Resin sheet laminate and process for producing semiconductor light-emitting element using same

A resin sheet and light-emitting element technology, which is applied in semiconductor devices, electrical components, electric solid-state devices, etc., can solve the problems of semiconductor light-emitting elements such as chromatic aberration, difficult weight, uneven thickness, etc., and achieve the effect of simple brightness and uniform color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

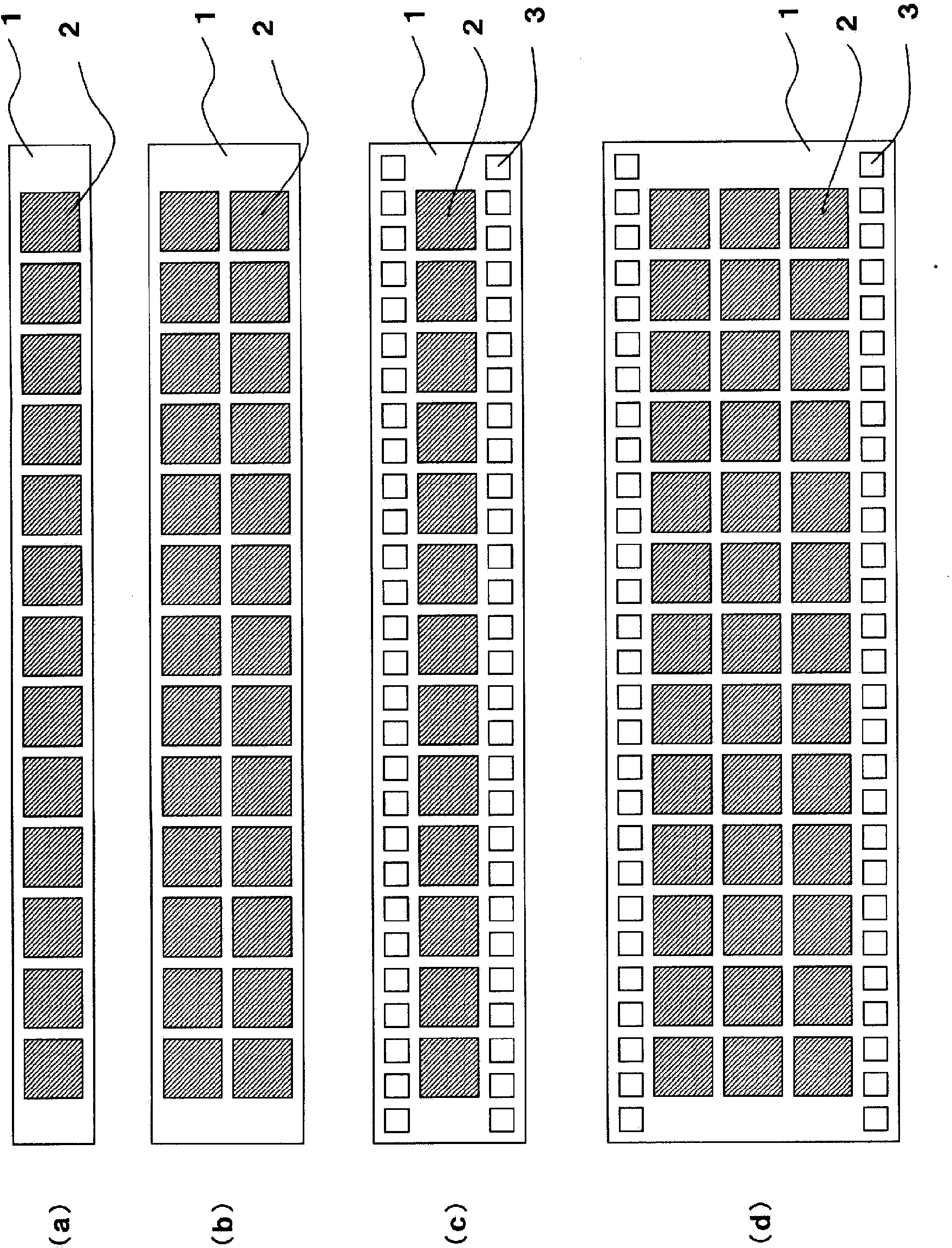

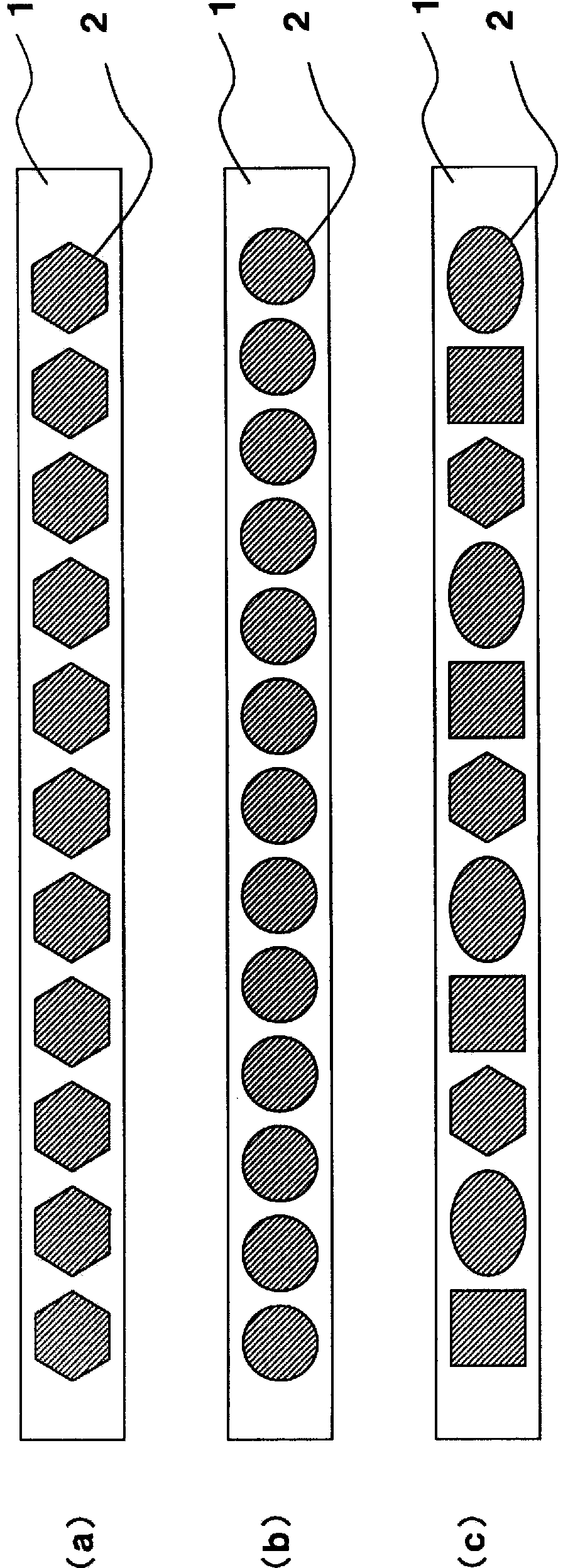

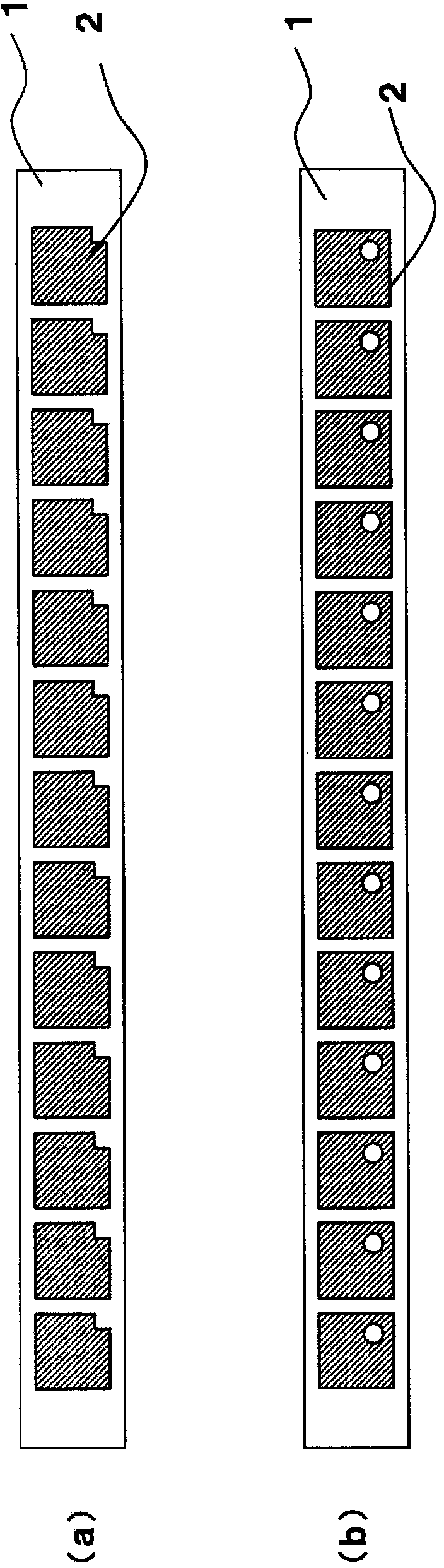

[0032] The resin sheet laminate of the present invention is characterized in that a resin sheet containing a phosphor and a resin is provided on an elongated substrate, and the resin sheets are repeatedly arranged in the longitudinal direction of the elongated substrate. block. Hereinafter, a resin sheet containing a phosphor and a resin is referred to as a "phosphor-containing resin sheet".

[0033] The blocks of the phosphor-containing resin sheet can be arranged in a desired shape, size, and number according to purposes. On the other hand, the base material supporting the blocks of the phosphor-containing resin sheet is integrated within the range of the plurality of blocks of the phosphor-containing resin sheet, and the blocks of the phosphor-containing resin sheet are not scattered separately. status.

[0034] In the resin sheet laminate of the present invention, since the blocks of the resin sheet in which the phosphors are uniformly dispersed are formed in advance wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com