Recovery method for valuable metals in copper anode slime

A recovery method, copper anode slime technology, applied to the improvement of process efficiency, instruments, optics, etc., can solve the problems of large dispersion of silver and gold in flotation tailings, high content of valuable metals, complicated treatment process, etc., and achieve base metal Low content, reduce the amount of slag output, and ensure the effect of removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

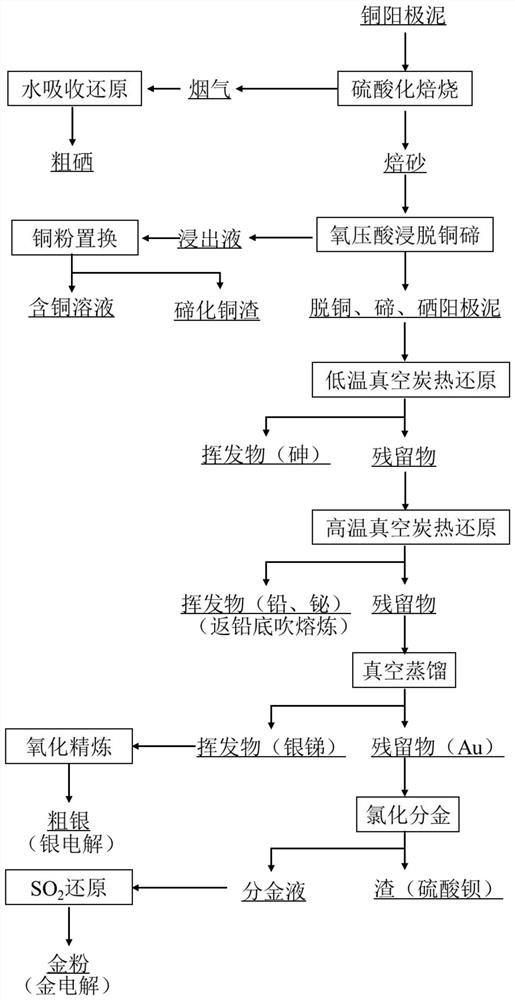

Method used

Image

Examples

Embodiment 1

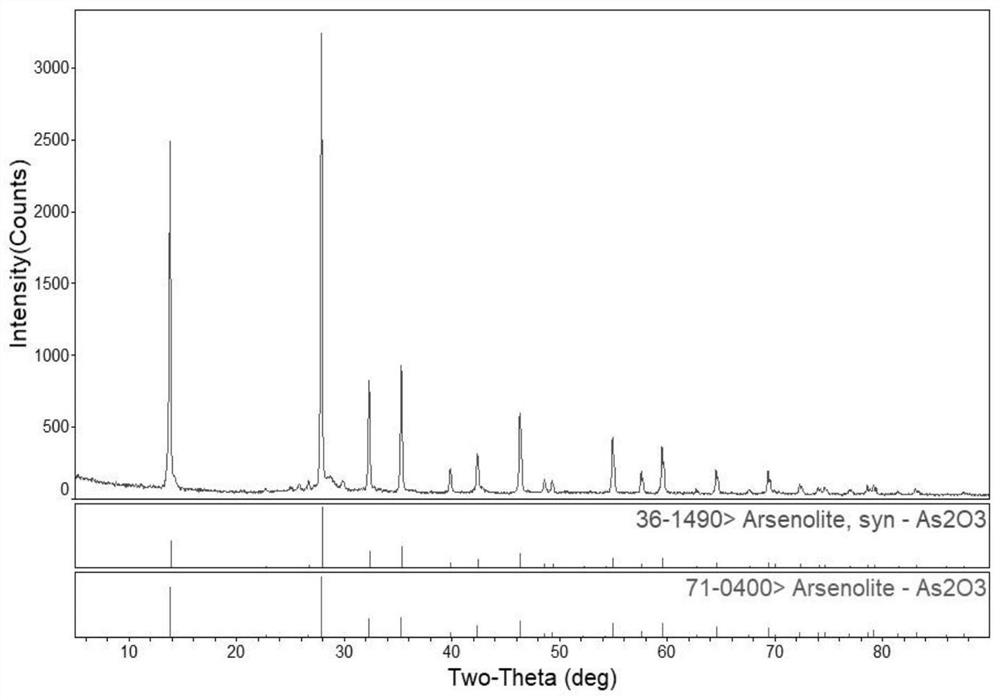

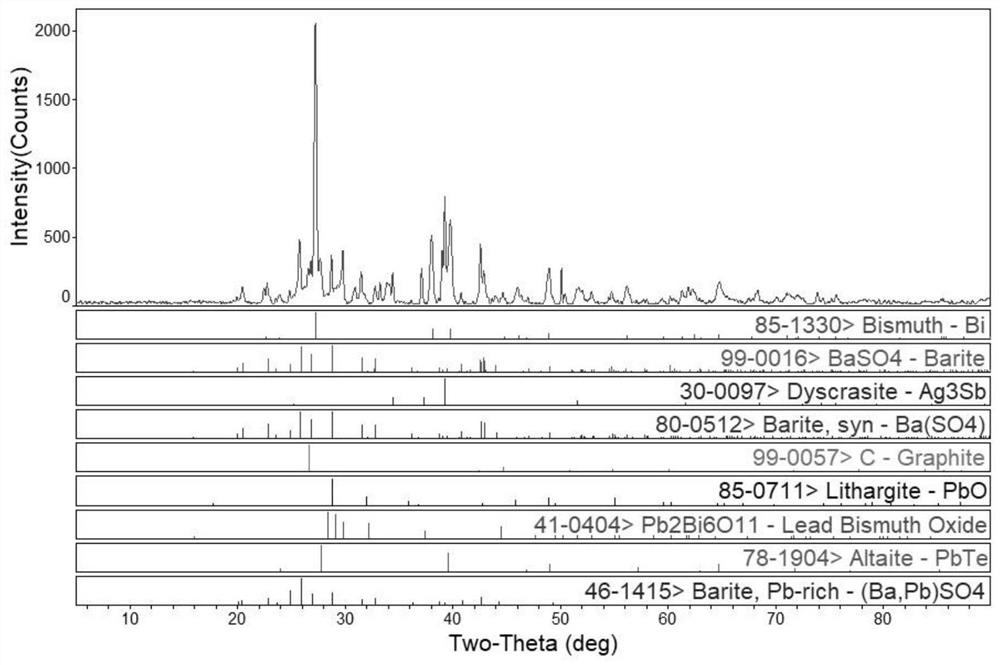

[0077] Sieve 2500kg copper anode slime with main composition as Pb 6.18%, Sb 4.2%, As 5.82%, Bi 7.28%, Cu 14.18%, Ag 10.65%, Se 4.03%, Te 1.02%, Ni 6.16% and Au 529.5g / t After removing large particle inclusions, the copper anode slime and concentrated sulfuric acid (98%) are slurried in the stirring tank at a mass ratio of 1:1, and the slurried anode slime is sent to the rotary kiln. The temperature at the head is 300°C, the temperature in the kiln is 500°C, and the temperature at the end of the kiln is 600°C. Sulphate roasting is carried out at a temperature of 500°C for 4 hours to obtain SeO-containing 2 Soot and calcine, containing SeO 2 Soot is absorbed by water into H 2 SeO 3 solution, by the SO in the soot 2 The gas is reduced to elemental selenium, and the crude selenium (purity is 89%) is obtained after drying;

[0078] Immerse the calcined sand in dilute sulfuric acid (acidity 100g / L), carry out oxygen pressure acid leaching (temperature 120°C, leaching time 30min...

Embodiment 2

[0094] Sieve 2500kg copper anode slime with main composition as Pb 6.18%, Sb 4.2%, As 5.82%, Bi 7.28%, Cu 14.18%, Ag 10.65%, Se 4.03%, Te 1.02%, Ni 6.16% and Au 529.5g / t After removing large particle inclusions, the copper anode slime and concentrated sulfuric acid (98%) are slurried in the stirring tank at a mass ratio of 1:1, and the slurried anode slime is sent to the rotary kiln. The temperature at the head is 300°C, the temperature in the kiln is 500°C, and the temperature at the end of the kiln is 600°C. Sulphate roasting is carried out at a temperature of 500°C for 4 hours to obtain SeO-containing 2 Soot and calcine, containing SeO 2 Soot is absorbed by water into H 2 SeO 3 solution, by the SO in the soot 2 The gas is reduced to elemental selenium, and the crude selenium (purity is 90%) is obtained after drying;

[0095] Immerse the calcined sand in dilute sulfuric acid (acidity 100g / L), carry out oxygen pressure acid leaching (temperature 120°C, leaching time 30min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com