Damping silicon rubber sound insulation material filled with glass microbeads

A technology of glass microbeads and sound insulation materials, which is applied in the field of glass microbead filling damping silicone rubber sound insulation materials and its preparation field, can solve the problems of heavy material quality, unfavorable material popularization and use, increase the density of silicone rubber materials, etc., so as to reduce the material density. , good chemical stability, the effect of increasing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: glass microsphere surface treatment

[0036] Add 100g of hollow glass microspheres into the glass reactor, stir and heat to 125°C, heat 0.5g of A-171 to boiling, and pass N 2 , and pass the nitrogen containing A-171 into the glass reactor, adjust the nitrogen flow rate, add it in about 20 minutes, continue the reaction for 10 minutes, and cool down for later use.

Embodiment 2

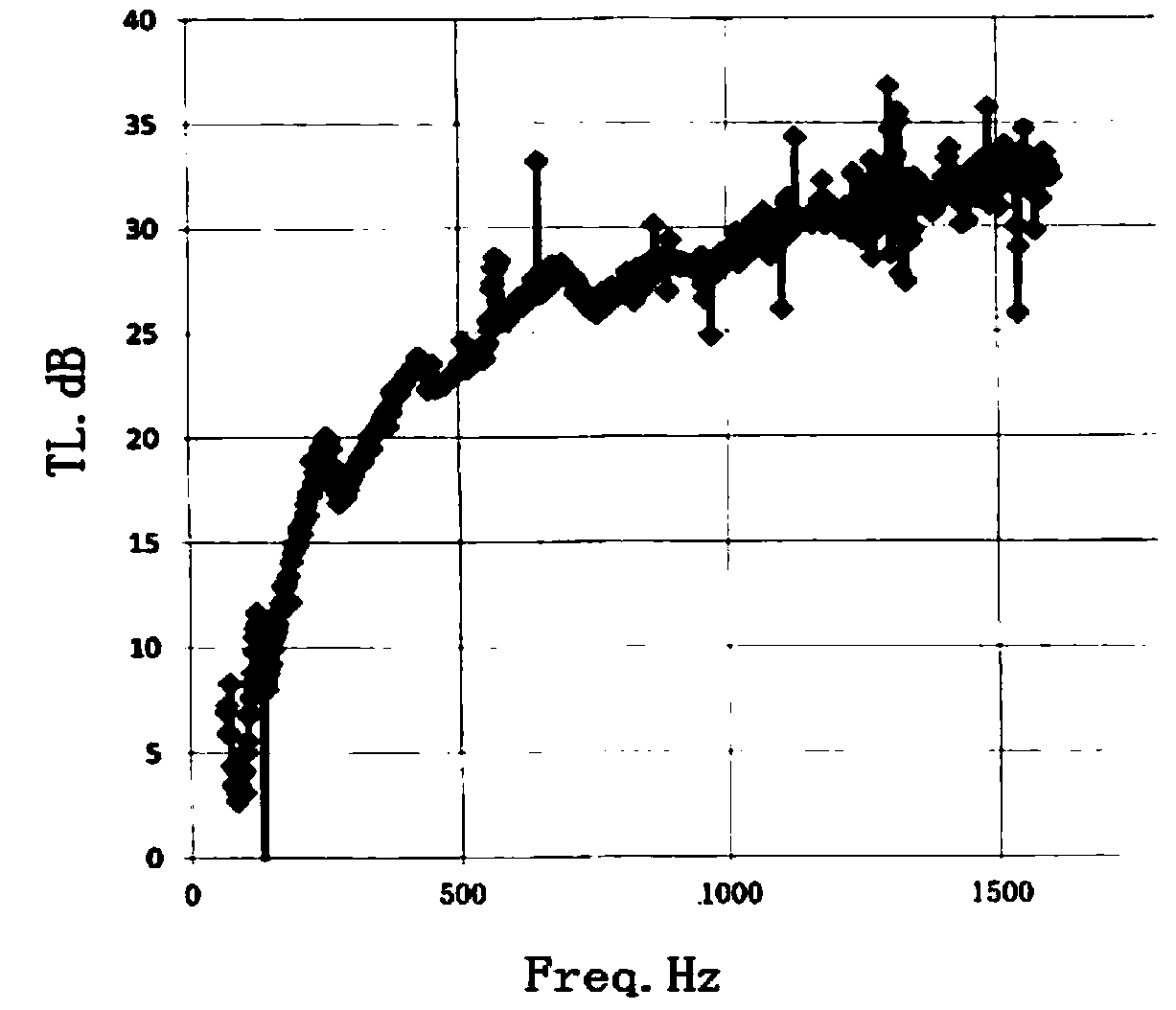

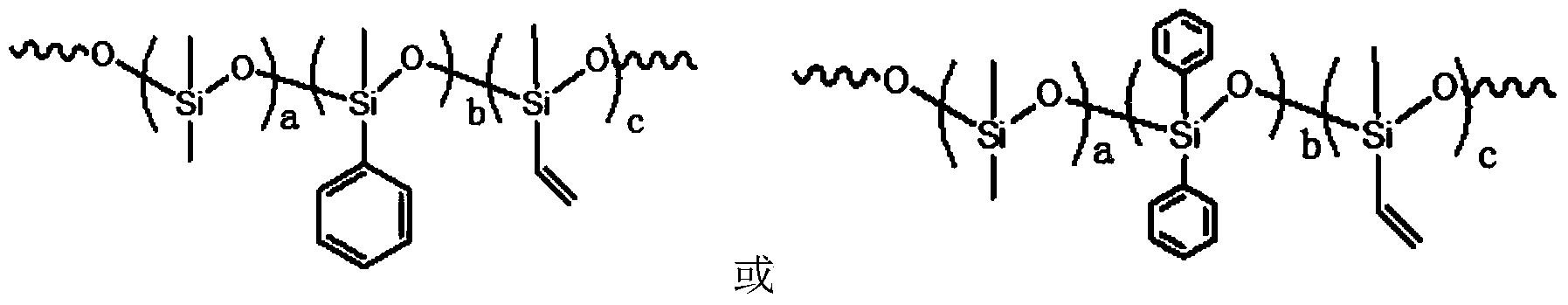

[0040] Put 100g of damping silicone rubber raw rubber with a molar percentage of 10% of phenyl chain segments and 0.5% of vinyl chain segments into the double rollers of an open rubber mixing machine, and add 40 g of it to be processed in Example 1. Fine glass beads, mix evenly, add 2g of peroxide vulcanizing agent Shuang24 paste and 0.5g of tetramethylthiuram disulfide into the mixture of damping silicone rubber and glass beads, mix evenly, and release Standby to obtain the sound-insulating rubber compound. Put the mixed rubber into the mold, and vulcanize it on a flat vulcanizing machine. The vulcanization conditions are: 150°C, 20MPa, heat preservation for 20min. The tensile strength of the obtained film is 6.5MPa, the tear strength is 20.2KN / m, and the sound insulation effect is as follows: figure 1 shown.

Embodiment 3

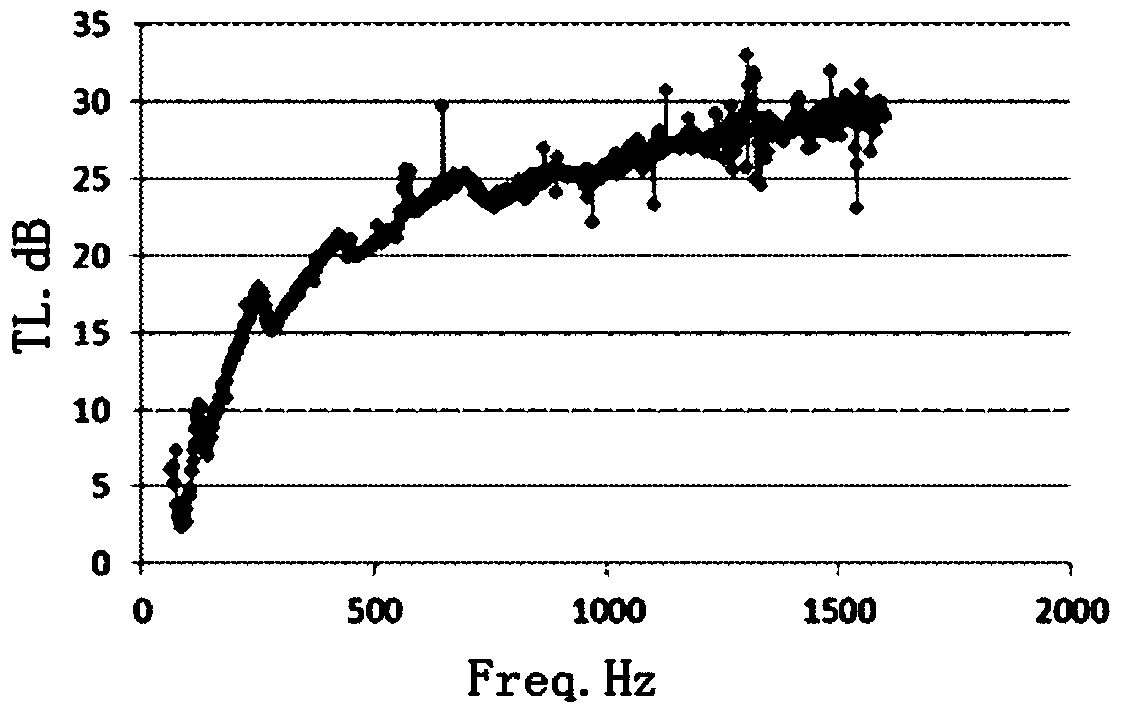

[0048]Add 100g of damping silicone rubber with a molar percentage of phenyl chains of 20% and a vinyl chain of 0.8% to the double rollers of an open rubber mixing machine, add 40g and process according to the method of Example 1 Fine glass beads, mixed evenly, add 2g of peroxide vulcanizing agent Shuanger four paste and 0.5g of tetramethylthiuram monosulfide into the mixture of damping silicone rubber and glass beads, mix evenly, and release Standby to obtain the sound-insulating rubber compound. Put the mixed rubber into the mold, and vulcanize it on a flat vulcanizing machine. The vulcanization conditions are: 150°C, 20MPa, heat preservation for 20min. The obtained film has a tensile strength of 6MPa and a tear strength of 20KN / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com