A Design Method for Hypersonic Inlet

A design method and hypersonic technology, which is applied to the intake port of the turbine/propulsion device, calculation, combustion air/combustion-air treatment, etc., can solve the problem of large total pressure recovery coefficient of the intake port, and achieve total pressure recovery The effect of large coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

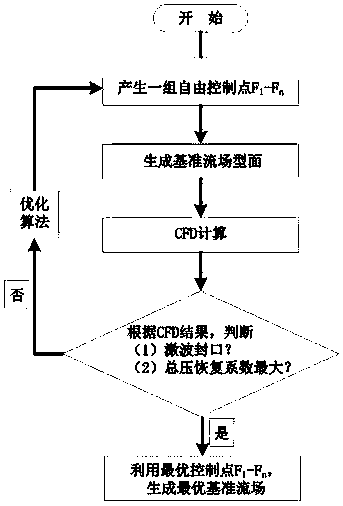

[0061] Embodiments of the present invention include the following steps:

[0062] S1, using the functional relationship to generate the reference flow field profile of the inlet, mainly including:

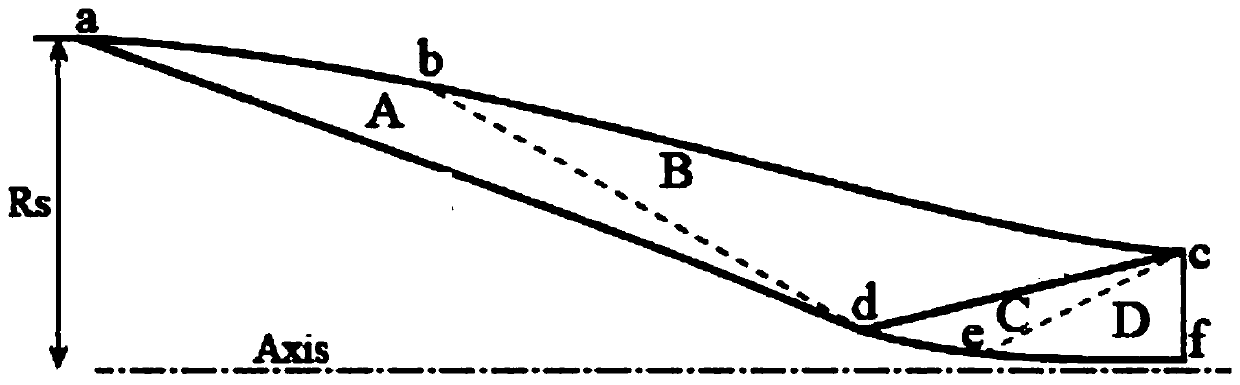

[0063] S101, according to the geometric constraints of the inlet structure design, determine the vertex of the reference flow field surface, the specific method is:

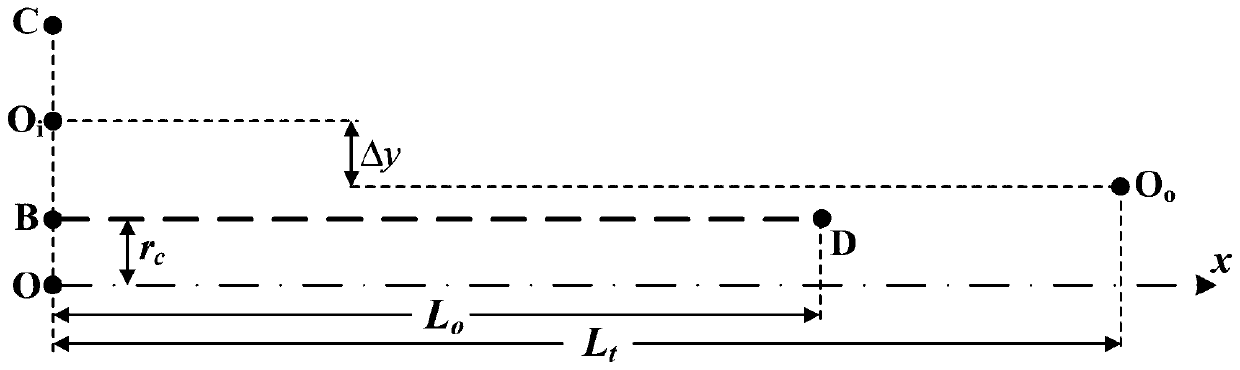

[0064] (1) According to the center body radius rc=0.1, determine the B coordinate (0,0.1) of the lower apex of the inlet inlet, and set the length of OC as unit 1, and determine the coordinate of point C (0,1);

[0065] (2) According to the lip distance from the inlet length Lo = 3.6, determine the inlet lip apex D (3.6, 0.1);

[0066] (3) According to the total length of the inlet channel Lt=5, and the eccentricity between the inlet and outlet is 0.3, determine the outlet center point Oo(5,0.25).

[0067] S102, according to the geometric constraints of the inlet structure design, determine the end point E of the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com