A plasma vortex generator-based inward-rotating inlet assembly and control method

A technology of internally rotating inlets and vortex generators, which is applied in the direction of machines/engines, jet propulsion devices, gas turbine devices, etc., can solve problems such as complex configuration, difficulty in design and production, loss of high-quality flow, etc., and achieve anti- The effect of improved reverse pressure gradient capability, improved performance, and improved total pressure recovery coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention is further described.

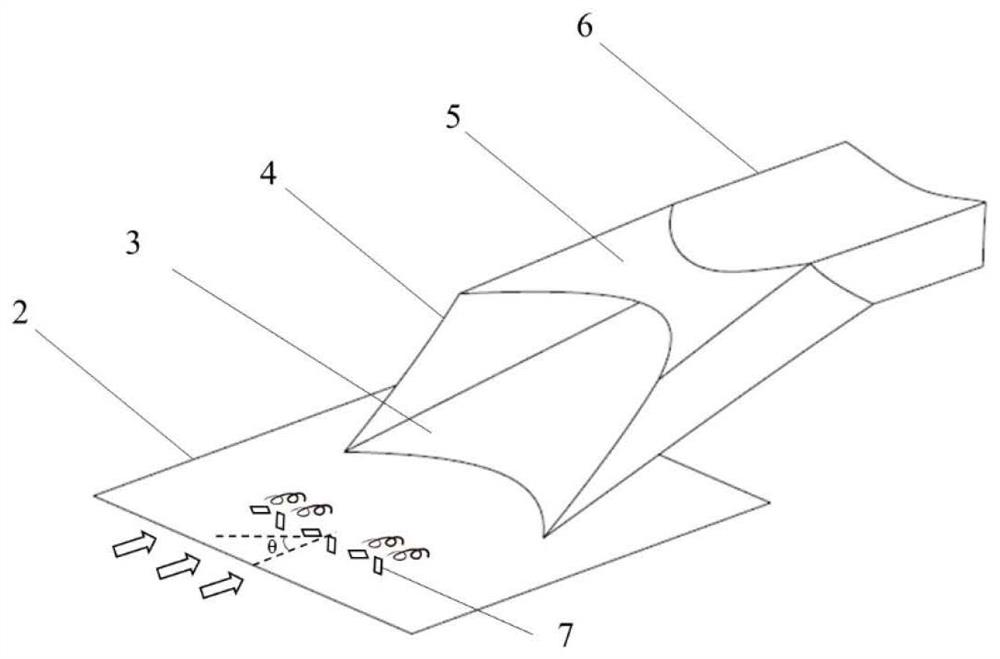

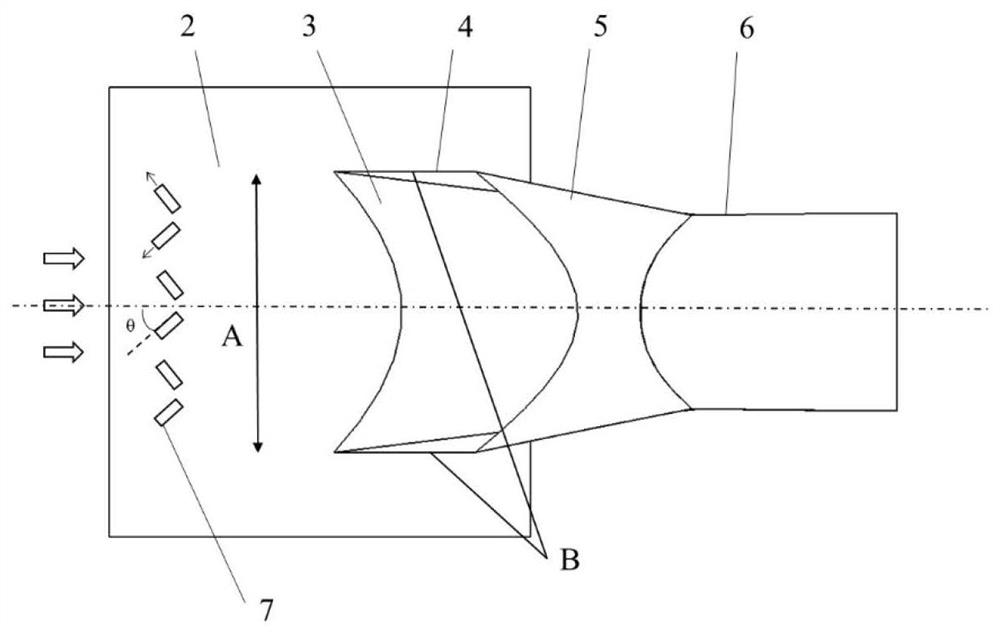

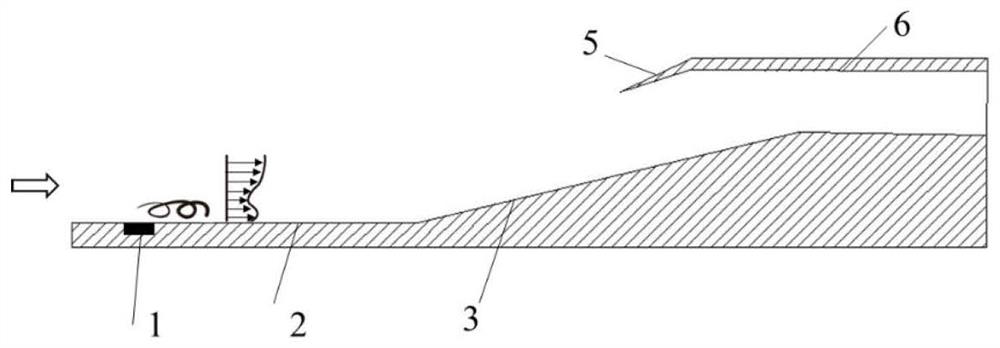

[0021] Such as figure 1 , 2 As shown in , 3, it is an embodiment of an inwardly rotating inlet assembly based on a plasma vortex generator provided by the present invention. The air inlet assembly includes a body plane 2 and an inward turning air inlet installed on the body plane 2 . The inner turning air inlet includes a lip cover 5, side walls 4 located on both sides of the lip cover, and an internal compression surface 3. The lip cover 5, side walls 4 and the surface of the internal flow channel form an internal flow air channel, and the internal flow air An airflow channel 6 is connected to the rear end of the channel. The inner compression surface 3 is a connection compression surface connecting the surface of the inner flow channel and the body plane 2 (inner compression means that the compression surface is formed by inward compression relative to the body plane). Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com