Contrarotating rotary spraying engine

An engine and counter-rotating shaft technology, which is used in machines/engines, mechanical equipment, jet propulsion devices, etc., can solve the problems of bad working environment of flame tube and turbine, low air compression efficiency, and inability to realize regenerative cycle, and achieve continuous fuel combustion. The effect of cleaning and thoroughness, improving the compression efficiency, and reducing the dependence of the atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

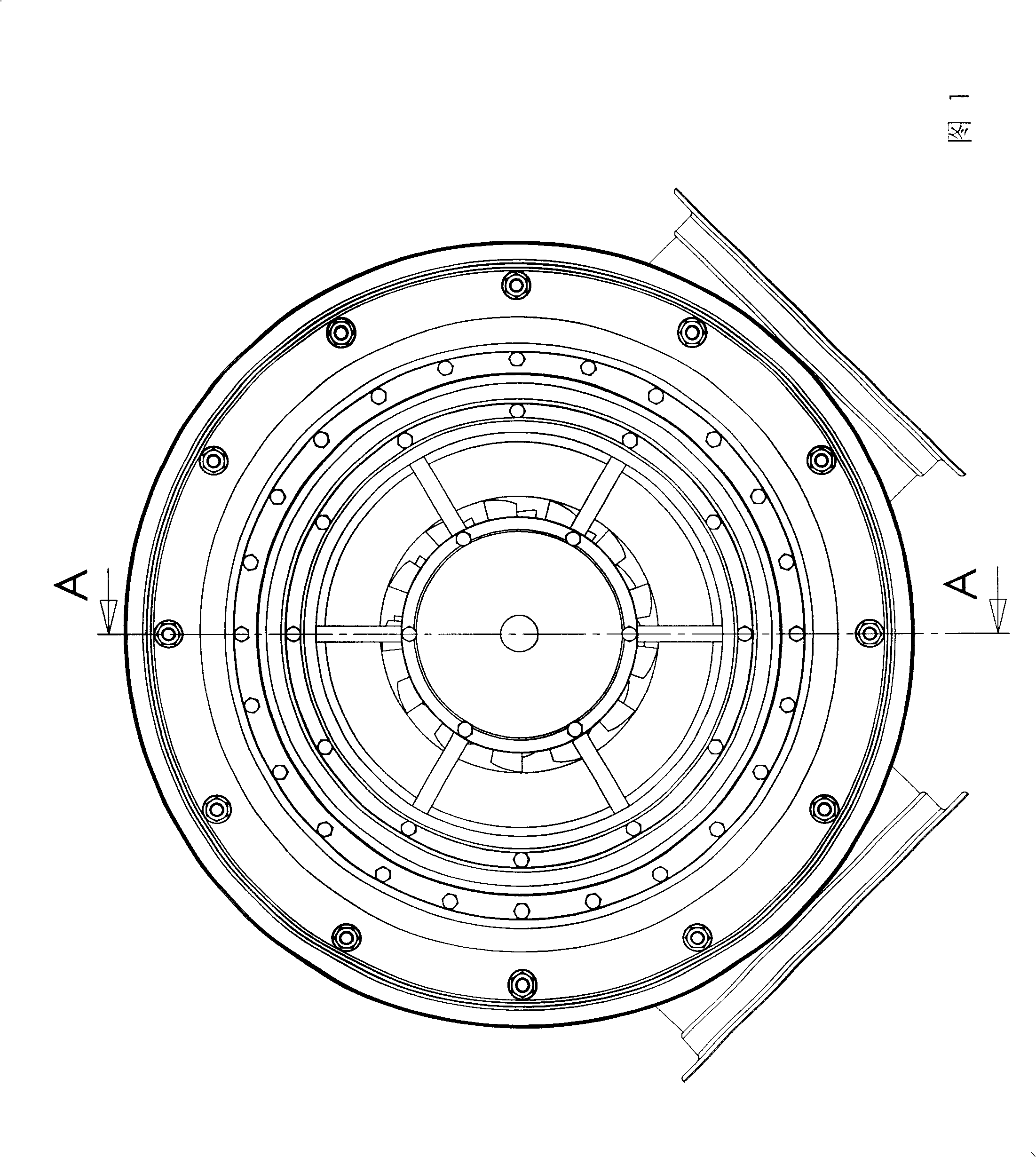

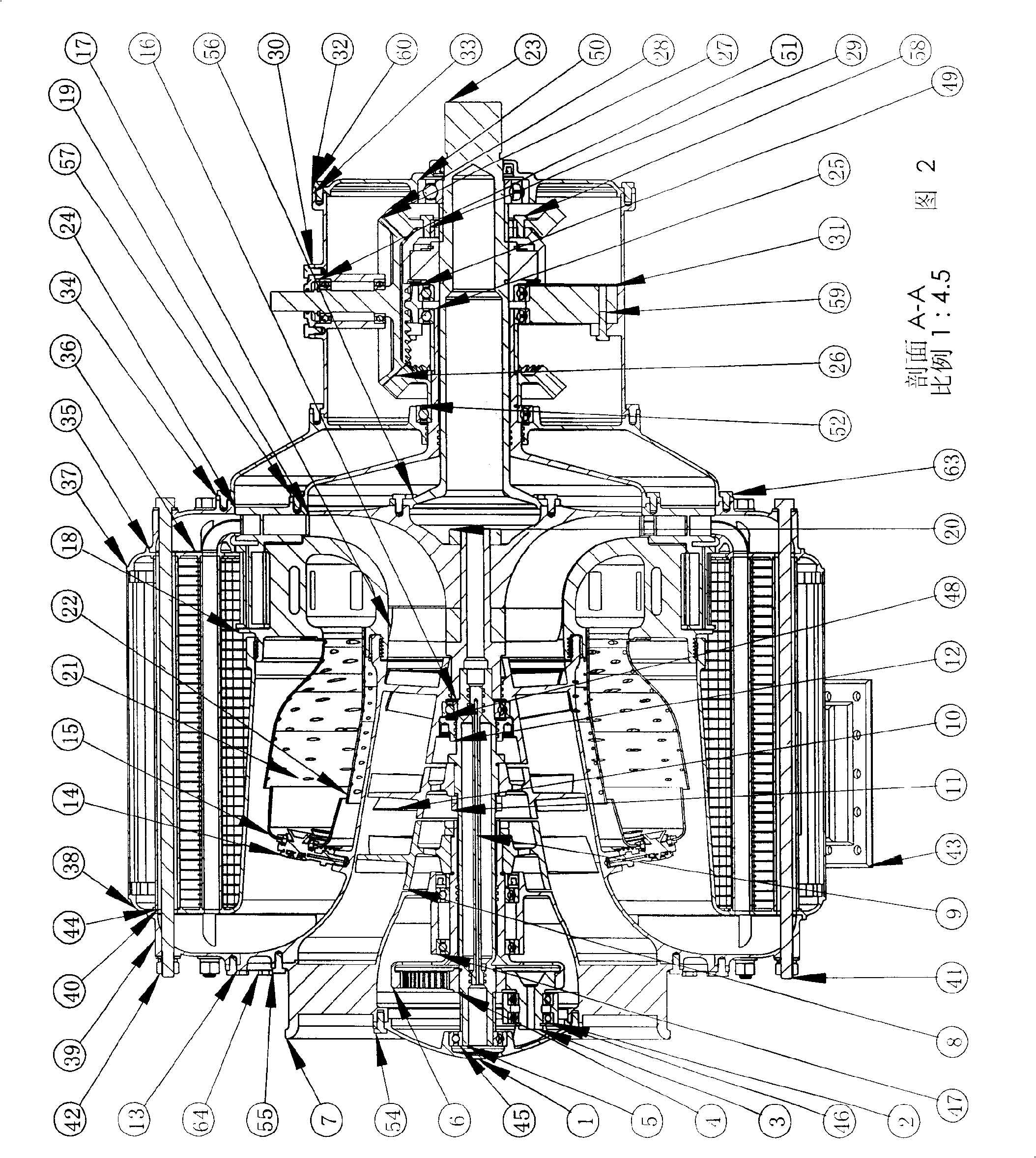

[0021] In Fig. 2, the intermediate gear (3), the central gear (4), the internal gear and the shaft (6) constitute the NGW negative sign mechanism; The other end shaft extension is fixedly connected with a nut (9); the counter-rotating axial flow compressor impeller (10) is installed on the central gear shaft (5) and is fixedly connected with a nut (11); the counter-rotating axial flow compressor impeller (8) and The counter-rotating axial flow compressor impeller (10) rotates in the opposite direction to form a counter-rotating axial flow compressor stage; the wind deflector (17), the rotating jet turbine (18), and the rotating jet turbine disc (19) are mounted on the rotating jet turbine shaft ( 16), fixedly connected with nuts (20); the rotating jet turbine disc (19) is fixedly connected with the main shaft (23) with screws to output torque externally; the combustion chamber shell (13) is equipped with a fuel nozzle (14) and a flame tube The hood (15); the flame tube outer t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com