Low External Resistance Hyper/Hypersonic Inlet and Shock/Boundary Layer Interference Control Method

A hypersonic and air inlet technology, which is applied in the direction of engine control, jet propulsion device, gas turbine device, etc., can solve the problems of limited bulge control effect, large additional deflation resistance, and heavy thermal protection burden, etc., to broaden the working range, The effect of increasing the total pressure recovery coefficient and reducing the drag of the aircraft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

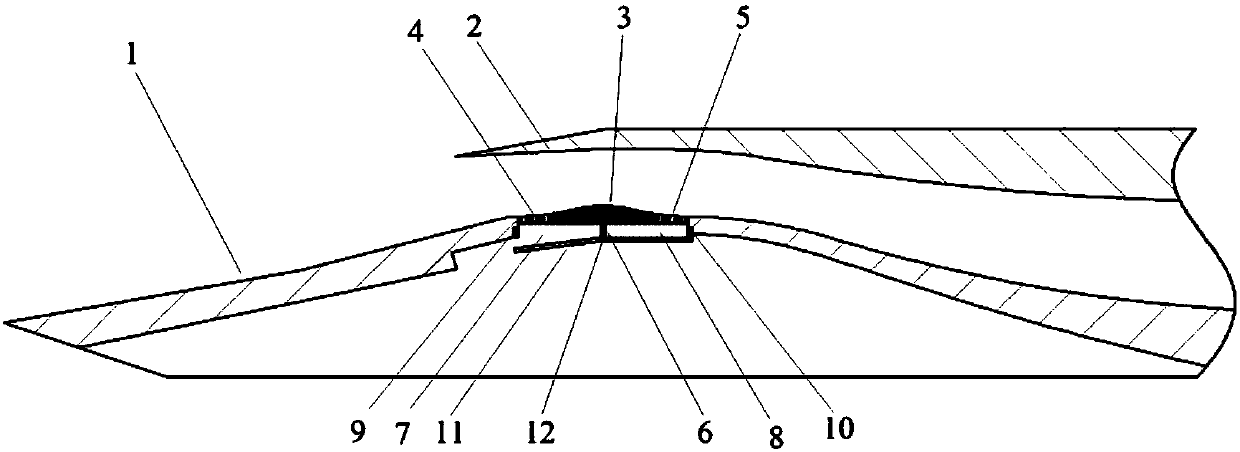

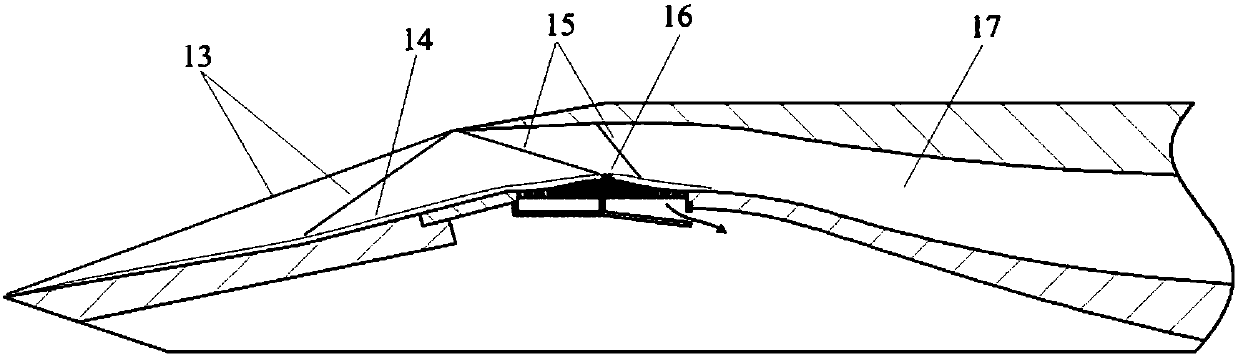

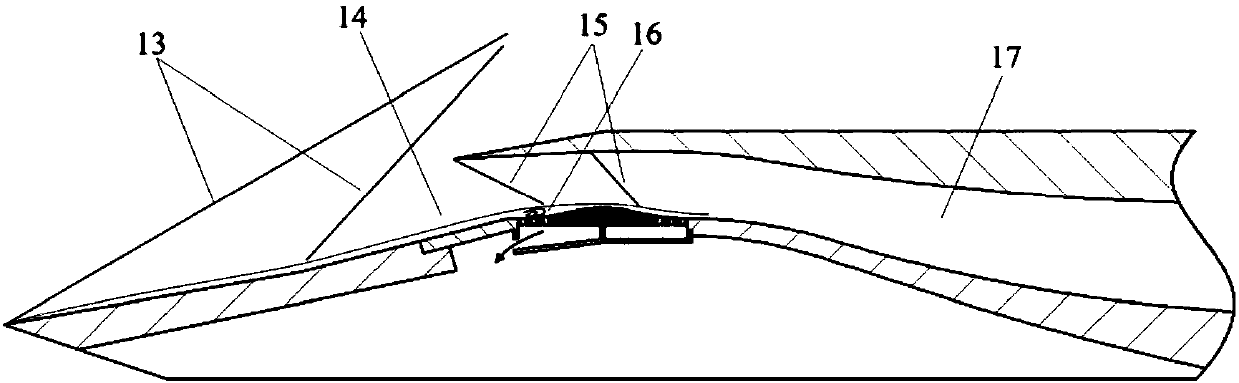

[0021] see figure 1 , the invention discloses a low external resistance super / hypersonic air intake, comprising a precursor compression surface 1, an air intake lip 2, and a two-dimensional protruding into the air intake is arranged on the lower wall surface of the air intake entrance. The wall surface bulge 3, the inner concave section of the two-dimensional wall surface bulge 3 is provided with the front air release slot / hole array 4, and the inner concave section of the two-dimensional wall surface bulge leeward surface is provided with the rear air release slot / hole array 5; The bottom of the two-dimensional wall surface bulge 3 is designed with a deflation cavity and a partition 6 located in the deflation cavity. The downstream deflation sub-cavity 8 below the rear deflation slot / hole array 5, the front wall of the upstream deflation sub-cavity 7 is provided with a front electromagnet 9, and the rear wall of the downstream deflation sub-cavity 8 is provided with a rear el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com