Electric topping and sprouting inhibition shear

An electric and drive plate technology, applied in the direction of germination remover, cutting tools, cutting equipment, etc., can solve the problems of large random spraying amount of germination inhibitor, large spraying dose of germination inhibitor, and high labor intensity, etc. The effect of accurate and controllable spraying amount, pesticide residue control and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

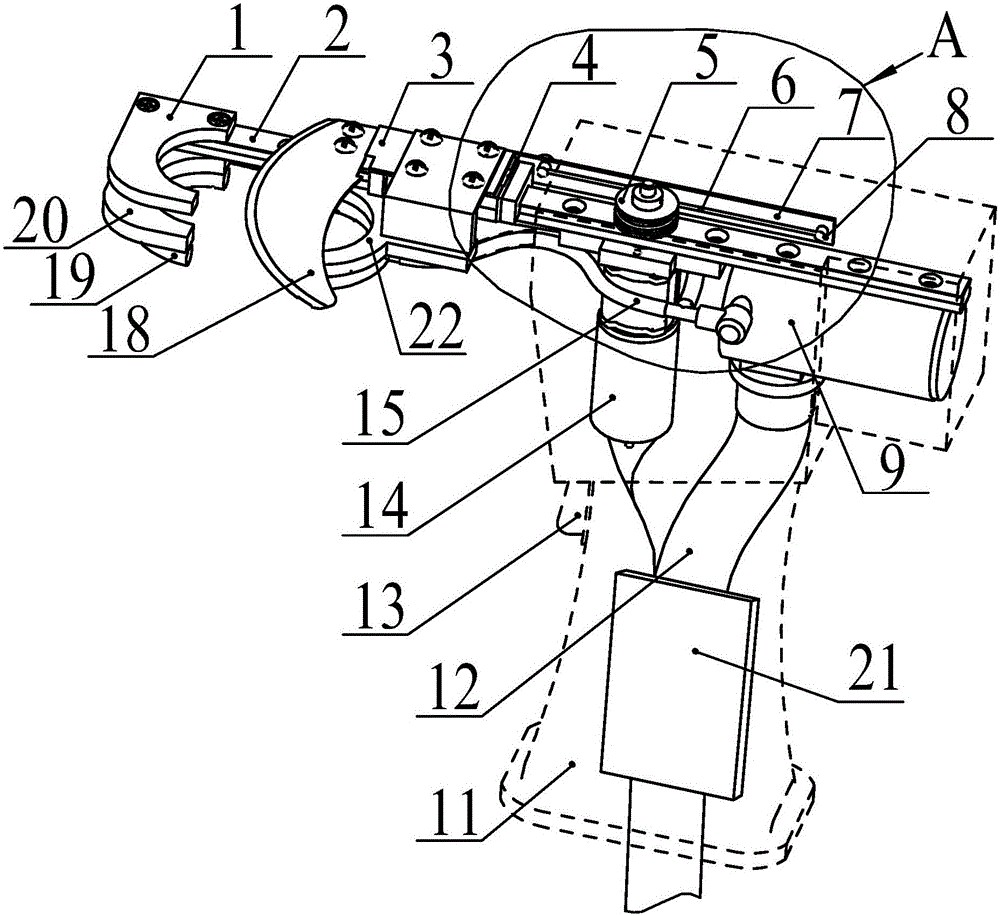

[0027] Example 1, such as figure 1 and Figure 4 As shown, a kind of electric topping and bud suppressing scissors comprises a handle housing 11, a cutting mechanism arranged on the handle casing 11, a spraying mechanism arranged on the cutting mechanism, and a control device for controlling the work of the cutting mechanism and the spraying mechanism. mechanism, and a switch 13 is provided on the handle housing 11.

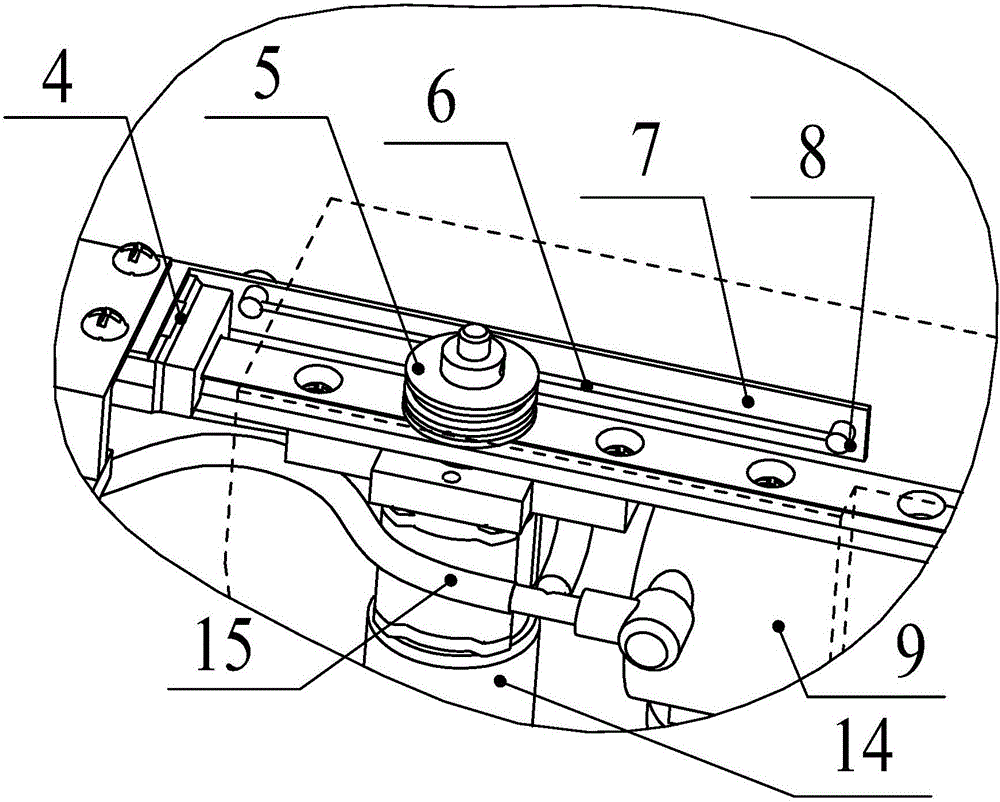

[0028] See figure 1 , the cutting mechanism includes a slide rail 2 arranged in the handle housing 11, the slide rail 2 is preferably a linear slide rail, and may also be a curved slide rail, and the slide rail 2 is provided with a A slide block 4 is provided with a driving assembly for reciprocating motion on the slide block 4. After the front end of the slide rail 2 stretches out from the handle shell 11, the first blade 1 is installed, and the slide block 4 passes through the The fixed block 3 is equipped with a second blade 18 that cooperates with the firs...

Embodiment 2

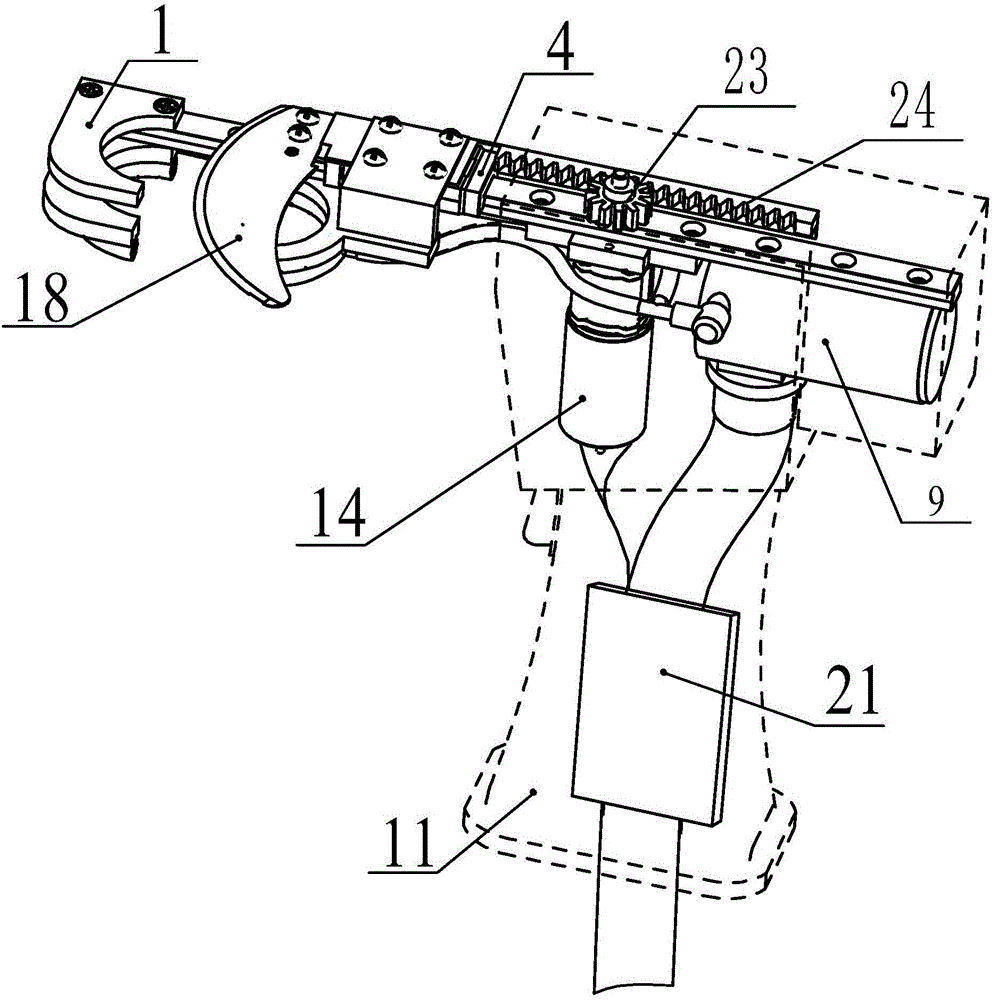

[0033] Example 2, such as figure 2 As shown, a kind of electric topping bud suppressing shears, other structures are all identical with embodiment 1 except transmission assembly. The transmission assembly of this embodiment includes a gear 23 sleeved on the output shaft of the motor 14 and a rack 24 fixedly connected with the slider 4. The rack 24 meshes with the gear 23, and the motor 14 drives the gear 23 to rotate. 23 drives the rack 24 to move horizontally, and then drives the slider 4 to slide along the slide rail 2 , even if the second blade 18 approaches or moves away from the first blade 1 .

[0034] Working process of the present invention is as follows:

[0035] Turn on the power supply, connect the medicine supply tube 12 to the pressure pump of the medicine box, and set the controller 21 to determine the single opening time of the solenoid valve 9. The arc-shaped concave part fixes the stem of the tobacco plant whose top advantage is to be removed, presses the swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com