Special air bag-based axially-symmetrical deformable air inlet channel

An inlet and axisymmetric technology, applied in the field of inlets, can solve the problems of poor cruise performance of fixed-geometry supersonic inlets and high additional cost of adjustable inlets, so as to make full use of internal space, improve cruise performance, Additional cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

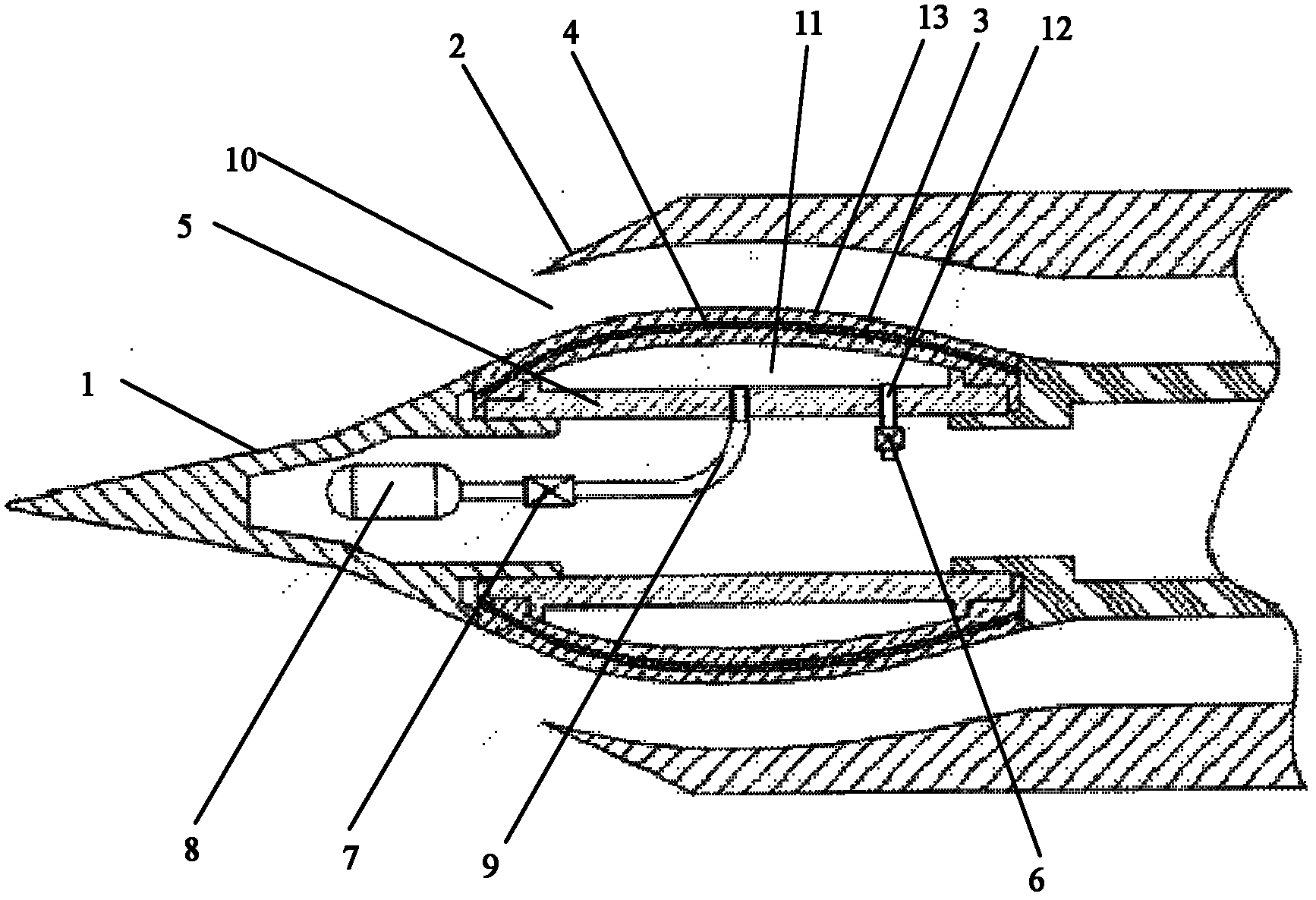

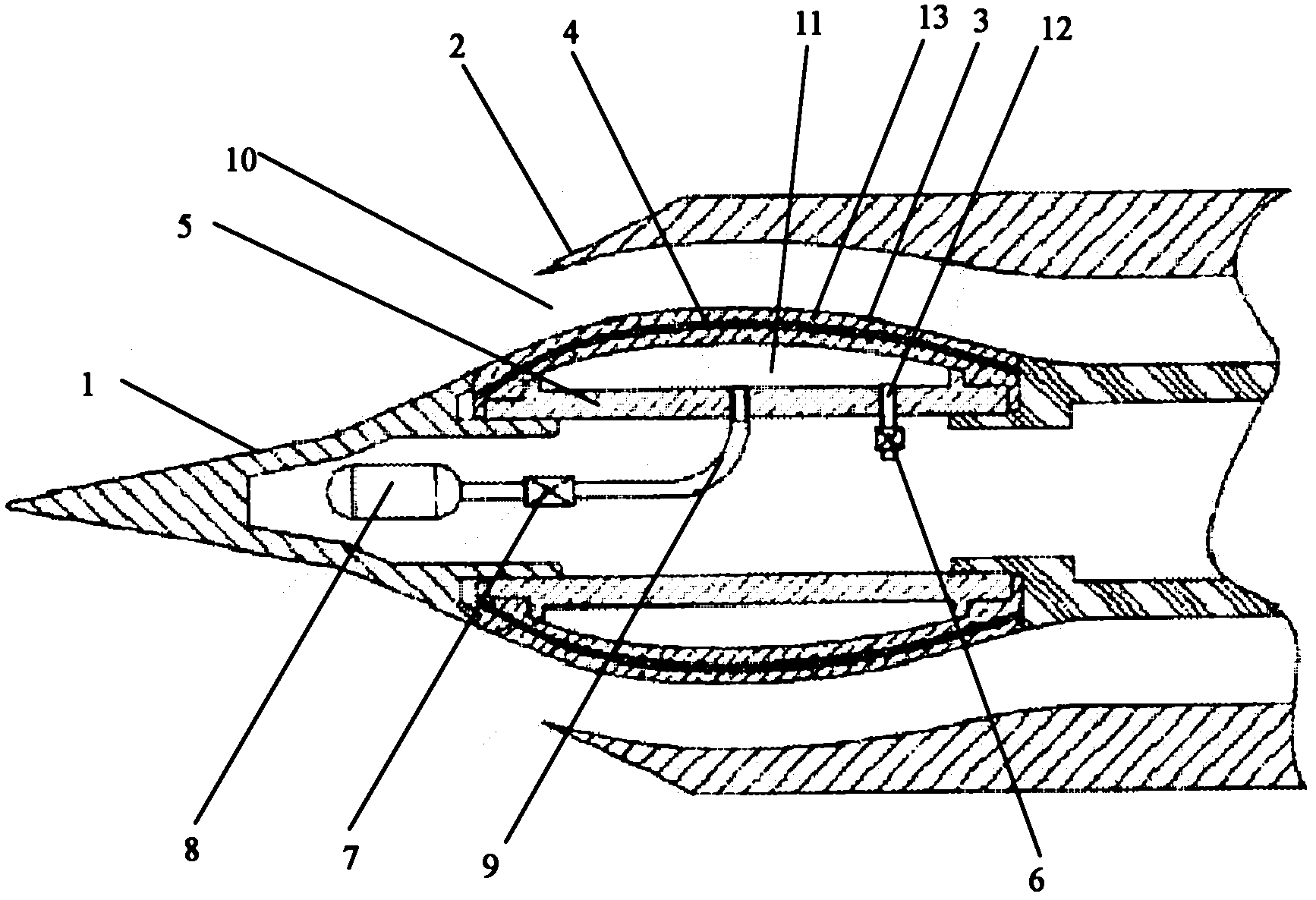

[0010] see figure 1 As shown, the present invention discloses an axisymmetric deformable air inlet based on a special airbag, which includes a front cone 1, an air inlet lip 2 located outside the front cone 1 and surrounding the front cone 1, and a front The special airbag 3 connected by the cone tip 1, the high-pressure air source 8, the intake pipe 9 connecting the high-pressure air source 8 and the special airbag 3, the inflation valve 7 arranged on the intake pipe 9, the deflation valve 6 and the connection deflation valve 6 and The deflation pipe 12 of the special airbag 3. An air inlet throat 10 is formed between the special airbag 3 and the air inlet lip cover 2 . The special airbag 3 is provided with a metal core 5 and an elastic layer 13 covering the metal core 5 , the elastic layer 13 and the metal core 5 enclose an air cavity 11 . The elastic layer 13 is made of heat-resistant rubber, and the inner braid 4 is accommodated in the elastic layer 13, and the deformati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com