Fluid-solid coupled gas shock wave adjusting bearing

A technology of fluid-solid coupling and bearing adjustment, applied in bearings, shafts and bearings, mechanical equipment, etc., can solve problems such as aerodynamic instability, reduced bearing capacity and stability, complex foil structure, etc., to improve total pressure recovery coefficient, improving aerodynamic stability, and broadening the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

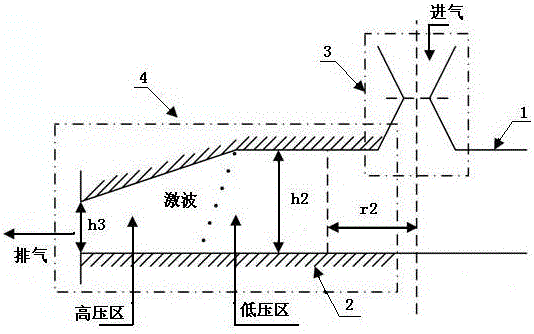

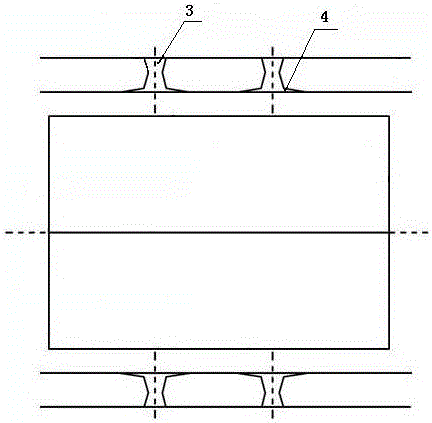

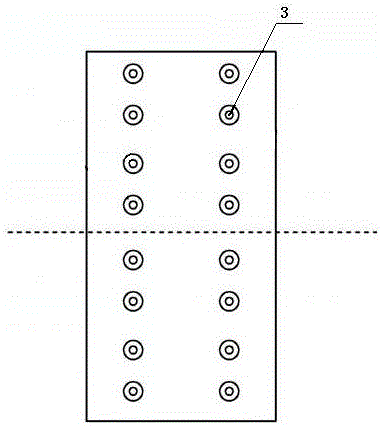

[0027] A fluid-solid coupling type gas shock wave adjusting bearing, which consists of: a bearing bush 1 with an air supply orifice 3, the outlet of the air supply orifice has a damping cavity 4, and the air supply The throttle hole and the structure of the damping cavity are evenly arranged in one row or multiple rows along the circumferential direction on the inner surface of the bearing bush, and a foil structure 7 is arranged between the outlet of the damping cavity and the rotor 2, and the foil structure includes The corrugated foil 6 and the flat foil 5 can be matched with the bearing working conditions of large clearance and large load by changing the bearing air supply pressure, the structure of the orifice and the structure of the damping cavity.

Embodiment 2

[0029] According to the fluid-structure coupling type gas shock wave adjusting bearing described in embodiment 1, the air supply orifice nozzle adopts a zoom-type Laval nozzle structure, and the damping cavity adopts a concave variable section cavity Structure, the air supply orifice directly faces the groove of the bump foil.

Embodiment 3

[0031] According to the fluid-structure coupling type gas shock wave adjusting bearing described in embodiment 1, a foil structure is arranged between the outlet of the damping cavity and the rotor, and the foil structure includes corrugated foils and flat foils. A flat foil is arranged between the cavity outlet and the rotor, and the air supply orifice directly faces the flat foil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com