Lower-jaw type supersonic/hypersonic inlet integrated with forebody and design method of lower-jaw type supersonic/hypersonic inlet

A hypersonic, air inlet technology, which is applied in the combustion of the air inlet of the power unit, the arrangement/installation of the power unit, and aircraft parts, etc. It is not high, the form is too simple, etc., to achieve the effect of improving flow capture capability and total pressure recovery capability, improving flow capture capability, and increasing utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

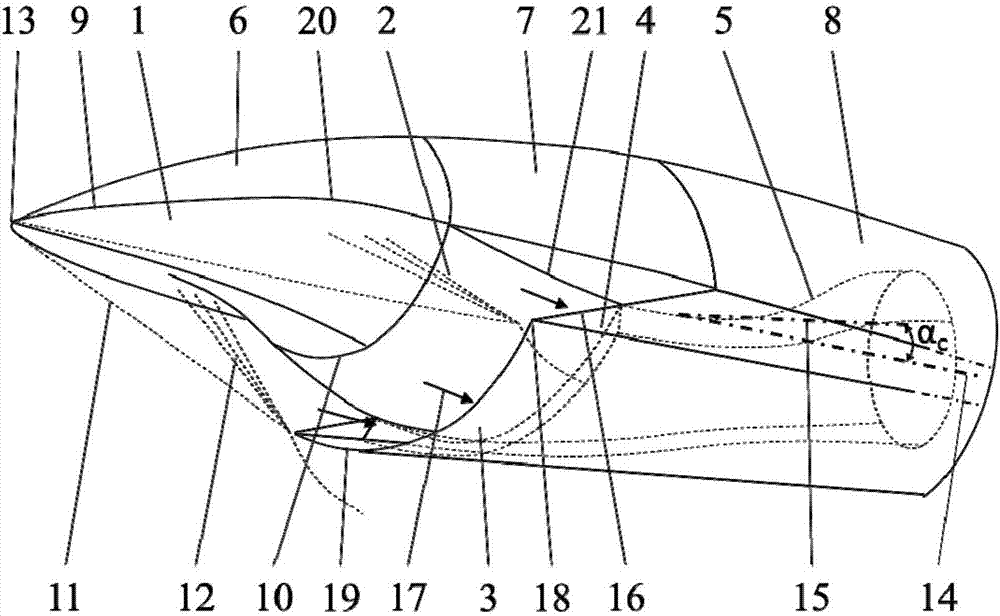

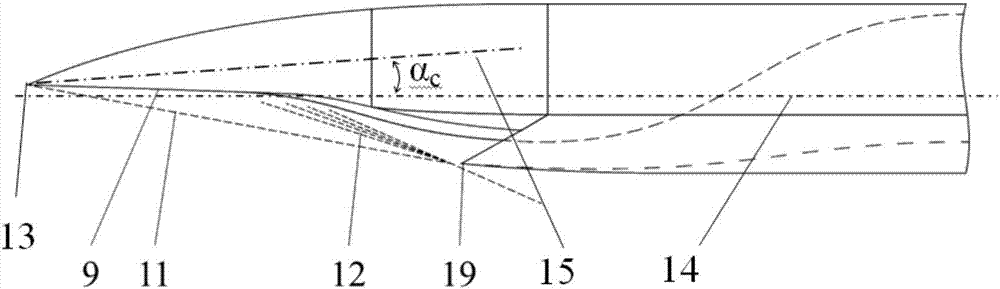

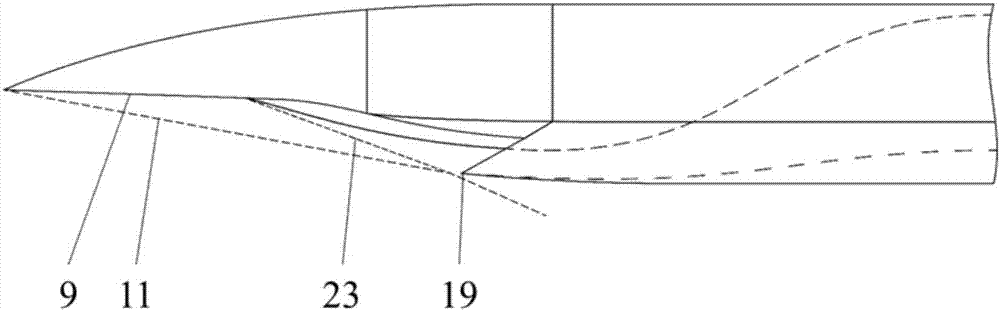

[0023] see Figure 1 to Figure 3 As shown, the mandibular supersonic or hypersonic air inlet integrated with the precursor of the present invention includes the upper surface 6 of the aircraft precursor head, the precursor head transition surface 7 connecting the rear side of the upper surface 6 of the aircraft precursor head 1. Connect the aircraft fuselage surface 8 on the rear side of the transitional surface 7 of the front body head; the local waveriding compression surface 1 located below the upper surface of the aircraft precursor head, the rotation into axisymmetric compression connected to the rear side of the local waveriding compression surface Surface 2, the axisymmetric lip cover 3 that revolves around the axisymmetric compression surface, the swept side plate 4 that is located on both sides of the axisymmetric lip cover 3 and connected to the aircraft fuselage profile 8, and is located on the aircraft fuselage profile 8. The inner ring-shaped curved expansion pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com