Side plate with overflow gap binary hypersonic air inlet channel

An air inlet and supersonic technology, which is applied to the air inlet of the turbine/propulsion device, engine components, combustion air/combustion-air processing, etc. Flow coefficient, improve performance, improve the effect of flow field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

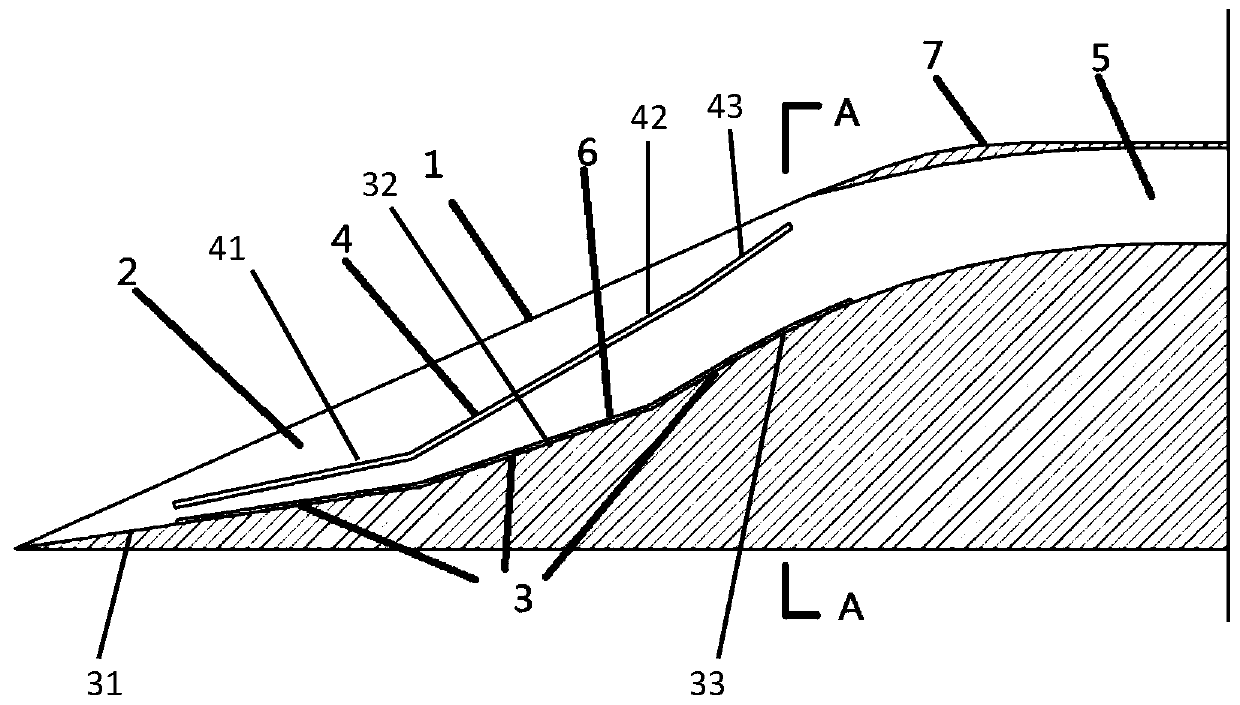

[0030] Next, the present invention will be further described in conjunction with the accompanying drawings.

[0031] Such as figure 1 As shown, a side plate supersonic binary inlet, including two symmetrical side plates 2, compression surface 3, lip cover 7; the inner channel is formed between the side plate 2, lip cover 7 and compression surface 3 5. The side plate 2 includes a front edge 1 of the front edge of the side plate 2, one end of the front edge 1 is connected to the front edge of the lip cover 7, and the other end is connected to any point on the front edge of the compression surface 3. connected. In the case of the present invention, preferably, the two ends of the front edge 1 are respectively tangent to the front edge of the compression surface 3 and connected to the front edge of the lip cover 7 .

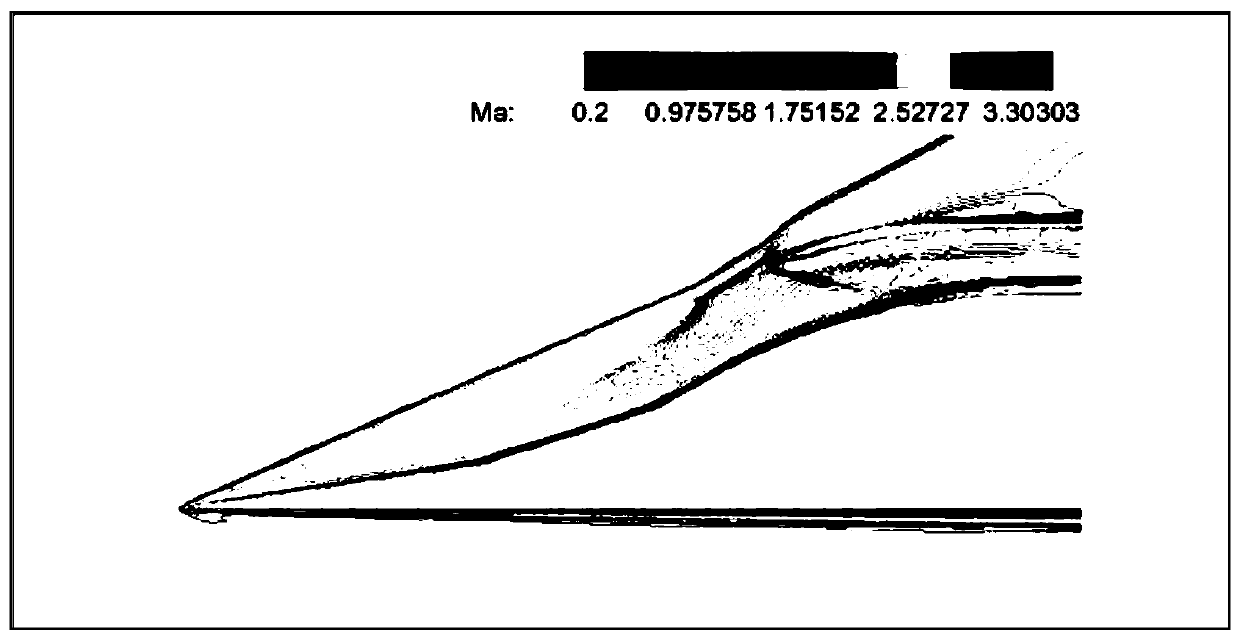

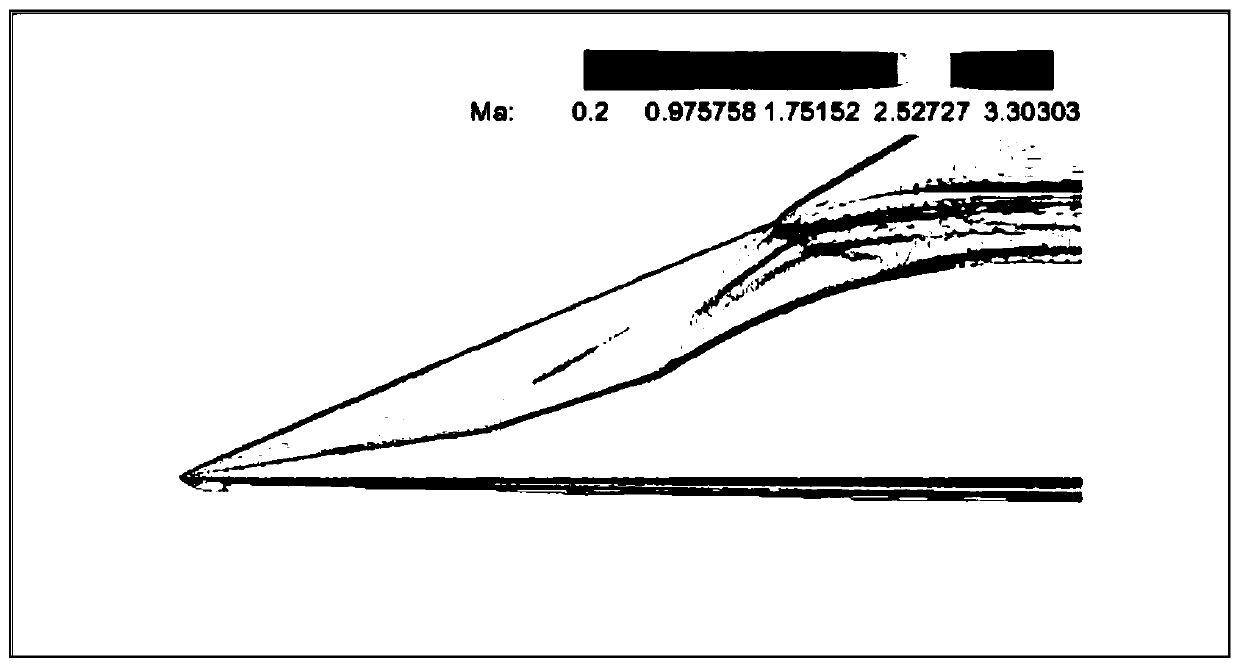

[0032] In order to weaken the influence of the supersonic binary inlet corner area and the side wall surface boundary layer on the flow field in the inlet, improv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com