Production mold for rubber product and method for producing rubber product

A technology for rubber products and molds, which is applied in the field of production molds for rubber products and rubber products. It can solve the problems of long vacuuming time, large investment in vacuum machines, and high production costs, and achieves short vulcanization time, improved production efficiency, and airtightness. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

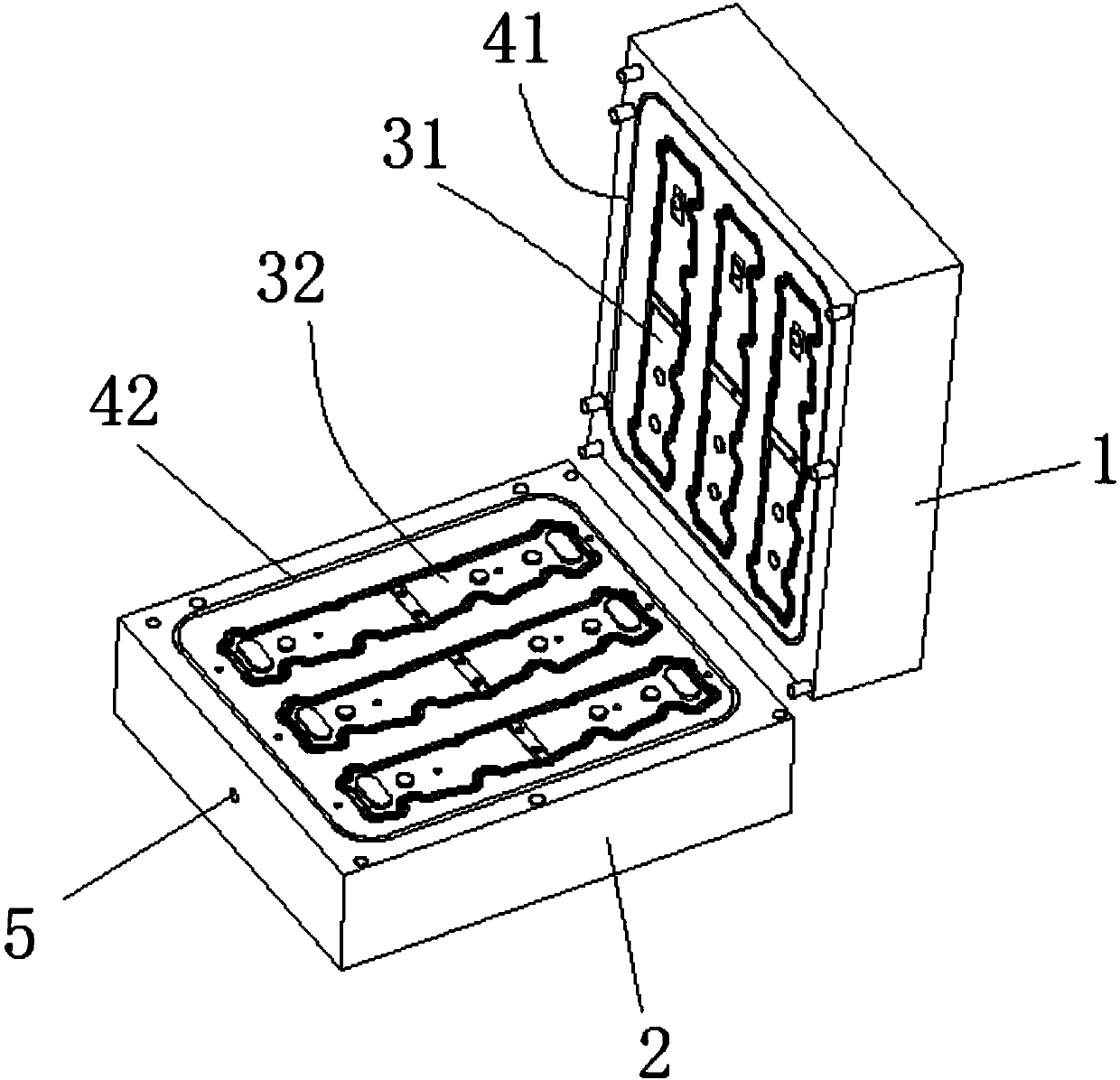

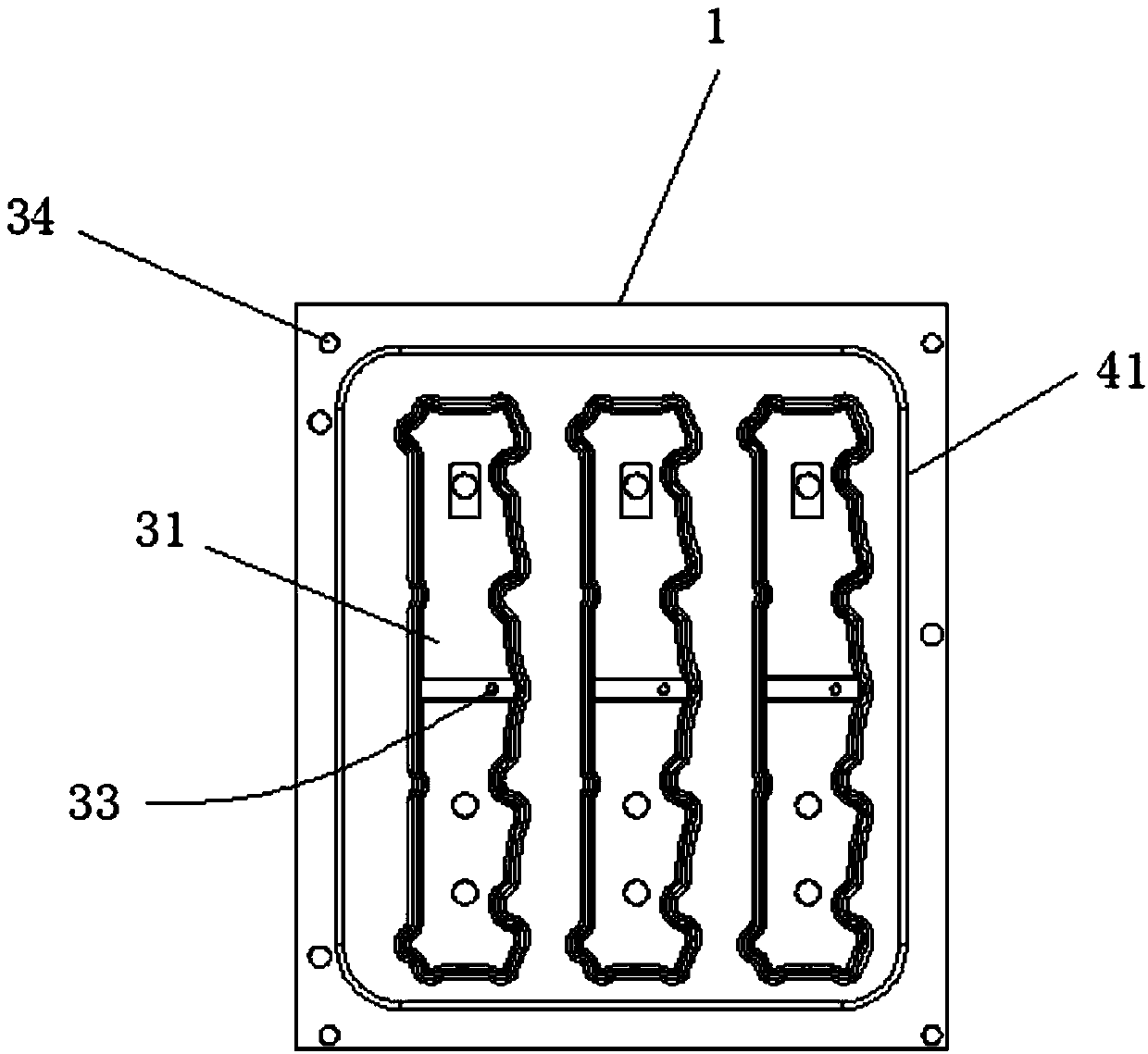

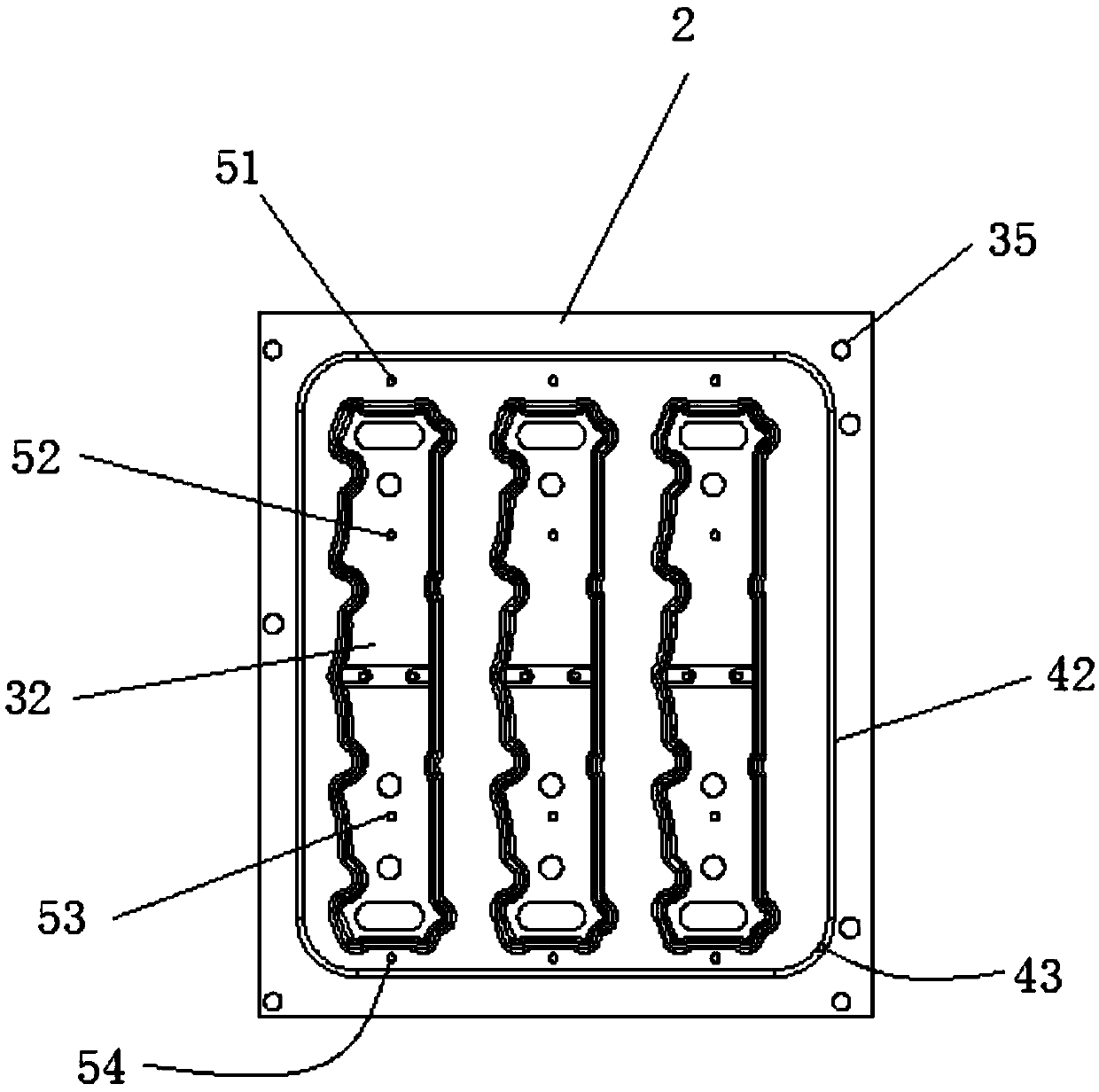

[0031] refer to Figure 1-Figure 3 , a production mold of a rubber product, the rubber product is a cylinder gasket, the production mold of the rubber product can produce 3 cylinder gaskets at a time, including an upper template 1 and a lower template 2, the upper template 1 and the lower template The template 2 is molded together to form a rubber product cavity and a sealing ring cavity surrounding the rubber product cavity, and the rubber product cavity is three cylinder gasket cavities arranged side by side.

[0032] In the present invention, the rubber product is not limited to the cylinder gasket, and correspondingly, the cavity of the rubber product is not limited to the cylinder gasket cavity. The number of products produced by a single mold at one time is not limited to 3, and can be adjusted according to the design situation. If a single mold is required to produce 5 rubber products at a time, it is enough to arrange 5 rubber product cavities in the mold.

[0033] T...

Embodiment 2

[0040] Utilize the mold production rubber product among the embodiment 1, step is as follows:

[0041] (1) Clamp the upper template 1 and the lower template 2, inject the mixed second rubber compound from the second rubber injection hole 43, vulcanize and form, obtain the sealing ring, vulcanize The temperature is 120°C, vulcanized under normal pressure;

[0042] (2) Inject the kneaded first rubber compound from the injection hole 33 of the first compound, vulcanize for 3 minutes, the vulcanization temperature is 170° C., and vulcanize under normal pressure to obtain a crude rubber product;

[0043] (3) Connect the air suction port 5 on the lower template 2 to a vacuum pump, vacuumize for 1 minute, and set the vacuum degree to 10 Pa, and continue vulcanizing and molding the crude rubber product in the step (2) to obtain a rubber product.

[0044] Utilize the production method of the rubber product described in the present invention, use the mold to connect the vacuum pump to ...

Embodiment 3

[0046] Utilize the mold production rubber product among the embodiment 1, step is as follows:

[0047] (1) inject the mixed first rubber compound from the first rubber compound injection hole 33, vulcanize for 5 minutes, the vulcanization temperature is 120 ° C, vulcanize at normal pressure, and obtain the rough product of rubber products; the sealing ring cavity A sealing ring is installed inside;

[0048] (2) Connect the air suction port 5 on the lower template 2 to a vacuum pump, vacuumize for 2 minutes, and set the vacuum degree to 200 Pa, and continue vulcanizing and molding the crude rubber product in the step (1) to obtain a rubber product.

[0049] Utilize the production method of the rubber product described in the present invention, use the mold to connect the vacuum pump to quickly complete the vacuuming of the cavity in the mold, which not only reduces the investment in production equipment for rubber products, but also improves production efficiency, saves labor c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com