Patents

Literature

30results about How to "Simple working environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

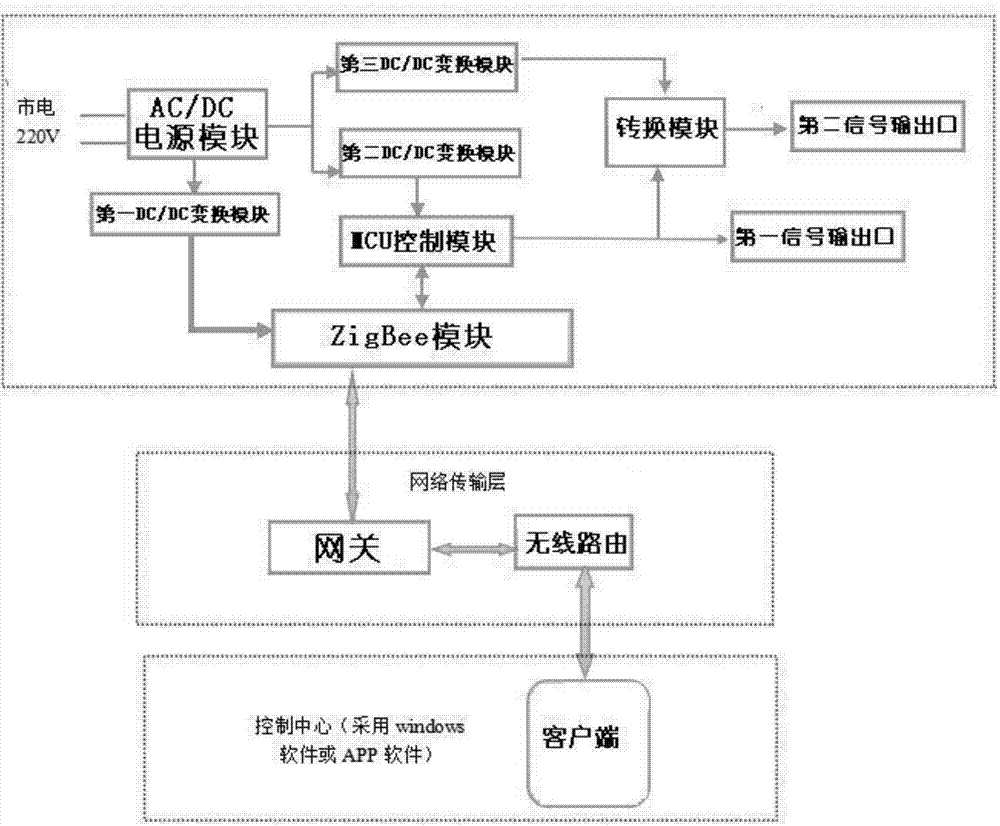

IoT (Internet of Things) lamp energy-saving controller based on ZigBee technology

InactiveCN104507231AGreat advantageImprove energy savingElectric light circuit arrangementEnergy saving control techniquesElectricityEngineering

The invention discloses an IoT (Internet of Things) lamp energy-saving controller based on a ZigBee technology. The IoT lamp energy-saving controller is characterized by comprising an AC / DC (alternating current / direct current) power supply module connected with commercial power, wherein the AC / DC power supply module is respectively connected with a first DC / DC (direct current / direct current) converting module, a second DC / DC converting module and a third DC / DC converting module, the first DC / DC converting module supplies electricity to a ZigBee module, the ZigBee module is in communication connection with an MCU (micro control unit) control module, the second DC / DC converting module supplies the electricity to the MCU control module, and the MCU control module is connected with a first signal output interface. The IoT lamp energy-saving controller based on the ZigBee technology provided by the invention has the advantages that the IoT lamp energy-saving controller can be regulated and controlled by mobile phone client software, and the LED (light emitting diode) switching on / off and the 0-100 percent brightness multistage regulation and control can be realized.

Owner:KUNSHAN SUNLAITE NEW ENERGY +1

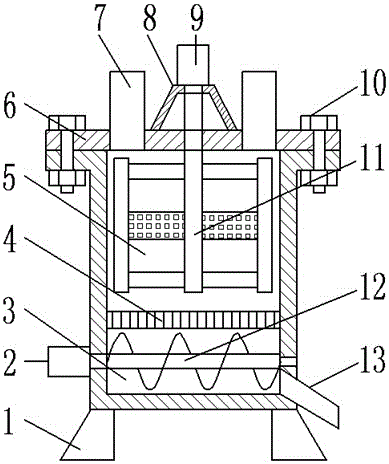

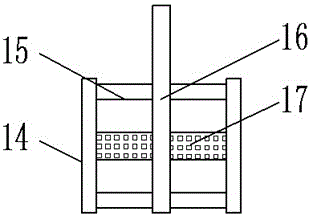

Convenient-to-discharge mixing tank for lithium ion battery cathode powder material

InactiveCN106807267AReduce falling speedReduce generationRotary stirring mixersTransportation and packagingResource utilizationWorking environment

The invention discloses a convenient-to-discharge mixing tank for a lithium ion battery cathode powder material. The convenient-to-discharge mixing tank comprises a base, wherein a discharge chamber is arranged at the top of the base; a striker plate is arranged at the top of the discharge chamber; a mixing chamber is arranged at the top of the striker plate; and a stirring device is arranged in the mixing chamber; and the stirring device consists of a stirring shaft, stirring cross bars, stirring vertical bars and a stirring blade. The convenient-to-discharge mixing tank is simple in structure, reasonable in design and convenient to use; owing to the discharge chamber, the material falling speed can be greatly reduced, and generation of dust is reduced; the material is discharged out from a discharge pipe through a spiral discharging device; secondary stirring and mixing of the battery cathode material can be conducted, so that the material can be mixed more radically; owing to inclined arrangement of the discharge pipe, dust is avoided, and sufficient resource utilization is realized; and a clean and comfortable working environment is provided for staff, and the production efficiency cannot be influenced too much.

Owner:SHENZHEN JUOCAN TECH CO LTD

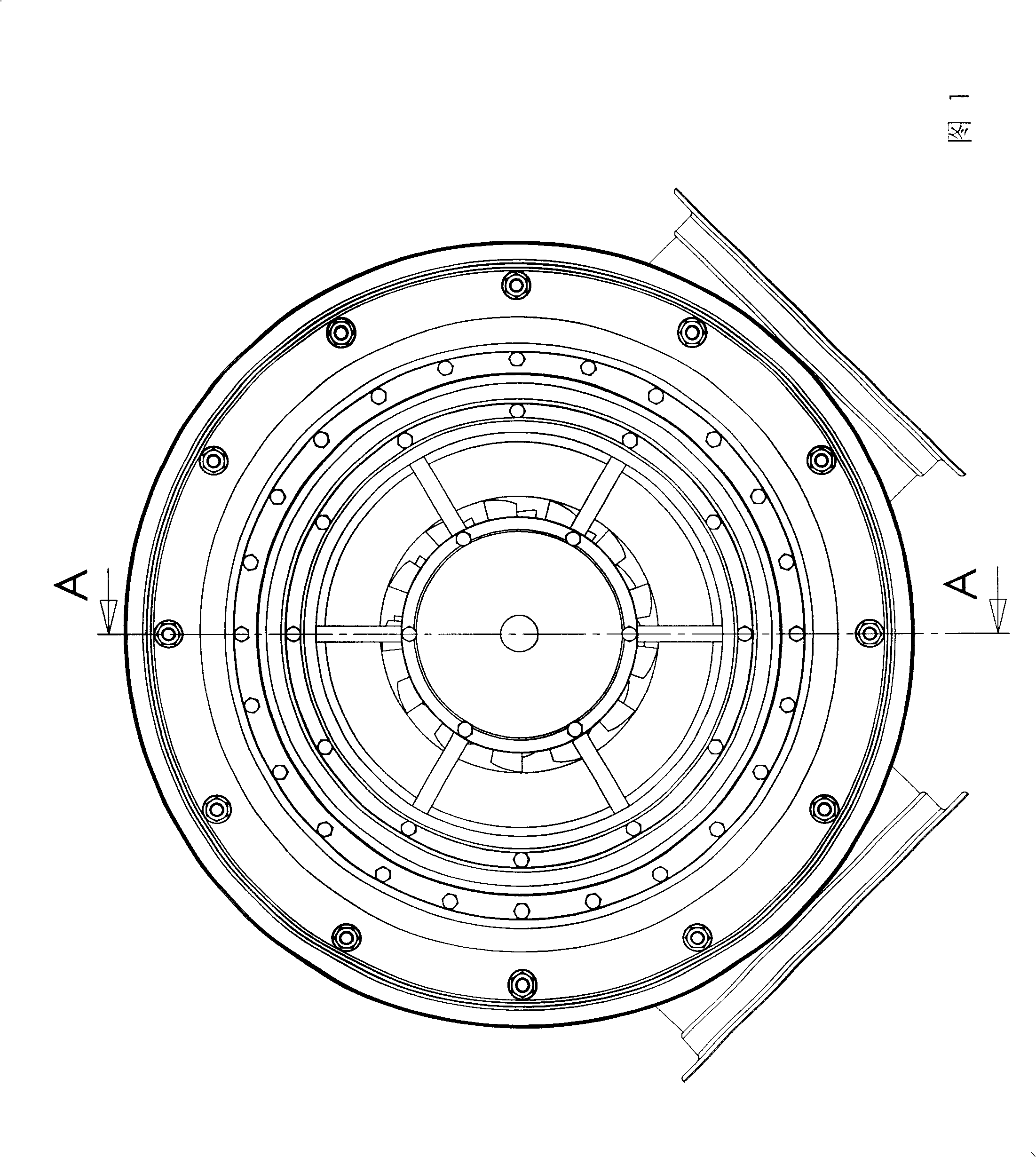

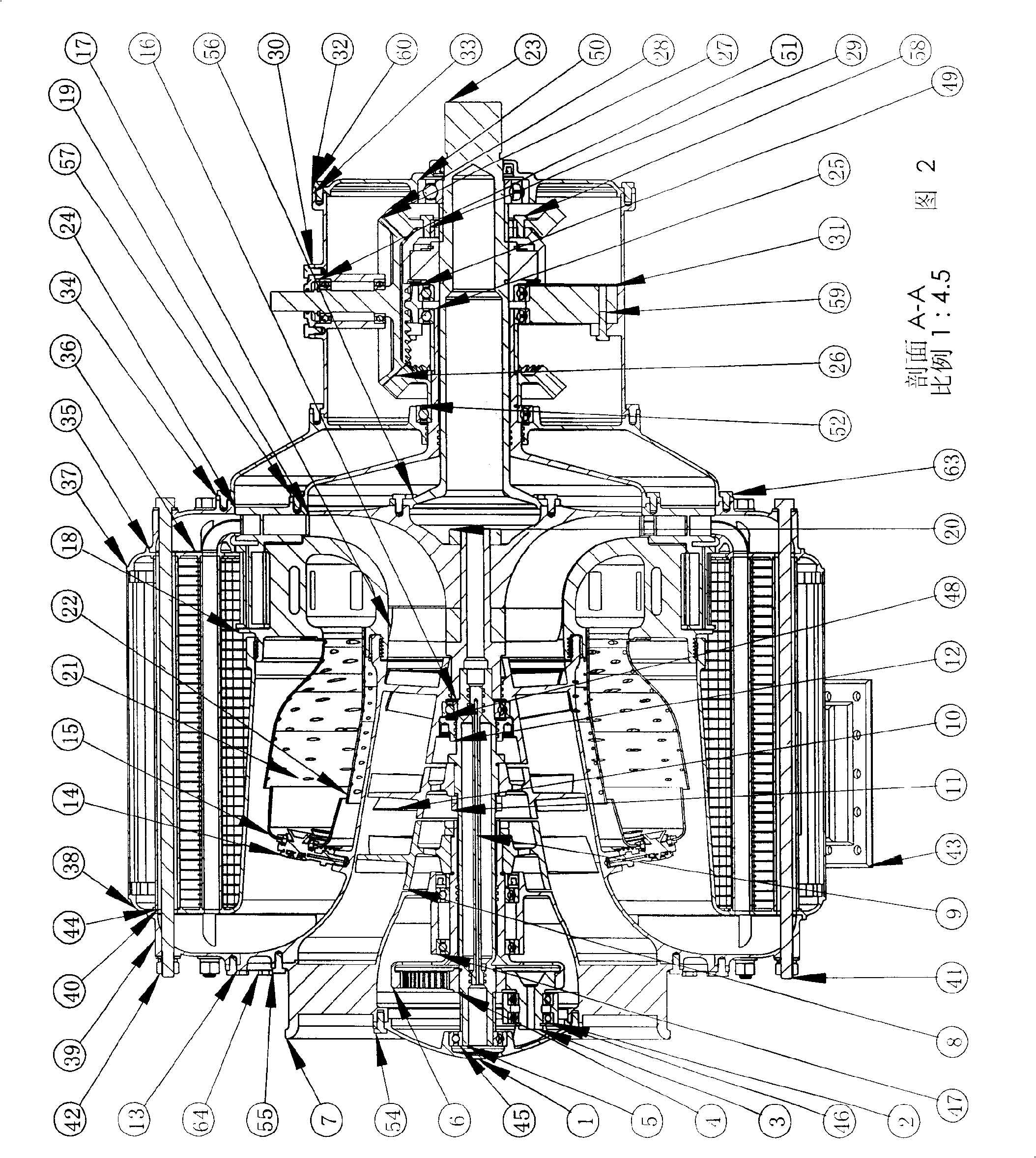

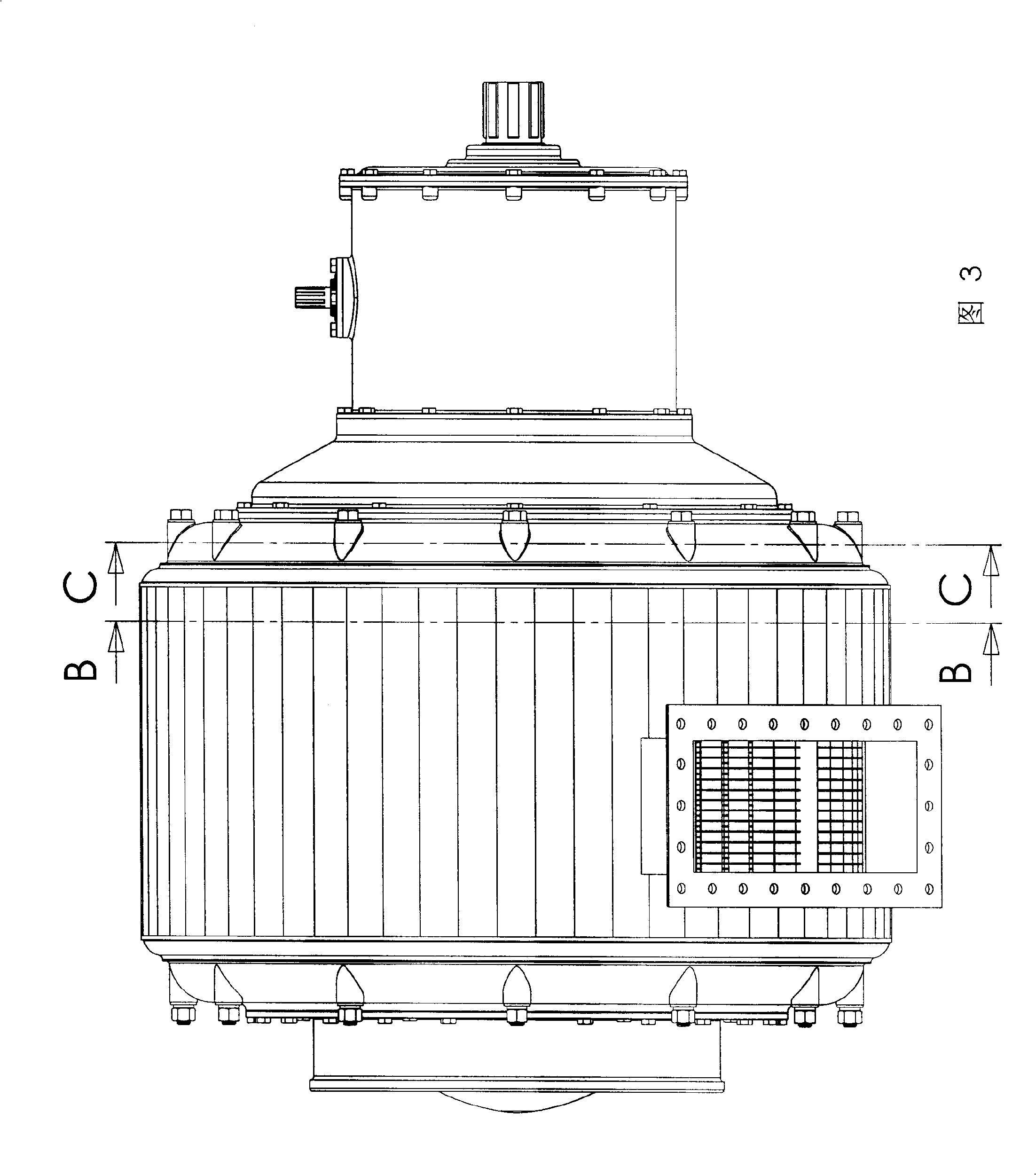

Contrarotating rotary spraying engine

InactiveCN101349197AShort axial distanceShort thermal stressContinuous combustion chamberGas turbine plantsHigh energyMechanical energy

The invention provides a contra-rotating rotary-jetting engine which can remarkably raise heat efficiency and reduce pollutant emission, manufacturing cost as well as maintenance cost. The engine works by utilizing a principle that a rotary jet turbine of the engine ejects fuel gas at high speed from a tangential spout to allow the self of the rotary jet turbine to rotate reversely so as to convert fuel gas internal energy into mechanical energy; meanwhile, the engine also utilizes a tangential impact turbine to recycle the kinetic energy of the fuel gas ejected from the rotary jet turbine, utilizes a heat regenerator to realize regenerative cycle, adopts a contra-rotating axial flow and contra-rotating centrifugal pressure gas technique to obtain high total pressure ratio, adopts a rotary flame tube technique to obtain high fuel gas temperature in front of the turbine, adopts the novel structural design to greatly reduce the number of components and the consumption of precious materials, and adopts a power confluence mechanism of a cone gear and an overrunning clutch to realize the power confluent output of the mechanical energy of the rotary jet turbine and the tangential impact turbine. Therefore, the engine has high energy conversion efficiency, low manufacturing cost and pollutant emission.

Owner:蔡盛龙

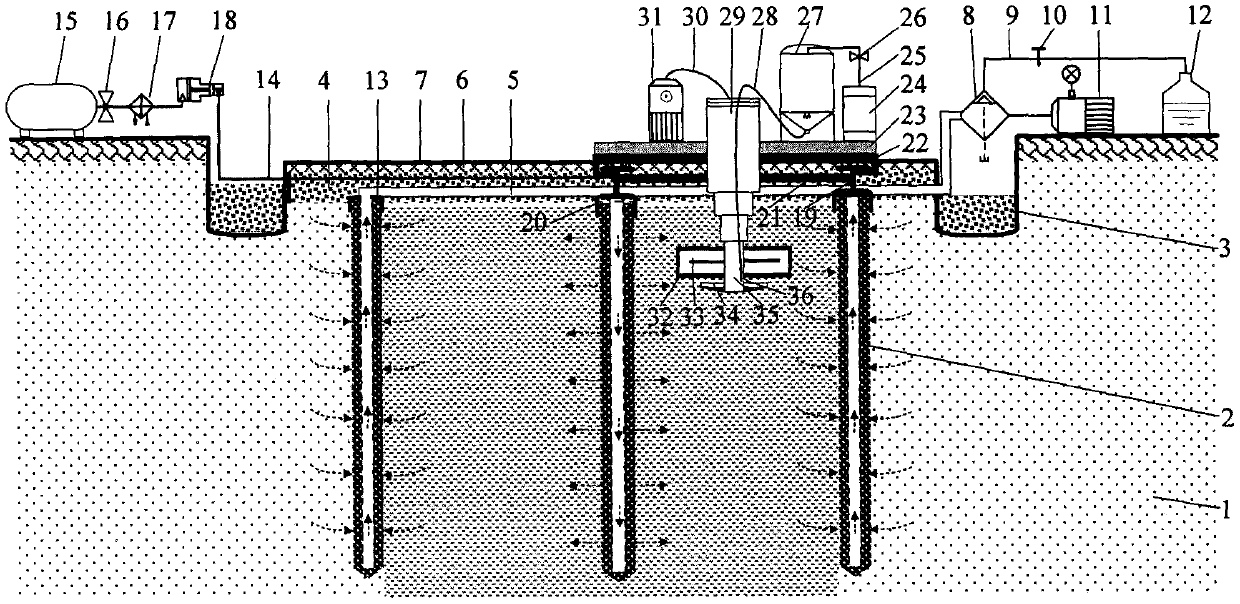

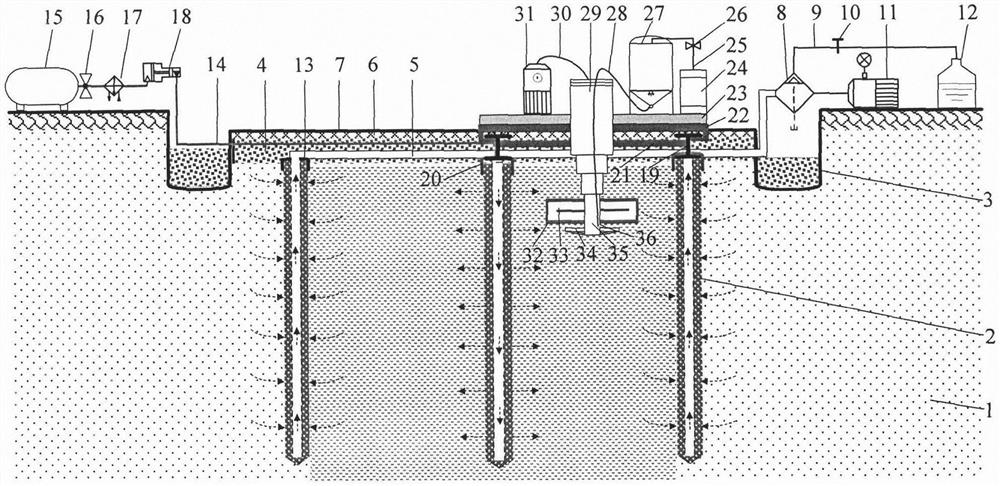

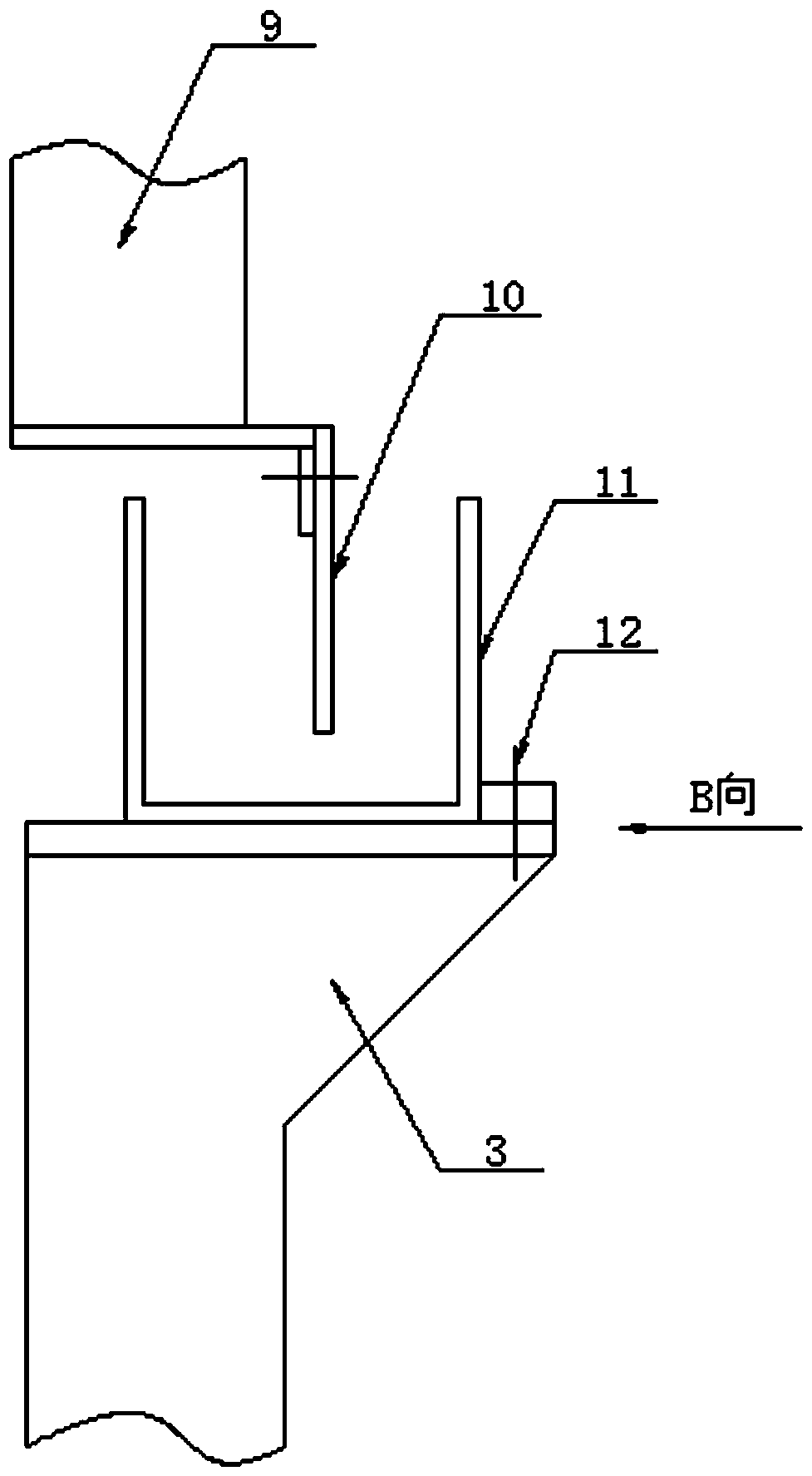

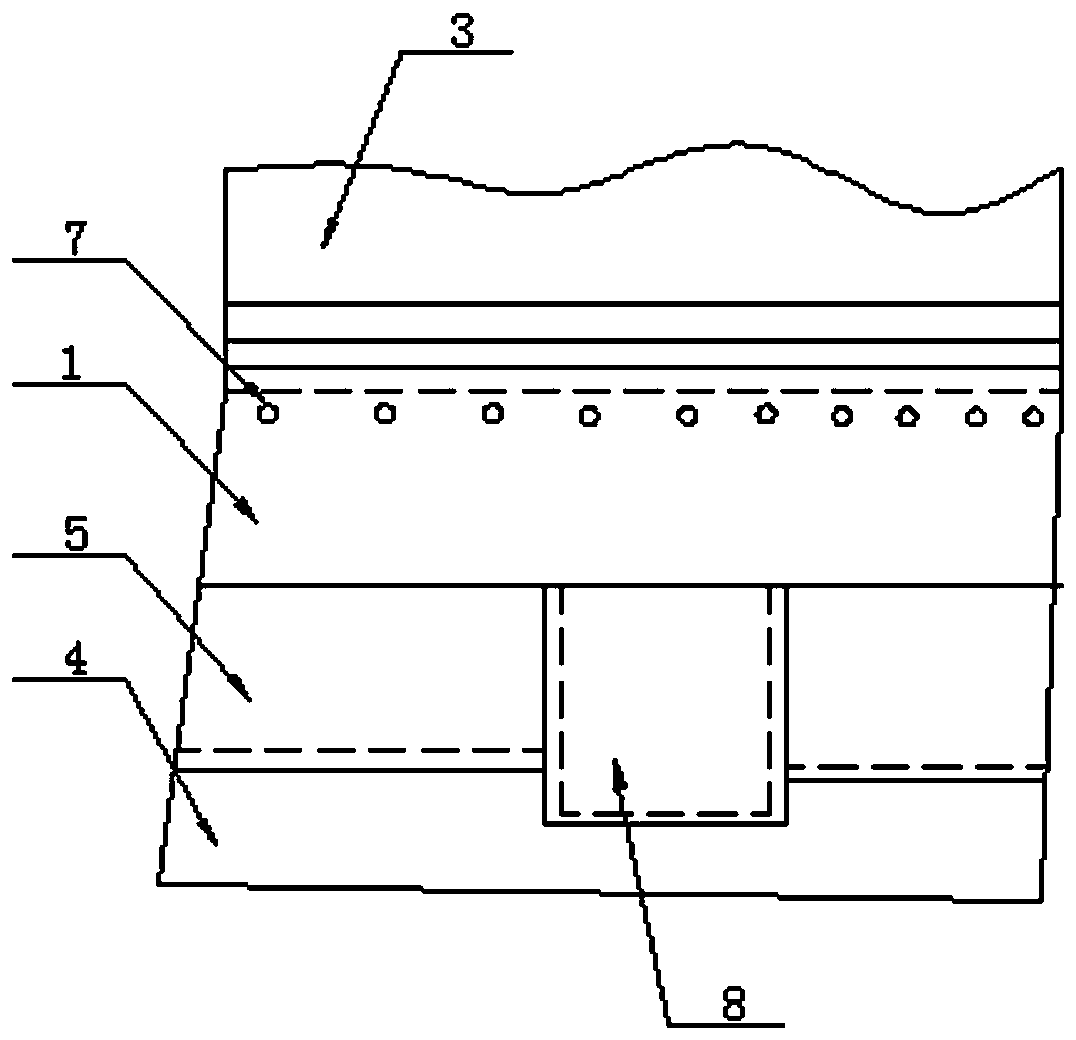

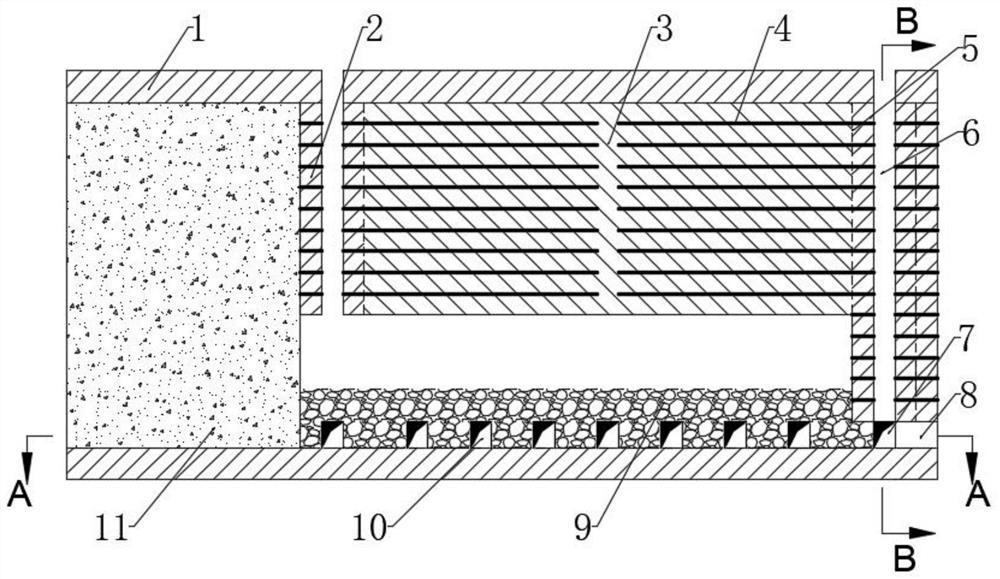

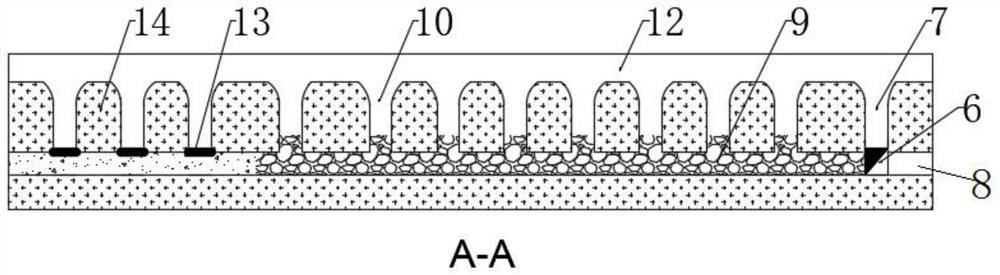

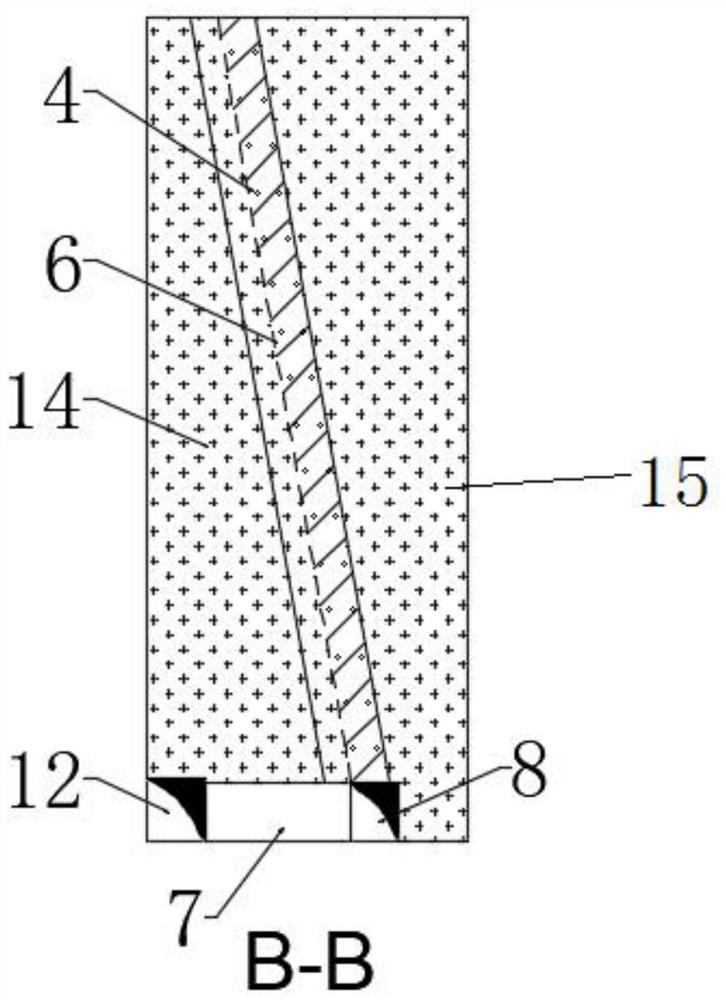

Reinforcing method of vacuum preloading lead pipe pile gas injection carbonized super-soft foundation

ActiveCN110512591AImprove compactionImprove displacement effectSoil preservationSites treatmentResource utilization

The invention discloses a reinforcing method of a vacuum preloading lead pipe pile gas injection carbonized super-soft foundation, and belongs to the technical field of super-soft foundation reinforcing treatment of geotechnical engineering. The reinforcing method comprises the steps of site treatment and exploration, first pile group construction and beating, spraying mixing equipment placement and debugging, curing agent spraying and mixing, first treatment system layout, vacuum preloading-gas injection carbonized treatment, first site treatment completing, continuous construction, final treatment and the like. The reinforcing method has the advantageous of a vacuum preloading method, a magnesium oxide carbonization curing method and a pipe pile composite foundation, the drainage efficiency and the infiltration diffusion efficiency of carbon dioxide are greatly improved through coordination work of vacuum preloading and pipe pile gas injection, the compacting displacement action of apipe pile on soft soil is fully utilized, mud soil is effectively glued through hydration products and carbonization products, thus the intensity of the soft soil composite foundation is enhanced, and the stability is improved. The reinforcing method has the characteristics that the treatment effect is good, the period is short, and low-carbon and environmentally-friendly and economic efficiencyare achieved, and resource utilization of industrial waste in soft foundation treatment is achieved.

Owner:NANJING FORESTRY UNIV

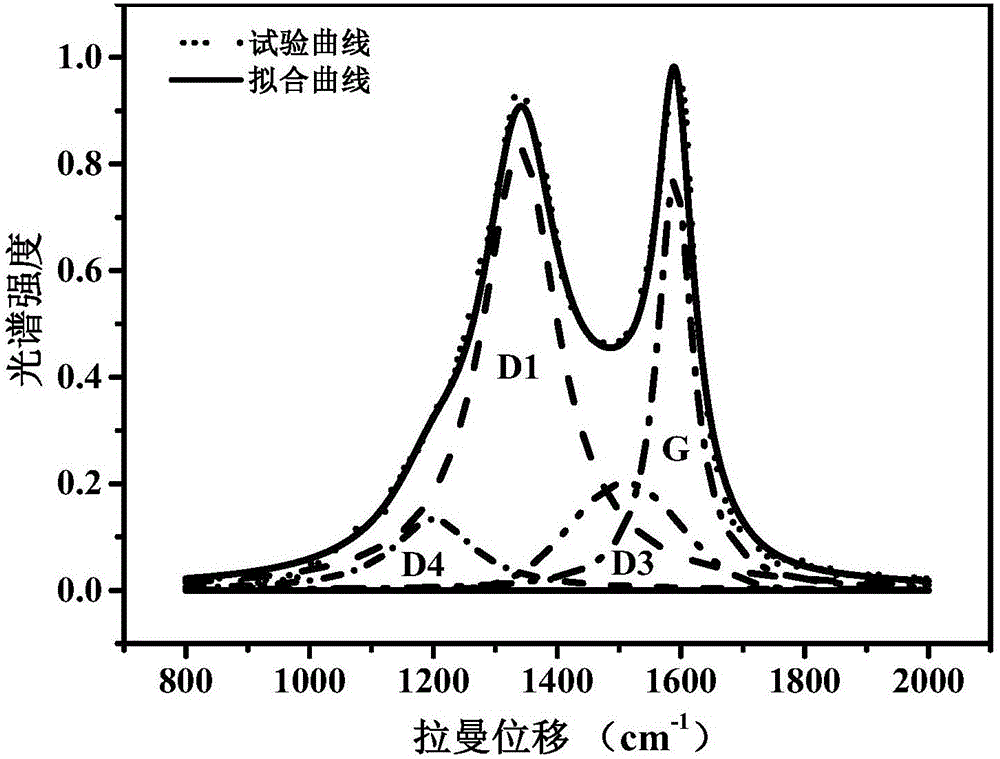

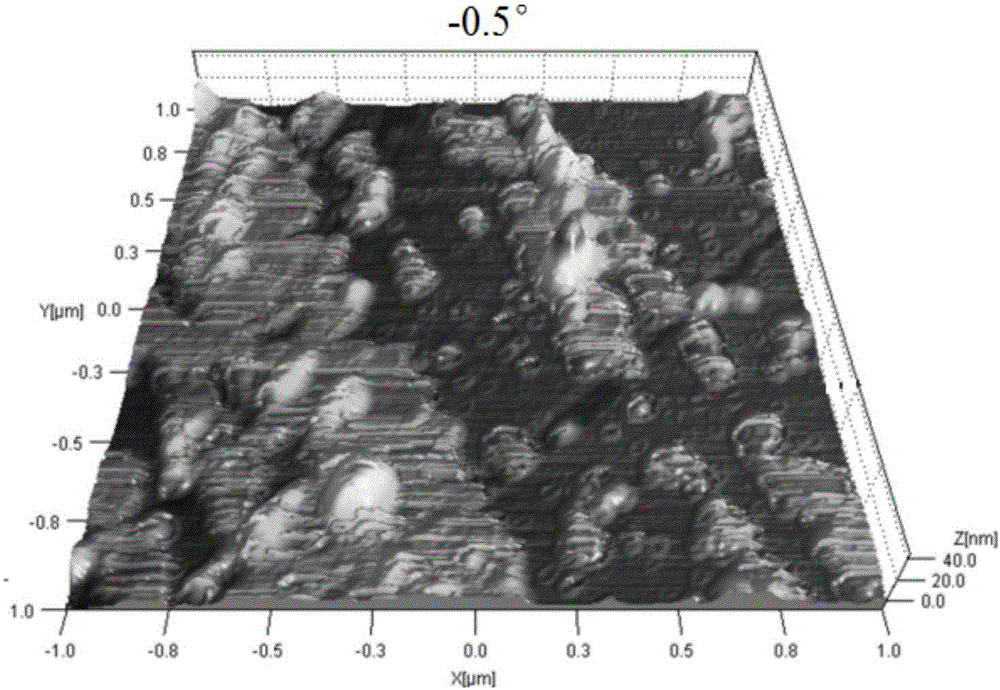

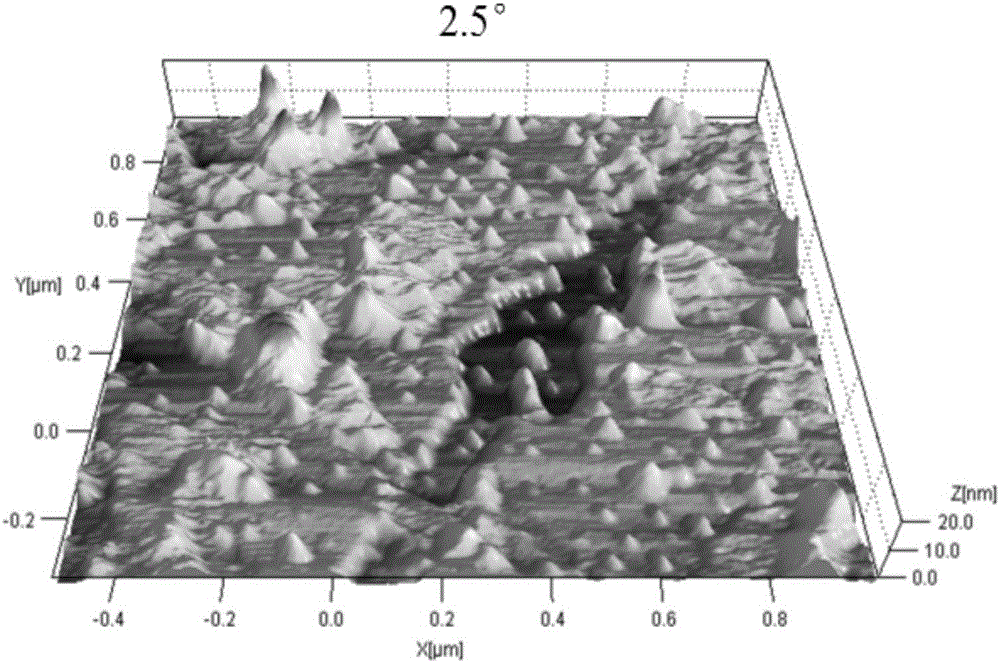

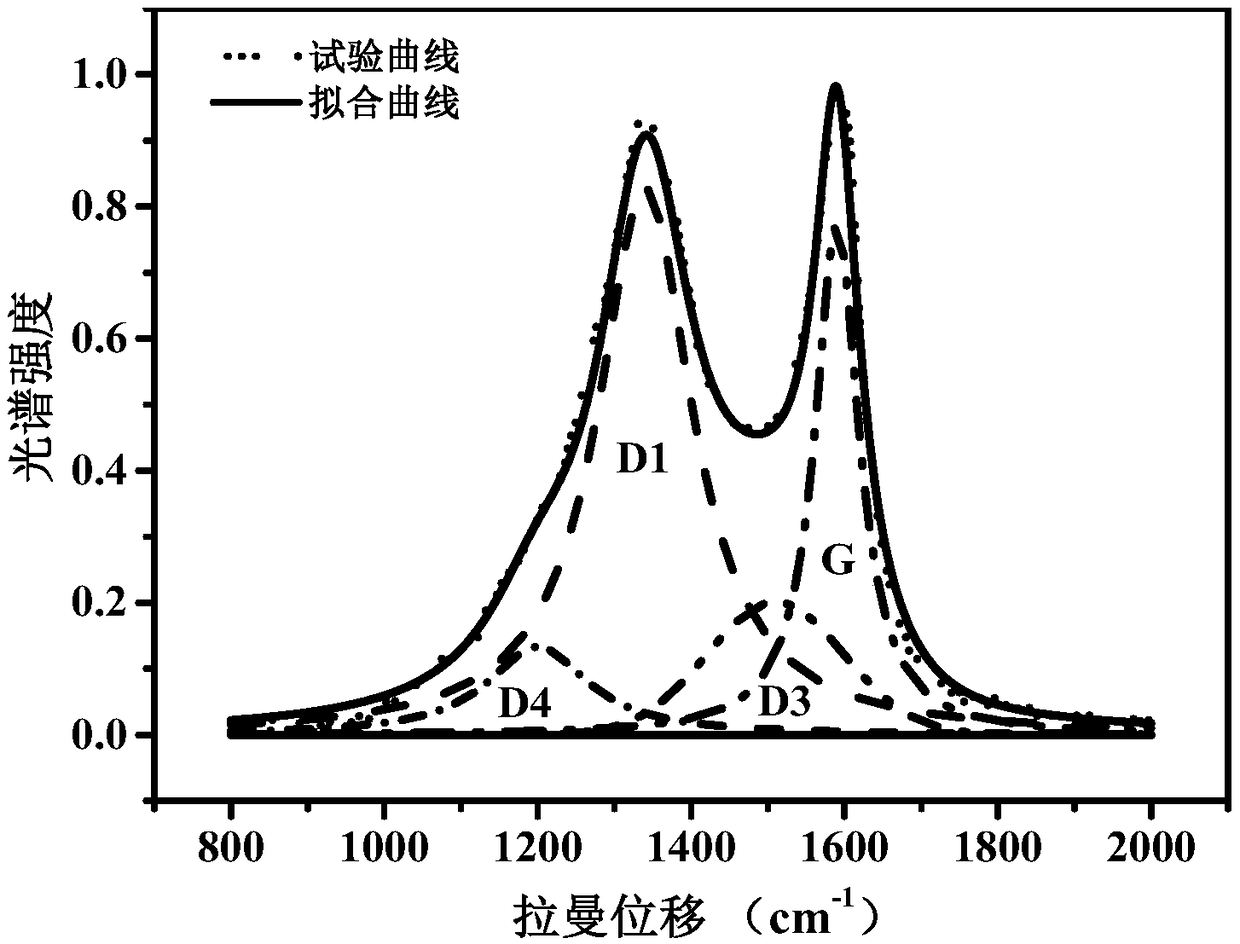

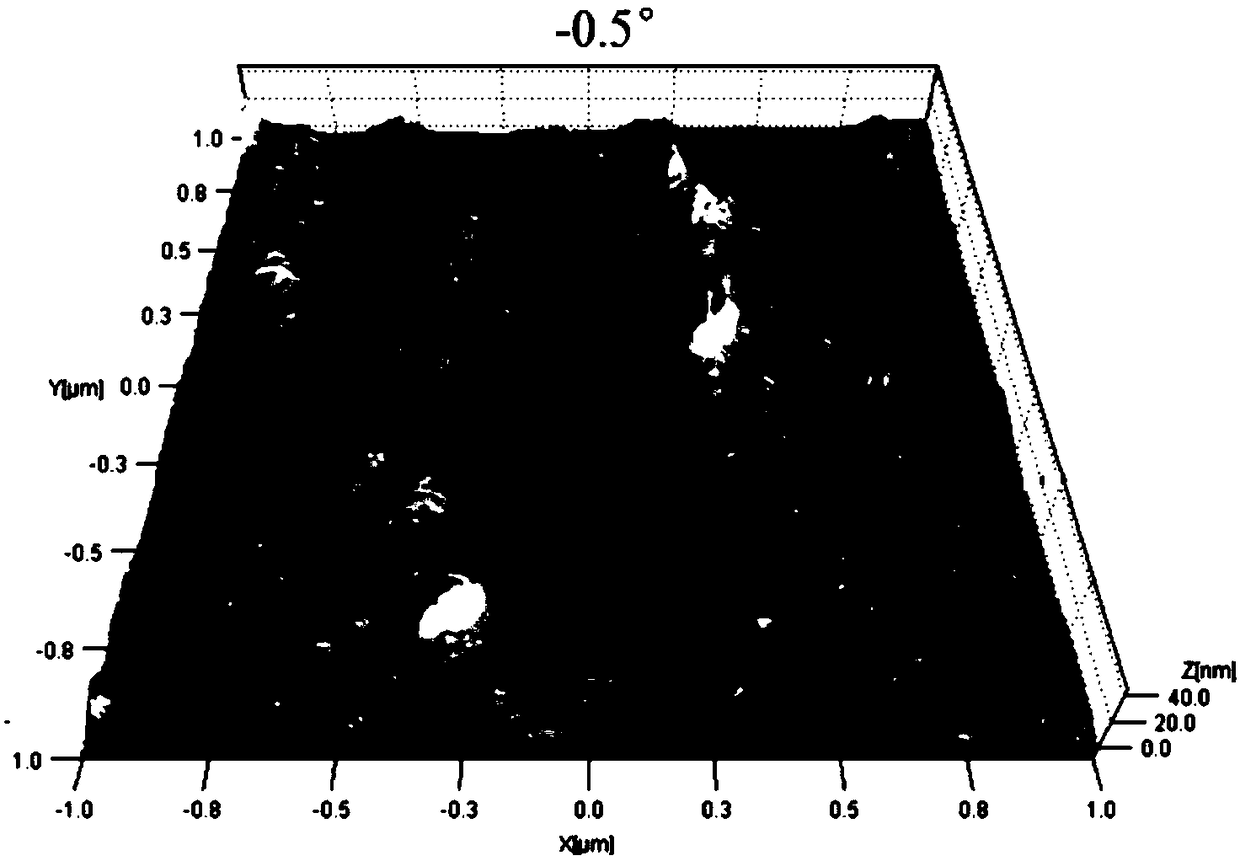

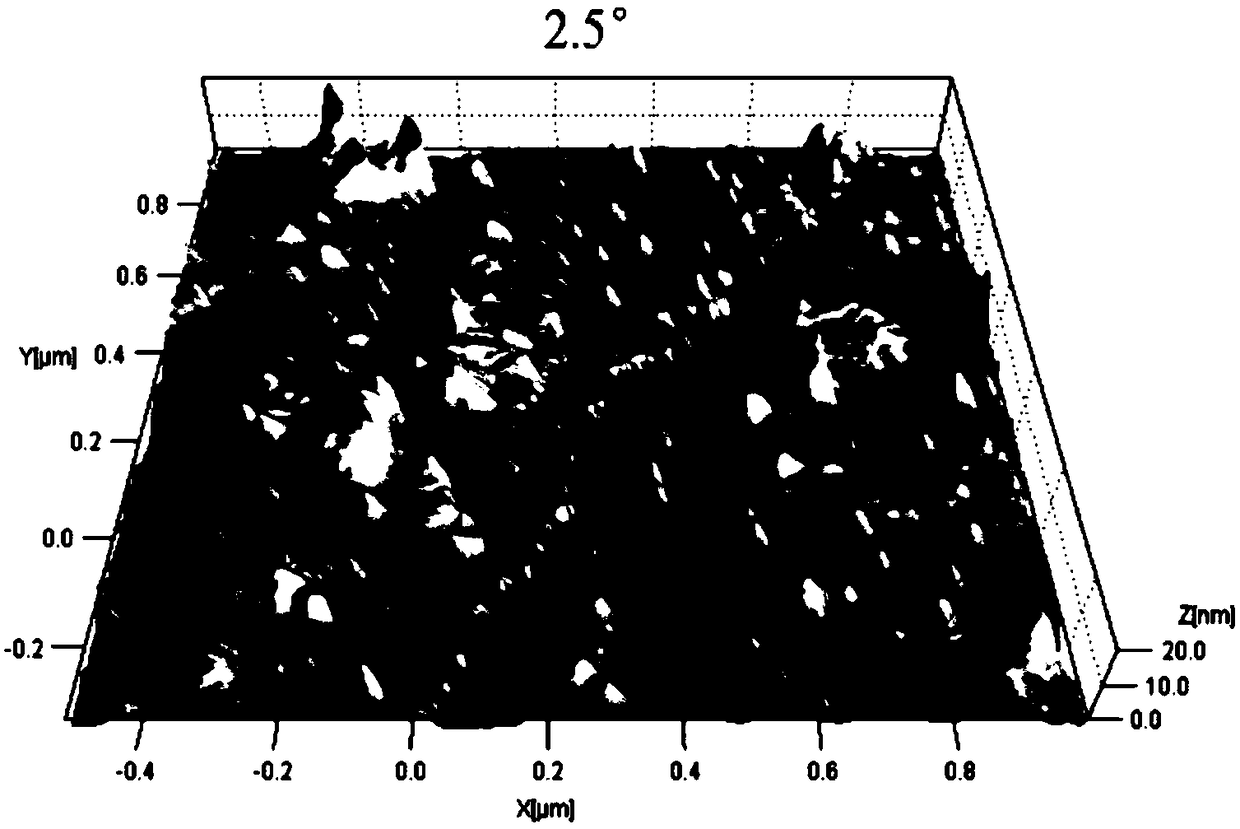

Method for detecting physical characteristics of nano-scale soot microparticles and application of method

The invention discloses a method for detecting physical characteristics of nano-scale soot microparticles. The method is used for simultaneously detecting the three-dimensional morphology, mechanical characteristics and degree of graphitization of the same position of each nano-scale soot microparticle by using an atomic force microscope and Raman spectrometer combination system and comprises the following steps: acquiring the three-dimensional morphology, force curve and Raman spectrogram of a nano-scale soot microparticle sample, and carrying out peak-differentiating-imitating on the Raman spectrogram by using software origin so as to evaluate the degree of graphitization of the nano-scale soot microparticle sample; finally obtaining the mechanical characteristics of the nano-scale soot microparticle sample, wherein the mechanical characteristics comprise an adsorption force, a van der Waals force and an adhesion force. According to the method and the application thereof, the rule of evolution of the three-dimensional morphology, mechanical characteristics and degree of graphitization of soot microparticles generated from different source combustion processes can be researched, and research results contribute to the deep understanding of generation and evolution mechanisms of the soot microparticles, so that a theoretical instruction is provided for the reduction of emission of the soot microparticles and the control on atmospheric environment pollution.

Owner:TIANJIN UNIV

Method for recycling sodium phenylacetate

InactiveCN111302932AEmission reductionReduce oxidationCarboxylic compound separation/purificationSodium acetateActivated carbon

The invention provides a method for recycling sodium phenylacetate. The method comprises the following steps: acidifying a pyrolysis waste liquid for producing 6-APA, carrying out extracting with an organic solution, alkalifying an extracted organic phase with liquid caustic soda, separating a water phase, and allowing a separated water phase into a rectifying tower to remove residual organic matters; and carrying out decoloration through active carbon, removing impurities through an ultrafiltration membrane, and carrying out evaporation and concentration so as to obtain a sodium phenylacetatesolution with a concentration of more than 25%. According to the invention, through improvement of the prior art, the method provided by the invention has the following advantages: the purity and yield of a recovered sodium phenylacetate product are improved; the production cost is reduced; the problems of high acidification crystallization cost, a plurality of related hazardous chemicals and thelike in a conventional process are solved; meanwhile, the problems of heavy wastewater discharge and difficulty in treating a waste liquid in an original process are effectively solved.

Owner:UNITED LAB INNER MONGOLIA CO LTD

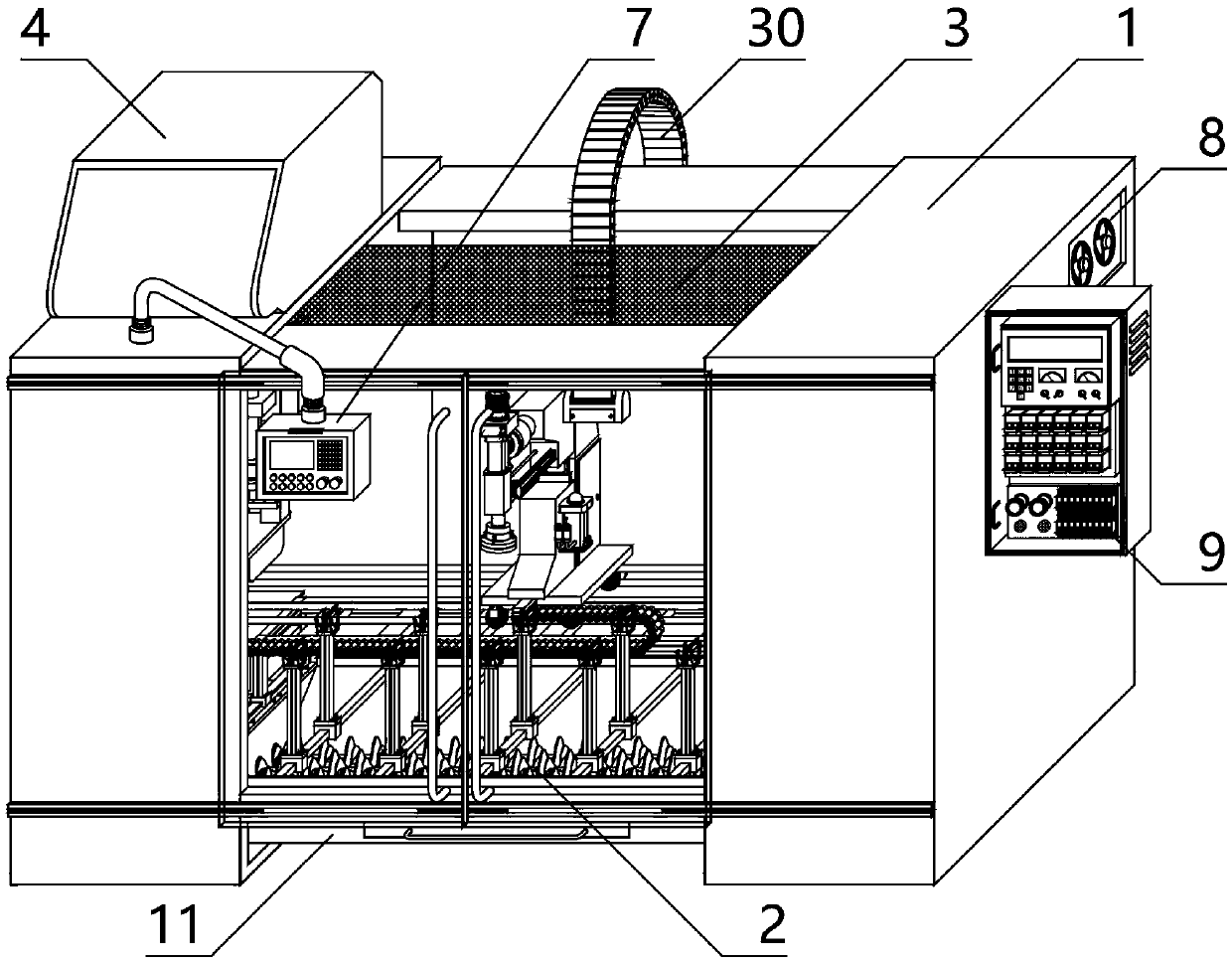

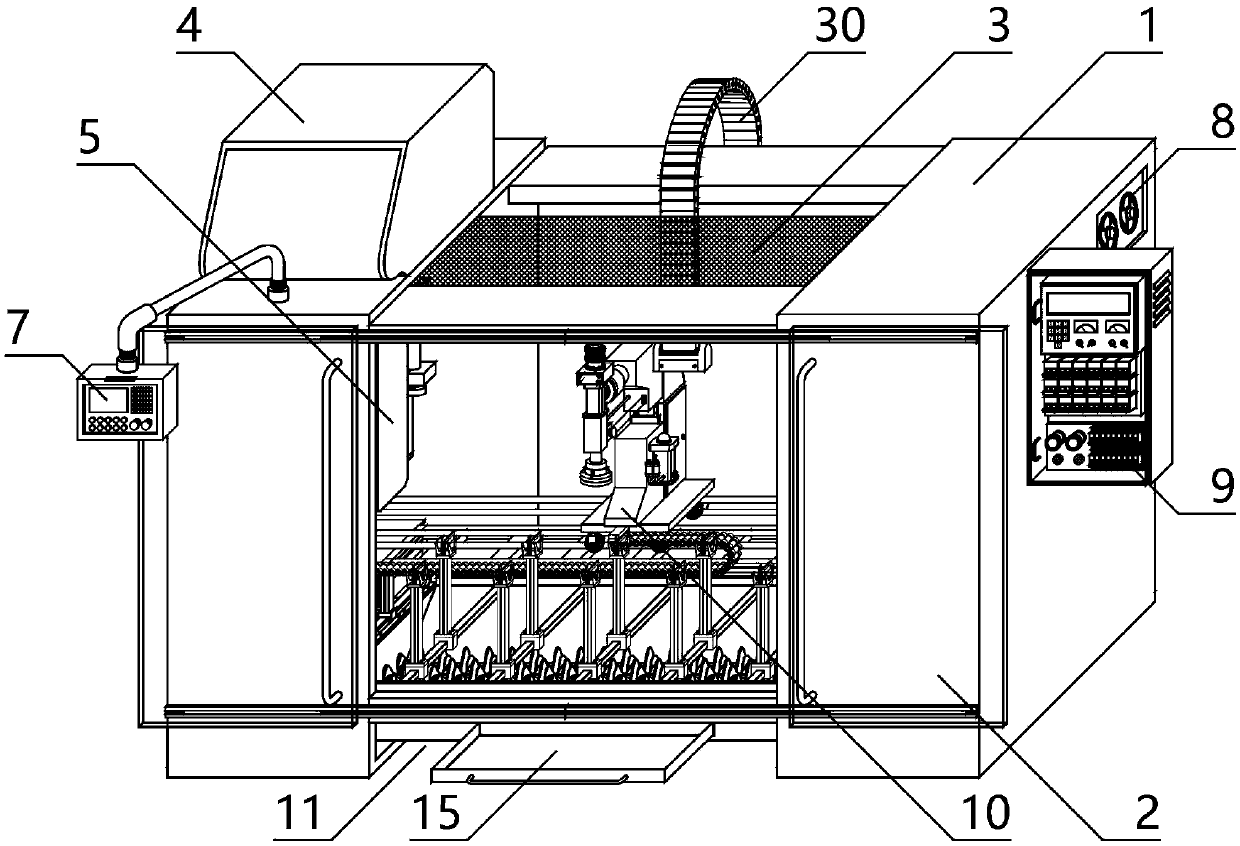

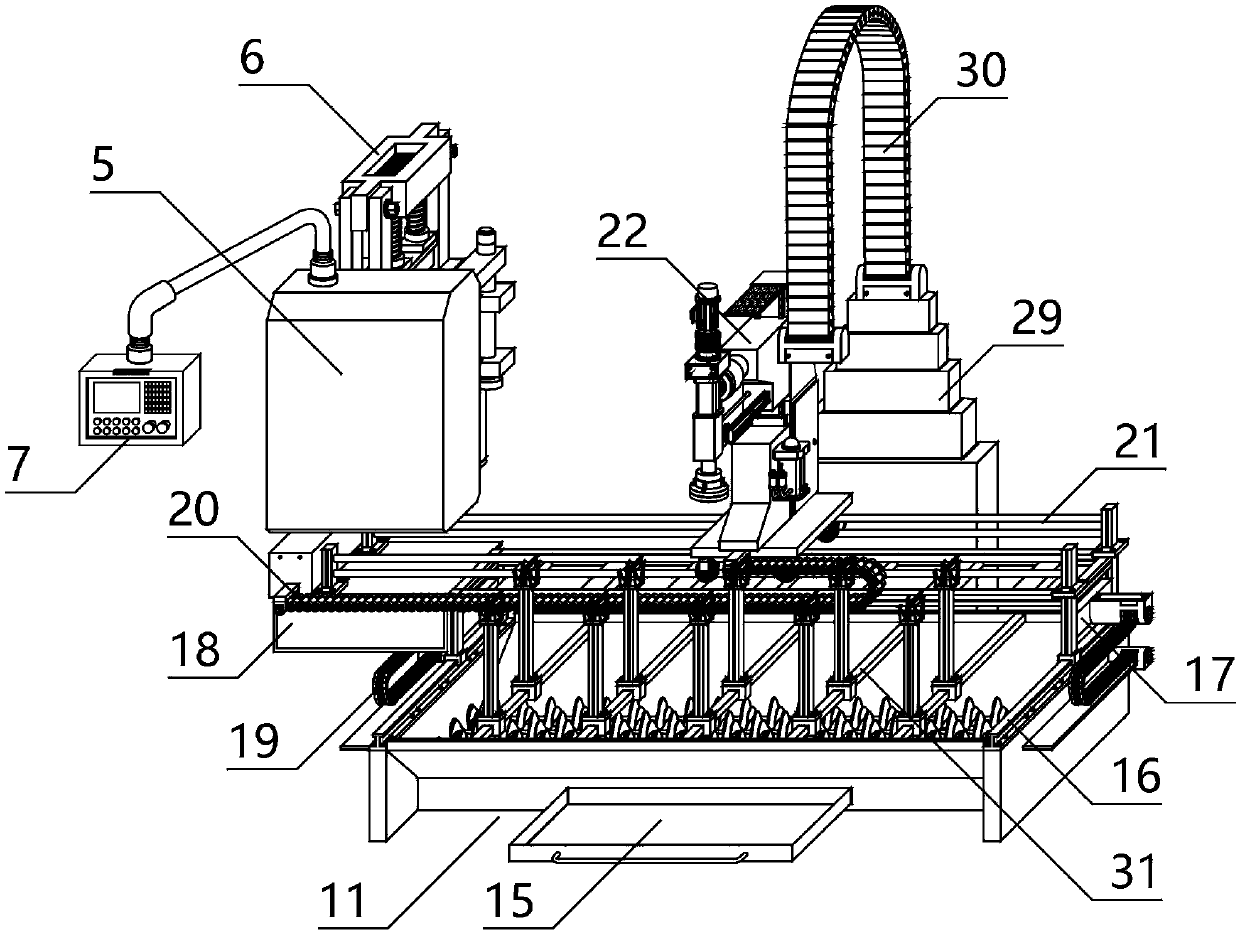

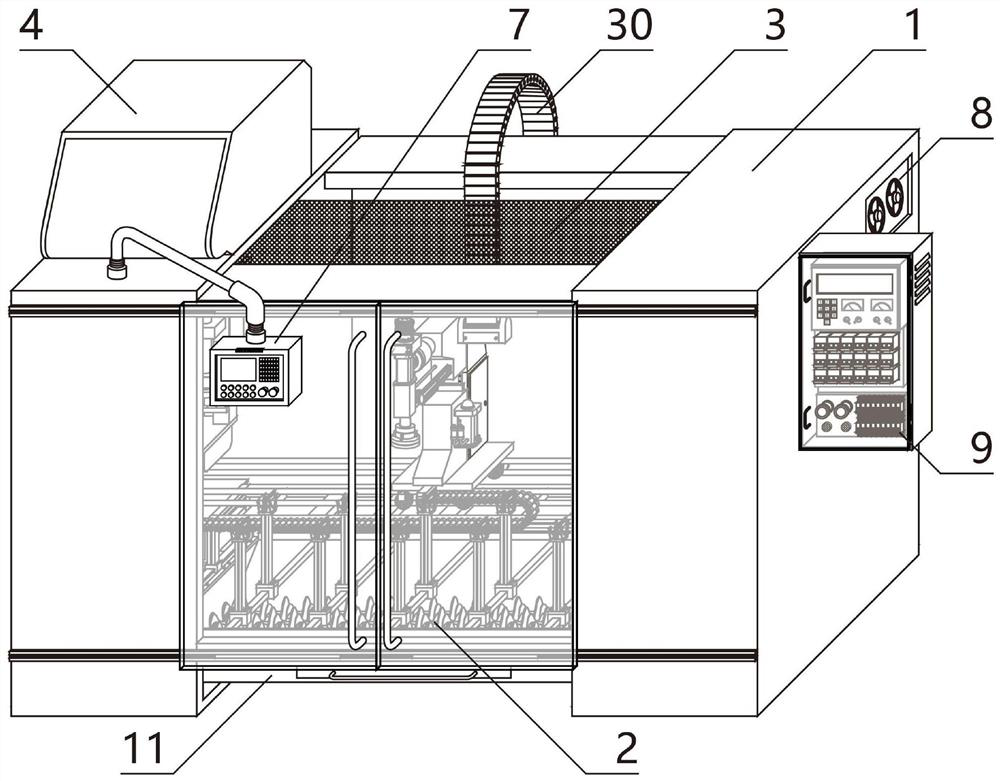

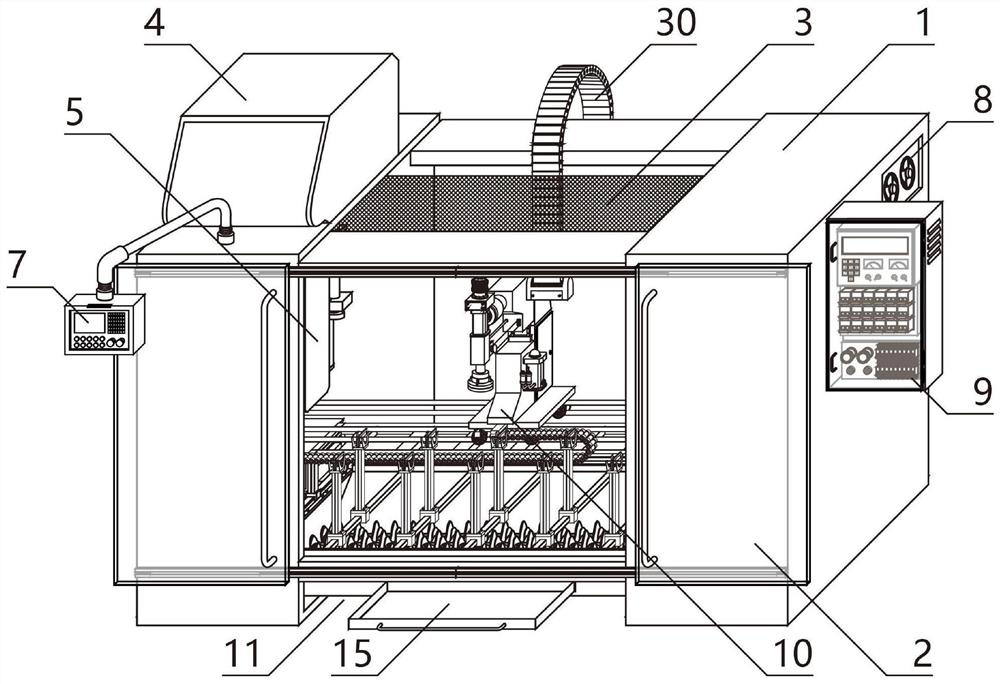

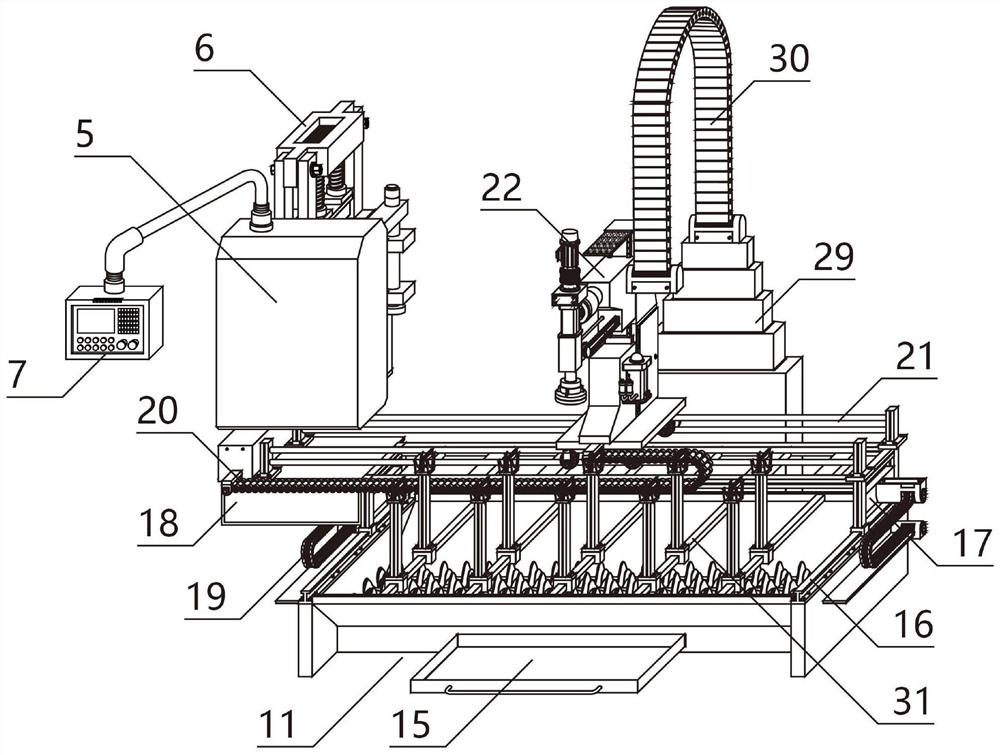

Four-axis linkage type computer numerical control machining center and working method thereof

ActiveCN109623439APrevent splashOperation specificFeeding apparatusLarge fixed membersNumerical controlMachine control

The invention aims to provide a four-axis linkage type computer numerical control machining center and a working method thereof. According to the technical scheme, the four-axis linkage type computernumerical control machining center is composed of a machining cabin, a tool bearing frame, a tool controller, a tool changing machine, a tool changing control table, a machining control cabinet and amachining mechanism, wherein the machine mechanism is composed of a machining bearing table, a Y-axis moving rail table, a Y-axis moving frame, an X-axis moving supporting table, an X-axis moving railtable, a Z-axis machining mechanism, a telescopic machine and a plurality of material bearing fixing frames, and the machining bearing table is composed of a waste material collecting tank, a waste material overturning device and a waste material recovering plate. According to the four-axis linkage type computer numerical control machining center, tool changing operation and machining operation form two independent control units so that misoperation caused by a single control unit is avoided, maintenance and overhaul are facilitated, then four-axis linkage type computer numerical control machining is more accurate, material fixing and position adjusting can be realized through the plurality of material bearing fixing frames, waste materials obtained after machining can be concentrated, sothat the internal operation environment of a machining space is guaranteed, and the quality of machined products is improved.

Owner:TIANJIN HUATIAN CENTURY MACHINERY

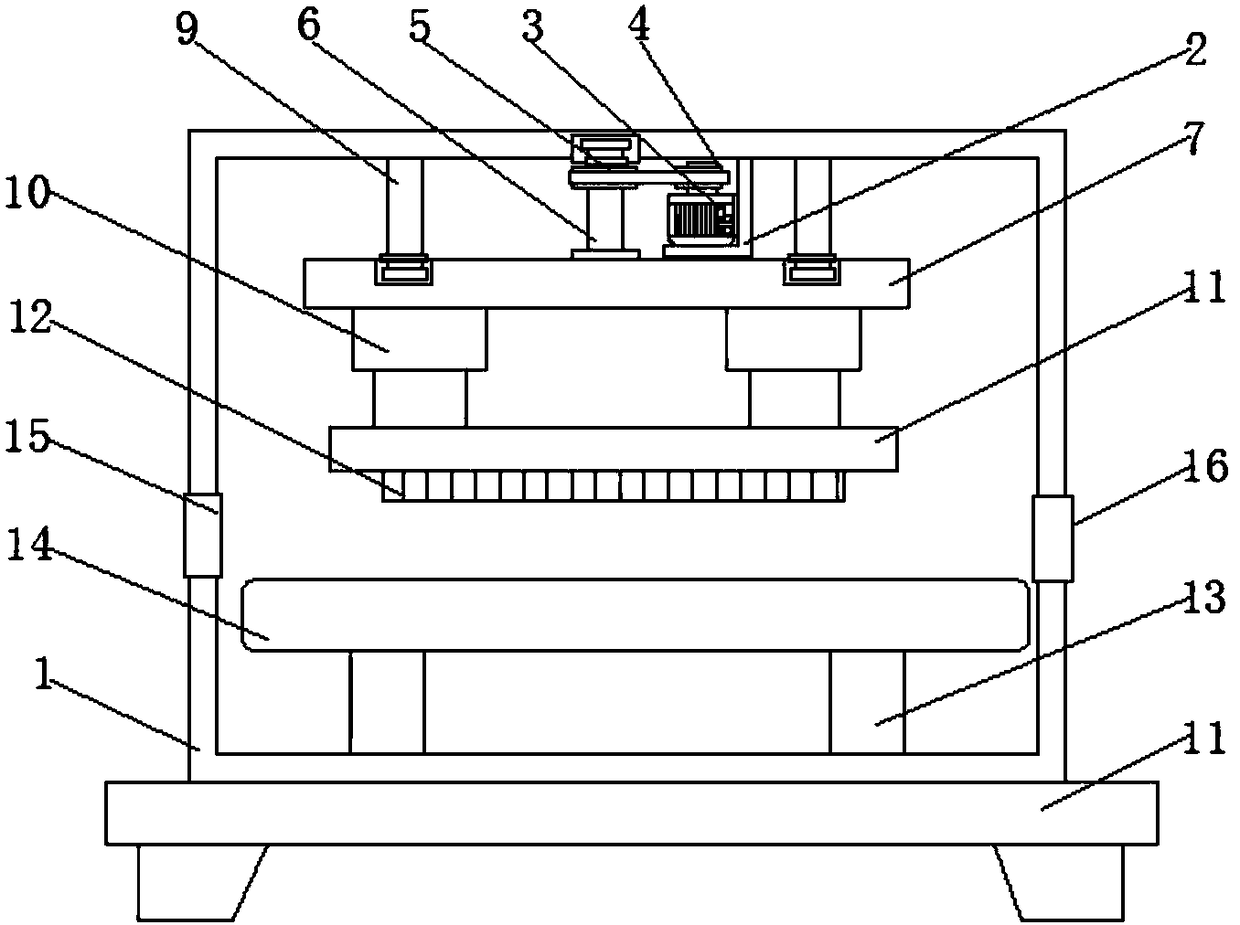

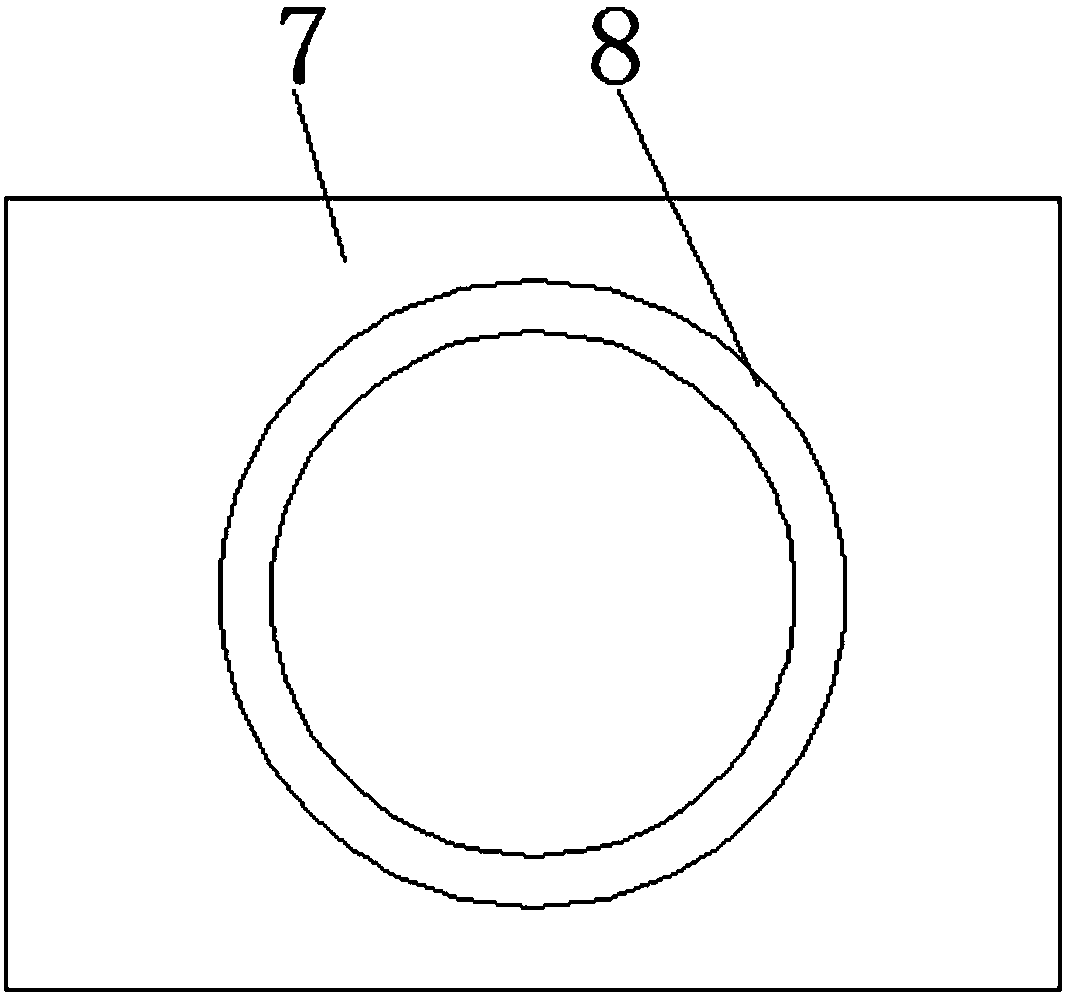

LED wafer cutting device

InactiveCN108081485ARealize automatic cuttingAchieve closureFine working devicesElectric machineryAgricultural engineering

The invention discloses an LED wafer cutting device. The LED wafer cutting device comprises a box c, the top of the inner wall of the box body is fixedly connected with an L-shaped connecting plate, and the top of the L-shaped connecting plate is fixedly connected with a motor; a first belt pulley is fixedly connected to an output shaft of the motor, and a second belt pulley is connected to the surface of the first belt pulley through a belt in a transmission mode; a first rotating shaft penetrates through the middle of the second belt pulley, and the top end of the first rotating shaft is rotatably connected with the top of the inner wall of the box body; the bottom end of the first rotating shaft is fixedly connected with a connecting plate, and both sides of the bottom of the connectingplate are fixedly connected with telescopic cylinders; and a cross bar is fixedly connected to the bottom parts of the telescopic cylinders, and a cutting blade is fixedly connected to the bottom endof the cross bar. The invention relates to the technical field of wafer cutting equipment. The LED wafer cutting device solves the problems of low safety performance, complicated procedures and low work efficiency of an existing LED wafer cutting device.

Owner:湖南华特光电科技有限公司

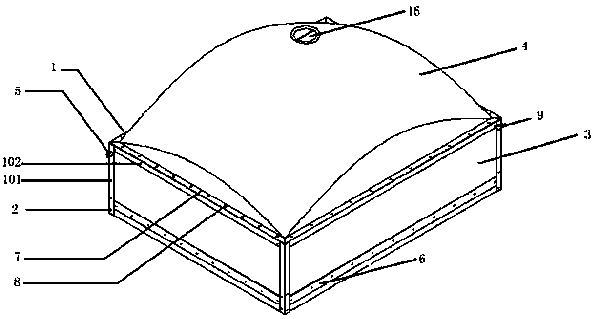

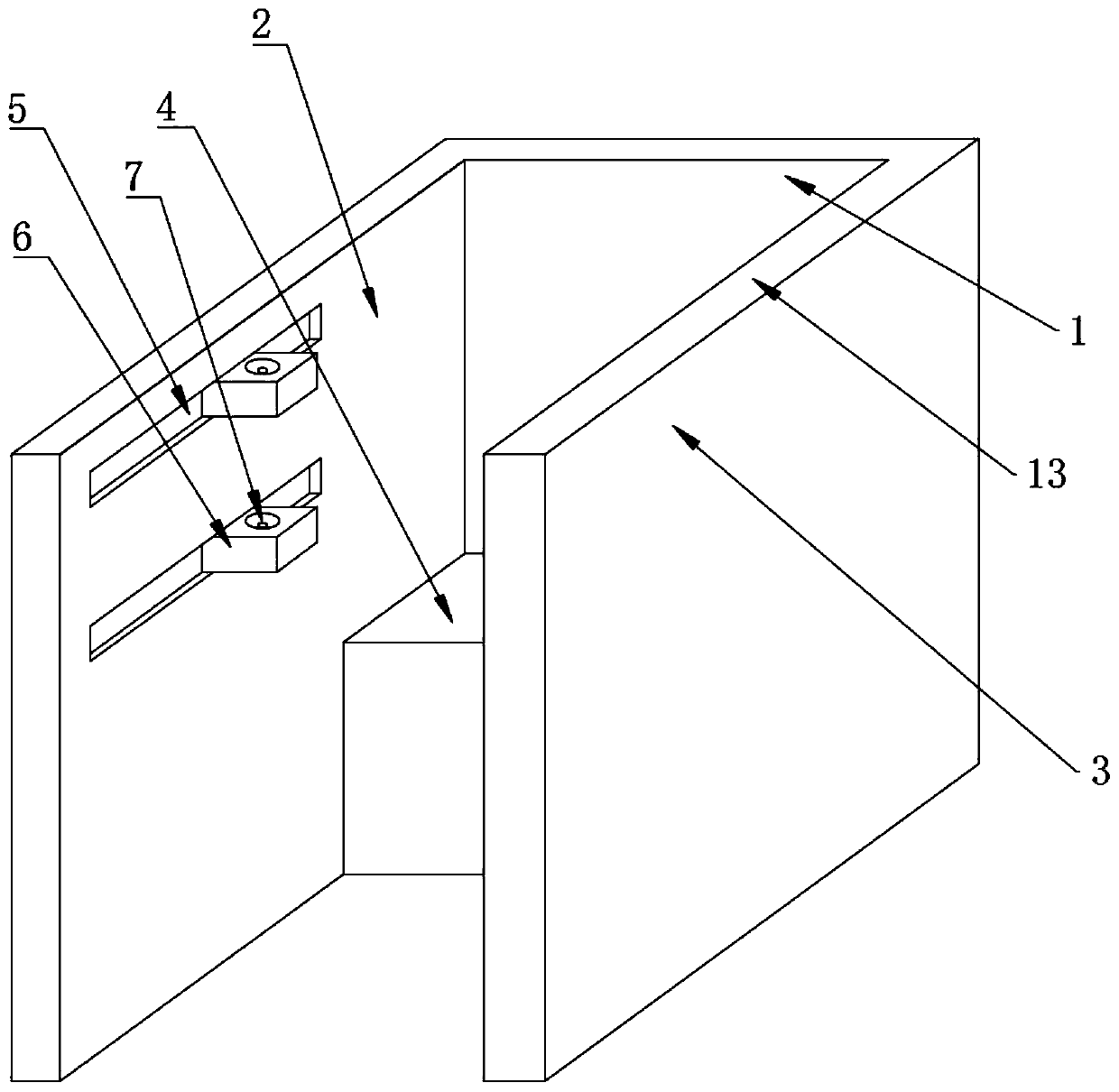

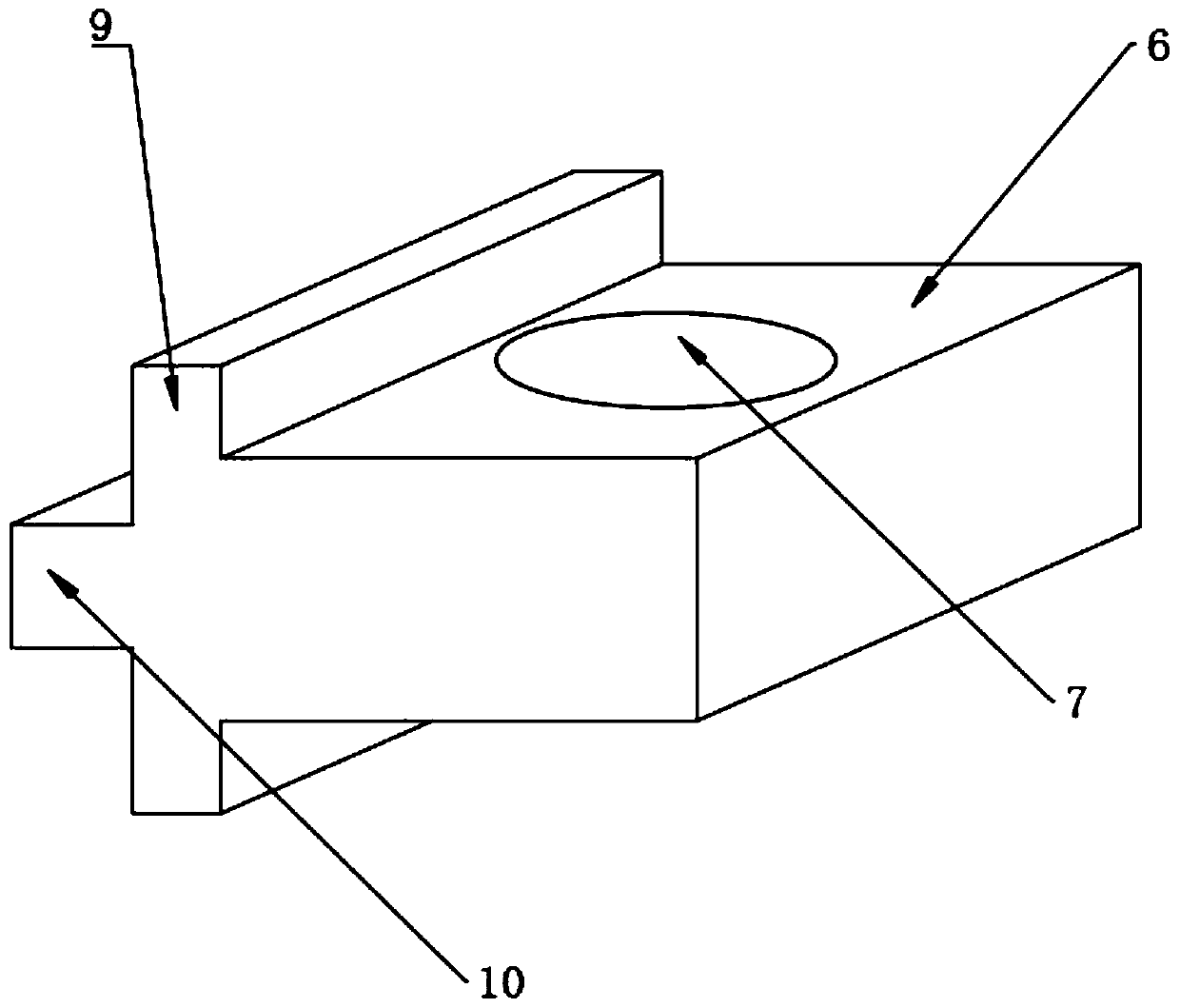

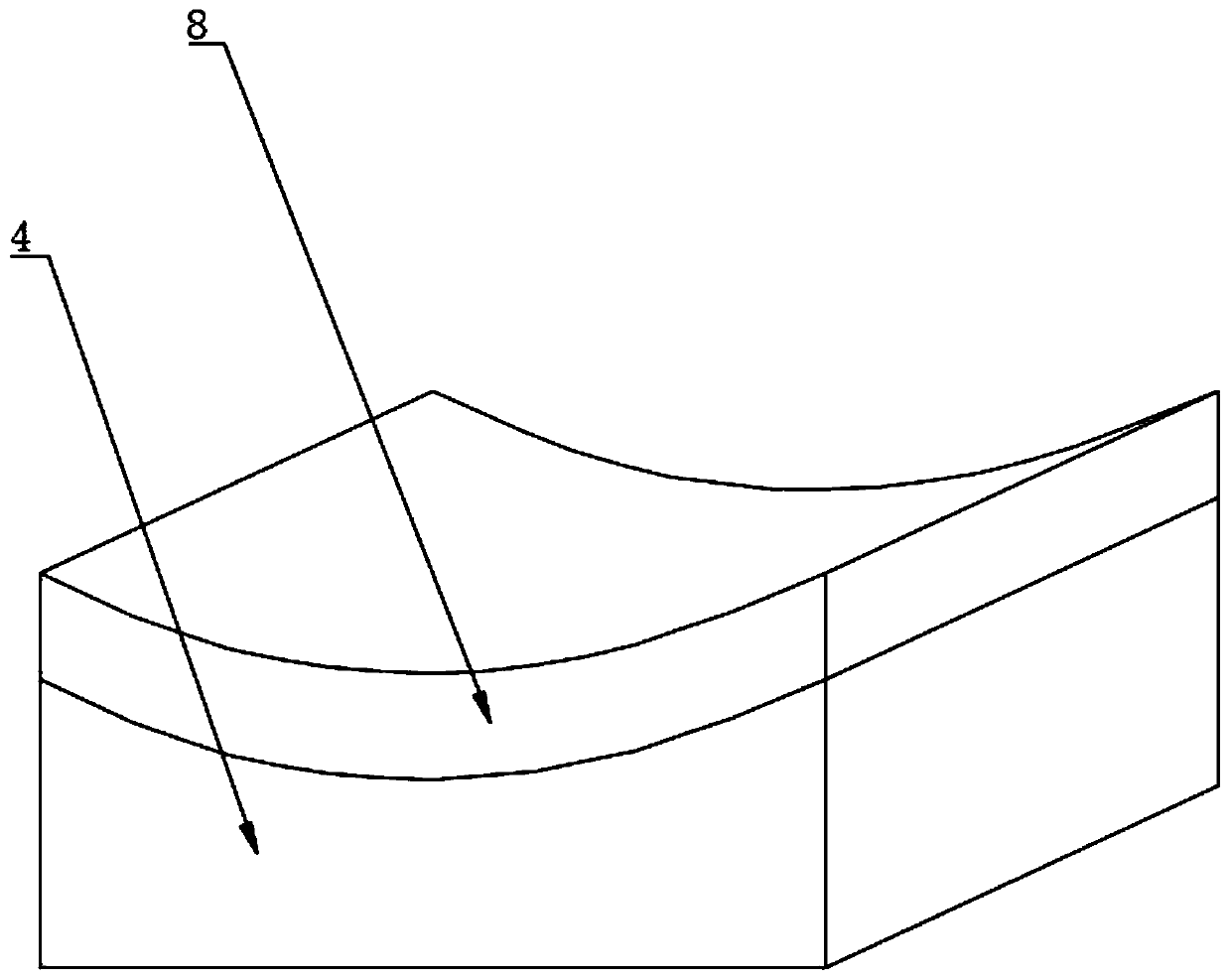

Three-dimensional printing forming sealing device

PendingCN109551767ASimple working environmentReliable working environmentAdditive manufacturing apparatusIncreasing energy efficiencyWater vaporShielding gas

The invention discloses a three-dimensional printing forming sealing device, which includes a working platform, a supporting mechanism with two opening ends and a sealing sleeve. One opening end of the supporting mechanism is arranged on the operating surface of the working platform, and the sealing sleeve is arranged on the other opening end of the supporting mechanism in a sealed mode; and the supporting mechanism is further provided with an air inlet and an air outlet, the sealing sleeve is provided with a connecting port, the connecting port is connected with a spindle of a three-dimensional printing laser head in a sealed mode, and the air inlet and the air outlet communicate with the gas environment inside and outside the sealing sleeve. By using the deformable sealing sleeve, the internal volume of the sealing device is changed during air intake and air exhaust, original gas in the sealing device can be fully replaced with protective gas in the sealing device, and the sealing device is internally kept dry by multiple cycles of air intake and exhaust, so that anti-steam performance and anti-oxidation gas explosion performance can be improved when the three-dimensional printing laser head conducts three-dimensional printing work.

Owner:TSC LASER TECH DEV BEIJING CO LTD

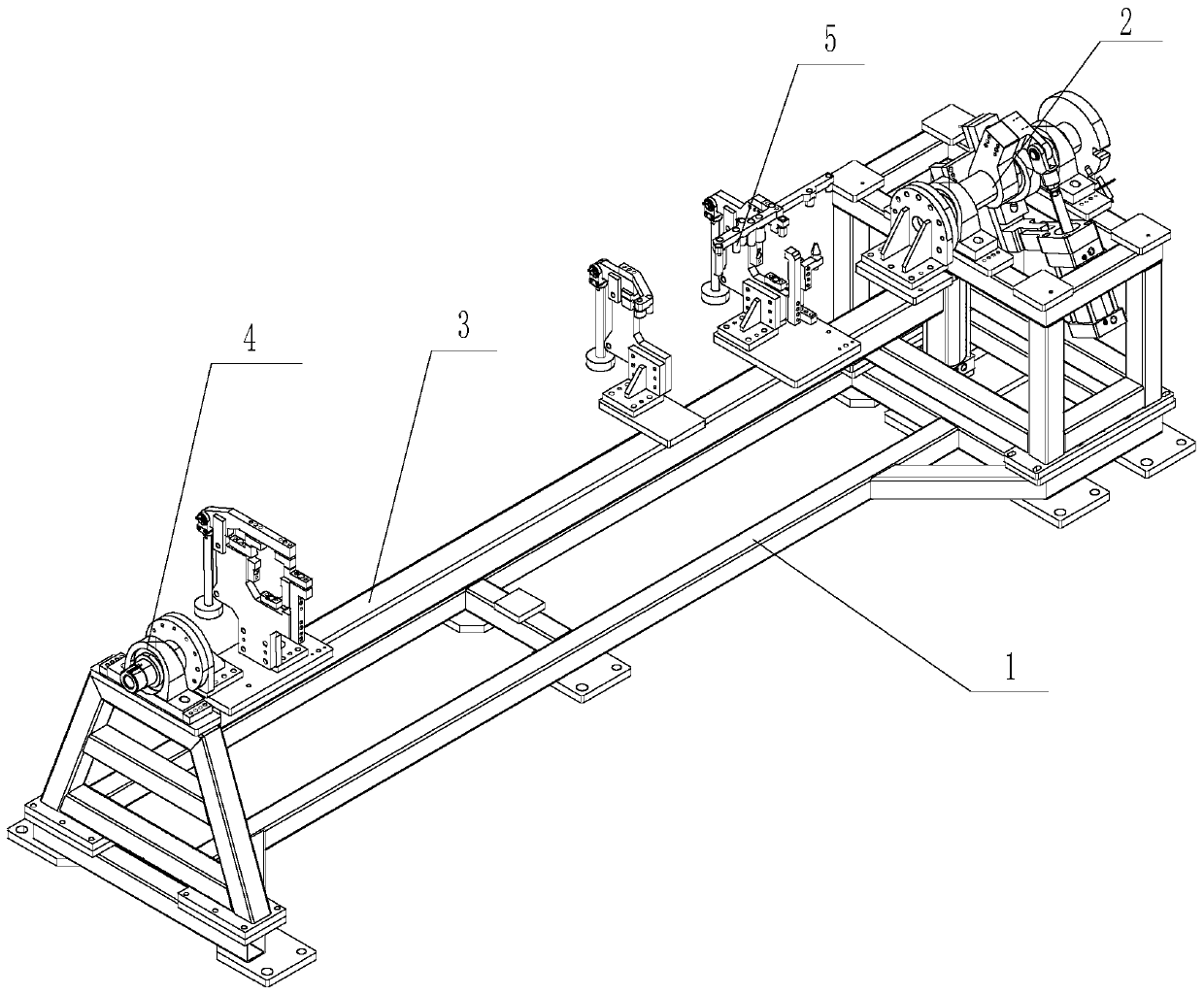

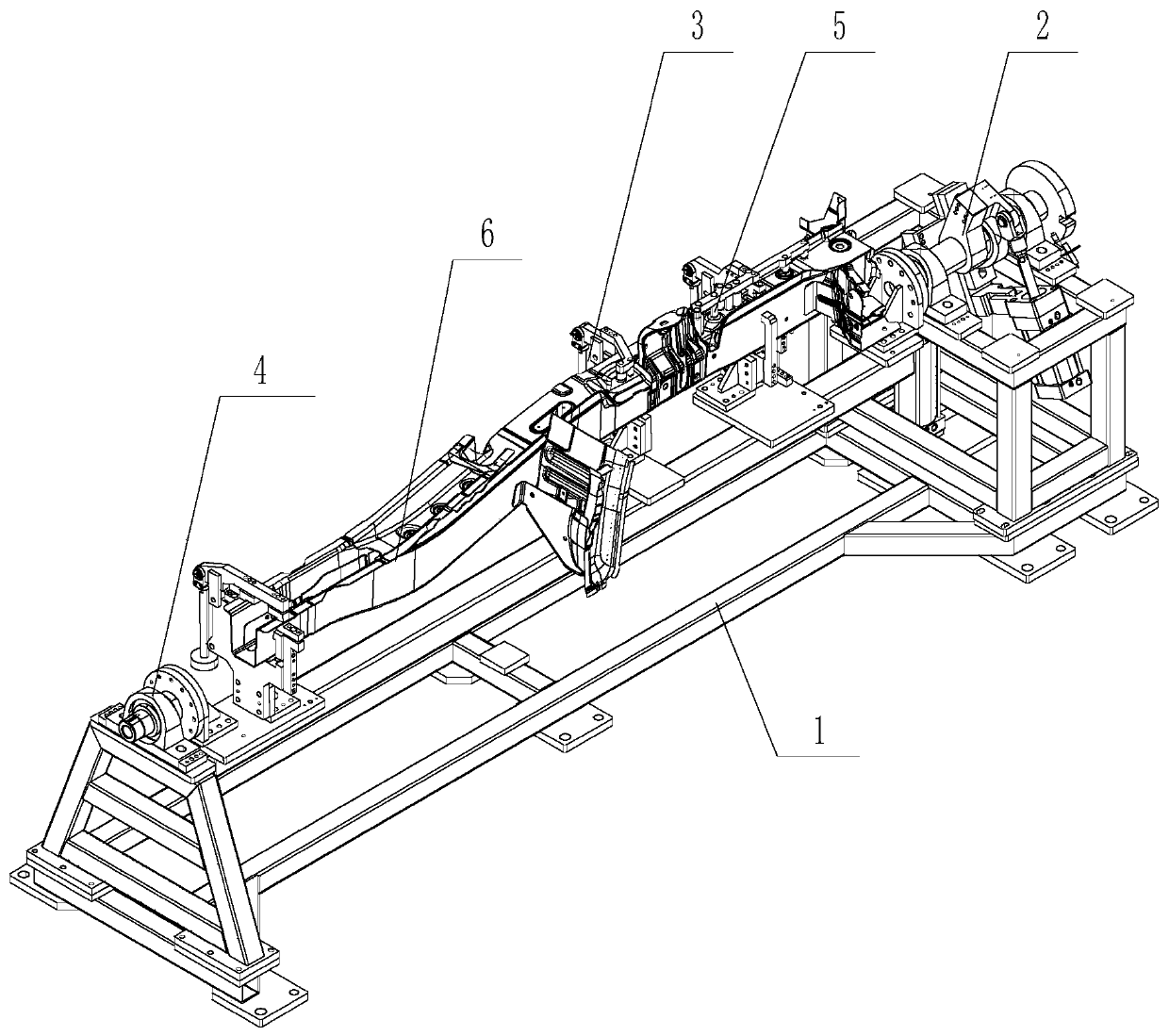

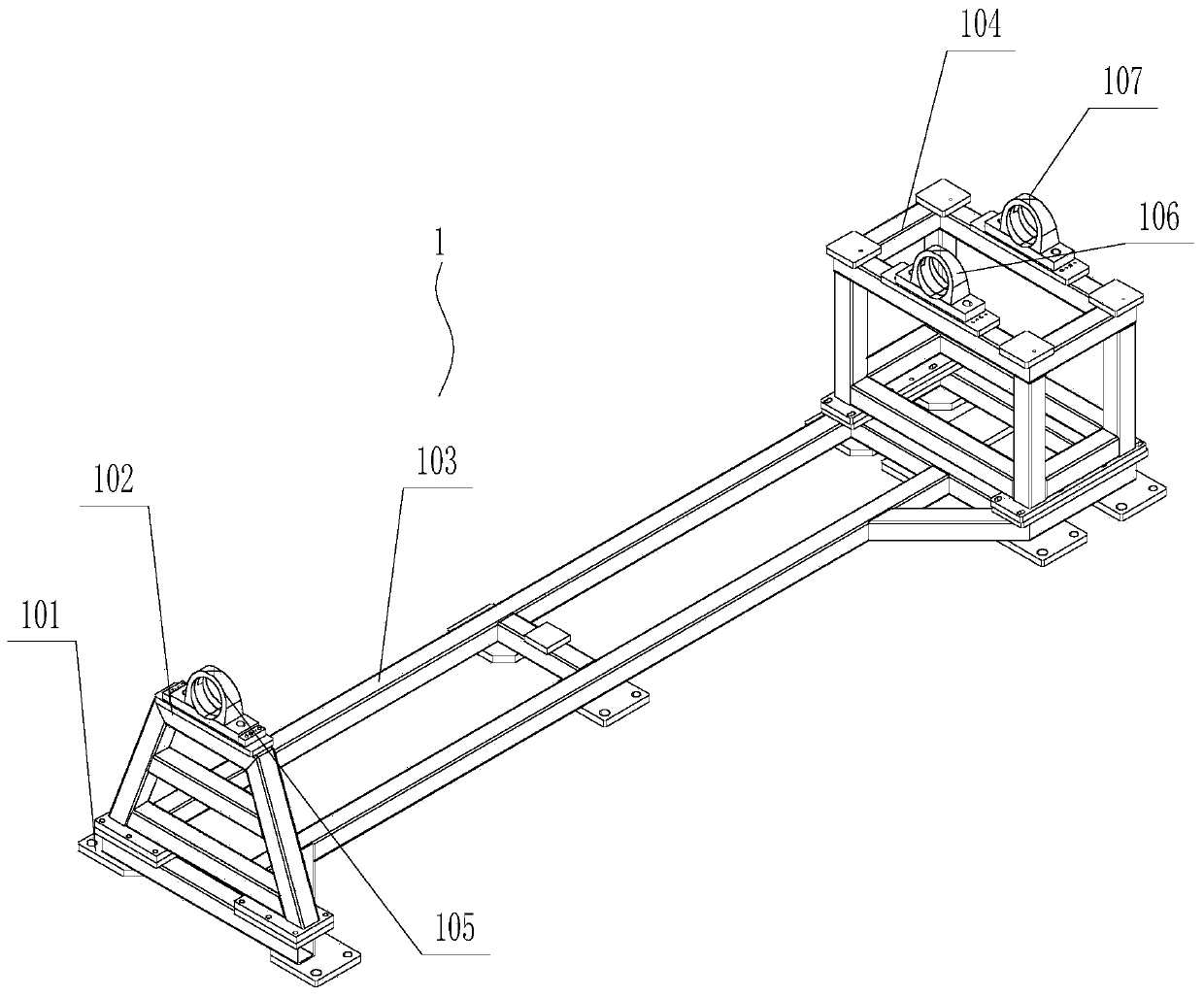

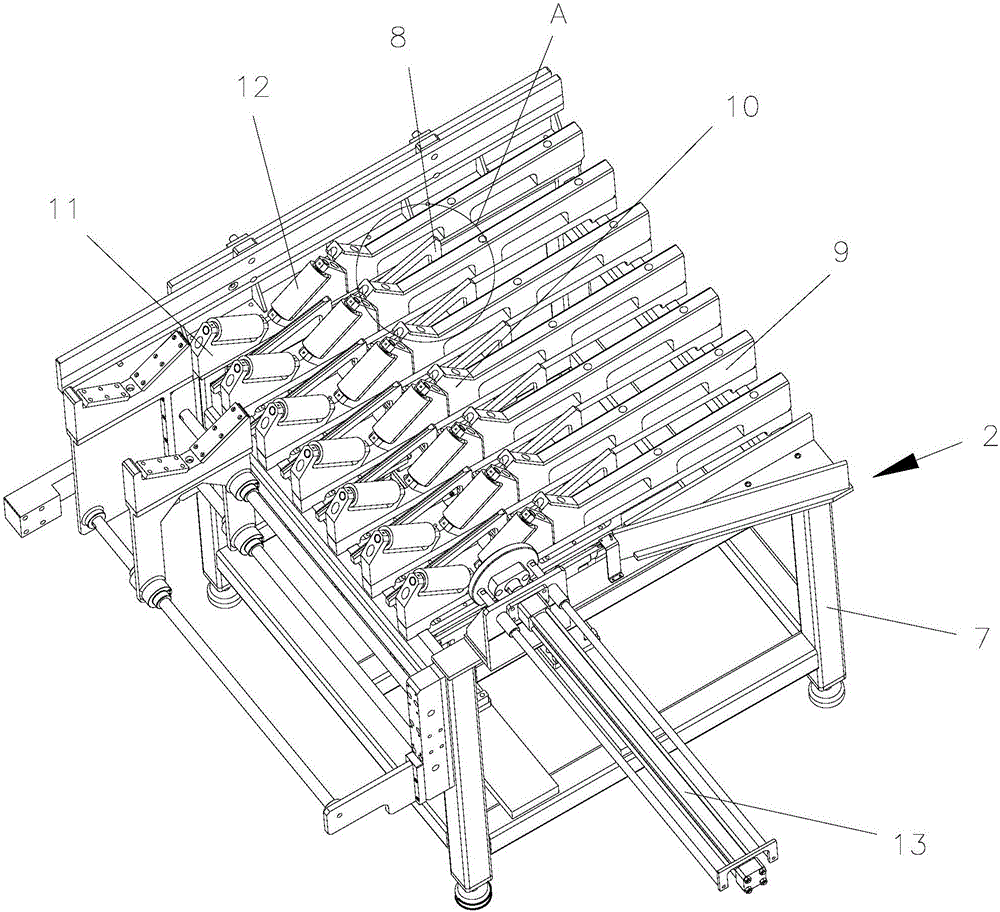

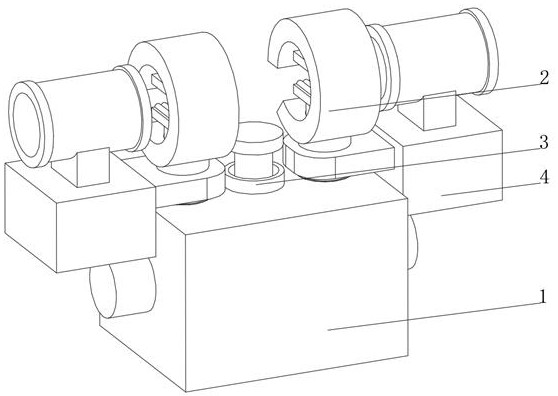

Automobile longitudinal beam weld reinforcement tool device

PendingCN109702408AEasy flipImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesDrive shaftRisk stroke

The invention discloses an automobile longitudinal beam weld reinforcement tool device and relates to a welding tool. The automobile longitudinal beam weld reinforcement tool device comprises a base support, a driving device, a clamping device, a driven device and a weld slag preventing device. The driving device and the driven device are installed at the two ends of the base support correspondingly. The driving device and the driven device are connected with the two ends of a workpiece correspondingly. The clamping device is installed between the driving device and the driven device. The weldslag preventing device is installed on the clamping device. The driving device comprises an installation support I, a driving air cylinder I, a connecting block I, a bearing seat installation block,an angle control device, a driving shaft, a driving shaft connecting block, a connecting block II, an installation support II, a driving air cylinder II and a driving disc. By means of the automobilelongitudinal beam weld reinforcement tool device, the driving device is used for driving the workpiece to rotate so that the workpiece can overturn to a proper angle, automatic overturning of the workpiece is very convenient, and the beneficial effects that the work efficiency is high, the product quality is high, work is stable, and the rotating precision is high are achieved; the work stroke ofa welding robot can be shortened, the robot swing space can also be reduced, and the automobile longitudinal beam weld reinforcement tool device is easy to use and popularize.

Owner:柳州福臻汽车冲压件有限公司

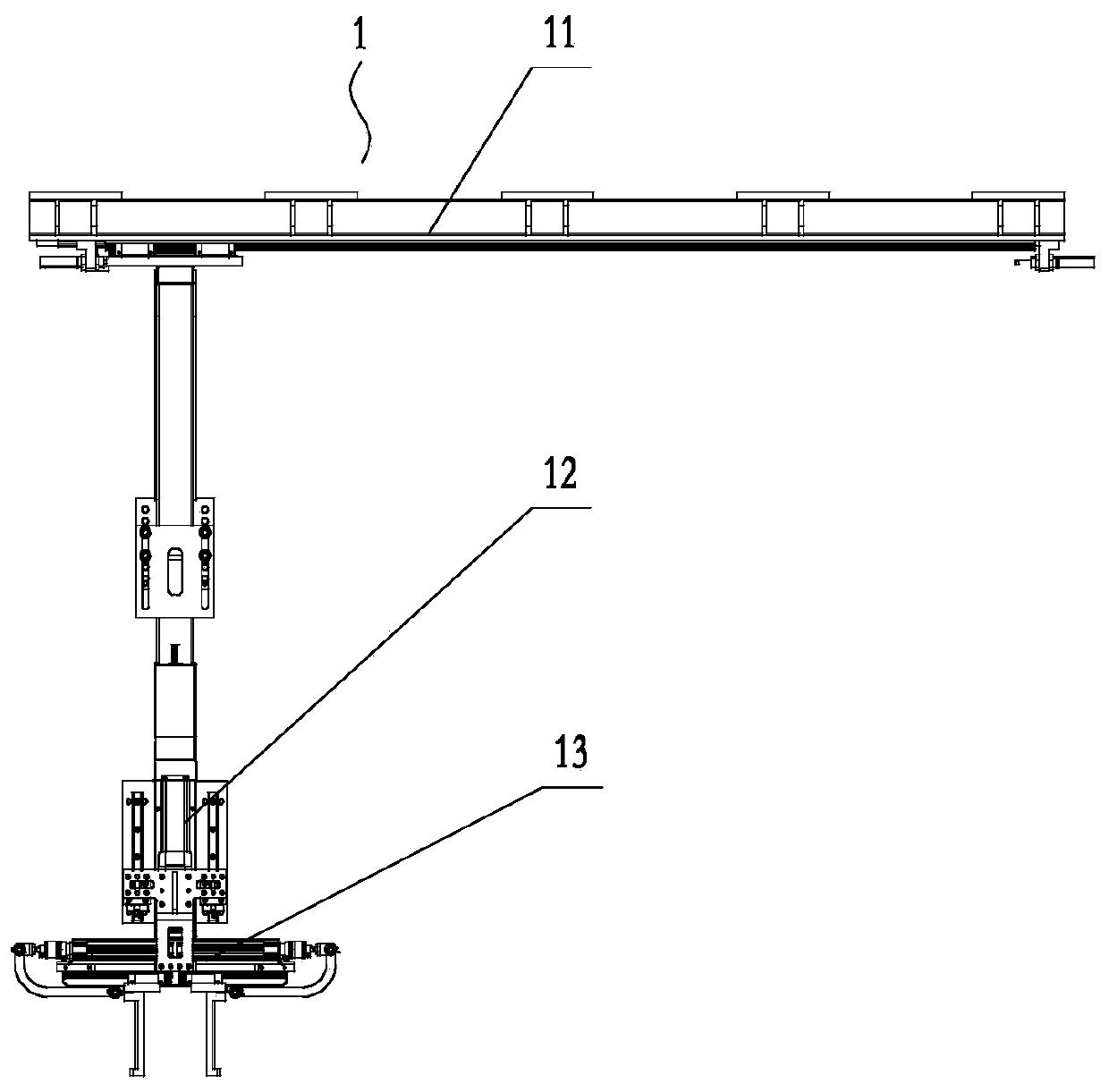

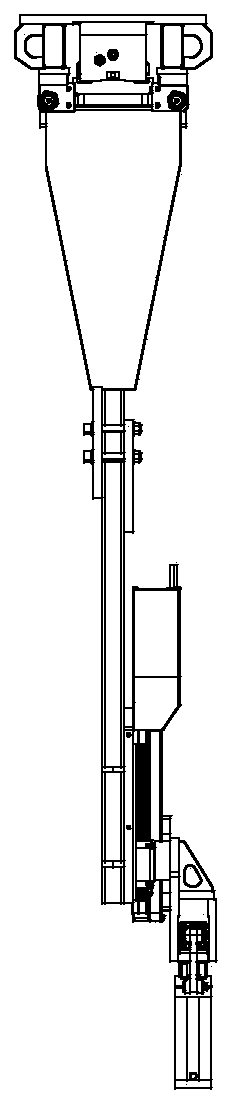

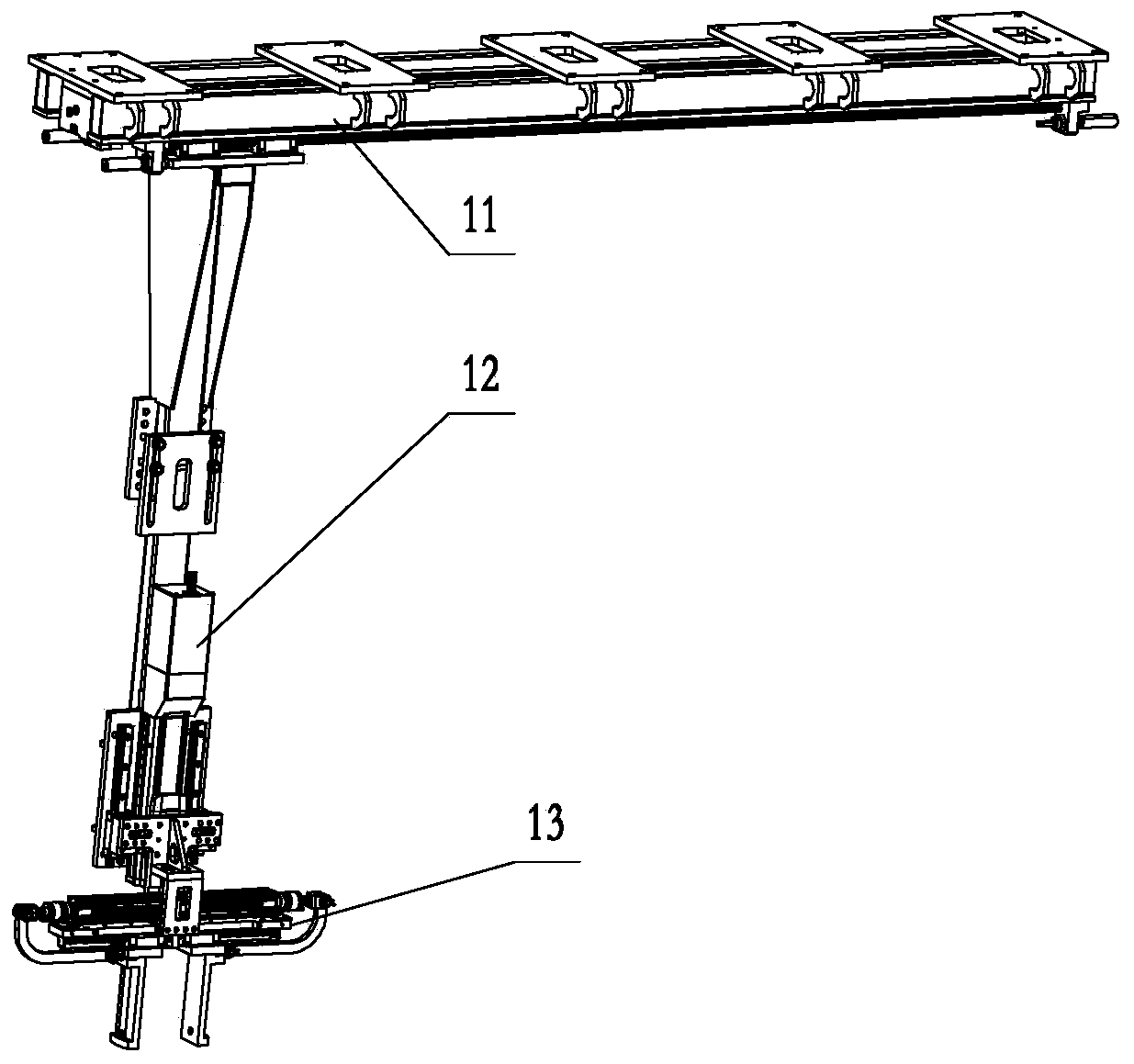

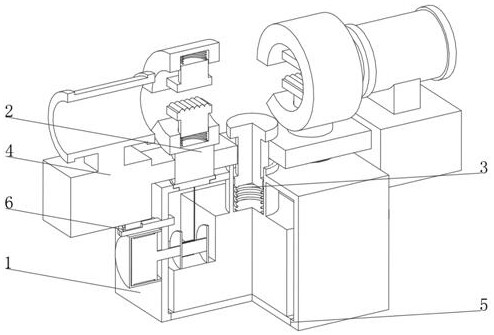

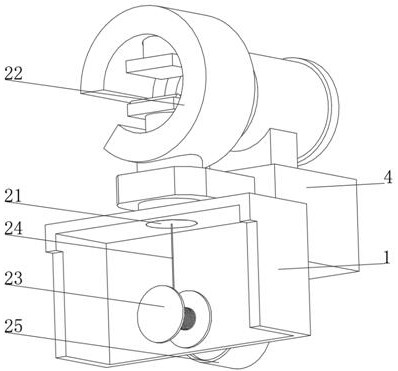

Driving axle housing waste automatic disassembling device and method

ActiveCN110625234AIncrease productivityRealize automatic disassemblyProgramme-controlled manipulatorGripping headsReduction driveReducer

The invention discloses a driving axle housing waste automatic disassembling device and method, and relates to a driving axle housing auxiliary machining device and method. The device comprises a transverse lifting device, a lifting connecting device and a material unloading device, wherein the material unloading device comprises an air cylinder base, air cylinders, pull rods and material unloading blocks, the lifting connecting device is fixedly connected with the lower end of the transverse lifting device and the air cylinder base of the material unloading device, the two air cylinders are fixed on the air cylinder base face to face and are hinged to the two material unloading blocks through the pull rods correspondingly, and the material unloading blocks are provided with vertical sections used for pressing the inner hole wall of a workpiece and bending sections used for bearing workpiece waste. The method comprises the following steps of S1, preparing; S2, pressing the workpiece bythe material unloading device; S3, cutting a main speed reducer mounting hole; S4, resetting a servo electric cylinder; S5, resetting a rodless cylinder; and S6, resetting the air cylinders to release the waste. According to the device and the method, the driving axle housing waste of different models can be automatically disassembled, the characteristics of high working efficiency, easy removalof the waste, high safety performance, reliable structure and the like are achieved, and popularization and use are easy.

Owner:柳州福臻汽车冲压件有限公司

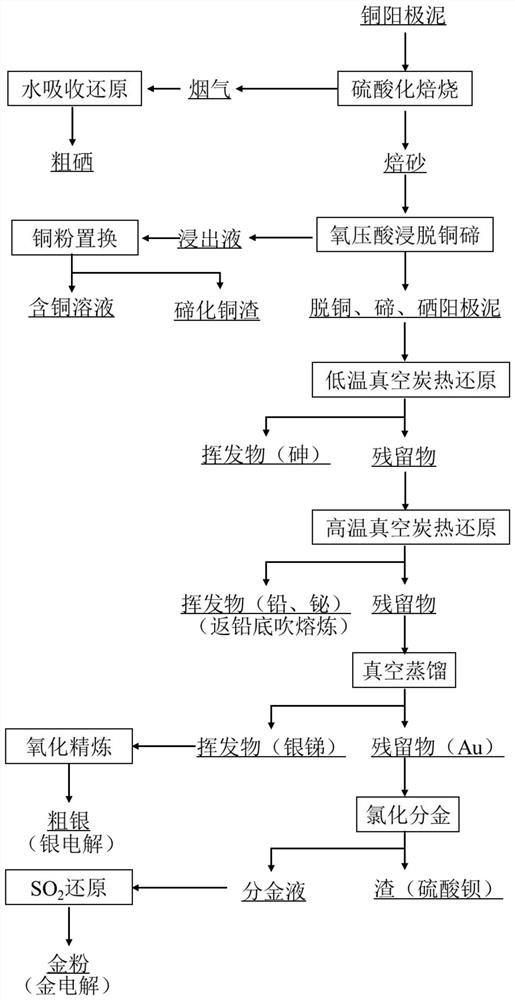

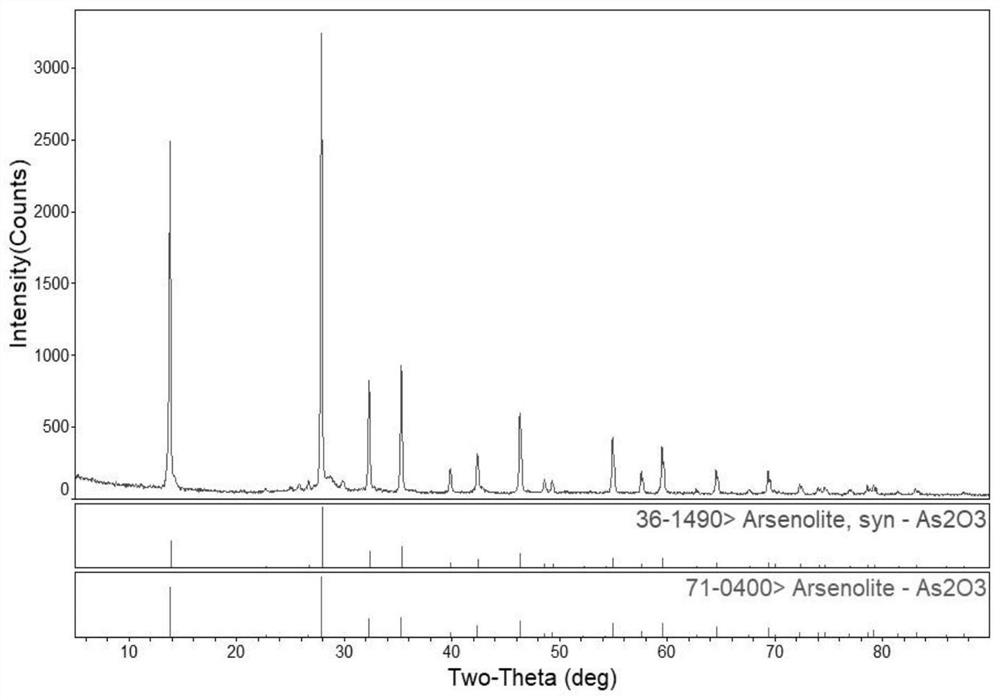

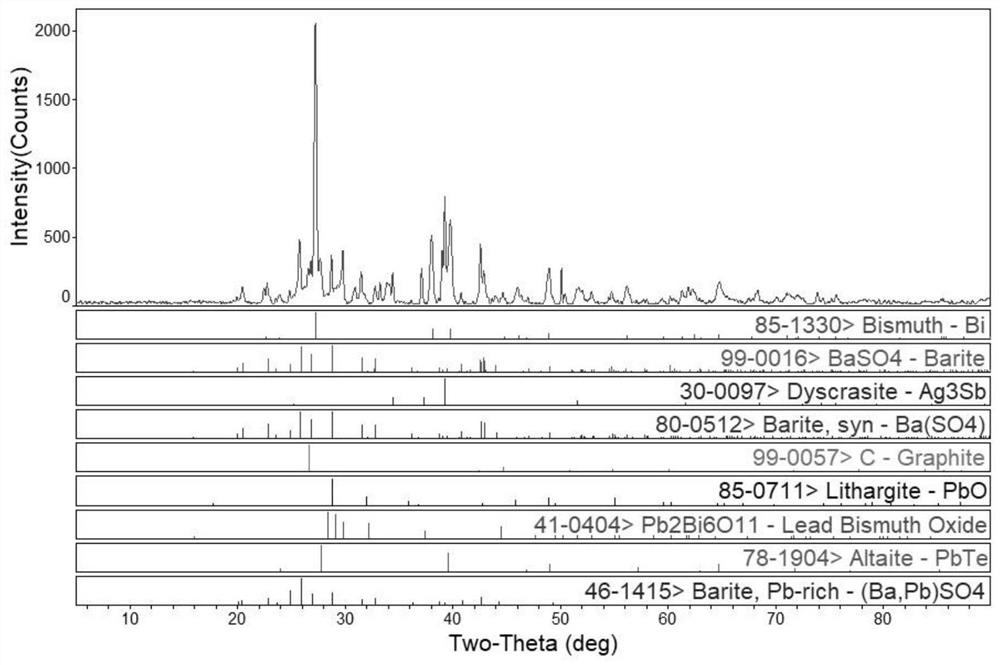

Recovery method for valuable metals in copper anode slime

ActiveCN113846222AAvoid emissionsSpeed up recovery timePhotography auxillary processesProcess efficiency improvementSlagSmoke Emission

The invention provides a recovery method for valuable metals in copper anode slime, and belongs to the technical field of comprehensive treatment of the copper anode slime. According to the recovery method, selenium, copper, tellurium, arsenic, lead, bismuth and precious metal gold and silver in the copper anode slime are efficiently recovered, a two-step vacuum carbon thermal reduction method is adopted to replace anode slime reduction smelting and precious lead step-by-step blowing in a traditional pyrogenic process, and emission of arsenic-containing smoke dust in a traditional process is avoided. Gold-rich residues obtained through the recovery method hardly contain base metal lead, the bismuth, the antimony, the arsenic and the like, gold powder can be obtained after chlorination gold separation and reduction, compared with the traditional process, the content of base metals is lower, the output slag amount is greatly reduced, the production period is greatly shortened, and the loss of precious metals in the slag is reduced. According to the whole recovery method, the recovery period of the precious metals is shortened, the direct recovery rate of the valuable metals is increased, the vacuum carbon thermal reduction process is a closed system, the whole process avoids smoke emission, the working environment is improved, meanwhile, the arsenic recovery and emission problem is solved, and the process is simple and environmentally friendly.

Owner:KUNMING UNIV OF SCI & TECH

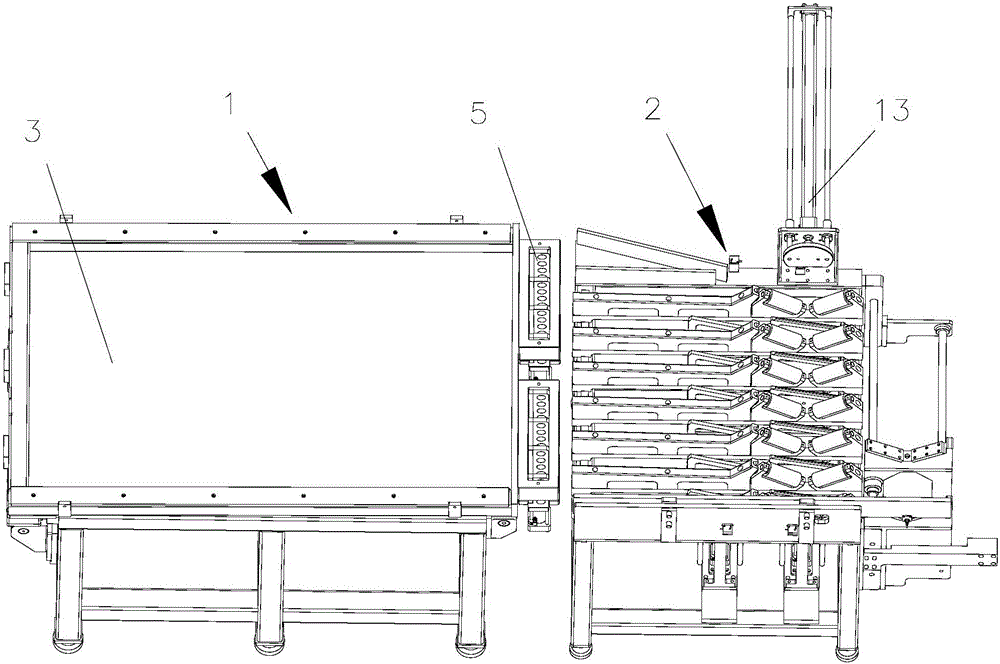

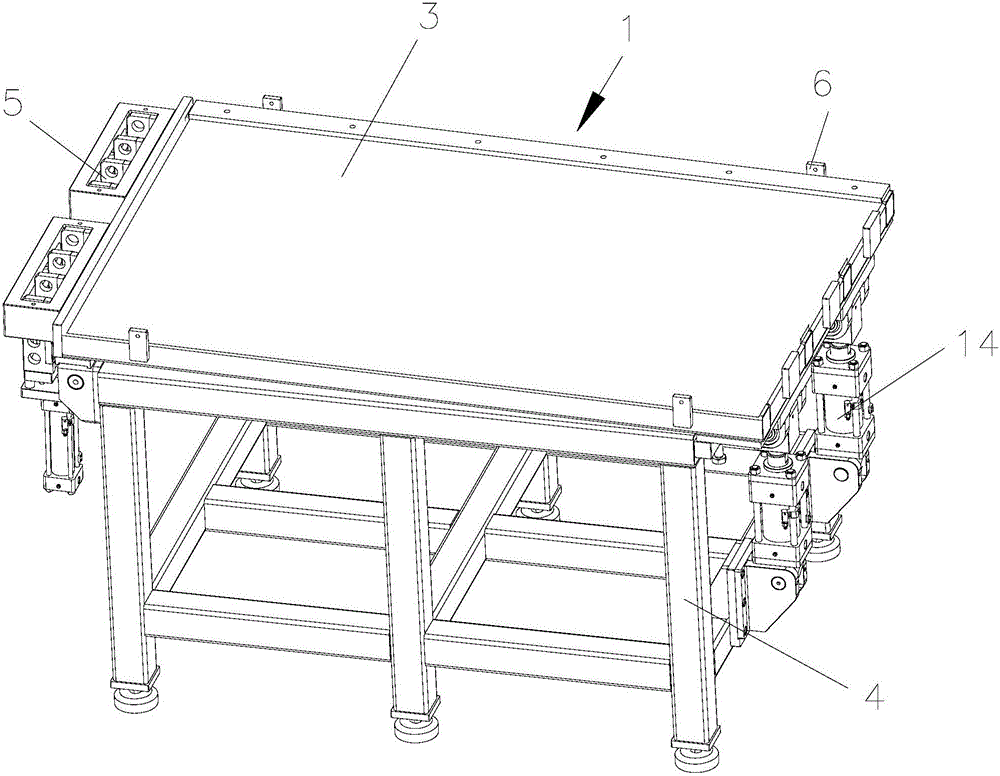

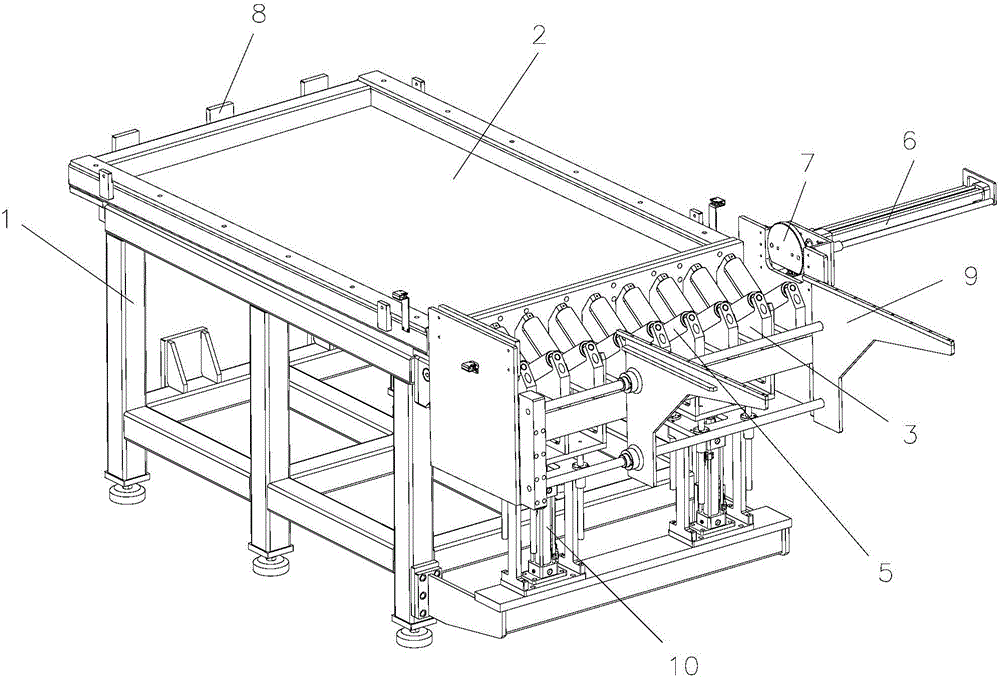

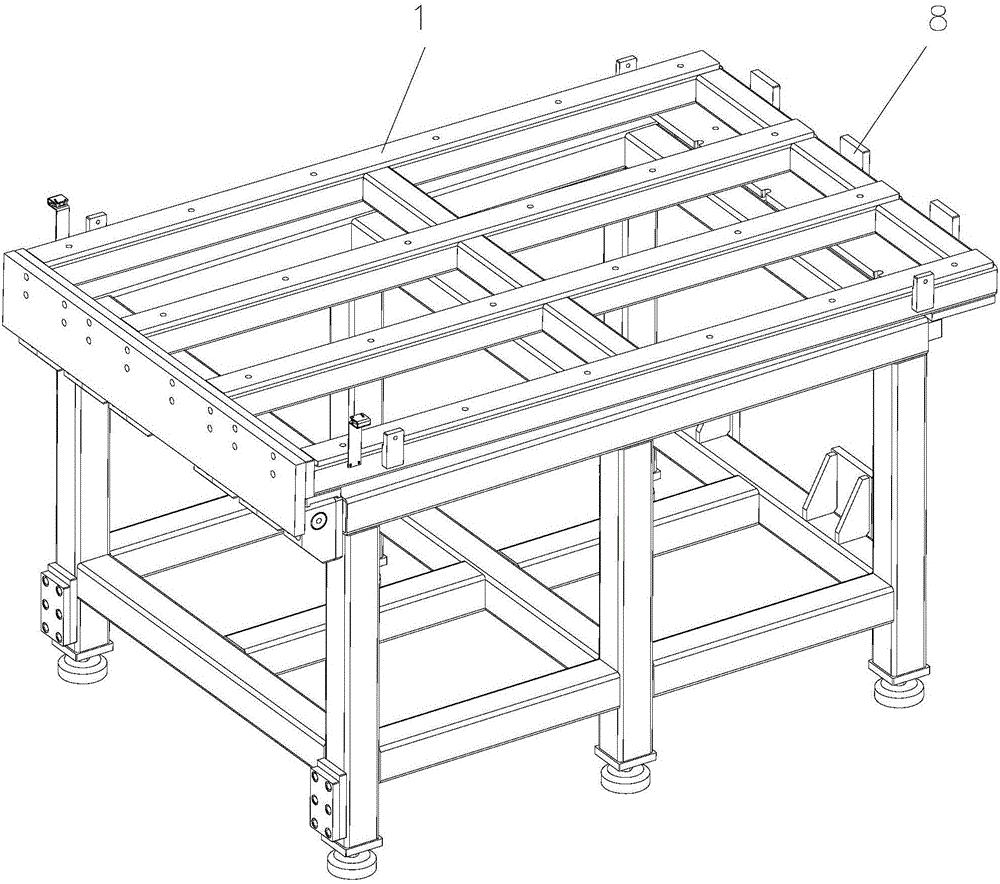

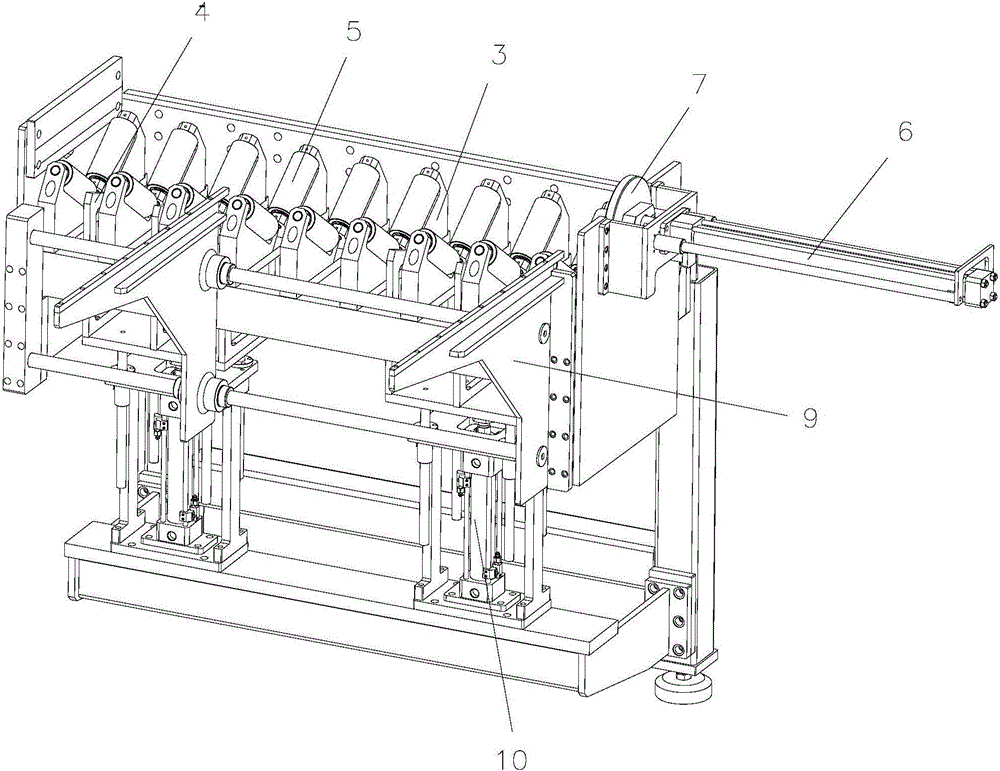

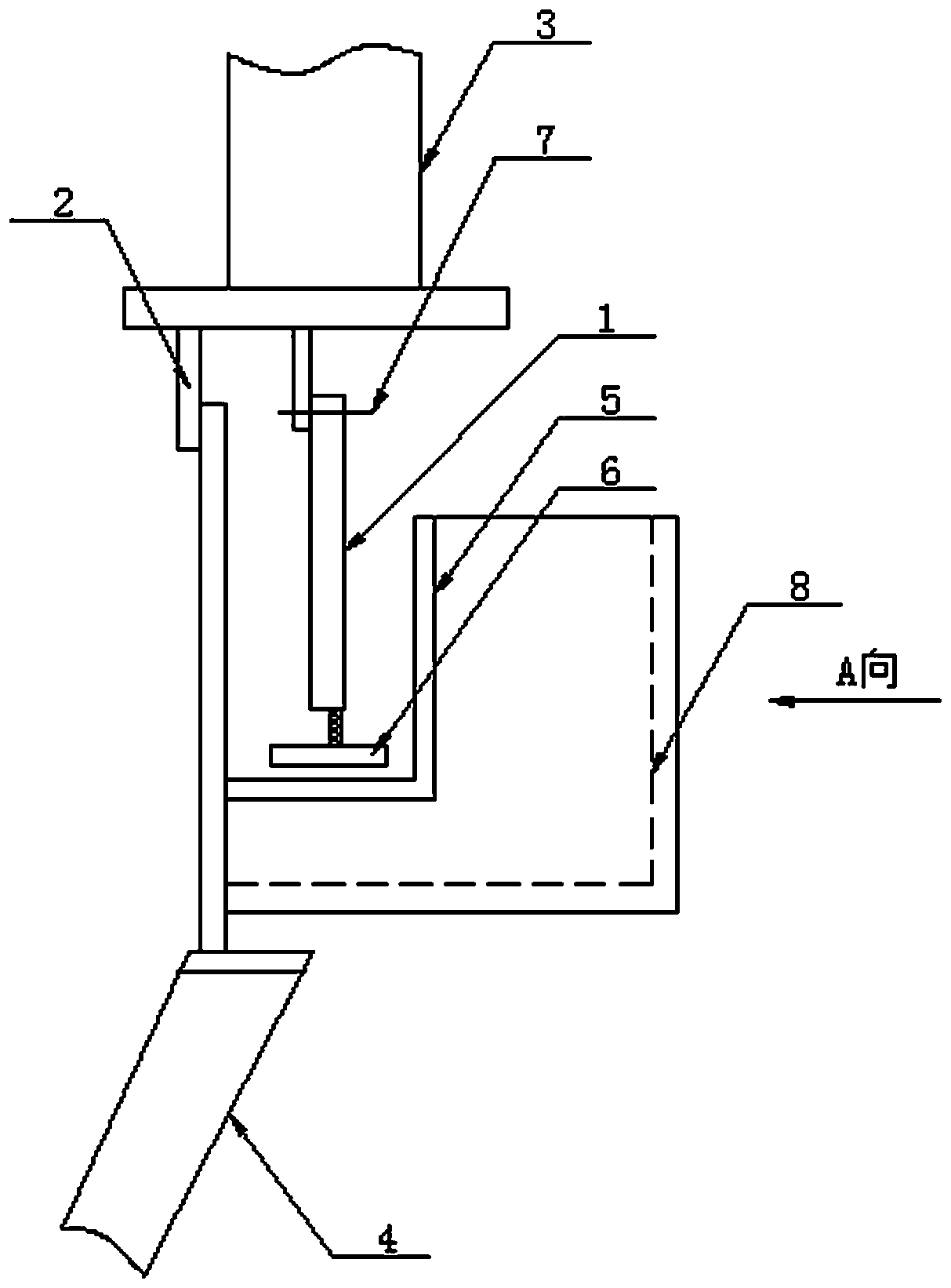

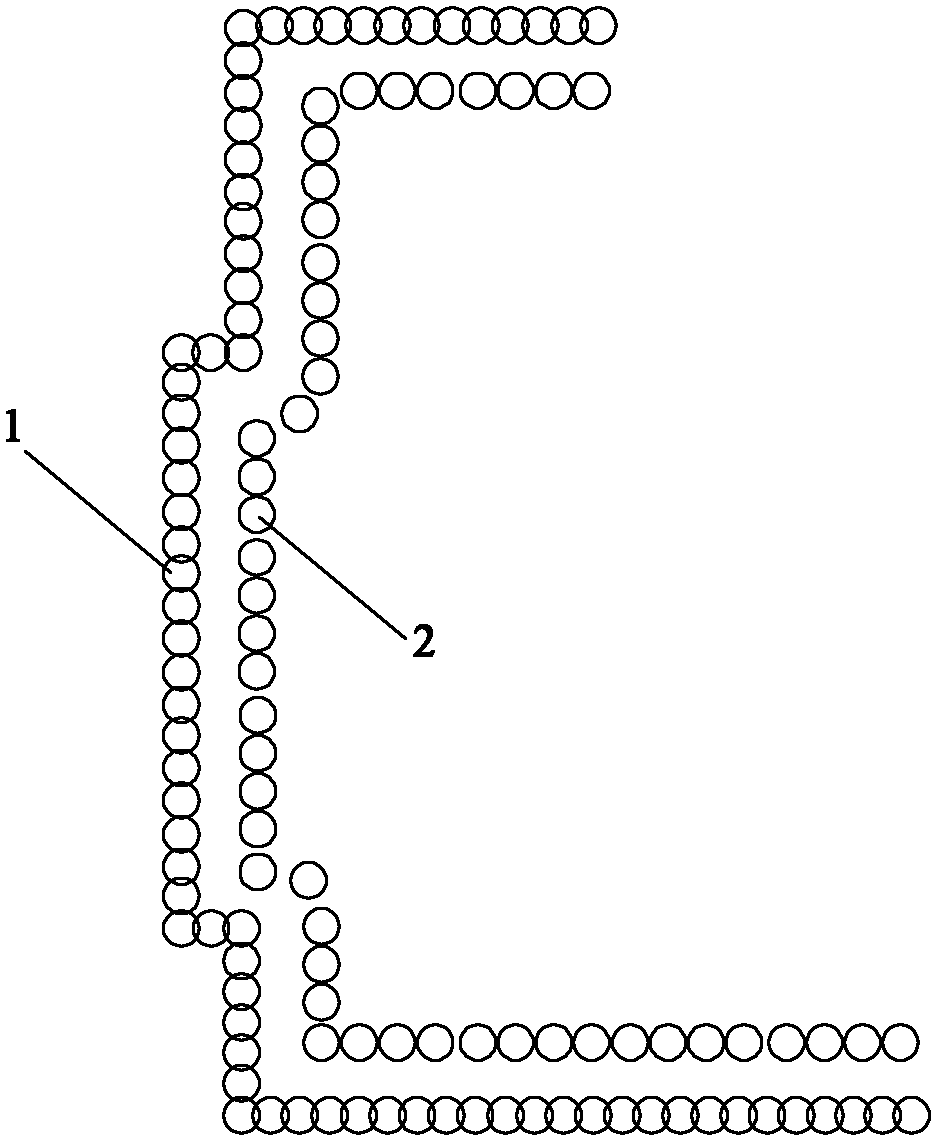

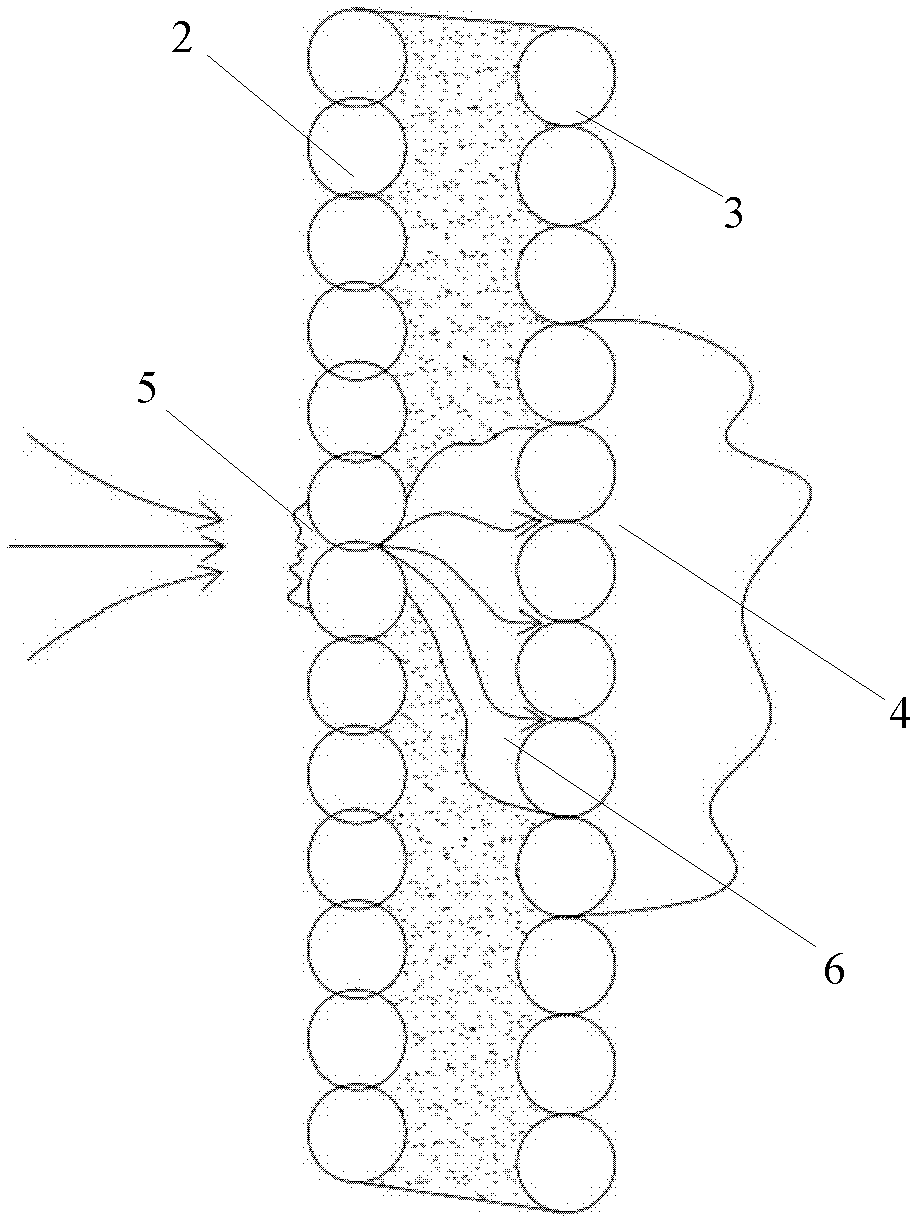

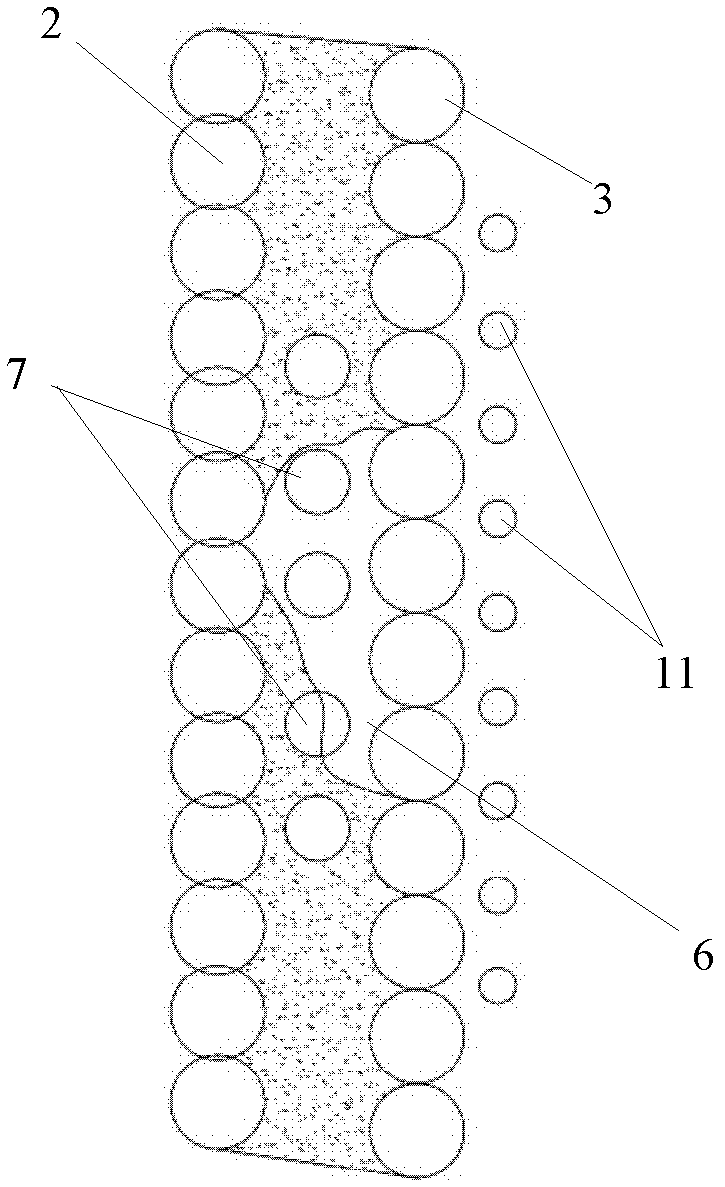

Feeding mechanism for fully automatic numerical control chamfering machine

ActiveCN105750979AEase of workImprove feeding efficiencyMetal working apparatusNumerical controlWorking environment

The invention relates to a feeding mechanism for a fully automatic numerical control chamfering machine. The feeding mechanism comprises a feeding device and a material pulling and conveying device, wherein the feeding device and the material pulling and conveying device are arranged in parallel. The feeding mechanism for the fully automatic numerical control chamfering machine has the advantages that the fully automatic feeding by using the feeding device and the material pulling and conveying device is realized; the machine is used for replacing manual feeding; the work difficulty of employees is reduced; the feeding efficiency is improved, so that the feeding is safer, faster and more convenient; the structure is simple; the occupied area is smaller; the work environment is simple and clean.

Owner:艾欧特克(江苏)机床有限公司

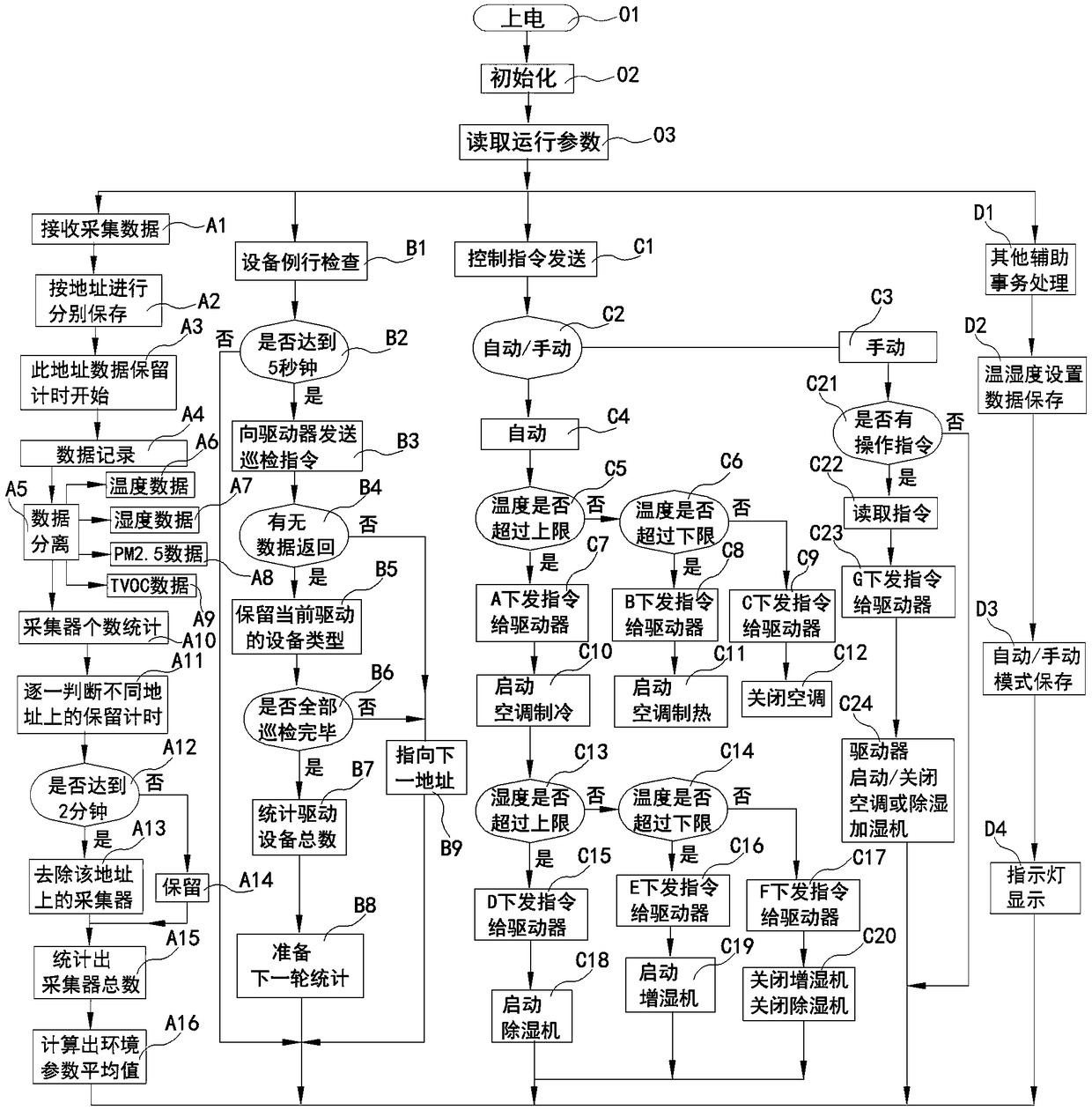

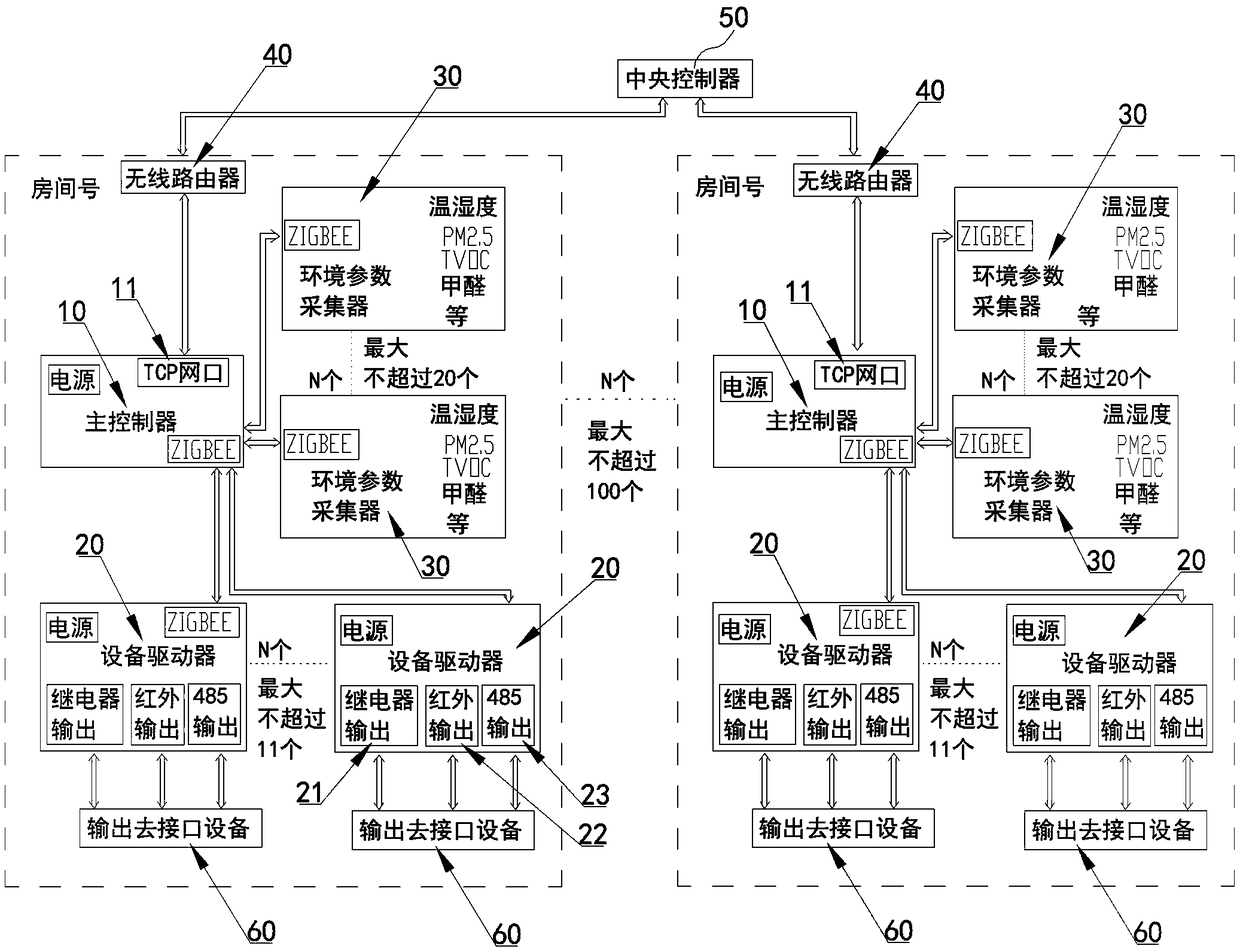

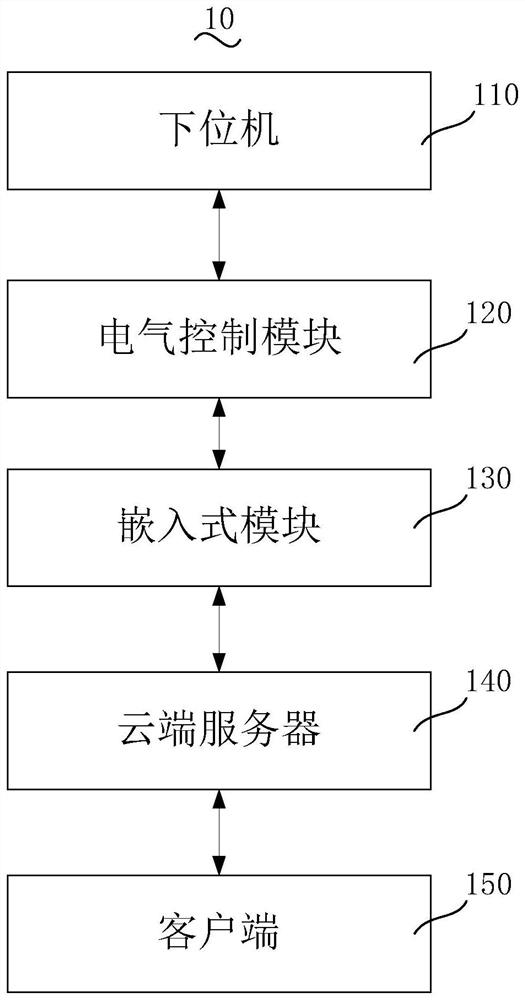

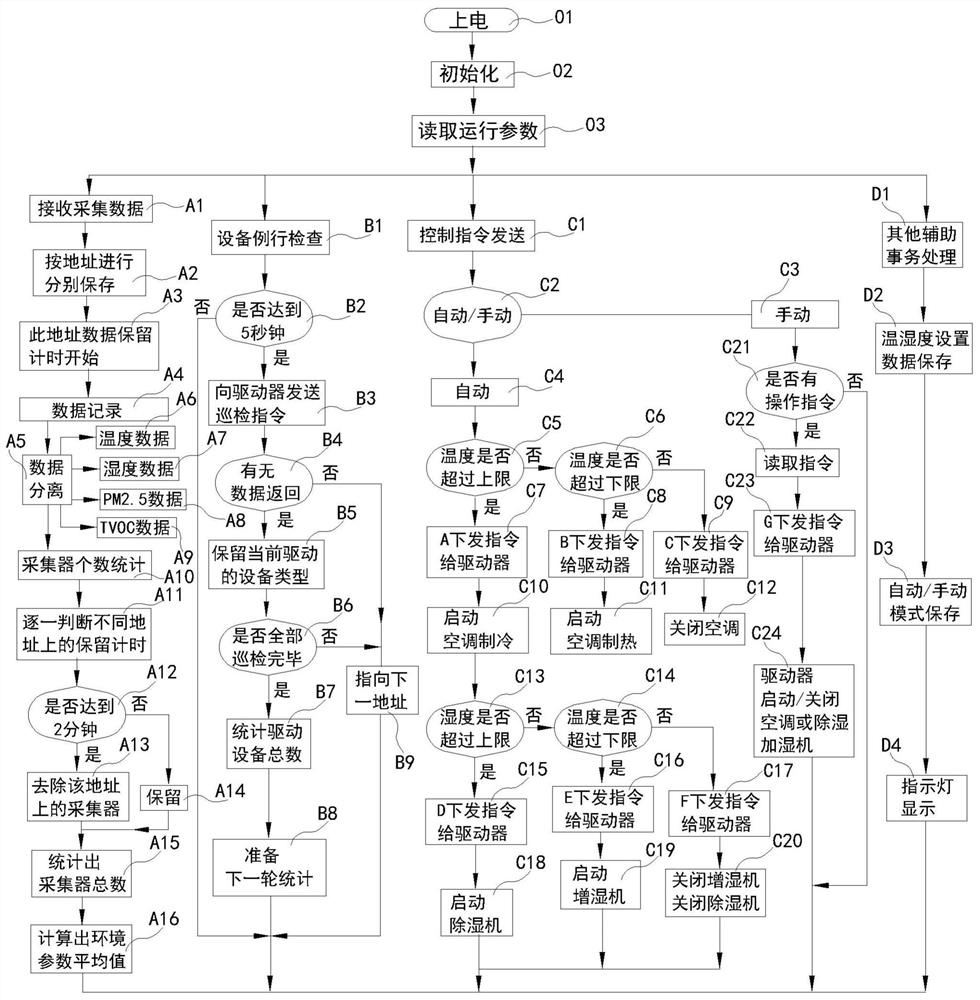

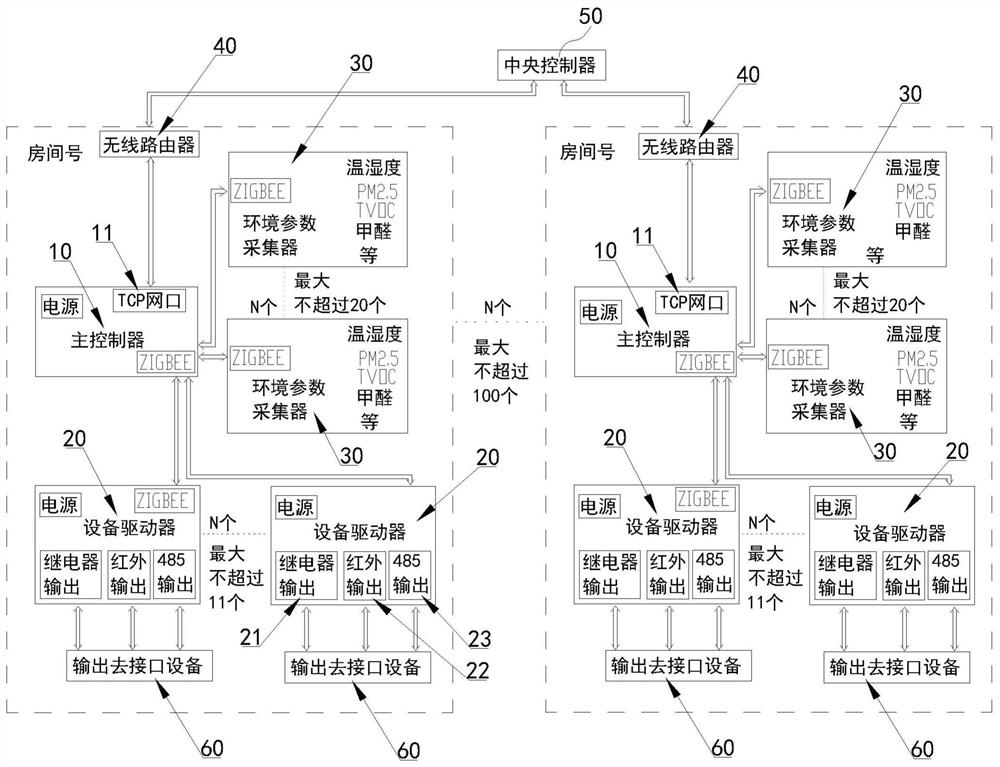

Running control method of wireless networking equipment controller in environment control system

ActiveCN108758988AImprove environmental automatic monitoring operation controlWiring is simple and convenientMechanical apparatusSpace heating and ventilation safety systemsControl systemAmbient data

The invention discloses a running control method of a wireless networking equipment controller in an environment control system. The method is characterized in that a main controller, a multi-way environment parameter acquiring device and a multi-way equipment driver in the same room do the following running control tasks: an environment parameter processing task that the main controller receivesthe environment condition acquiring data from the multi-way environment parameter acquiring device and then separates the environment data, counts and determines and finally calculates the average value of the environment parameters; an information management task that the main controller runs to manage the state property information of the multi-way equipment driver; a driver control task that the main controller drives the multi-way equipment driver to control an environment control port device; and a driving management task that the multi-way equipment driver receives an instruction from the main controller and starts or stops the corresponding environment control port device. With the adoption of the method, automatic driving running of various machines or household appliances is automatically started; the wire arrangement and the operation control management are simple and quick, and manual operation for controlling interference is avoided.

Owner:NINGBO BAYI IND

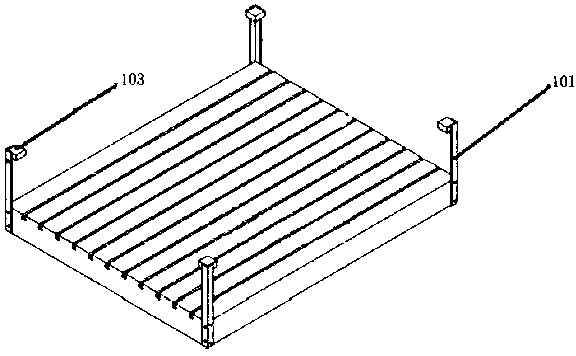

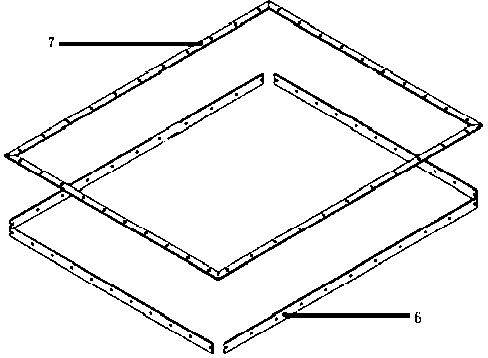

Rapid disassembling safety protection screen

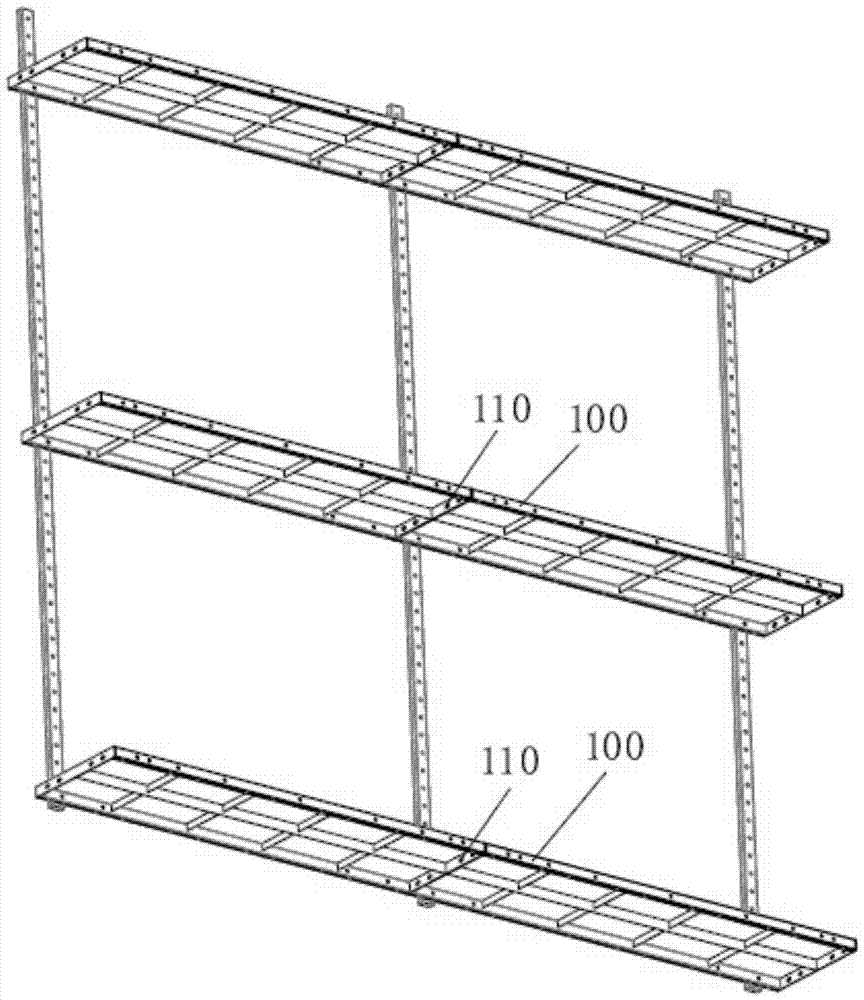

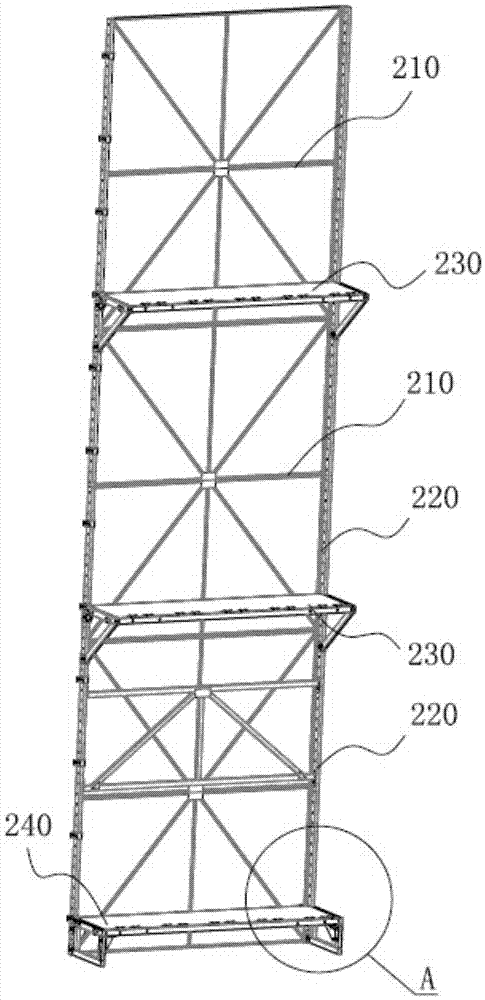

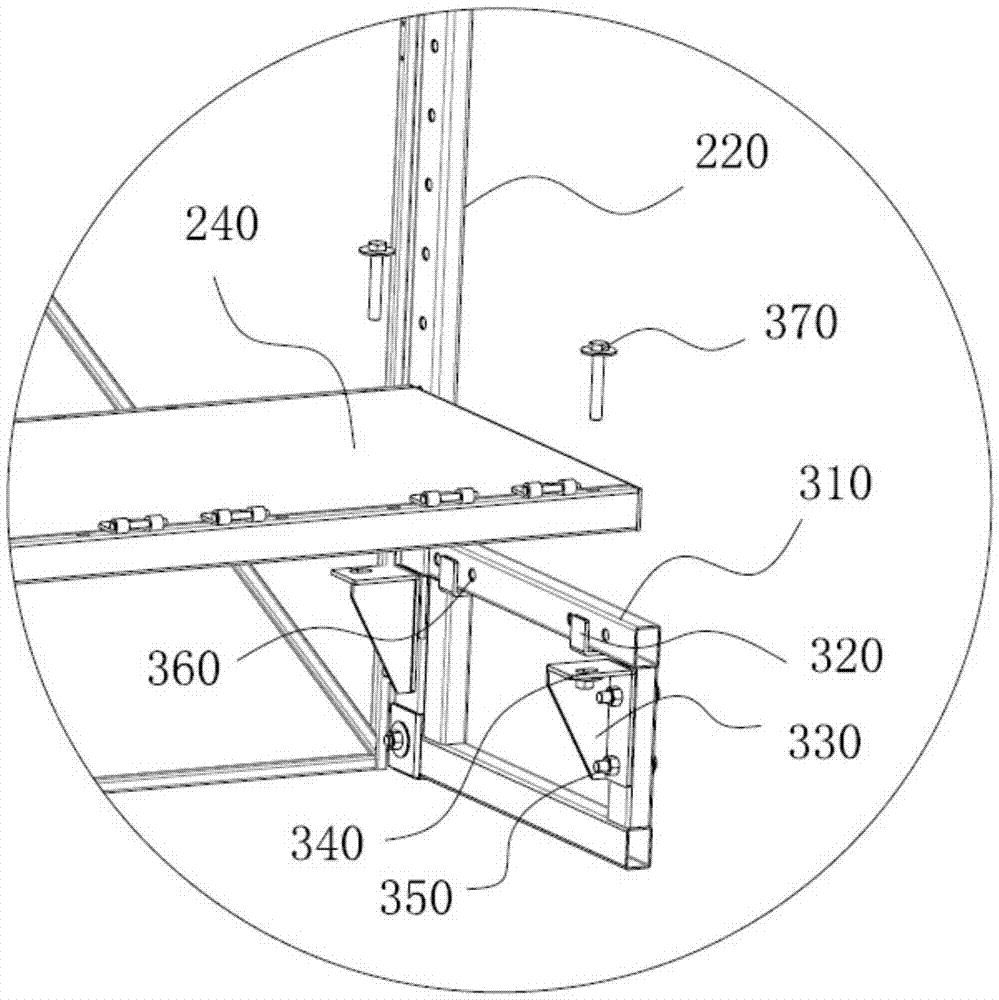

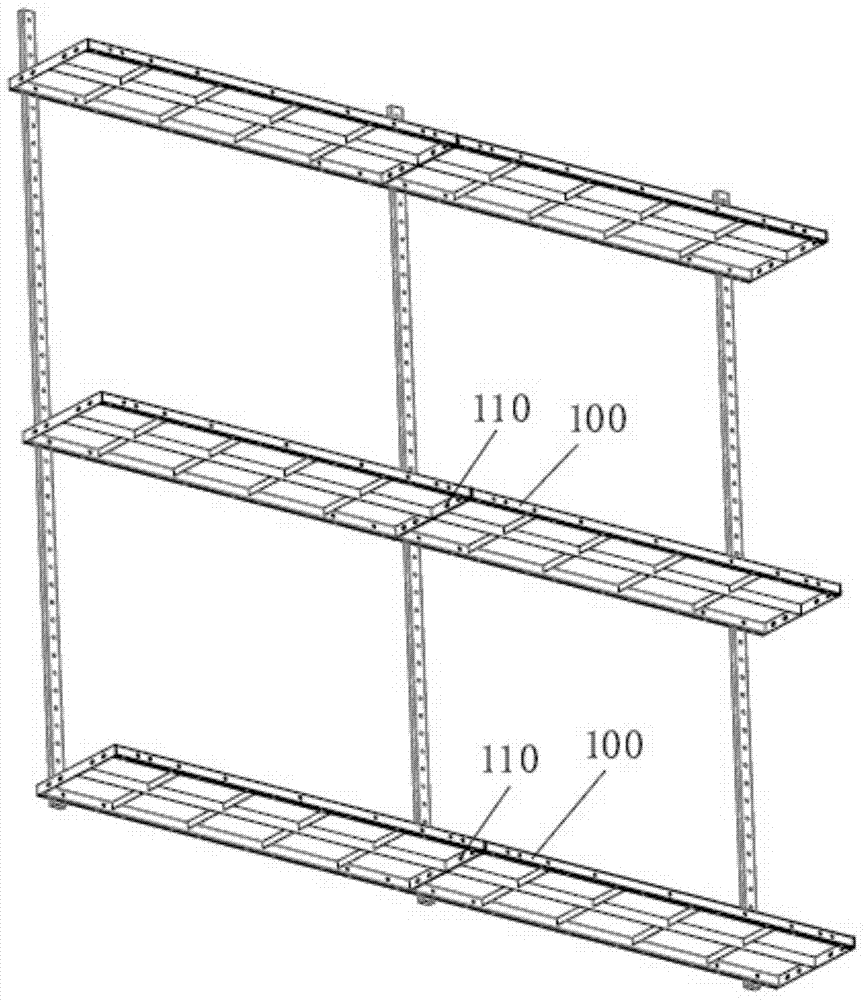

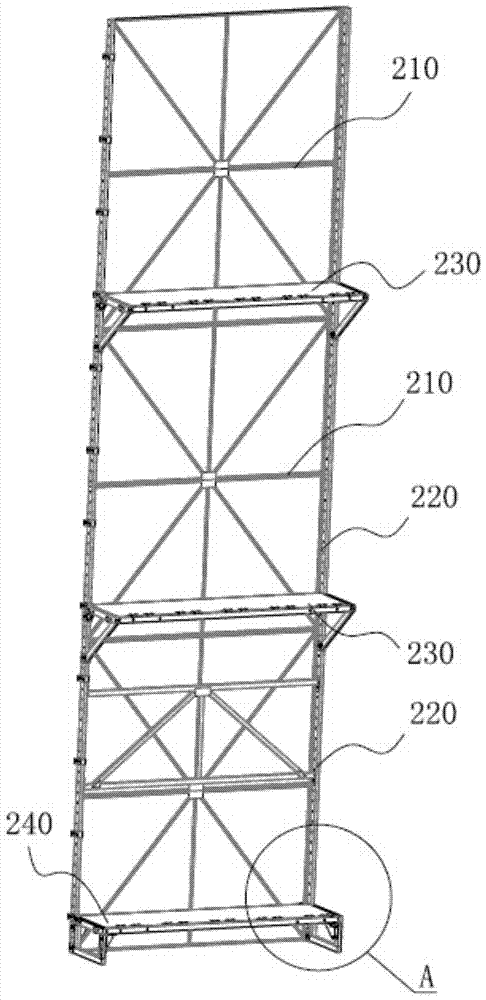

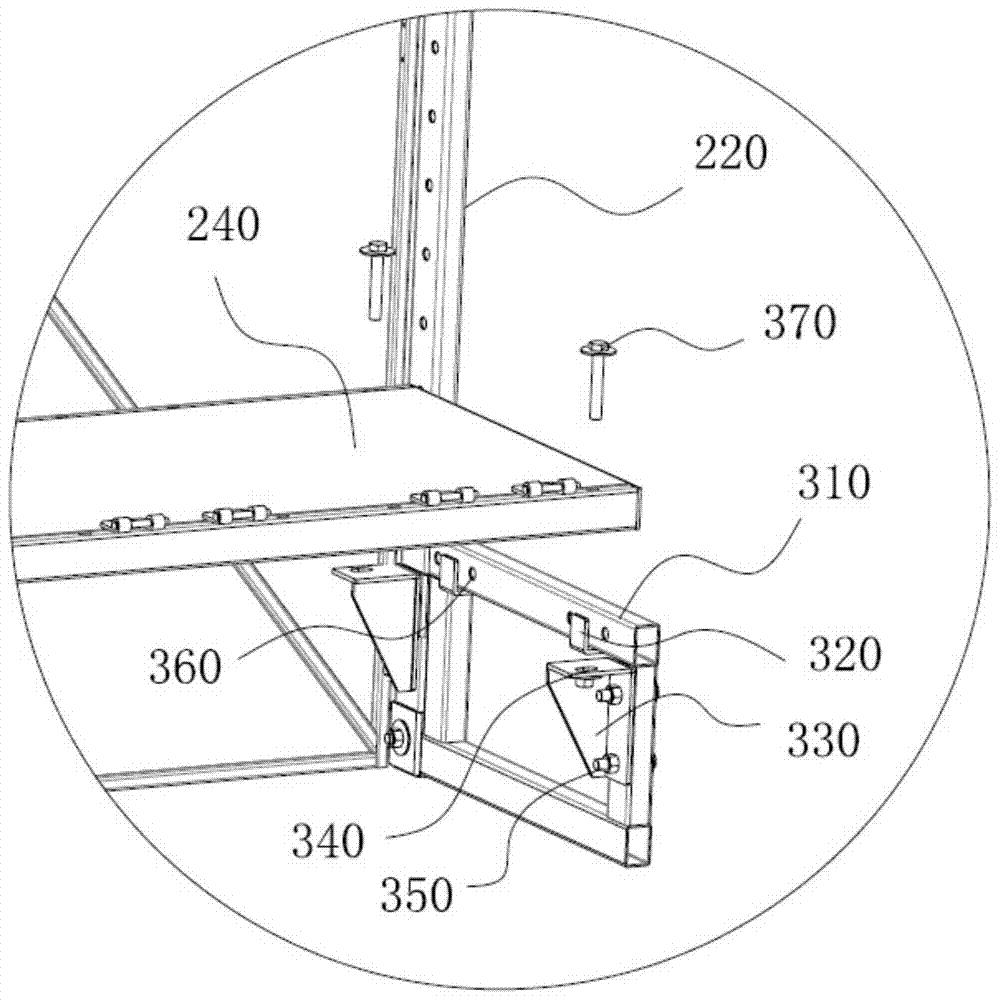

ActiveCN105442828AImprove splicing efficiencySimple stepsScaffold connectionsScaffold accessoriesMechanical engineeringBuilding construction

The invention relates to the field of building construction, and discloses a rapid disassembling safety protection screen, which comprises a protection screen, a vertical rod and bottom layer scaffold floor platforms, and further comprises bottom layer trusses which are used to connect two adjacent bottom layer scaffold floor platforms, wherein the bottom layer platform trusses are provided with U-type slots with upward openings, the end portions of one side of the bottom layer scaffold floor platforms are arranged in the U-type slots, and pass through the end portions of the bottom layer scaffold floor platforms through screws to connect with the bottom layer scaffold floor platforms and the bottom layer trusses. The rapid disassembling safety protection screen further can be provided with upper layer trusses, guide rails and lift devices and the like, and can complete lapping work of the bottom layer scaffold floor platforms during the splicing process just by transporting the bottom layer scaffold floor platforms onto an assigned height, then placing the bottom layer scaffold floor platforms into the bottom layer platform trusses and then locking the bottom layer scaffold platforms and a bottom layer truss main body.

Owner:深圳市中升建科科技发展有限公司

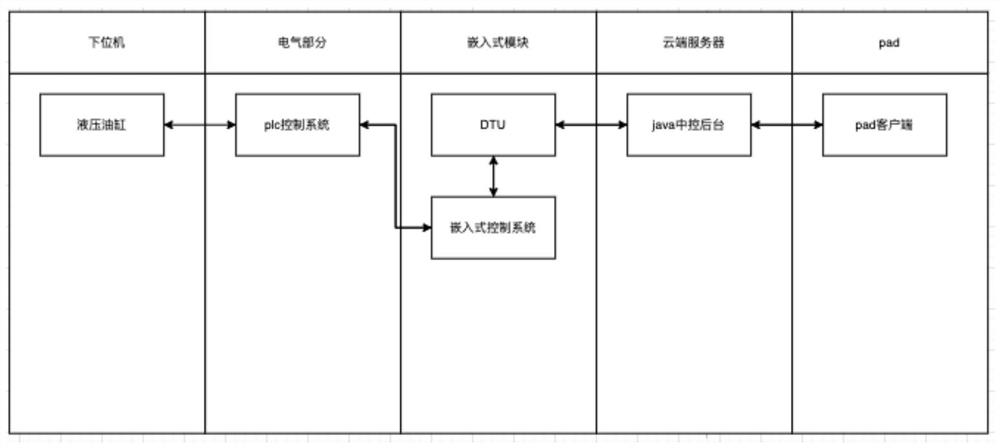

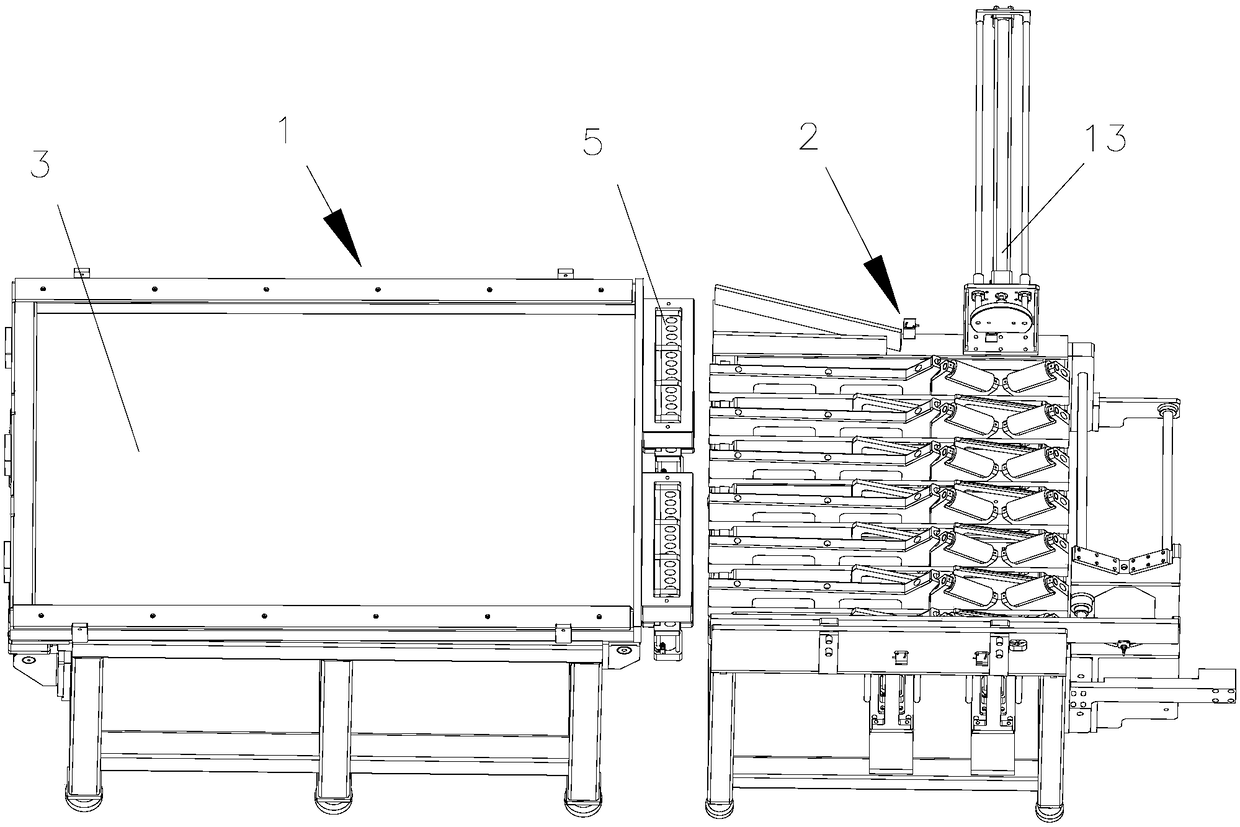

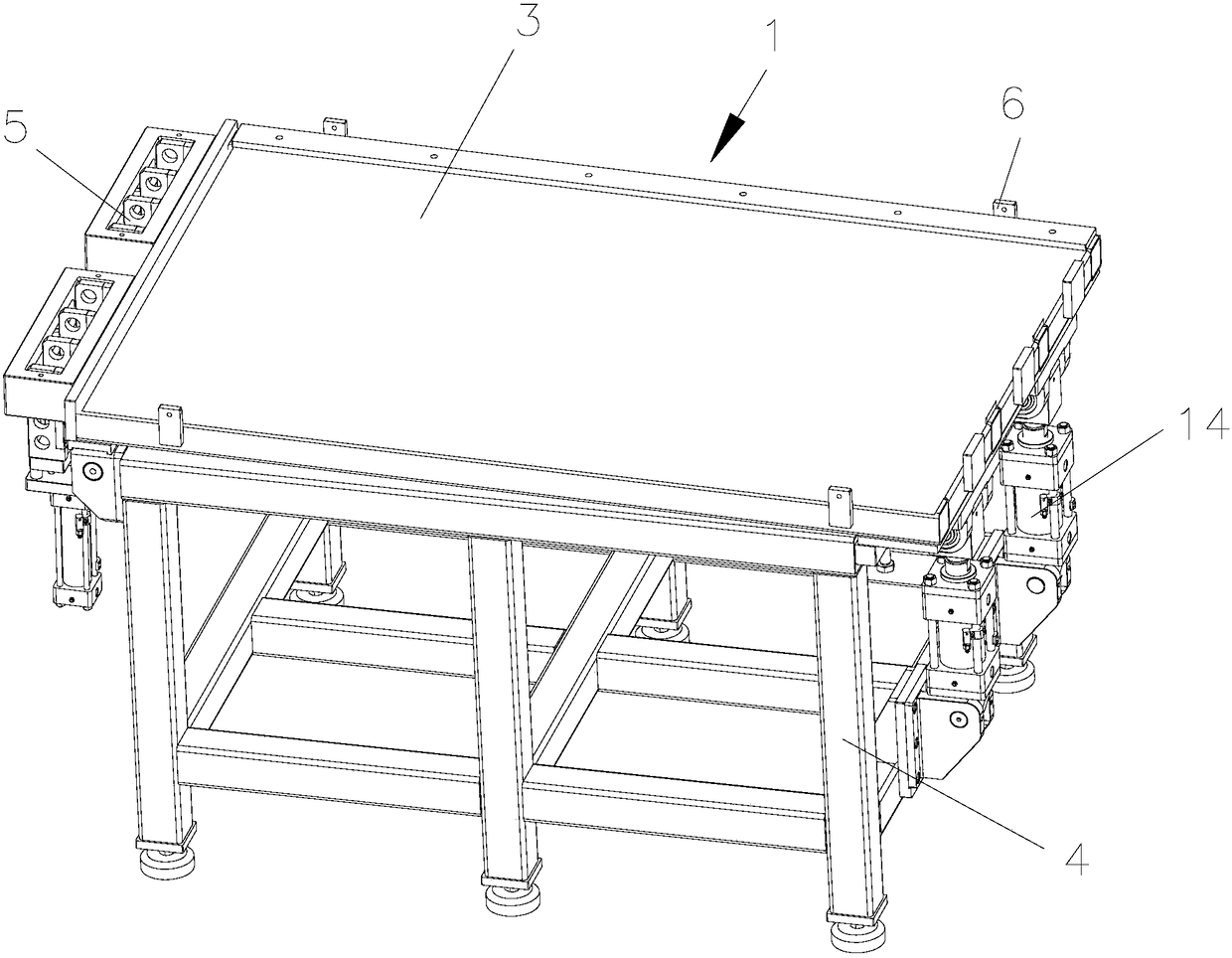

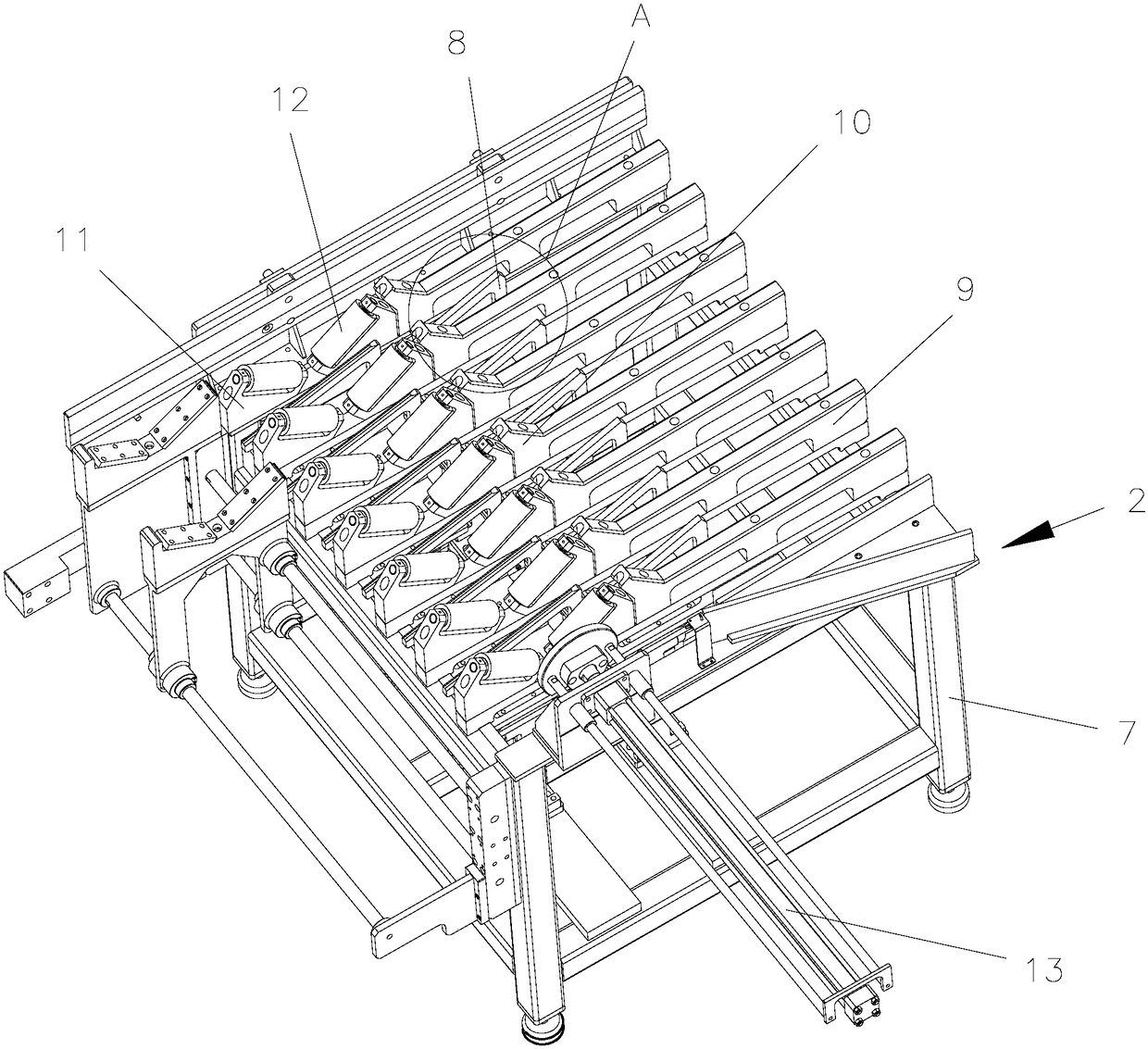

Hydraulic oil cylinder control system

PendingCN114791005ASimple structureVisual work environmentFluid-pressure actuator componentsWireless controlControl system

Owner:广东天凛高新科技有限公司

Feeding mechanism for automatic CNC chamfering machine

ActiveCN105750979BEase of workImprove feeding efficiencyMetal working apparatusNumerical controlWorking environment

The invention relates to a feeding mechanism for a fully automatic numerical control chamfering machine. The feeding mechanism comprises a feeding device and a material pulling and conveying device, wherein the feeding device and the material pulling and conveying device are arranged in parallel. The feeding mechanism for the fully automatic numerical control chamfering machine has the advantages that the fully automatic feeding by using the feeding device and the material pulling and conveying device is realized; the machine is used for replacing manual feeding; the work difficulty of employees is reduced; the feeding efficiency is improved, so that the feeding is safer, faster and more convenient; the structure is simple; the occupied area is smaller; the work environment is simple and clean.

Owner:艾欧特克(江苏)机床有限公司

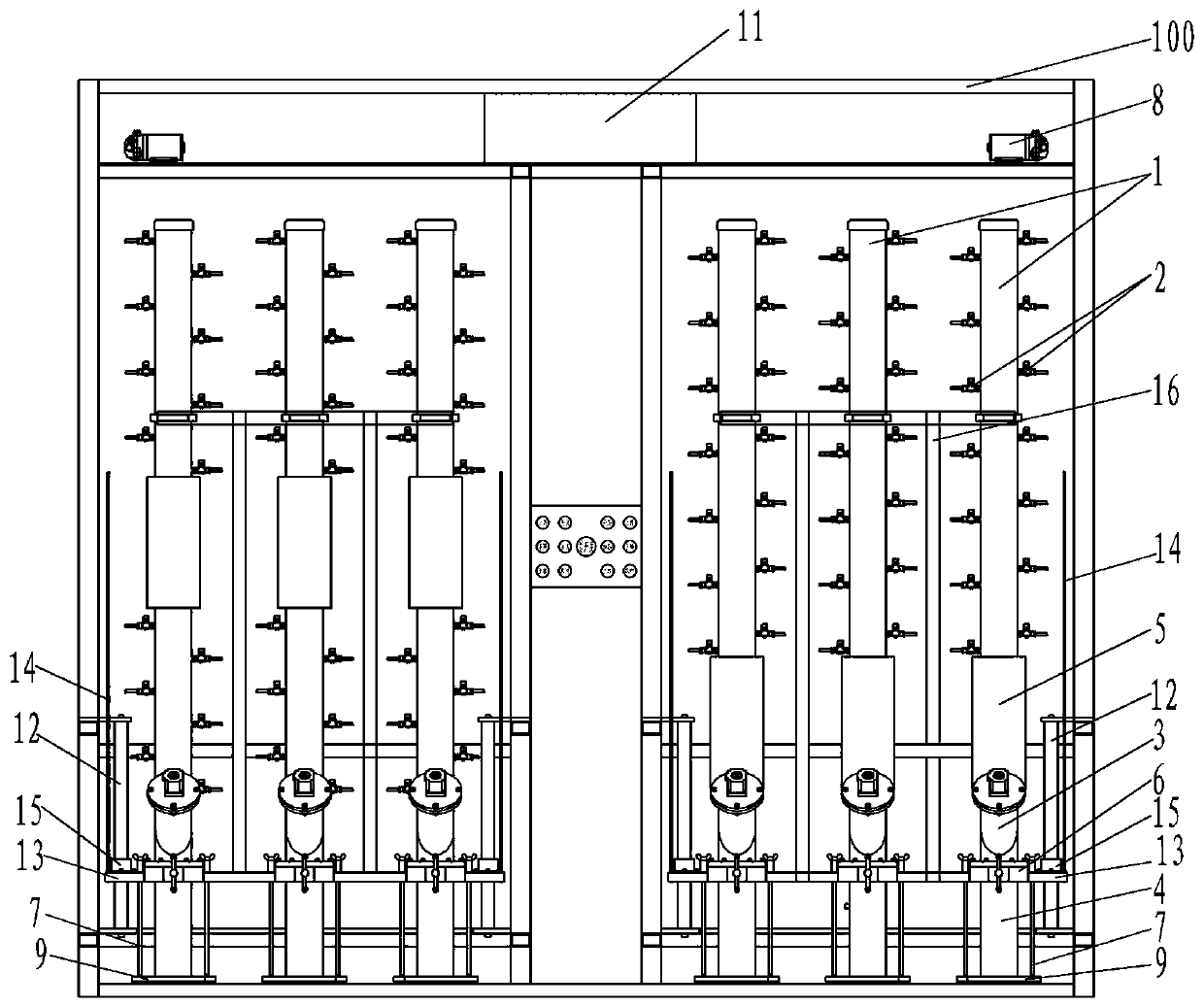

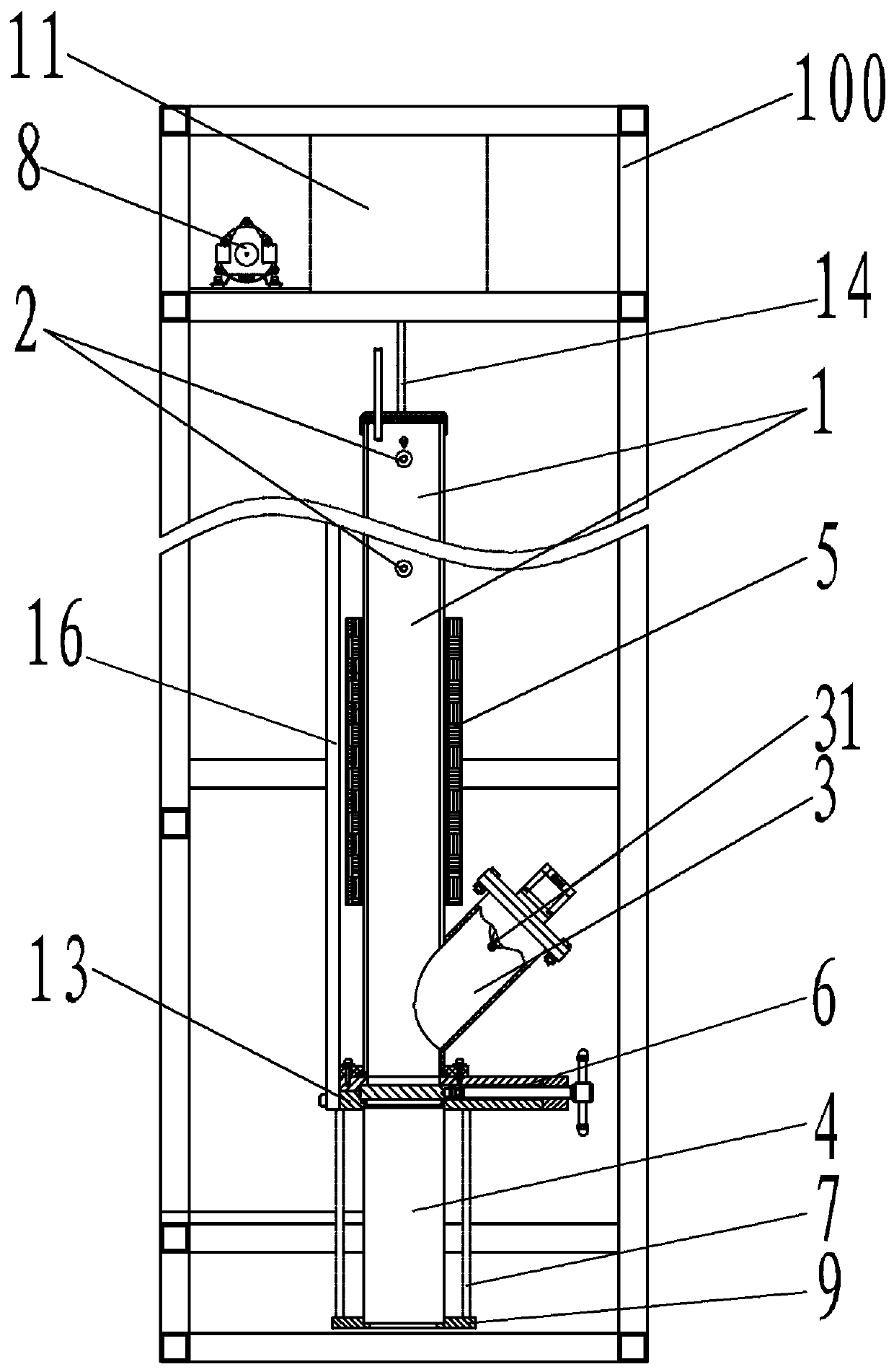

On-line monitoring device convenient to maintain and used for alternating-current power transmission project

InactiveCN114518508AHigh maintenance operational safetyEasy maintenance and operationFault location by conductor typesMeasurement instrument housingTransmission towerWorking environment

The invention discloses a convenient-to-maintain online monitoring device for AC power transmission engineering, and the device specifically comprises a monitoring box, the two ends of the top of the monitoring box are provided with fixing devices, the inner wall of the monitoring box is fixedly connected with a monitoring device, and the top of the monitoring device penetrates through the monitoring box and extends to the top of the monitoring box; one side of the induction electricity taking device is fixedly connected with the side face of the fixing device, a coil on the induction electricity taking device is installed on the power transmission line, and a power plug is arranged at the bottom of the induction electricity taking device; and the maintenance opening is formed in the bottom of the monitoring box, and the inner wall of the maintenance opening is fixedly connected with a maintenance baffle through a bolt. The on-line monitoring device convenient to maintain for the alternating current power transmission project is convenient to maintain and operate, a worker does not need to climb a power transmission tower pole, the working environment is simple, the maintenance and operation safety is high, and the monitoring position is convenient to change.

Owner:肖艳利

Operation control method of wireless networking equipment controller in environmental control system

ActiveCN108758988BEasy wiringEasy to useMechanical apparatusSpace heating and ventilation safety systemsControl systemControl engineering

The invention discloses a running control method of a wireless networking equipment controller in an environment control system. The method is characterized in that a main controller, a multi-way environment parameter acquiring device and a multi-way equipment driver in the same room do the following running control tasks: an environment parameter processing task that the main controller receivesthe environment condition acquiring data from the multi-way environment parameter acquiring device and then separates the environment data, counts and determines and finally calculates the average value of the environment parameters; an information management task that the main controller runs to manage the state property information of the multi-way equipment driver; a driver control task that the main controller drives the multi-way equipment driver to control an environment control port device; and a driving management task that the multi-way equipment driver receives an instruction from the main controller and starts or stops the corresponding environment control port device. With the adoption of the method, automatic driving running of various machines or household appliances is automatically started; the wire arrangement and the operation control management are simple and quick, and manual operation for controlling interference is avoided.

Owner:NINGBO BAYI IND

Throwing auxiliary device for pottery making

InactiveCN111015898ASimple structureEasy to useAuxillary shaping apparatusMechanical engineeringIndustrial engineering

Owner:TANGSHAN NORMAL UNIV

A quick disassembly and assembly safety protection screen

ActiveCN105442828BImprove splicing efficiencySimple stepsScaffold connectionsScaffold accessoriesElectrical and Electronics engineeringBuilding construction

The invention relates to the field of building construction, and relates to a quick disassembly and assembly safety protection screen, which includes a protection screen, a pole and a bottom scaffolding platform, and the quick disassembly and assembly safety protection screen also includes a foot for connecting two adjacent bottom floors. The bottom truss of the hand platform, the bottom platform bracket has a U-shaped groove with an upward opening, one side end of the bottom scaffold platform is placed in the U-shaped groove, and passes through the bottom scaffold platform by screws The end of the base and the first positioning hole connect the base scaffolding platform with the base truss. This protective screen can also be equipped with upper trusses, guide rails, lifting devices and other devices. The bottom scaffolding platform and the main body of the bottom truss are locked, and the overlapping work of the bottom scaffolding platform can be completed.

Owner:深圳市中升建科科技发展有限公司

A method for strengthening ultra-soft foundation with vacuum preloading and gas injection carbonization

ActiveCN110512591BImprove compactionImprove displacement effectSoil preservationCarbonizationStructural engineering

The invention discloses a method for strengthening supersoft foundations by vacuum preloading and gas injection carbonization of conduit piles, and belongs to the technical field of supersoft foundation reinforcement treatment in geotechnical engineering. The method includes site treatment and exploration, driving of the first pipe pile group, placement and commissioning of spraying equipment, spraying of curing agent, layout of the first treatment system, vacuum preloading-gas injection carbonization treatment, completion of the first site treatment, continuous Steps such as construction and final processing. The invention has the advantages of vacuum preloading method, magnesia carbonization solidification method and pipe pile composite foundation, and the coordinated work of vacuum preloading and pipe pile gas injection increases drainage efficiency and carbon dioxide infiltration and diffusion efficiency, and makes full use of pipe piles For the compaction and replacement of soft soil, the hydration products and carbonization products can effectively cement the silt soil, so that the strength and stability of the soft soil composite foundation are enhanced. The method has the characteristics of good treatment effect, short cycle, low-carbon environmental protection and cost-effectiveness, and realizes the resource utilization of industrial waste in soft soil treatment.

Owner:NANJING FORESTRY UNIV

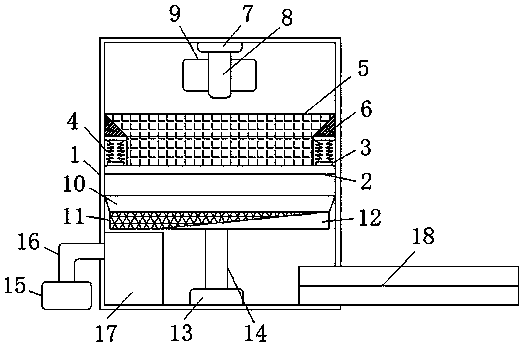

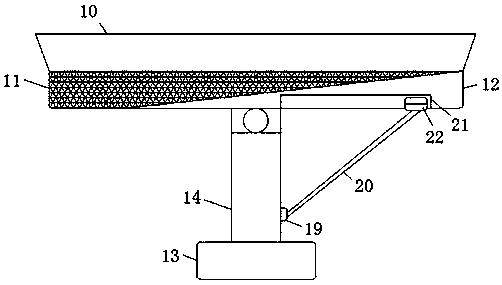

Separation and bagging device in environment-friendly vanadium nitrogen alloying pellet production

InactiveCN109094907AClean working environmentSimple structureGas current separationDirt cleaningSlagEngineering

The invention discloses a separation and bagging device in environment-friendly vanadium nitrogen alloying pellet production. The separation and bagging device in the environment-friendly vanadium nitrogen alloying pellet production comprises a box body shell and a supporting plate. Symmetrical vibration motors are arranged on two sides of the upper end of the supporting plate, and strong springsare separately and fixedly connected to the upper ends of the two vibration motors. Inclined blocks are arranged at the ends, away from the vibration motors, of the two strong springs, and a separation mesh is arranged between the two inclined blocks. A hopper is arranged at the lower end of the supporting plate, a screen and a fixed block are arranged at the lower end of the hopper, a driving device is arranged on one side of a supporting rod, a telescopic rod is arranged at one end of the driving device, a sliding block is arranged at the end, away from the driving device, of the telescopicrod, a feeding tank is formed below the fixed block, and a collection box is arranged at the lower end of the screen. The separation and bagging device for in the environment-friendly vanadium nitrogen alloying pellet production is simple in structure and easy to operate, and can separate vanadium nitrogen alloying pellets in batches, the recycling of dust and disintegrating slag is achieved, energy conservation and environment protection are achieved, and the separation and bagging device is convenient and ingenious to use, and is suitable for popularizing widely.

Owner:吴志锋

Sediment resuspending experimental device

PendingCN110095310AEasy to observe and operateSimple working environmentWithdrawing sample devicesSample waterWater flow

The invention relates to a sediment resuspending experimental device. The experimental device comprises a frame, experimental tubes vertically and fixedly arranged on the frame, sampling tubes uniformly arranged in the upper sidewall of each experimental tube, a disturbance tube arranged in the bottom sidewall of each experimental tube, and a sediment sample tube fixedly arranged in the bottom endof each experimental tube; the sampling tubes are communicated with the corresponding experimental tube, and provided with valves respectively, the bottom of the disturbance tube is communicated withthe experimental tube, and the other end of the disturbance tube is provided with a stirring paddle; and the experimental tube and the sediment sample tube are provided with a sealing flashboard. Thewater layers and depths are simulated in the experimental tubes of the whole experimental device, the sediment sample tubes contain sampled sediment, and are fixed to the corresponding sealing flashboards via long bolts, the sealing flashboards are opened to start the stirring paddles and further simulate disturbance of water current, the sampling tubes sample water in different depths, and the temperature can be simulated by a heating sleeve.

Owner:河北省水利科学研究院

Blanking mechanism for fully automatic numerical control chamfering machine

InactiveCN105750980AEase of workImprove cutting efficiencyMetal working apparatusNumerical controlWorking environment

The invention relates to a blanking mechanism for a fully automatic numerical control chamfering machine. The blanking mechanism comprises a blanking rack, wherein a blanking material disc is detachably arranged on the blanking rack; a feeding device is fixedly arranged on the blanking rack; the feeding device and the blanking device are arranged in parallel. The blanking mechanism for the fully automatic numerical control chamfering machine has the advantages that workpieces are pulled into the blanking material disc by a material pulling assembly so that the fully automatic blanking is realized; the machine is used for replacing labor blanking; the work difficulty of employees is reduced; the blanking efficiency is improved; the blanking is safer, faster and more convenient; the structure is simple; the occupied area is smaller; the work environment is simple and clean.

Owner:艾欧特克(江苏)机床有限公司

Power generation type annular cooler sealing structure

PendingCN108468808ASolve efficiency problemsSolve environmental problemsEngine sealsHandling discharged materialWorking environmentEngineering

The invention discloses a power generation type annular cooler sealing structure, and relates to the technical field of smelting equipment. The upper end of a first wind shield is fixed to the lower portion of an annular cooler rotating body through a first fastener, a plurality of sweepers are fixed to the lower end of the first wind shield, a first water containing mechanism is arranged on the upper portion of an air bellow and is of a U-shaped groove body structure, a groove opening is downward, ash removal grooves are arranged on the two sides of the first water containing mechanism, a dustproof plate is arranged on the inner side of the first water containing mechanism and is in tight fit with the lower portion of the annular cooler rotating body, negative fall is set between the bottoms of the ash removal grooves and the bottom of the first water containing mechanism, a second wind shield is arranged on the lower portion of an annular cooler heat collection cover, a second watercontaining mechanism is fixed to the upper portion of the annular cooler rotating body through a second fastener, and the second wind shield extends downwards to be located in the second water containing mechanism. The time, labor and cost are saved, working environment is comfortable, the problems that the air leakage efficiency is high and operation environment is poor in traditional seal are effectively solved, the power consumption cost of a fan is reduced, and the overhaul work frequency is reduced.

Owner:唐山瑞泰机械有限公司

Mining device of steeply inclined thin ore deposit and deep hole rock drilling stage chamber method using same

PendingCN113700485AAvoid enteringAvoid manual handlingUnderground miningDirectional drillingRock cuttingMineralogy

The invention discloses a mining device of a steeply inclined thin ore deposit and a deep hole rock drilling stage chamber method using the mining device. The mining device comprises a rock drilling and pedestrian courtyard, a ladder, ladder compartment safety platforms, guide rails and a liftable rock drilling platform, the rock drilling and pedestrian courtyard is arranged in studs on two sides of an ore block corresponding to the inclination of an ore body; the bottom of the ore body is provided with an undercut roadway parallel to the trend of the ore body, the undercut roadway communicates with the rock drilling and pedestrian courtyard, a footwall of the ore body is provided with a stage transportation roadway corresponding to the trend of the ore body, the stage transportation roadway and the undercut roadway are communicated through an ore removal access, and the ladder is fixedly connected in the rock drilling and pedestrian courtyard and close to one side of footwall surrounding rock. The ladder compartment safety platforms are distributed on the outer side of the ladder at intervals corresponding to the inclination of the ladder, the guide rails are fixed to the sides, away from the ladder, of the ladder compartment safety platforms, the liftable rock drilling platform is slidably connected to the guide rails, horizontal deep holes are formed in the direction parallel to the ore body, one end of each horizontal deep hole communicates with the rock drilling and pedestrian courtyard, and the horizontal deep holes are filled with explosives.

Owner:WUHAN UNIV OF SCI & TECH

A detection method and application of physical characteristics of nano-scale soot particles

The invention discloses a method for detecting physical characteristics of nano-scale soot microparticles. The method is used for simultaneously detecting the three-dimensional morphology, mechanical characteristics and degree of graphitization of the same position of each nano-scale soot microparticle by using an atomic force microscope and Raman spectrometer combination system and comprises the following steps: acquiring the three-dimensional morphology, force curve and Raman spectrogram of a nano-scale soot microparticle sample, and carrying out peak-differentiating-imitating on the Raman spectrogram by using software origin so as to evaluate the degree of graphitization of the nano-scale soot microparticle sample; finally obtaining the mechanical characteristics of the nano-scale soot microparticle sample, wherein the mechanical characteristics comprise an adsorption force, a van der Waals force and an adhesion force. According to the method and the application thereof, the rule of evolution of the three-dimensional morphology, mechanical characteristics and degree of graphitization of soot microparticles generated from different source combustion processes can be researched, and research results contribute to the deep understanding of generation and evolution mechanisms of the soot microparticles, so that a theoretical instruction is provided for the reduction of emission of the soot microparticles and the control on atmospheric environment pollution.

Owner:TIANJIN UNIV

Leakage-plugging method for water-stopping curtain

ActiveCN102587400BReduce consumptionAvoid washing awayArtificial islandsUnderwater structuresRock coreWater leakage

The invention discloses a leakage-plugging method for a water-stopping curtain, which is good in effect, simple in steps and less in consumption and can rapidly accomplish leakage plugging. The method comprises the two processes of leaking point exploration and leakage management, wherein in the process of leaking point exploration, a plurality of exploration holes are drilled in a water-leakage zone in a foundation pit, the position of a leakage zone is determined according to the loose degrees of rock core structures in the exploration holes, and the loose positions in the rock core structures are the positions of the leakage zone; the process of leakage management comprises the following steps of: (1) downwards drilling at least one hole to the leakage zone from construction ground above the leakage zone between the water-stopping curtain and a supporting pile; (2) placing plastic pipelines in the drilling holes; (3) sliding plastic bags to the bottom of the pipeline along the inner wall of the plastic pipeline, wherein leakage-plugging materials are enclosed in the plastic bags; and (4) breaking the plastic bags at the bottom of the plastic pipeline. With the adoption of the leakage-plugging method for the water-stopping curtain, the leakage-stopping materials are directly thrown in the leakage zone, so that leakage plugging is fundamentally accomplished in one step, and the leakage-plugging effect is good.

Owner:天津建岩岩土工程有限公司

A four-axis linkage CNC machining center and its working method

ActiveCN109623439BPrevent splashProtect the processing environmentFeeding apparatusLarge fixed membersNumerical controlMachine control

The invention aims to provide a four-axis linkage type computer numerical control machining center and a working method thereof. According to the technical scheme, the four-axis linkage type computernumerical control machining center is composed of a machining cabin, a tool bearing frame, a tool controller, a tool changing machine, a tool changing control table, a machining control cabinet and amachining mechanism, wherein the machine mechanism is composed of a machining bearing table, a Y-axis moving rail table, a Y-axis moving frame, an X-axis moving supporting table, an X-axis moving railtable, a Z-axis machining mechanism, a telescopic machine and a plurality of material bearing fixing frames, and the machining bearing table is composed of a waste material collecting tank, a waste material overturning device and a waste material recovering plate. According to the four-axis linkage type computer numerical control machining center, tool changing operation and machining operation form two independent control units so that misoperation caused by a single control unit is avoided, maintenance and overhaul are facilitated, then four-axis linkage type computer numerical control machining is more accurate, material fixing and position adjusting can be realized through the plurality of material bearing fixing frames, waste materials obtained after machining can be concentrated, sothat the internal operation environment of a machining space is guaranteed, and the quality of machined products is improved.

Owner:TIANJIN HUATIAN CENTURY MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com