Base sheet for optical sheet

A technology of optical sheets and substrates, applied in optics, optical components, nonlinear optics, etc., can solve problems such as decreased brightness and uneven brightness of liquid crystal display devices, achieve high total light transmittance, excellent anti-adhesive properties, and promote high The effect of brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

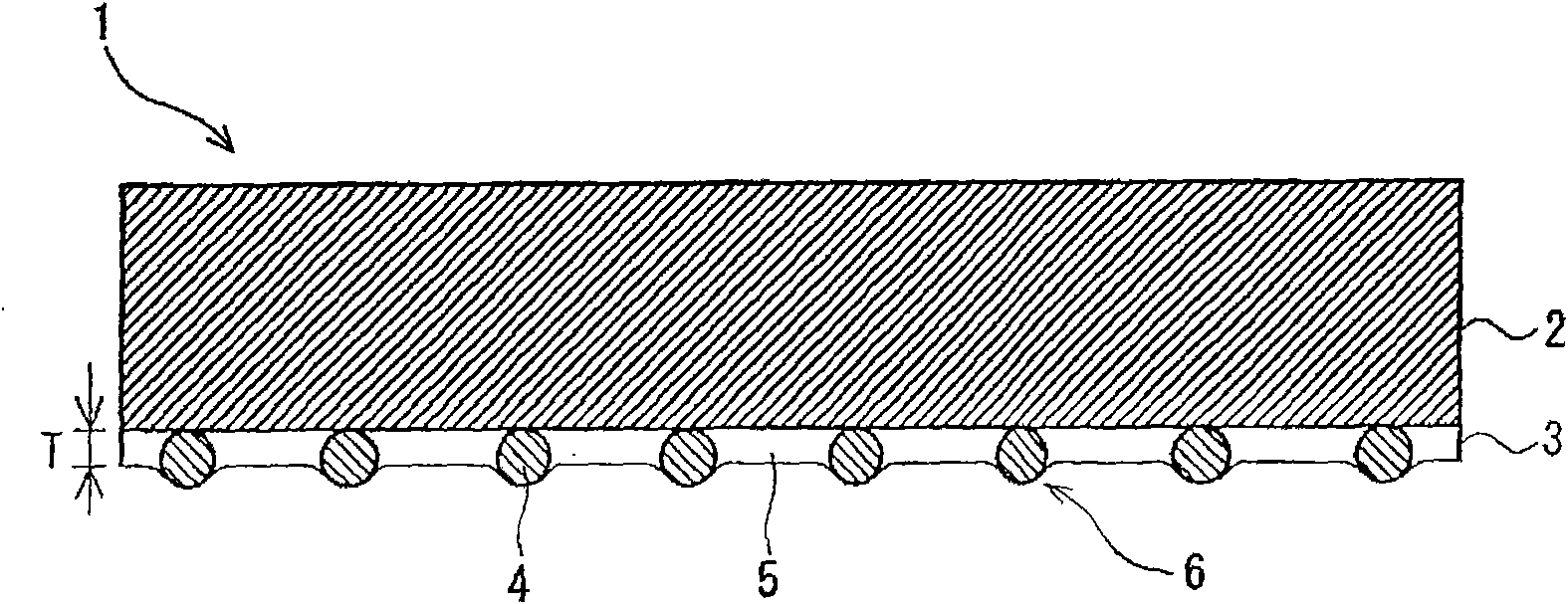

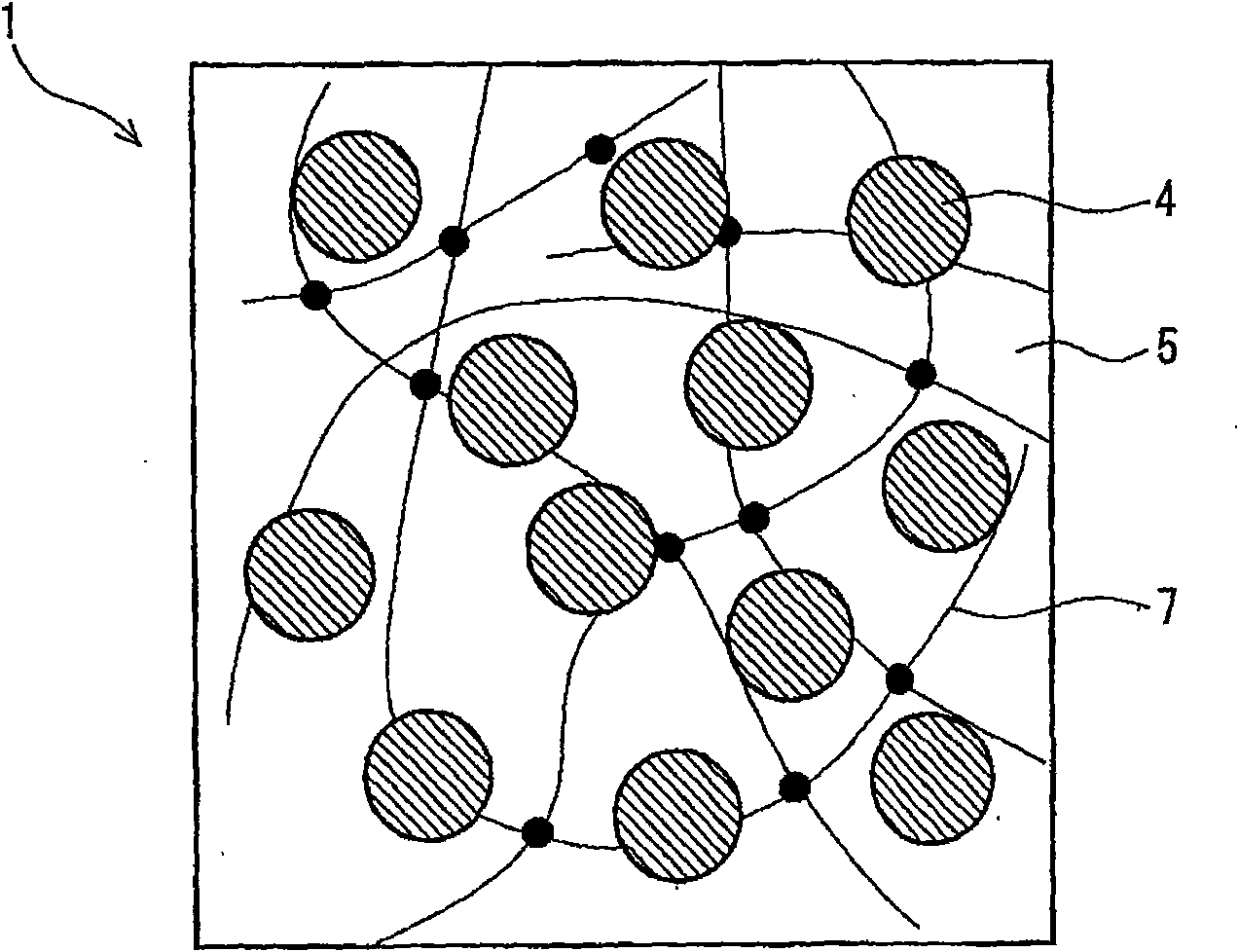

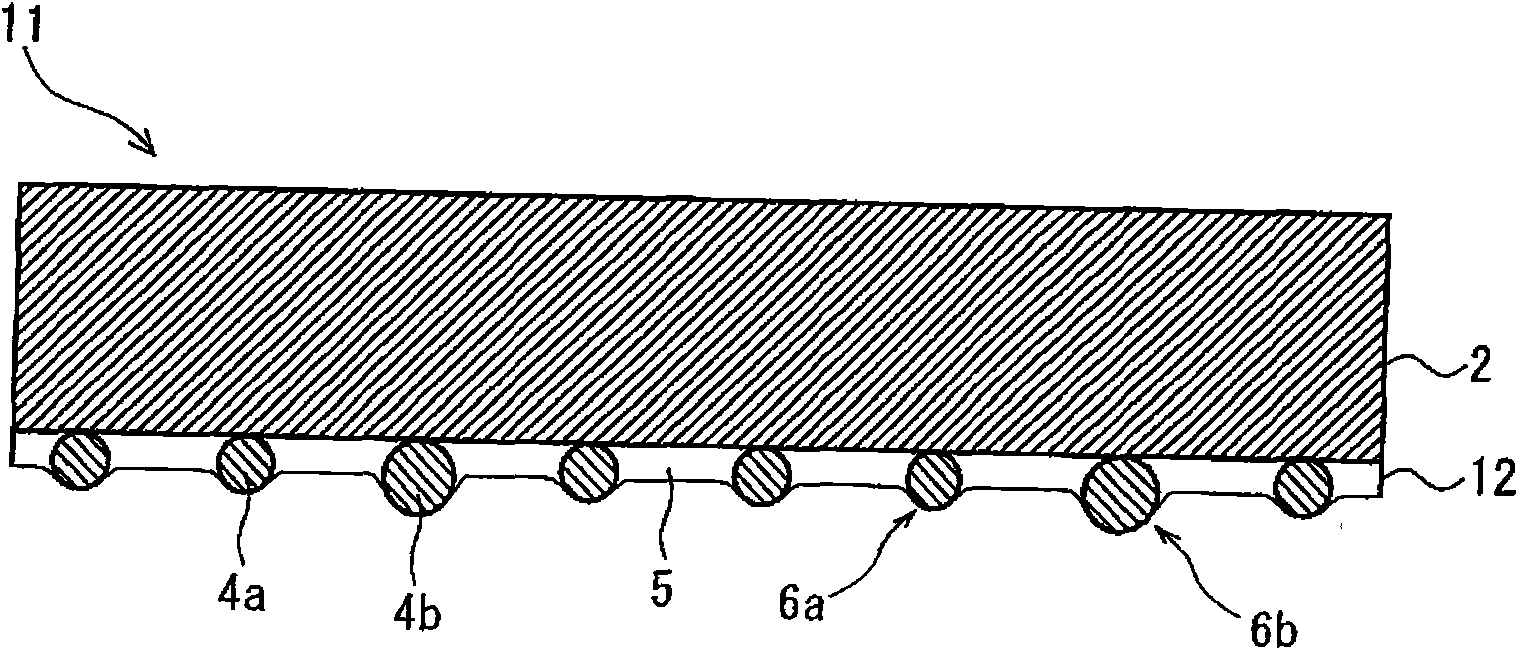

[0104] Polyethylene terephthalate (hereinafter referred to as "PET") is supplied to a T-die and extruded to form a PET film extrusion, which is stretched 3 times along the film length direction . Next, in terms of solid content, 100 parts of polyester polyol ("Vylonal MD1250" manufactured by Toyobo Co., Ltd.), 120 parts of blocked isocyanate ("Elastron H-3" manufactured by Daiichi Kogyo Pharmaceutical Co., Ltd.), and 50 parts of a composition for a release layer of colloidal silicon dioxide having an average particle diameter of 100 nm, which is coated on a PET film extruded body by a roll coating method to form the release layer A laminate of a layer of the layer composition and the extruded PET film. Next, the laminate was stretched 3 times in the film width direction to obtain a substrate sheet for an optical sheet with an average thickness of 188 μm (the average thickness of the release layer is 100 nm). The above steps are carried out continuously on the same production...

Embodiment 2

[0107] The same release layer composition and PET used in Example 1 were supplied to a multi-layer mold and co-extruded to form an extruded body consisting of a release layer composition layer and a PET film. A coextrusion formed of layers. Then, the coextruded product was simultaneously biaxially stretched at a stretching ratio of 3 times in the film length direction and 3 times in the film width direction, thereby obtaining a substrate sheet for an optical sheet with an average thickness of 188 μm ( The average thickness of the release layer is 100 nm). The above steps are carried out continuously on the same production line.

[0108] The base sheet for optical sheets was cut into a 20 cm square, and no interference pattern was generated even if the release layer was overlapped with the acrylic plate, and the release effect was good. Also, the substrate sheet for optical sheets cut out in the above-mentioned manner was superimposed on the acrylic plate in a state where the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com