Half split hierarchical S-shaped air inlet channel design method

A design method, a technology for air intakes, applied in turbine/propulsion inlets, calculations, combustion air/combustion-air processing, etc., which can solve the uncertainty and limitations of design results, and cannot effectively establish Problems such as dynamic correlation of large curvature S-shaped intake port, unfavorable pressure gradient, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The design method of the "half-layered" S-shaped inlet of the present invention, the specific embodiment is based on the condition that the Mach number is 0.85 at an altitude of 11000m, and the present invention will be further described in conjunction with the accompanying drawings.

[0021] (1) Obtain the design parameters, as shown in Table 1 below. The throat area can be determined by the flow formula. In order to maximize the intake of the boundary layer, the inlet of the S-shaped inlet is composed of upper and lower ellipses, and the shape of the inlet is determined;

[0022] Table 1 Design parameters of the inlet port

[0023]

[0024] (2) Obtain the basic geometric parameters of the inlet, as shown in Table 2 below, and the outlet can be determined according to the circular section of the outlet and the area of the outlet;

[0025] Table 2 Basic geometric parameters of the inlet

[0026]

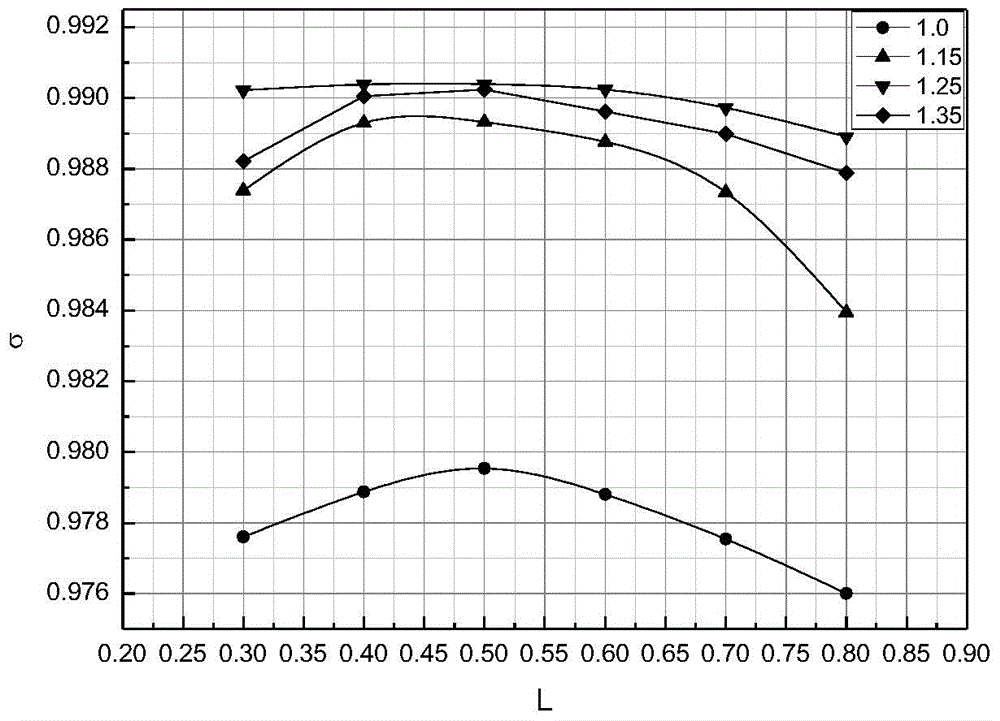

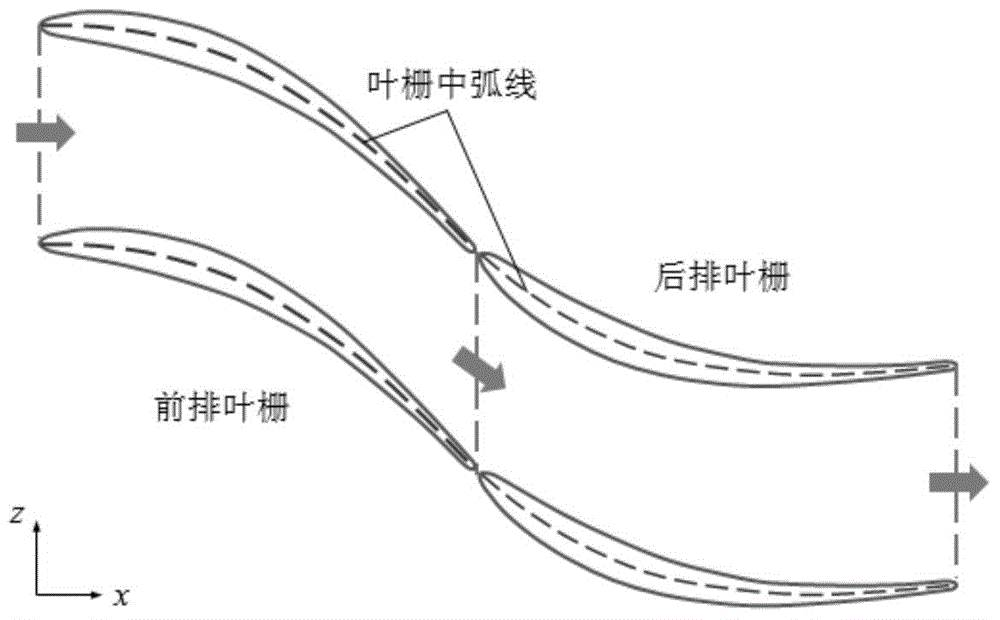

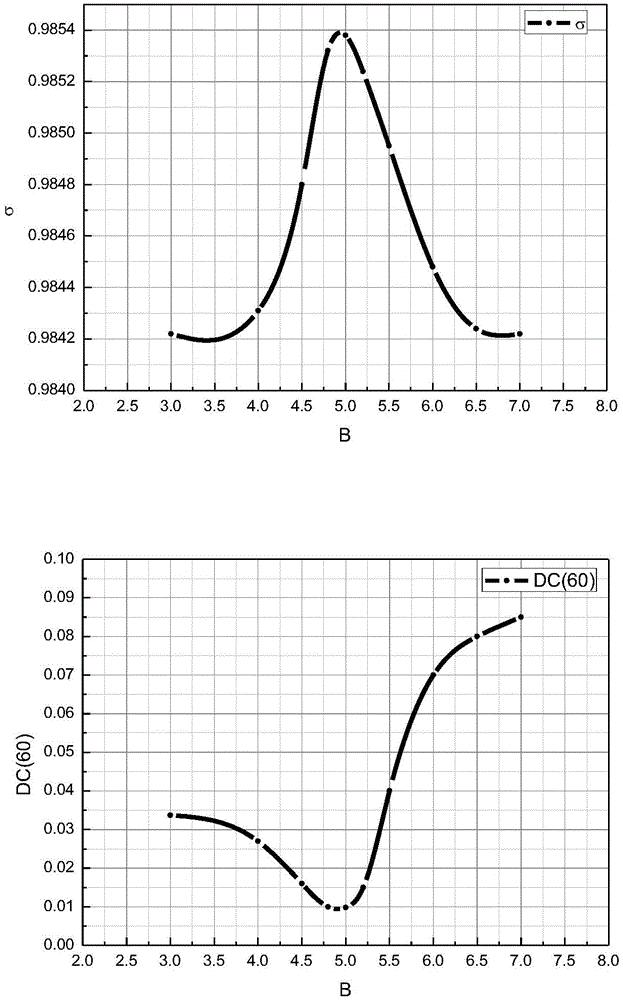

[0027] (3) Referring to the arc design of the two rows of stator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com