Low-resistance and high-efficiency subsonic speed air inlet channel

A low-resistance, high-efficiency, air-intake technology, which is applied to the combustion and drag reduction of the air intake of the power unit, can solve the problems of aircraft aerodynamic resistance increase, weight increase and structural complexity, etc., and achieve the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

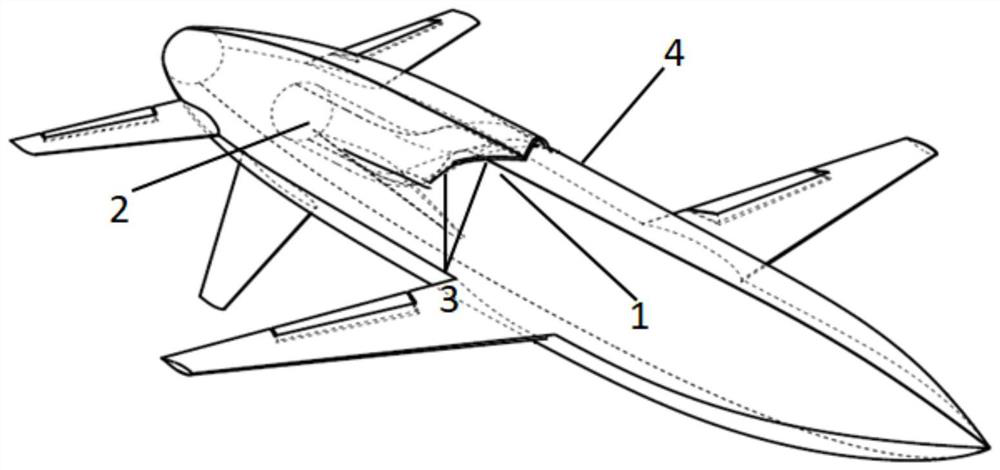

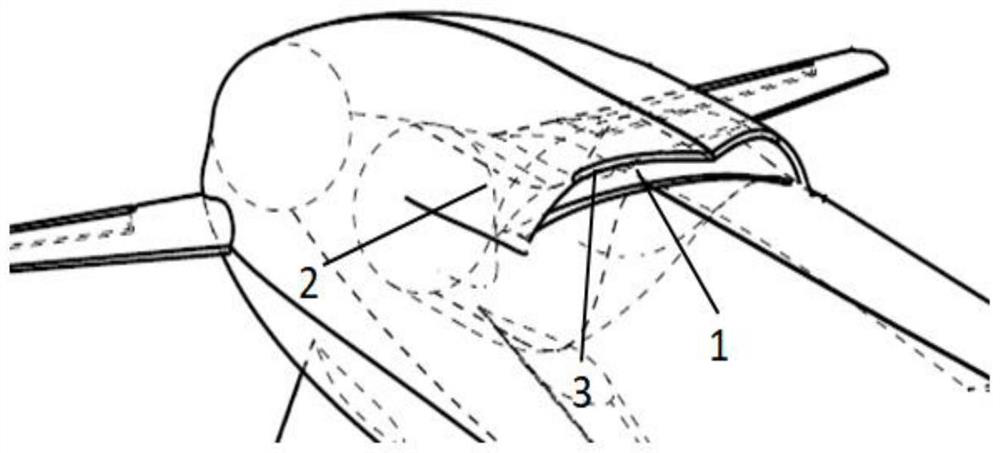

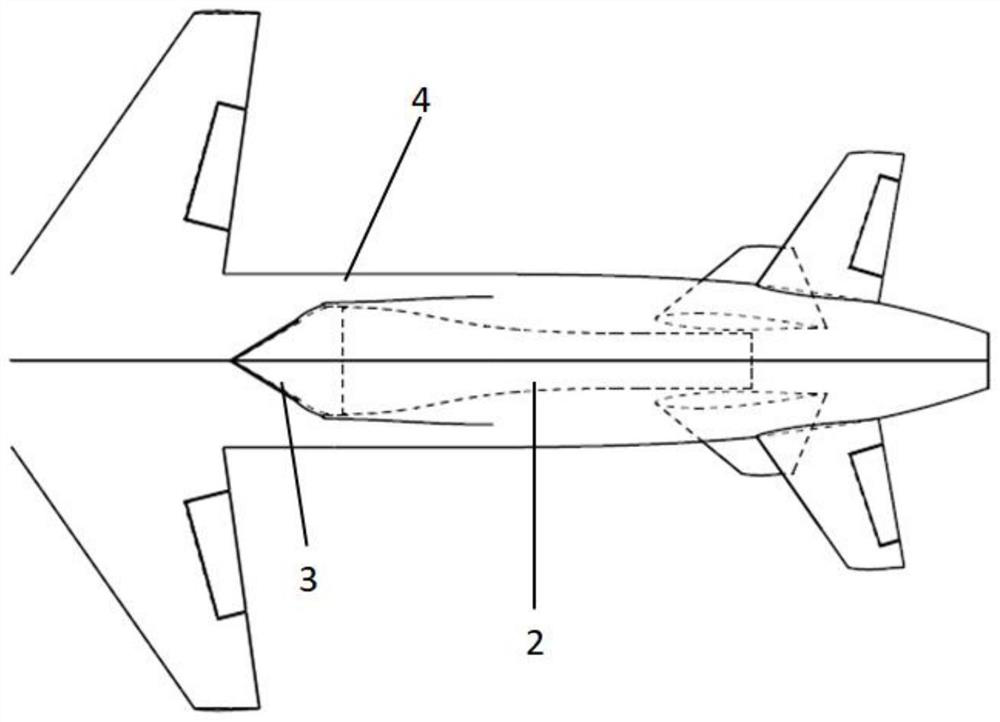

[0018] like Figure 1-Figure 4 A low-resistance and high-efficiency subsonic intake port is shown, the intake port face 1 at the front end of the intake port, the intake port inner channel 2 extending backward from the intake port port face 1, surrounding the intake port port face 1. The intake port lip cover 3 is the fuselage 4 connected with the intake port port face 1 and the intake port lip cover 3 . The shape of the air inlet surface 1 is determined according to the shape of the fuselage 4 , and it is required to achieve the effect of integration and fusion with the fuselage 4 . The inner passage 2 of the air intake duct includes an inner pipe which is bent backward from the inlet surface 1 of the air intake duct and extends toward the interior of the fuselage, and the rear end of the inner passage 2 of the air intake duct is the outlet surface of the air intake duct.

[0019] Among them, the lip cover 3 surrounds the air inlet surface 1 and is smoothly connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com