Supersonic flow channel design method and apparatus

A supersonic flow and design method technology, applied in design optimization/simulation, turbine/propulsion device inlet, calculation, etc., can solve the problem that the aerodynamic performance of the inlet is difficult to control the total/internal contraction ratio of the inlet, etc. Achieve the effect of adjustable and controllable geometric parameters and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

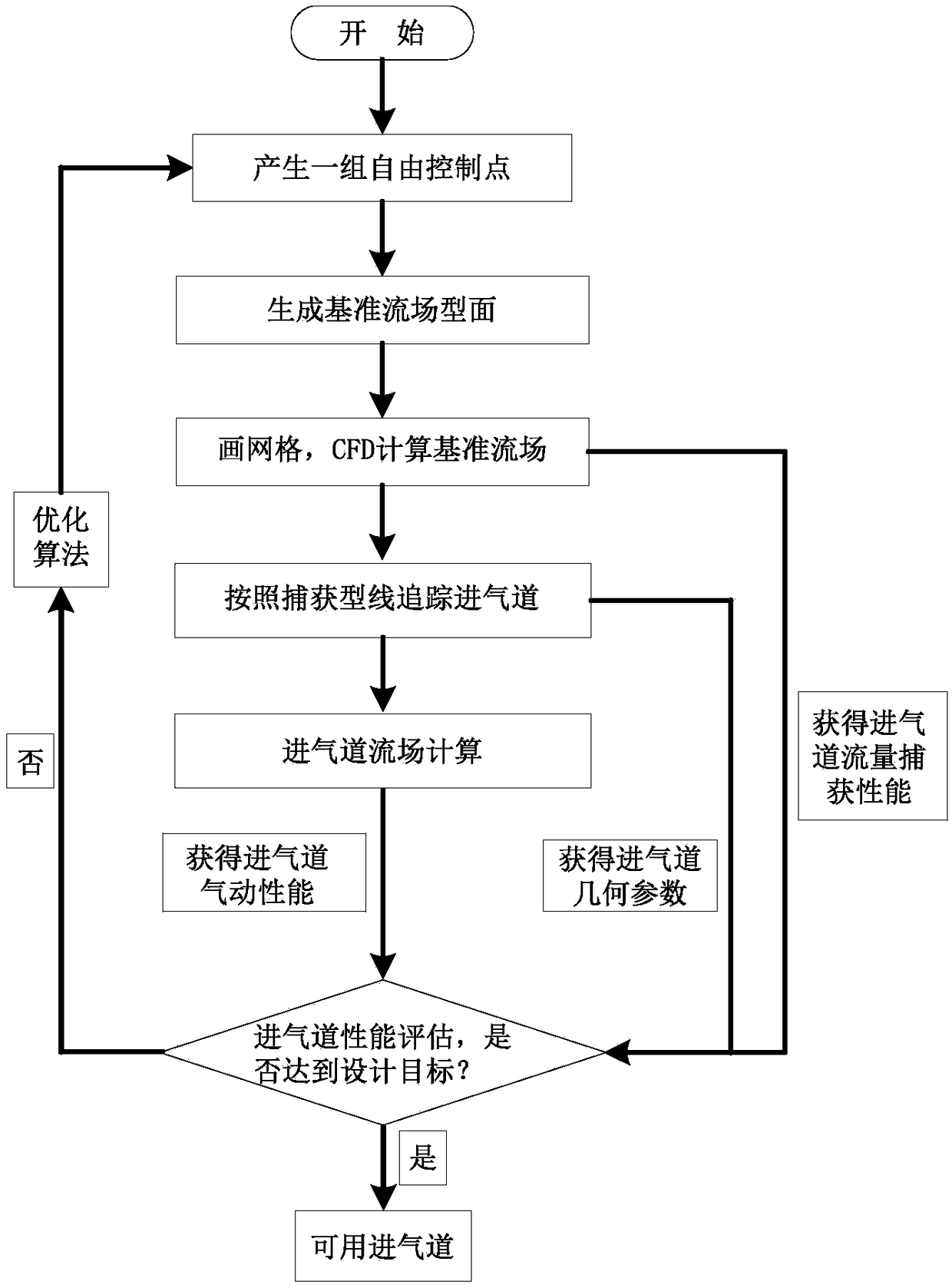

[0037] refer to figure 1 , an embodiment of the present invention provides a hypersonic inlet design method, including the following steps:

[0038] Step S1, according to the preset control parameters, a group of free control points is generated by parameterization method, and the control points are connected by spline curves to generate a reference flow field profile; the preset control parameters include the design condition of the inlet port as Mach number, Pressure, temperature, shrinkage ratio inside the inlet, total shrinkage ratio of the inlet, etc.;

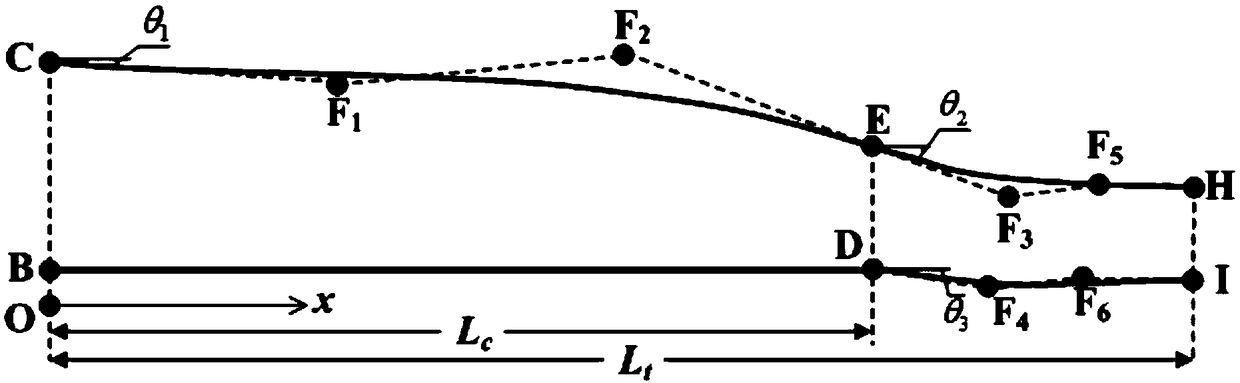

[0039] Step S11, obtaining the wall profile of the reference flow field according to a part of the preset control parameters;

[0040] Step S12, obtaining the coordinates of free control points F1, F2, F3, F4, F5, and F6 according to the preset control parameters described in another part;

[0041] Below in conjunction with concrete design parameter, provide an embodiment:

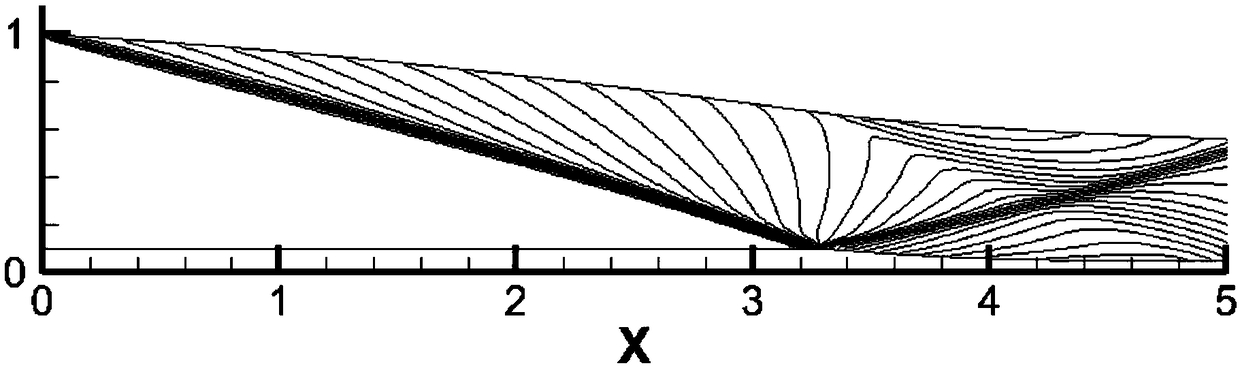

[0042] According to the overall requirements...

Embodiment 2

[0087] see Figure 7 , an embodiment of the present invention provides a hypersonic inlet design device, including: a reference flow field profile generation module 1, a reference flow field calculation module 2, a streamline tracking module 3, a flow field calculation module 4, and an optimization module 5; in:

[0088] The reference flow field profile generation module 1 is used to generate a group of free control points through a parameterization method according to preset control parameters, and connect the control points with spline curves to generate a reference flow field profile;

[0089] The reference flow field calculation module 2 is used to draw a grid for the reference flow profile obtained by the reference flow profile generation module 1, calculate the reference flow field profile by computational fluid dynamics method to obtain a reference flow field, according to the The flow capture performance parameters of the inlet are obtained from the reference flow fie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com