Aircraft supersonic air inlet channel with variable deflation system

A supersonic air inlet and air release system technology, which is applied to the combustion of the air intake of the power plant, can solve the problems of difficult to effectively deal with the boundary layer air release control, interference, etc., to expand the working envelope range and increase the total pressure Restitution coefficient and discharge coefficient, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

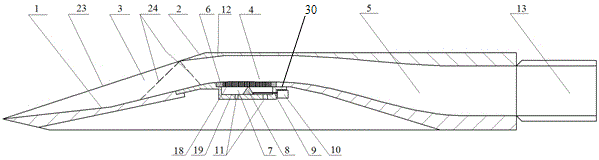

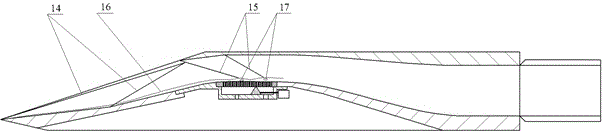

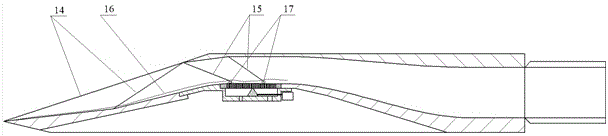

[0014] The precursor compression surface 1 is composed of 2 to 4 stages of compression inclined plates / curved plates, and the upstream part of the inlet throat 4 on the inner surface 12 of the air inlet lip cover 2 is composed of less than three sections of inclined plates, The first-stage slanted plate can be replaced by a curved plate.

[0015] One end of the leading edge edge 23 of the air inlet side plate 3 is connected to the leading edge point of the air inlet lip cover 2, and the other end may be connected to the leading edge point of the air inlet precursor compression surface 1, or It is connected to any point on the edge of the precursor compression surface 1 upstream of the inlet throat 4 , such as any one of the leading edge edges 24 .

[0016] The aircraft supersonic inlet with variable deflation system of the present invention can change the size of each sub-cavity by moving the deflation chamber partition 8 according to the working Mach number and attitude angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com