A fuel injector for internal combustion engines

A technology for fuel injectors and internal combustion engines, which is applied to fuel injection devices, machines/engines, charging systems, etc., can solve the problem that the total number of nozzle holes cannot be increased, and achieve the effect of improving spray quality and fuel combustion and optimizing spray quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

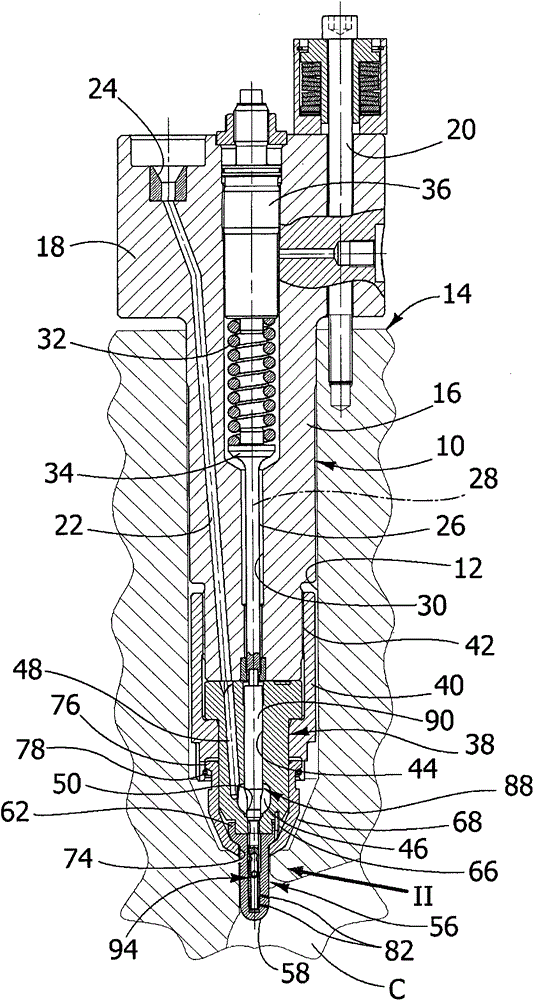

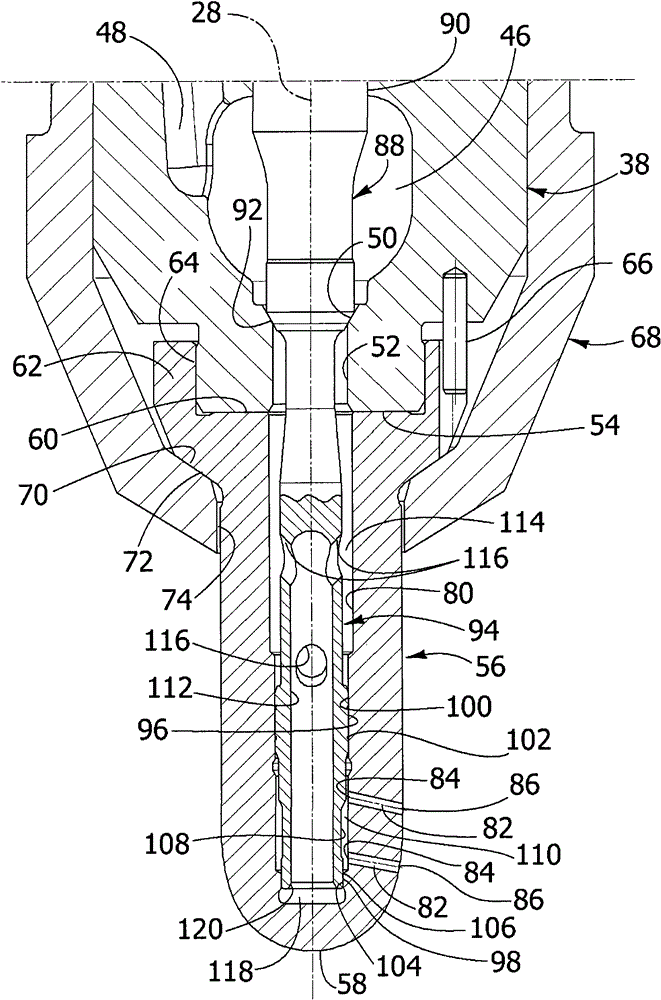

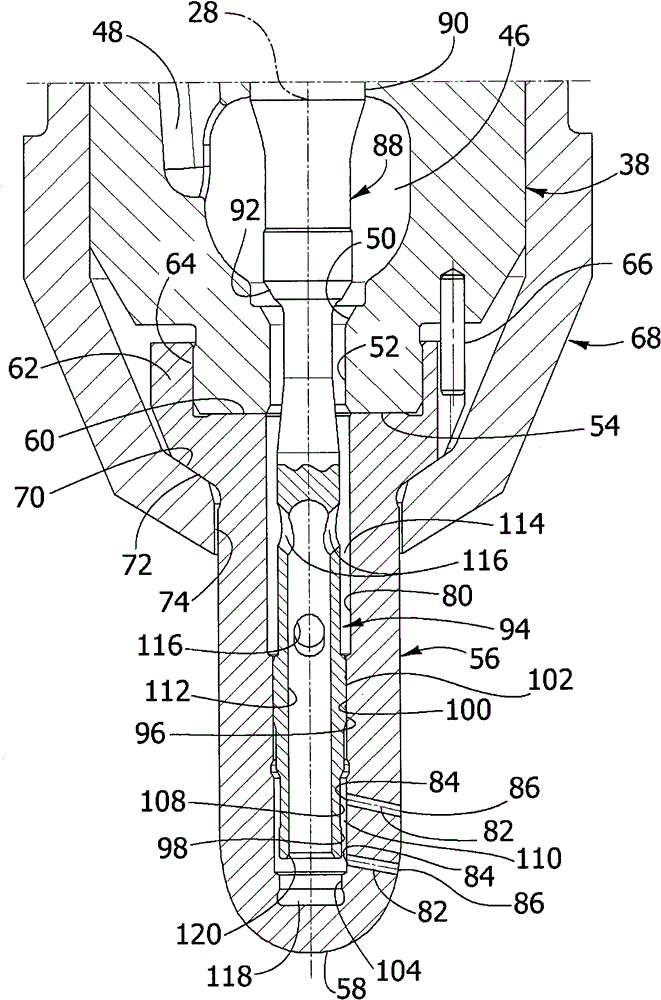

[0026] see figure 1 , Reference numeral 10 denotes a fuel injector for a diesel engine of the present invention. The injector 10 is intended to fit into an axially long cavity 12 formed in a head 14 of the engine. The injector 10 includes an elongated housing 16 having at its top an enlarged head 18 which protrudes outside the lumen 12 and is capped with a screw 20 ( figure 1 Only one of the screws is visible) to the engine head 14.

[0027] In the following description and claims, the terms "above", "below", "top", "bottom" and the like refer to the normal usage position of injector 10 . However, it is contemplated that injector 10 could be mounted in a more or less inclined position with respect to the vertical axis.

[0028] A fuel supply conduit 22 is formed in the housing 16 and is connected at its upper end to an opening 24 which is connected to a fuel supply line (not shown). The propulsion element 26 is axially movable along the longitudinal axis 28 inside a throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com