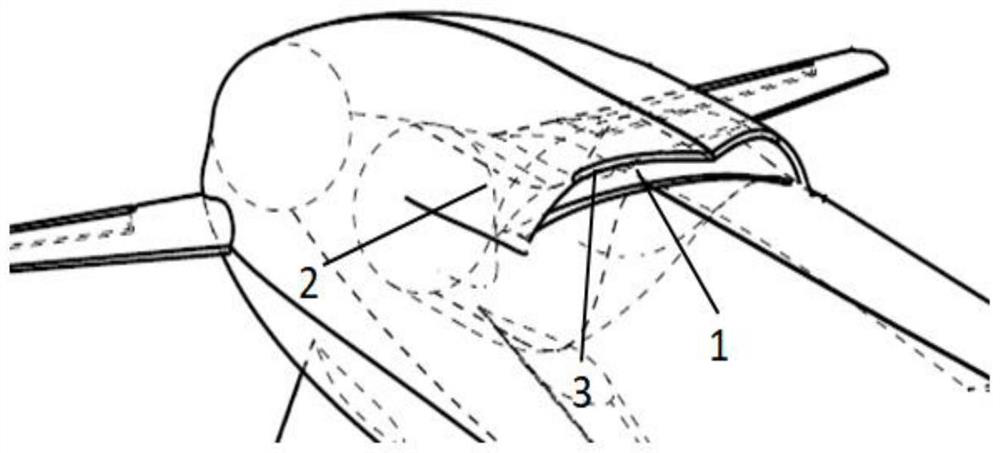

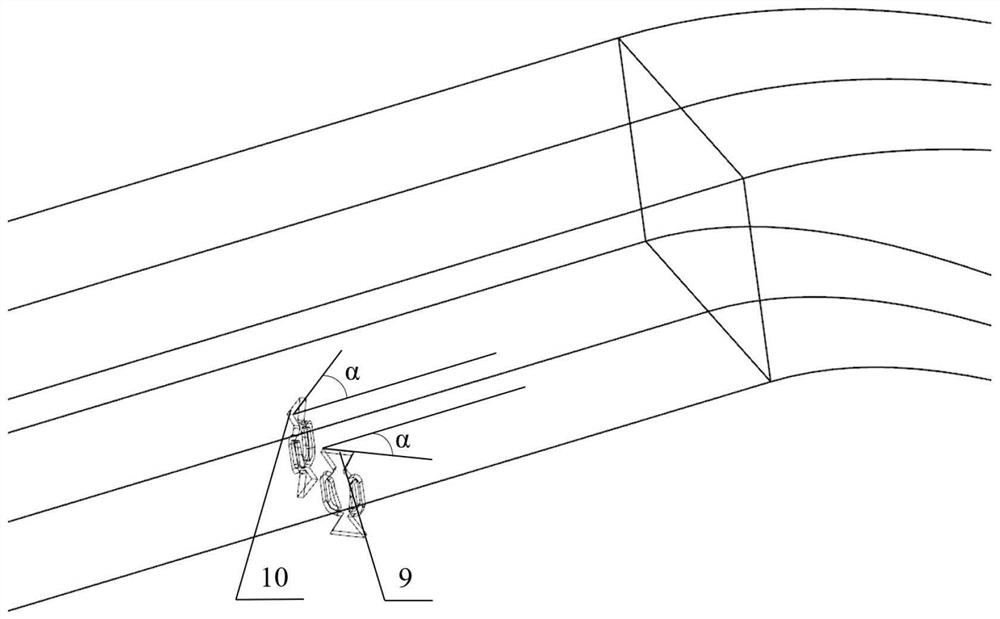

Airplane forebody vortex flow control device

InactiveCN106218865ASimple structureSimple installation and maintenanceAir-flow influencersPower plant air intake arrangementsDistortionAirplane

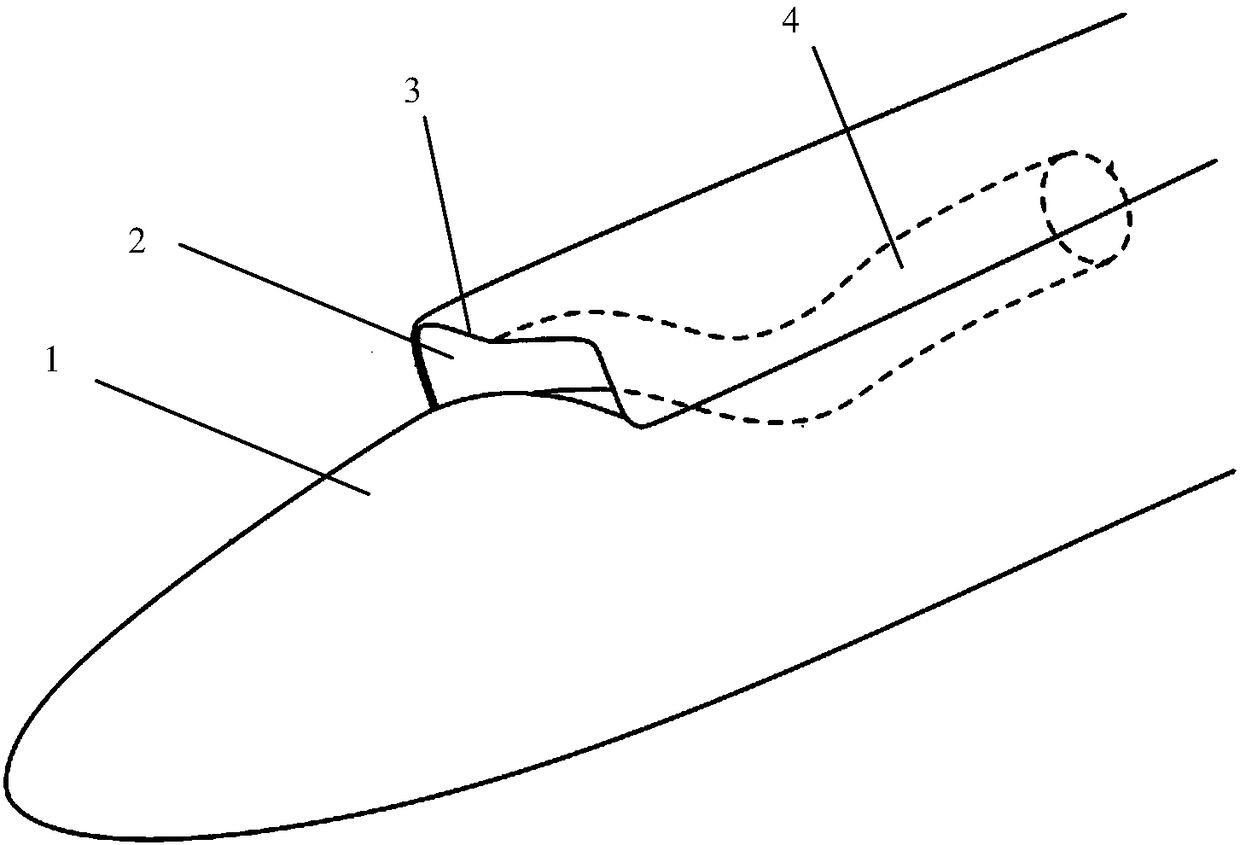

An airplane forebody vortex flow control device comprises a forebody vortex knapper and a plurality of flow deflectors. The forebody vortex knapper is installed above the airplane forebody ridge and in front of an air intake duct inlet in the flow direction. The multiple flow deflectors are sequentially installed behind the forebody vortex knapper and on an original low energy flow direction path, guide low energy flow behind the forebody vortex knapper, and enable the low energy flow not to flow into the air intake duct inlet but to flow backwards along a groove between an air intake duct outer cover and a fuselage. The airplane forebody vortex flow control device is simple in structure, easy to install and maintain, and remarkable in flow control effect. In the typical flight state, the total pressure recovery coefficient of an air intake duct can be increased by 1% or above, and the value of the flow field distortion index show in the specification is reduced by 30% or above.

Owner:AVIC SHENYANG AERODYNAMICS RES INST

Embedded type stealth air inlet channel

PendingCN113895636AAvoid rising costsIncrease the total pressure recovery coefficientGround installationsPower plant air intake arrangementsInlet channelFlight vehicle

The invention belongs to the field of air inlet channels of aircrafts, and particularly relates to an embedded type stealth air inlet channel. The air inlet channel comprises a lip, a channel inlet section and a channel outlet section, the lip is in a polygon-like lip shape, and the channel inlet section is a low-scattering shape cavity. By applying the embedded type invisible air inlet channel, the radar scattering amount sectional area of the air inlet channel can be effectively reduced, meanwhile, a high total pressure recovery coefficient and small flow field distortion are kept, the stealth / flow field integrated design is achieved, the forward radar stealth problem of the air inlet channel is solved from the appearance, and the stealth performance of the aircraft is greatly improved.

Owner:BEIJING RES INST OF MECHANICAL & ELECTRICAL TECH

Low-resistance and high-efficiency subsonic speed air inlet channel

PendingCN114852351AIncrease the total pressure recovery coefficientLow Flow Field Distortion IndexDrag reductionPower plant air intake arrangementsInlet channelFlight vehicle

The invention discloses a low-resistance efficient subsonic speed air inlet channel which comprises an air inlet channel opening face located at the front end of the air inlet channel and an air inlet channel inner channel extending backwards from the air inlet channel opening face, an air inlet channel lip cover is arranged outside the air inlet channel opening face in a surrounding mode, and the air inlet channel opening face and the air inlet channel lip cover are connected with a machine body. The air inlet channel structure is different from a conventional subsonic air inlet channel, no boundary layer separation channel and no protruding bulge exist in front of the opening of the air inlet channel, through integrated fusion of the sweepback sharp lip and the fuselage, the windward area of an aircraft can be reduced while the high total pressure recovery coefficient and the low flow field distortion index of the air inlet channel are kept, and the air inlet channel is more compact in structure. Therefore, resistance is reduced.

Owner:上海甘石星经智能科技有限公司

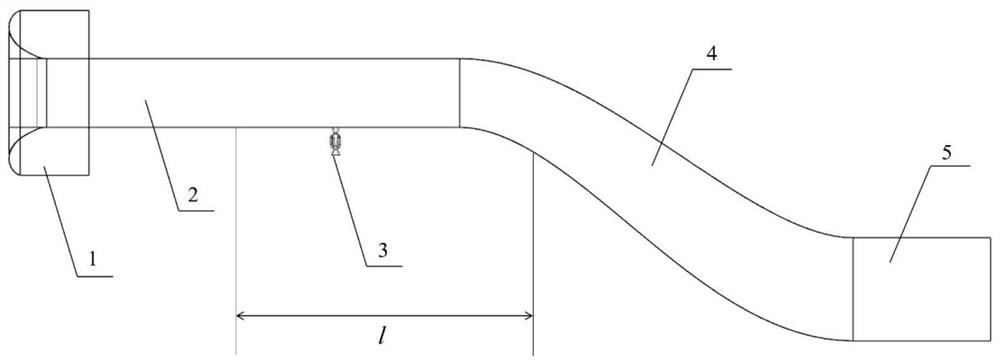

Rotational flow distortion flow control device for S-shaped air inlet channel based on fluid oscillator

InactiveCN113074047AImprove qualityIncrease the total pressure recovery coefficientGas turbine plantsTurbine/propulsion air intakesInlet channelFluidic oscillator

The invention discloses a rotational flow distortion flow control device for an S-shaped air inlet channel based on a fluid oscillator. The rotational flow distortion flow control device is characterized in that the fluid oscillator is arranged in an inlet stabilizing section of the air inlet channel, and oscillation jet flow of an outlet of the fluid oscillator interacts with air flow of the inlet stabilizing section, so that vortex is induced to control flow separation and secondary rotational flow in the air inlet channel. Compared with an existing flow control device, the rotational flow distortion flow control device has the advantages of being simple in structure, free of movable parts, capable of achieving a good control effect by inputting small flow and the like, can increase the total pressure recovery coefficient of an outlet of the air inlet channel effectively, reduces the total pressure distortion index, and improves the outlet flow field quality.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

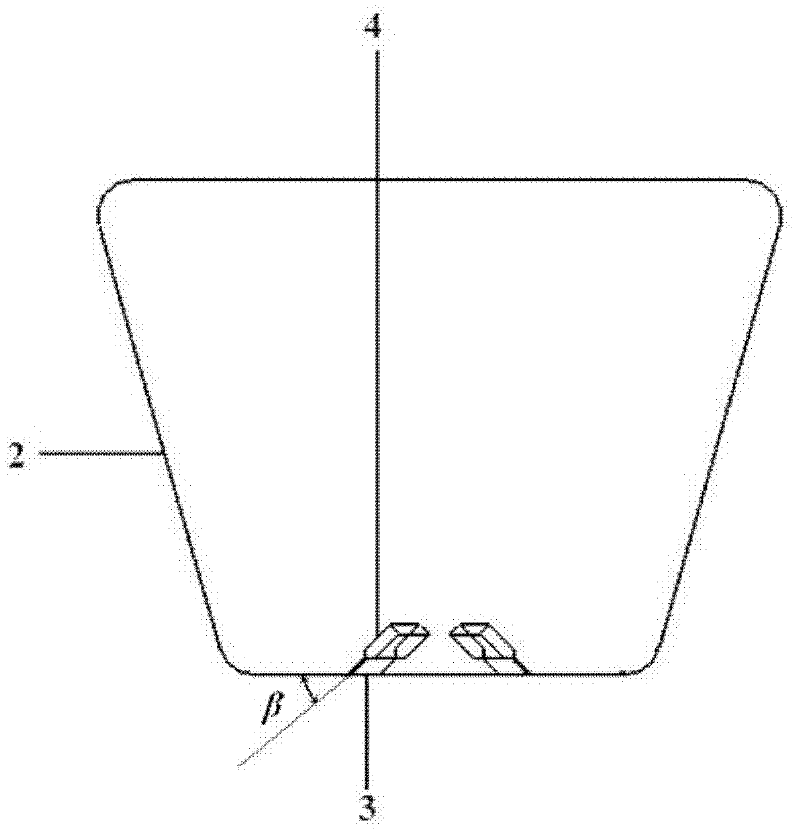

Subsonic aircraft air inlet channel

PendingCN113071689AIncrease the total pressure recovery coefficientLow Flow Field Distortion IndexPower plant air intake arrangementsInlet channelFlight vehicle

The invention discloses a subsonic aircraft air inlet channel which comprises an air inlet channel opening face, the bottom of the air inlet channel opening face is connected with an aircraft body and is integrally fused with the machine body, the rear end of the air inlet channel opening face communicates with an air inlet channel inner channel, a flow separation plate is fixedly supported in the air inlet channel inner channel, and the air inlet channel opening face is surrounded by a lip cover; the front side of the air inlet opening face is provided with a similar triangular step compression surface, the similar triangular step compression surface is fixed on the machine body, and the lip cover is in smooth connection with the machine body and the similar triangular step compression surface. According to the structure, a boundary layer separation channel independently arranged on the machine body is canceled, and a bulge protruding out of the surface of the machine body is replaced by the similar triangular step compression surface; meanwhile, by means of integrated fusion of the sweepback lip cover, the air inlet channel opening face, the similar triangular step compression face and the machine body, the boundary layer of the machine body can be effectively eliminated, the high total pressure recovery coefficient and the low flow field distortion index of the air inlet channel are kept, and meanwhile the attack angle and sideslip angle characteristics of the air inlet channel can be considered.

Owner:上海甘石星经智能科技有限公司

Side plate with overflow gap binary hypersonic air inlet channel

ActiveCN110594022AImprove flow coefficientIncrease the total pressure recovery coefficientTurbine/propulsion air intakesAirflowExternal pressure

The present invention discloses a side plate with an overflow gap binary hypersonic air inlet channel. The air inlet passage body includes a lip cover, a compression surface, two symmetrical side plates; the lip cover, the two symmetrical side plates and the compression surface form an air flow inner channel; the two side plates are symmetrically provided with an overflow gap, and the overflow gapalong the compression surface direction; and the supersonic binary air inlet channel arranged on the side plate through the overflow gap, using airflow air inlet internal and external pressure difference, the side plates and the compression surface boundary of the corner region, a boundary layer of the side plate of the low-speed flow discharge port the outer side plate. The side plate with the overflow gap binary hypersonic air inlet channel increasing the total pressure recovery coefficient of the air inlet channel and the flow coefficient, improving the structure of the internal flow fieldof the air inlet channel.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Embedded type gas charging channel for supplementing gas for gas charging channel based on high-pressure gas cylinder

InactiveCN104389681AIncrease the total pressure recovery coefficientImprove air flowGas turbine plantsJet propulsion plantsAutomatic controlGas cylinder

The invention discloses an embedded type gas charging channel for supplementing gas for a gas charging channel based on a high-pressure gas cylinder. The embedded type gas charging channel comprises a gas charging hole, a gas discharging hole and a gas flow passage of a gas charging channel, wherein the gas charging hole is connected with the gas discharging hole by virtue of the gas flow passage of the gas charging channel; a gas spraying hole is formed in the inner wall of the gas flow passage of the gas charging channel and is communicated with the high-pressure gas cylinder by virtue of a gas flow guide pipe; the gas flow guide pipe is provided with an automatic control valve. According to the embedded type gas charging channel for supplementing gas for the gas charging channel based on the high-pressure gas cylinder, the gas spraying hole is formed in the gas flow passage of the gas charging channel; the gas in the high-pressure gas cylinder is supplemented for the gas charging channel by virtue of the gas flow guide pipe and the gas spraying hole; the total pressure recovery coefficient of the gas charging channel in a starting stage of an engine is increased; meanwhile, the gas flow is increased.

Owner:JIANGXI HONGDU AVIATION IND GRP

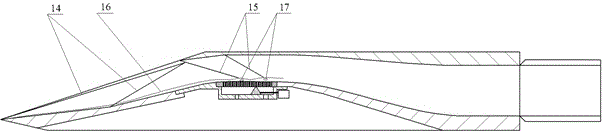

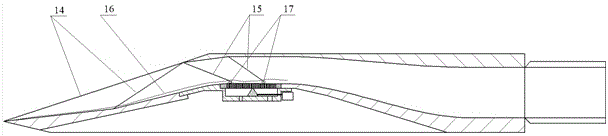

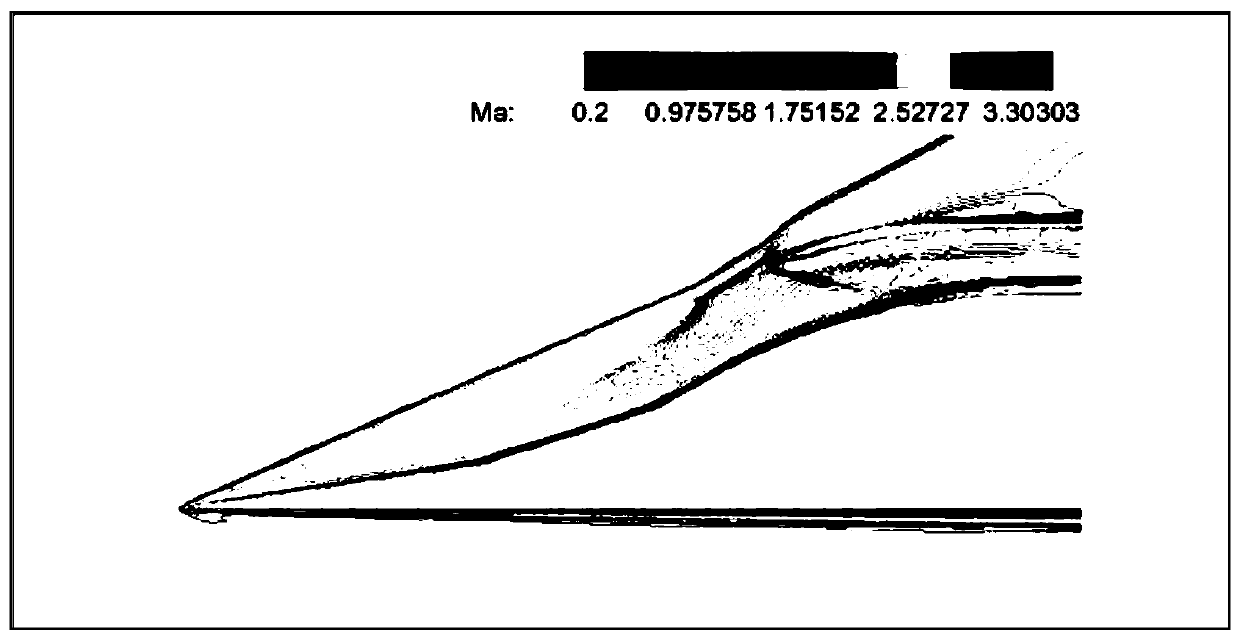

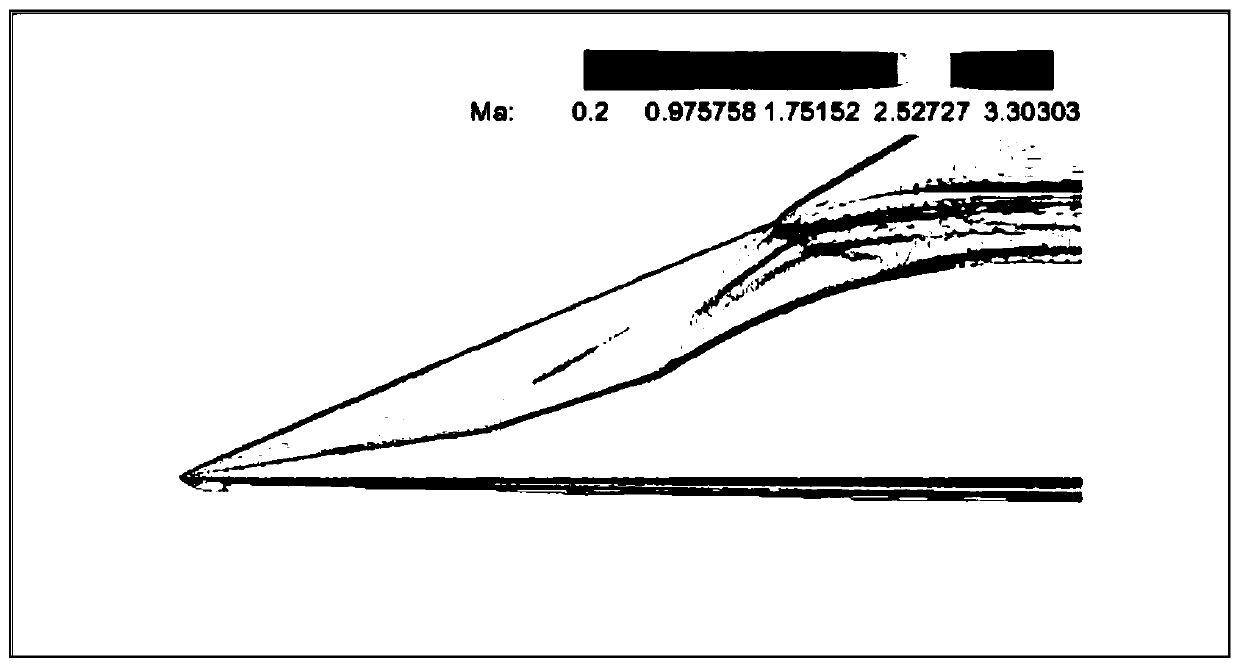

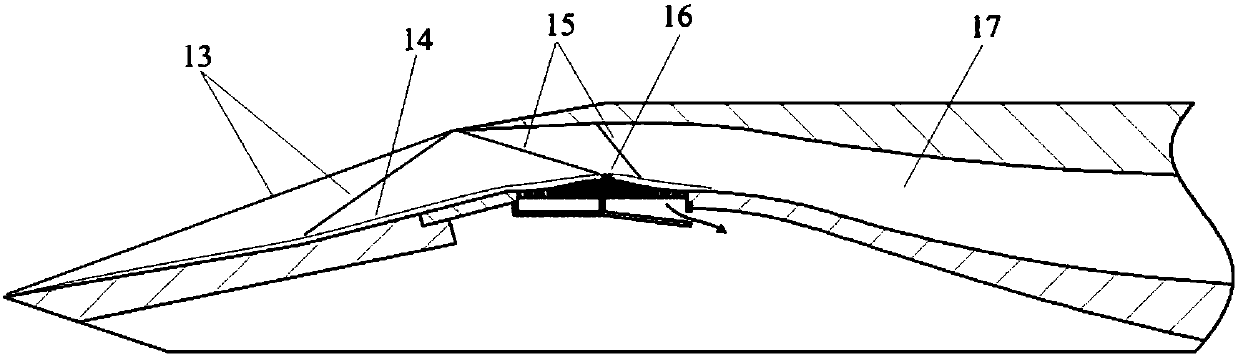

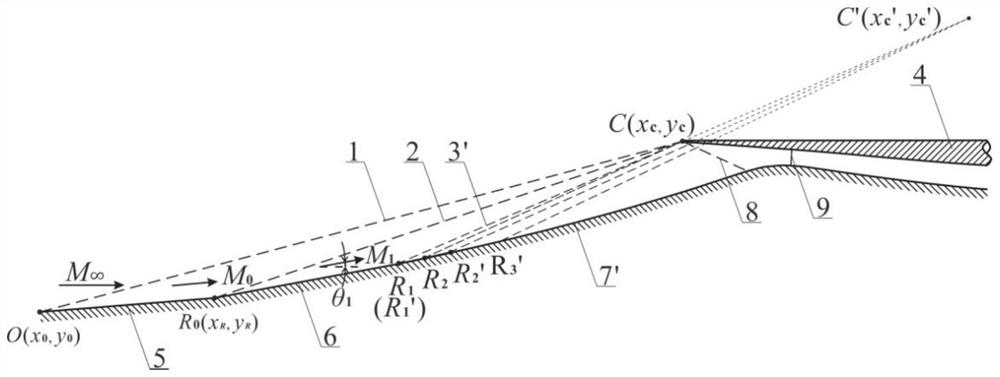

Low External Resistance Hyper/Hypersonic Inlet and Shock/Boundary Layer Interference Control Method

ActiveCN107091158BReduce resistanceStrong control abilityGas turbine plantsEngine controlShock waveInteraction control

The invention provides a low-external-resistance supersonic / hypersonic speed inlet. A two-dimensional bump is arranged at an inlet of the supersonic / hypersonic speed inlet, and partial air discharge seam / hole arrays are arranged at the inward concave positions of the windward side and the leeward side; and meanwhile, an air discharge cavity below the bump is divided into two sub-cavities, and electromagnets and a metal plate with a folded corner are adopted for achieving control over opening and closing of the two air discharge sub-cavities. By means of control over opening and closing of the two air discharge sub-cavities, the low-external-resistance supersonic / hypersonic speed inlet can adapt to shock wave intensity and incidence point position changes brought by inlet working mach number and attitude angle changes, the optimal control ability on boundary layer separation caused by shock wave / boundary layer disturbance of a lip cover is obtained, and the remarkable effects of widening the working range of the low-external-resistance supersonic / hypersonic speed inlet and increasing the total pressure recovery coefficient are achieved. Due to the high flowing control ability of the low-external-resistance supersonic / hypersonic speed inlet, the inlet is allowed to adopt the design of the horizontal lip cover, and therefore the external pneumatic resistance of an aircraft can be effectively reduced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for designing fixed-geometry two-dimensional mixed-compression type supersonic velocity air inlet channel

InactiveCN102748135BSatisfy the starting ability requirementReduce the starting Mach numberTurbine/propulsion air intakesWedge angleInlet channel

The invention discloses a method for designing a fixed-geometry two-dimensional mixed-compression type supersonic velocity air inlet channel. A basic structure of the adopted two-dimensional mixed-compression type air inlet channel comprises an outer pressing section, an inner pressing section, a throat section, an expanding section and a lip. The lip is of a sharp plate structure with a certain wedge angle. When the air inlet channel is designed, designed starting Mach number is improved appropriately, the lip shape is changed, and the starting mach number is effectively reduced to be lower than a requested value through a certain flow on the premise that the flow requirement of the air inlet channel is met. By means of the method, the requirement for starting performance can be met, contraction ratio of the air inlet channel can be increased in design, and accordingly high back pressure resisting capability and low outlet Mach number are obtained in a wide working range to facilitate efficiently combusted organizations in a combustion chamber. Furthermore, small total pressure loss in the working process of the air inlet channel can be achieved through the change of the lip shape. The method for designing the fixed-geometry two-dimensional mixed-compression type supersonic velocity air inlet channel has good actual application value.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

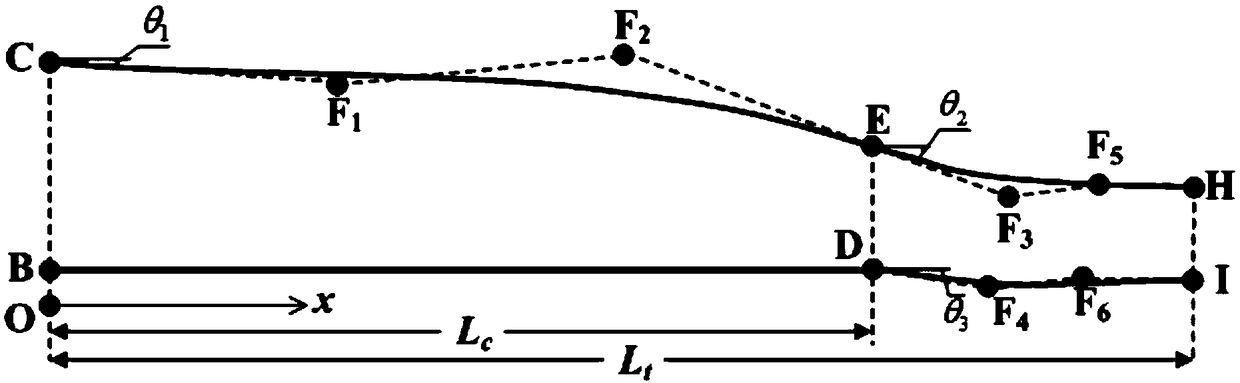

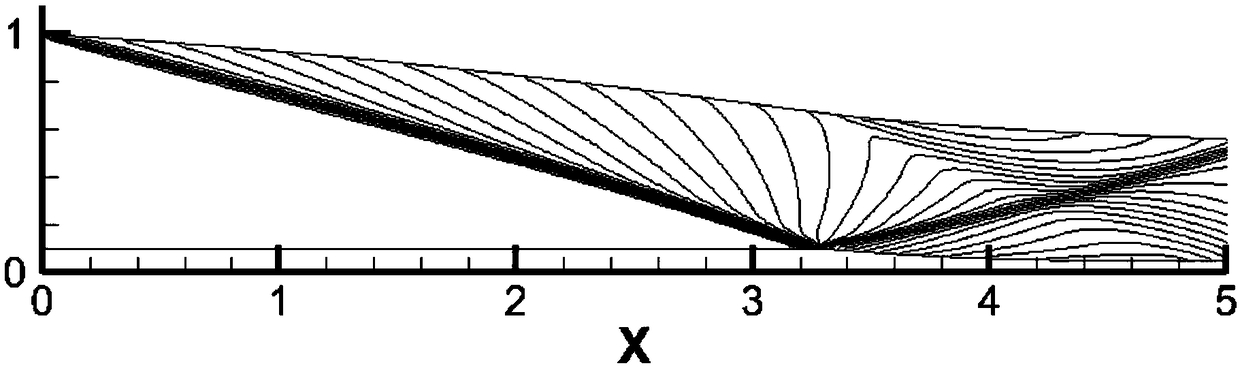

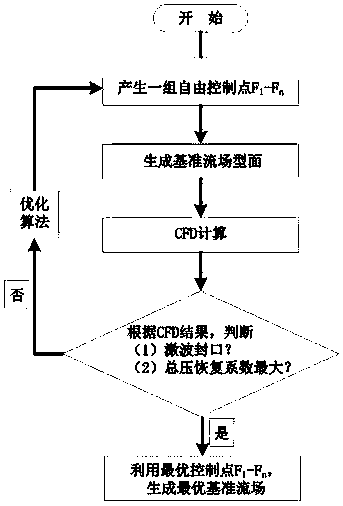

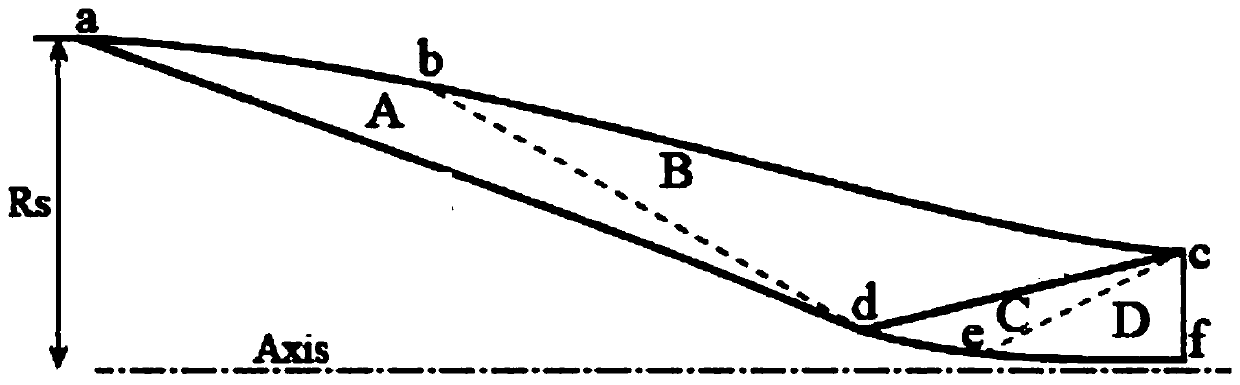

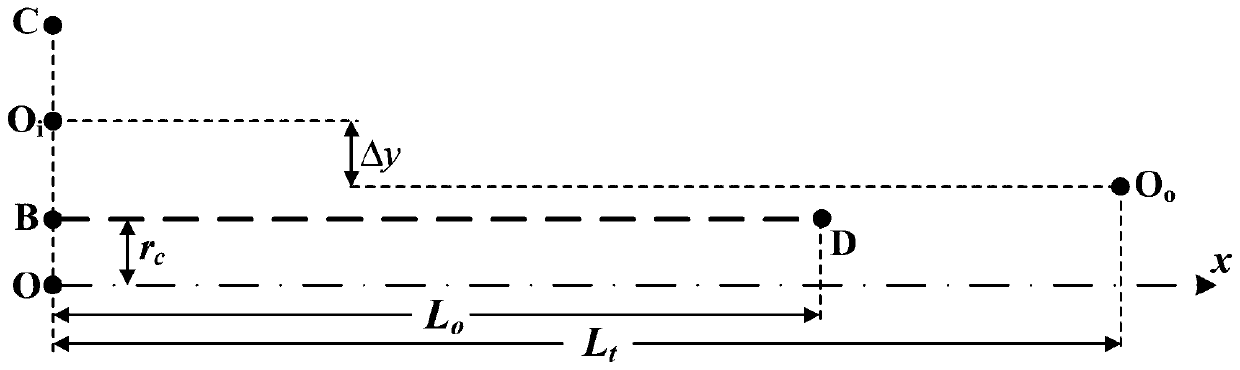

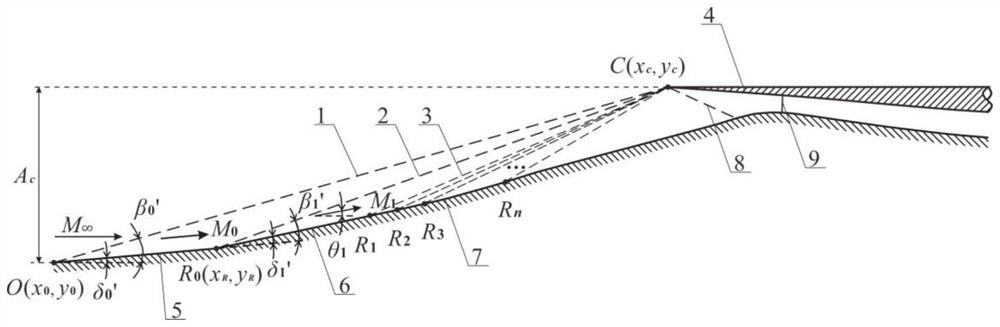

A Design Method for Hypersonic Inlet

ActiveCN108019279BIncrease the total pressure recovery coefficientGeometric CADTurbine/propulsion air intakesShock waveInlet channel

The invention relates to a design method of a hypersonic velocity air inlet channel. The design method comprises the steps of creating a reference flow field profile based on a functional relation; optimally designing axial symmetric reference flow fields of the air inlet channel; and then obtaining a three-dimensional profile of the air inlet channel through a streamline tracking method. Comparedwith the prior art, the method has the advantage that the problem that the design of a traditional air inlet channel is performed by designing inner flow field condition firstly, and the total pressure recovery coefficients of the air inlet channel cannot reach the maximum value while the shock wave sealing of a port is realized, can be solved.

Owner:NAT UNIV OF DEFENSE TECH

A plasma vortex generator-based inward-rotating inlet assembly and control method

ActiveCN110985208BFacilitate momentum mixingImproved resistance to adverse pressure gradientsGas turbine plantsJet propulsion plantsPlasma jetEngineering

The invention discloses a plasma vortex generator-based inward-rotating air inlet component and a control method thereof. The assembly includes a machine body plane and an inward turning air inlet body, wherein one or more sets of arc spark discharge plasma vortex generators are arranged at a certain distance upstream along the compression surface below the machine body plane. This method uses the flow vortex formed by the interaction between the plasma jet and the free flow to promote the momentum exchange between the main flow and the low-energy flow in the boundary layer, enhance the ability of the boundary layer to resist the reverse pressure gradient, and reduce the shock wave / boundary layer induced by the downstream internal compression surface. The interference separation zone has a certain delay or inhibition effect, thereby effectively improving the performance of the intake port. Compared with the traditional method, the control method proposed by the present invention does not require additional air source, no flow loss, no additional resistance, and the control method is accurate and efficient, which has great advantages for the wide speed range and integrated design of the internal rotation air inlet. important promotion.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A subsonic air inlet integrated with aircraft without partition

InactiveCN107215473BIncrease the total pressure recovery coefficientLow Flow Field Distortion IndexPower plant air intake arrangementsFlight vehicleRadar

The invention provides a diverterless subsonic air inlet passage integrated with an aircraft. The diverterless subsonic air inlet passage comprises a lip cover on the basis of electromagnetic stealth and pneumatic consideration and a fully shielded inner pipeline. The shape of an air inlet passage opening surface and a fuselage are in integrated combination designs, and boundary layers at the fronts of inlets can be eliminated by pressure gradients formed by the lip cover and the surface of the fuselage. The lip cover is in sweepback designs in the overlooking and side-looking directions, and sweepback angles are consistent with preset stealth angles of the aircraft. The inner pipeline with an air inlet passage is provided with a selected fully shielded double-S bending type air inlet passage, and the cross sections of outlets of the air inlet passage cannot be seen from optional angles of air inlets. The diverterless subsonic air inlet passage has the advantages that specific bumps, which are protruded on the surfaces of existing fuselages, of conventional diverterless air inlet passages and boundary layer diverters on the existing fuselages can be omitted on the premise that requirements on total pressure recovery coefficients and flow field distortion indexes of the air inlet passage are met, and accordingly pneumatic resistance of the aircraft can be lowered; the radar stealth performance of the air inlet passage can be enhanced under the joint effect of the aircraft, the sweepback lip cover and the fully shielded inner pipeline.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

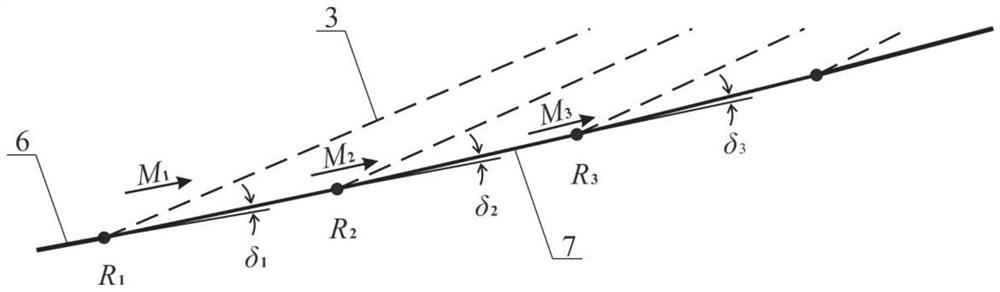

Air inlet wave system configuration method for independent convergence of shock waves and isentropic compression waves

ActiveCN113022861AImprove work efficiencyIncrease the total pressure recovery coefficientGround installationsPower plant air intake arrangementsShock waveInlet channel

The invention provides an air inlet wave system configuration method for independent convergence of shock waves and isentropic compression waves. According to the method, shock waves of a compression surface of an air inlet are all converged at a lip position, and a virtual convergent point of isentropic compression waves behind the shock waves is arranged at the right upper part of the lip of the air inlet, so that the isentropic compression waves and other shock waves of the compression surface of the air inlet are independently converged, and the isentropic compression waves and lip cover shock waves generated by the lip cover of the air inlet form heterogeneous shock wave-isentropic compression wave interference. Compared with a conventional wave distribution mode that all shock waves and isentropic compression waves are converged at the lip position, the method has the advantages that the total pressure recovery coefficient of the throat of the air inlet can be greatly improved, the strength of the shock waves of the lip cover of the air inlet is weakened, the scale of a separation area formed by interference of the shock waves / boundary layers of the lip cover is reduced, and the low Mach number flow coefficient of the air inlet is improved. Especially for an air inlet with strong lip cover shock waves, the technical advantages of the invention are more obvious.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com