Delta 3d printer

A 3D printer, delta technology, applied in 3D object support structure, additive manufacturing, processing platform/substrate, etc., can solve the problems of low work efficiency, cumbersome installation and disassembly, unsafe, etc., to achieve low manufacturing and maintenance costs, easy to adjust and maintenance, good effect of structural rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

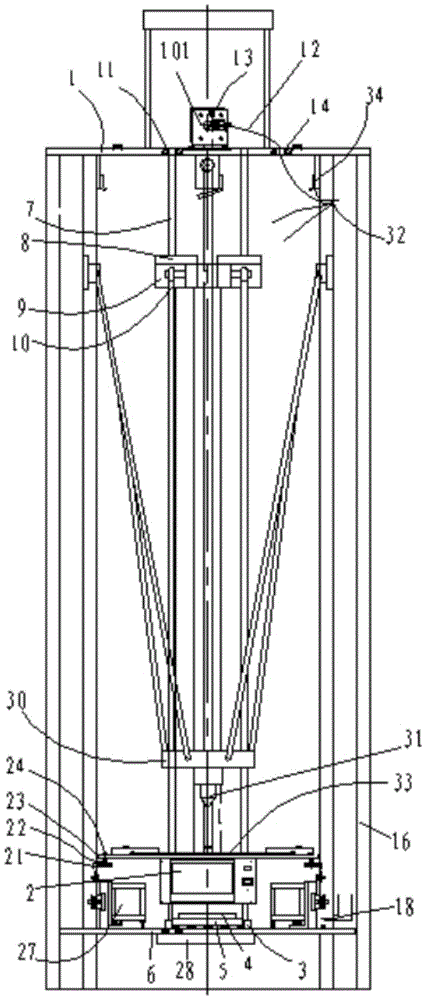

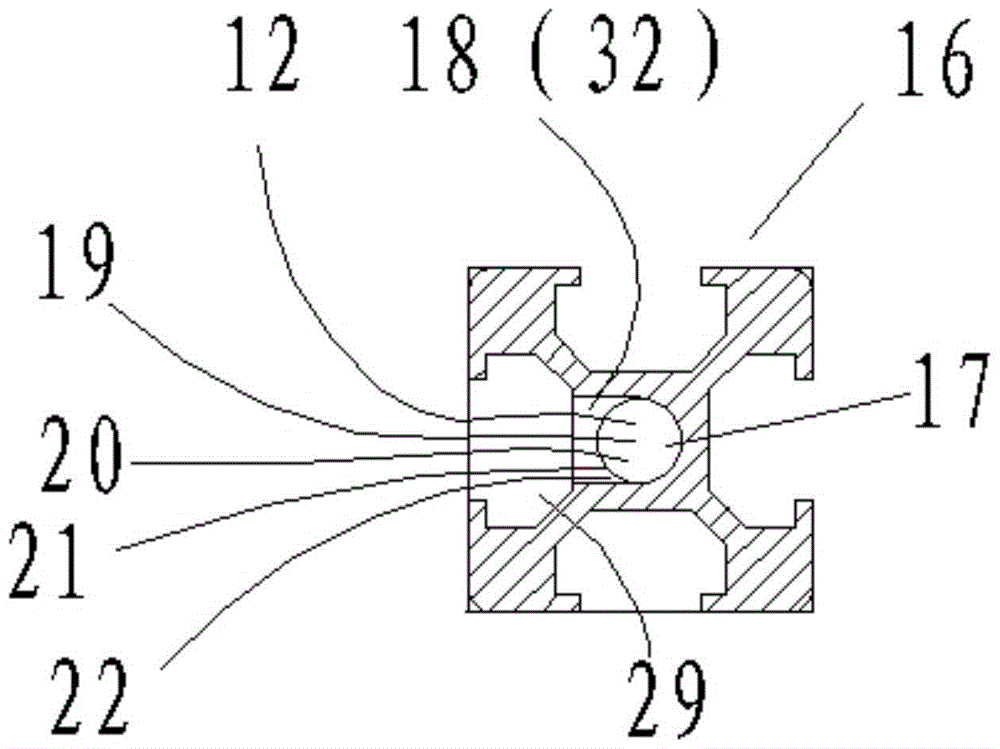

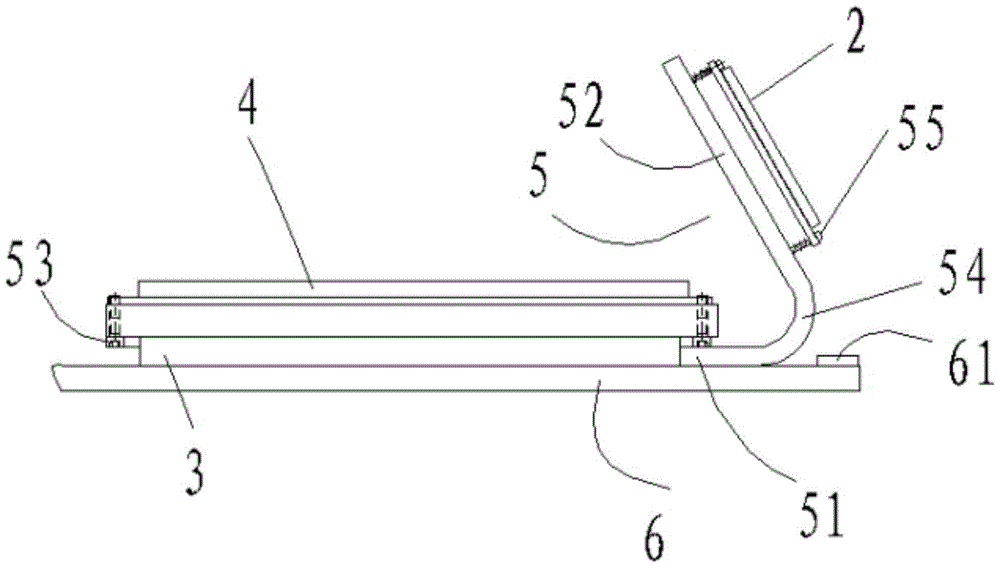

[0030] Such as Figure 1 to Figure 7 As shown, a delta 3D printer includes three profile structure columns 16, a control panel 4, a switching power supply 28, a display screen 2, and a printed product connecting seat 23, and the printed product connecting seat 23 is provided with a printing product workbench 33, and the printed product Taking the upper end surface of the workbench as the printing reference plane, the printed product connection seat 23 is connected to the profile structure column 16, an upper support plate 1 is provided at the upper end of the profile structure column 16, and a lower support plate 6 is provided at the lower part of the profile structure column 16. The finished product connection seat 23 is on the top of the lower support plate 6, and a wire feed motor 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com