Boundary-layer-free separation air inlet channel

A technology of air inlet and boundary layer, which is applied in the field of aviation air inlet, can solve problems such as the decrease of radar stealth performance, the difficulty of manufacturing air inlet, and the increase of aircraft aerodynamic resistance, so as to eliminate the effect of angle emitter and improve the stealth effect , Reduce the effect of windward area and drag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

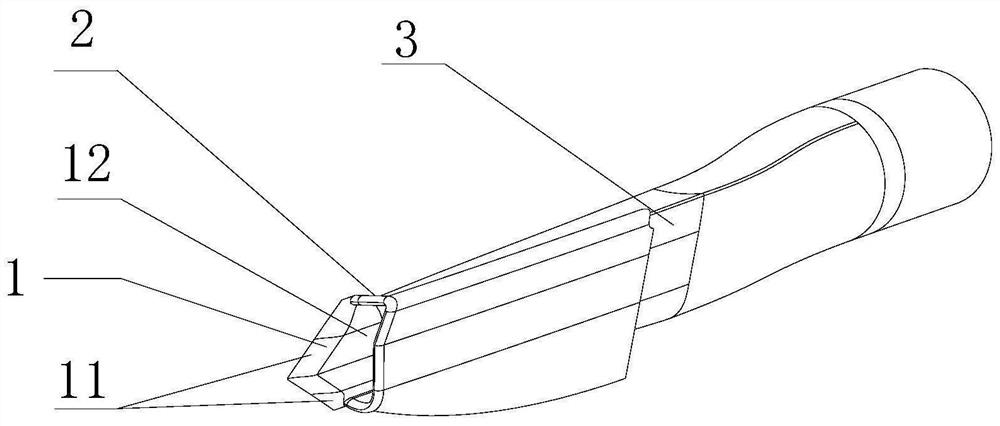

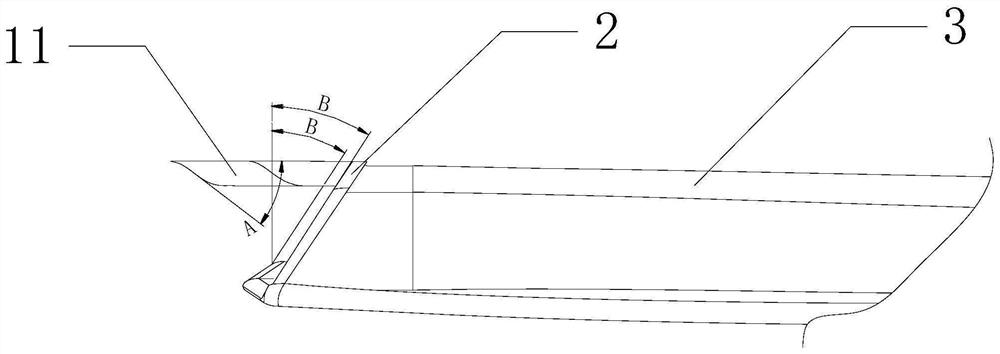

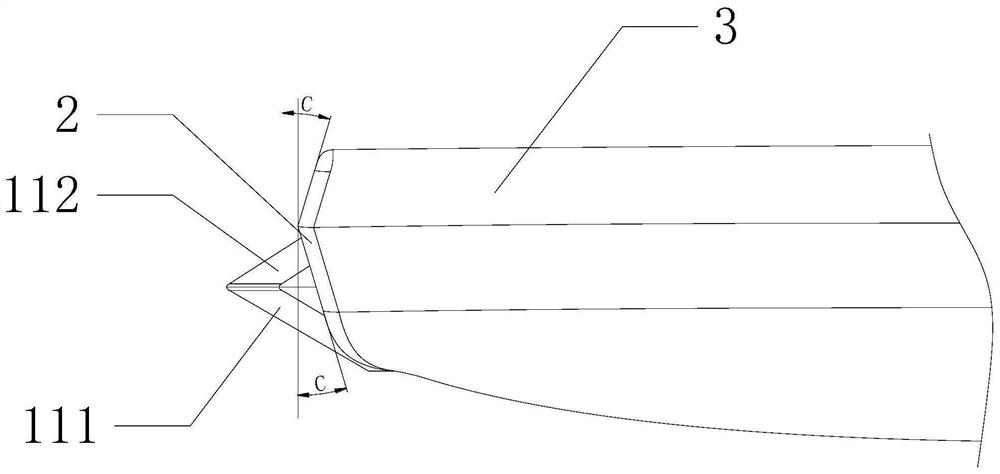

[0023] like Figure 1-3 As shown, an air inlet without a boundary layer, including an air inlet pipe 3, a lip 2 and a bulge 1, which are sequentially formed as one, and the bulge 1 includes a step surface 11 and a main surface 12 of the bulge formed integrally with each other. , the stepped surface 11 includes an upper stepped surface 112 and a lower stepped surface 111, and the edge of the lip 2 is provided with a sweep angle.

[0024] Wherein, the upper stepped surface 112 and the lower stepped surface 111 are both planes. The included angles between the upper step surface 112 , the lower step surface 111 and the heading are all A, and A is preferably 30°-45°.

[0025] The main surface of the bulge 1 is parallel to the course, and the connection between the main surface 12 of the bulge 12 and the step surface 11 is rounded.

[0026] The height of the main surface 12 of the bulge is 40mm.

[0027] The sweep angle includes a top view sweep angle B and a front view sweep ang...

Embodiment 2

[0030] like Figure 1-3 As shown, an air inlet without a boundary layer, including an air inlet pipe 3, a lip 2 and a bulge 1, which are sequentially formed as one, and the bulge 1 includes a step surface 11 and a main surface 12 of the bulge formed integrally with each other. , the stepped surface 11 includes an upper stepped surface 112 and a lower stepped surface 111, and the edge of the lip 2 is provided with a sweep angle.

[0031] Wherein, the upper step surface 112 and the lower step surface 111 are both planes, and the included angles between the upper step surface 112, the lower step surface 111 and the heading are A, A is preferably 33°, and there is The rounding of R10 or other curves transition smoothly, and there is rounding of R10 between the body and the intersection of the upper step surface 112 and the lower step surface 111. The height of the main surface 12 of the bulge is 40mm, and the bulge The main face 12 is parallel to the heading.

[0032] The sweep ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com