Subsonic aircraft air inlet channel

An air intake and aircraft technology, which is applied to the combustion of the air intake of the power unit, aircraft parts, and power units on the aircraft. Boundary layer, poor performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

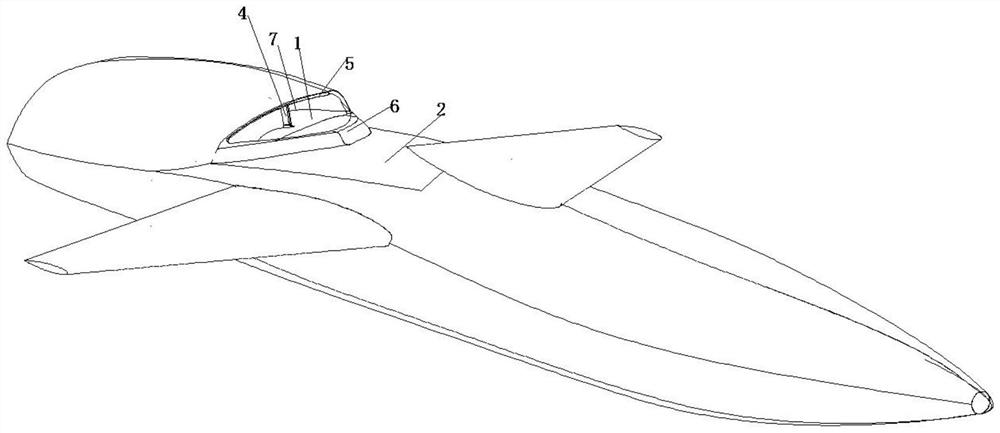

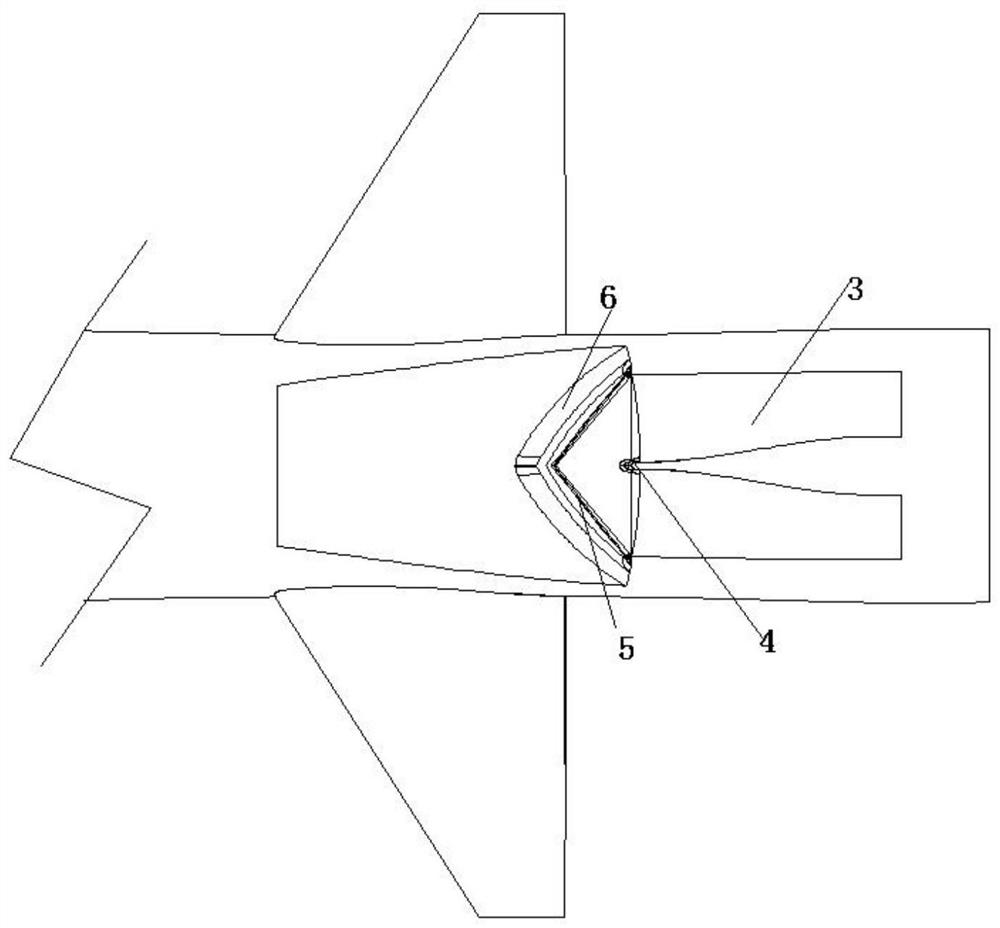

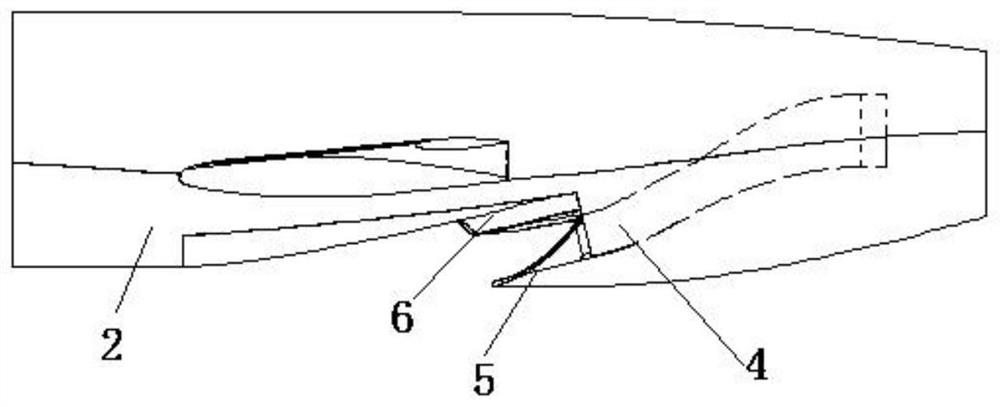

[0018] Such as figure 1 The air inlet of a subsonic aircraft is shown as an air inlet of a subsonic aircraft, including an air inlet surface 1, the bottom of which air inlet surface 1 is connected to a fuselage 2, and integrated with the fuselage 2, The rear end of the air inlet surface 1 is connected to the inner channel 3 of the air inlet, and the internal support of the inner channel 3 of the air inlet is fixed with a cutoff plate 4, and the mouth surface 1 of the air inlet is surrounded by a lip cover 5, and the air inlet The front side of the crossing surface 1 is provided with a quasi-triangular step compression surface 6, the triangular-like step compression surface 6 is fixed on the fuselage 2, and the lip cover 5 is smoothly connected with the fuselage 2 and the triangular-like step compression surface 6.

Embodiment 2

[0020] Such as Figure 1-Figure 4 The air inlet of a subsonic aircraft shown includes an air inlet surface 1, the bottom of the air inlet surface 1 is connected to the fuselage 2, and the shape of the air inlet surface 1 is determined according to the shape of the fuselage 2, And integrated with the fuselage 2, the rear end of the air inlet surface 1 communicates with the inner passage 3 of the air inlet, and the inner passage 3 of the air inlet includes an inner pipe 7 bent and extended toward the inside of the fuselage, and the inner pipe 7. The rear end is connected to the outlet surface 8 of the air inlet, and the front end is connected to the mouth surface 1 of the air inlet. The inner channel 3 of the air inlet is supported and fixed with a cutoff plate 4, and the flow divider 4 not only increases the structure of the inner passage 3 of the air inlet. Intensity, the airflow captured by the inlet surface 1 can also be divided into two streams in the inner channel 2 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com