Embedded type air inlet channel using combined opening surface vortex control method

A technology of embedded air inlet and control method, which is applied in the field of embedded air inlet, can solve the problems of increasing structural complexity and occupying space of the machine body, and achieves avoiding adverse aerodynamic effects, reducing distortion index, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

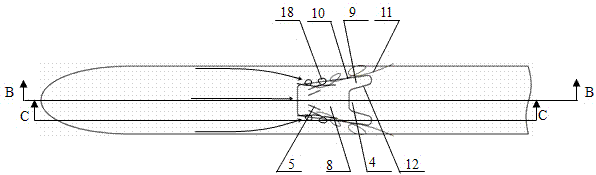

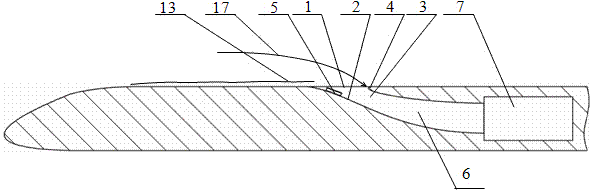

[0013] see Figure 2 to Figure 4 As shown, the present invention discloses a buried air intake adopting a combined oral surface vortex control method, including an air intake inlet 1, a diversion surface 2, a side wall 3, a rear lip 4, and a Some miniature vortex generators 5 on the surface 2, passages 6 in the air inlet. The passage in the air inlet communicates with the turbine engine 7 on the aircraft. The air inlet 1 includes a main inlet 8 located at the front of the entire air inlet 1 and a pair of overflow grooves 9 extending backward from both sides of the rear of the main inlet 8 . The edges 10 on both sides of the inlet 1 of the inlet are expanded, so that the width of the inlet 1 of the inlet gradually increases from front to back, so that a strong main vortex 11 of intake air on the orifice can be generated during intake. . The front end of the rear lip 4 is located between the two overflow grooves 9 and separates the two overflow grooves 9; match. The main in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com